Leaderboard

Popular Content

Showing content with the highest reputation on 07/07/23 in all areas

-

Full details of costs, all labour by myself, so not costed Panels 12x 285W, used £700 £40 fuel to collect panels Inverter £150 Posts and postcrete. £400 Unistrut, £300. 4 core cable and three core cable £300 Isolators AC and DC, generation meter, stickers and MC4 connectors, £99 M20 glands £2.50 M25 glands £30 Coach screws £9 M4 bolts and nuts £9 Square plate washer £13 M8 Allen bolt £18 Panel mounts £32 DC cable £70 MC4 connectors £7 So cost all in £2210, for a fully installed ground mount 3.4kW PV system. Array mounted 52m from inverter.3 points

-

2 points

-

2 points

-

2 points

-

2 points

-

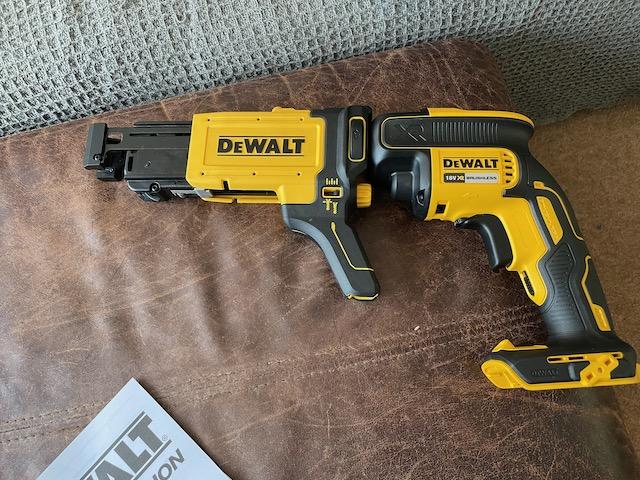

it is a lovely machine! I think I'm a convert @pocster also had fun with the drywall screwdriver today @MikeSharp01 and @crispy_wafer it certainly makes it a lot easier. I've had a few issues with screws not going in straight and even going enough sideways to screw into the guide at the nose of the screwdriver! I'm not sure if it's me and my technique or the machine. I'll persevere with it and see what happens. can always take it back to Toolstation for a replacement if it keeps happening. but I do honestly think it was beginners mishap.2 points

-

You need to take out some of the concrete and have a look at how far down the issue goes. The significant diagonal crack suggest an issue with the wall or foundation. It may be due to degradation of the bricks. The insurers should be able to send out an engineer to take a look.2 points

-

I am more concerned with pictures 2 and 4, that looks like subsidence to me. If so the repair is much more serious and in the process of doing that the failed bricks could be replaced in sections like you do with underpinning. How old are the elderly owners? Is there a case for not actually doing much if it is likely to see them out without major work to spare them the worry and let the next owner down the line deal with it?2 points

-

1 point

-

More or less what I paid for a Grant 13kW HP MCS installed. I would have installed one myself but no time and benefit of 7 year warranty (for what it’s worth …)1 point

-

1 point

-

No 35mm is probably the shortest length for fixing plasterboard if into timber. For plasterboard 9.0mm or 12.5 mm thick I use a min screw length of 38mm. The rule of thumb is that of you are fixing something to timber the embedment length of the screw needs to be 2 x the material thickness you are fixing. Thus a 12.5mm plasterboard needs 3 * 12.5 = 37.5mm. One key thing about fixing plasterboard is you use a bugle head type of screw and screw it in so it lies just under flush of the face of the plasterboard without breaking the paper face. It takes a bit of practice unless you have an auto feed type of screw fixing tool with a depth setting. I would encourage you to do it with an ordinary battery operated screw driver as when you get to corners you may need to use a battery drill anyway. If you go onto the Gyproc website and Utube you can watch videos about how to fix plasterboard correctly. Gyproc tell you how close to the edge of the plasterboard the screws can be and the correct screw spacing for walls and ceilings etc.. There are two edge distances. One is if the paper is left intact at the edge of the board, you get this with tapered edge plaster board, the other when you have cut the plaster board and you have a weak edge, you also get this with square edge plasterboard as the paper does not continue around the edge. Main thing is to read up and then have fun!1 point

-

Whatever you want . Beggars can’t be choosers1 point

-

It will need some kind of fixing to tie the two skins together-Ancon used to do a tie which was basically a slot which the tie fed into (a miniature version of an Abbey Channel)-I’ll have a look & if it’s still available I’ll post a link. From memory the slot was around 50mm deep so gives a bit more scope for variation in depth of stone.1 point

-

1 point

-

1 point

-

we were charged £4k to install the ASHP (8.5kW Ecodan), pre-plumbed Ecodan 300l cylinder and all pipework in between. they also plumbed in our water mains and ran pipework to our basement UFH manifold in that cost and MCS paperwork. we're in the expensive South East though for when you compare prices!1 point

-

Bit confusing none of the younger ones call it scrim Use what you have pictured on everything1 point

-

Good to help out. Yes looks like some potentially significant movement has taken place. Photos showing the wider context would help a lot. Don't forget to include the roof so folk can get a full picture of how the building may be loading the wall.1 point

-

Makita one jams way too many times. The guys working for me all have the DeWalt as you do. Good choice.1 point

-

No, you can DIY the lot. I know of a 100% DIY install with a G98 signed off by the DIYer. DNO accepted it. It's not legit as it should have a spark test and certify but it's seems DNO doesnt care/notice. Other DNOs may be more scrupulous but I think they're likely to be pretty appreciative that someone's bothered to notify them regardless whos signature is on the form??1 point

-

Why would that stop you notifying your DNO. If you can't fill in a G98 and do a single line sketch, you probably shouldn't be doing a DIY install.....both are straight forward to do1 point

-

Can we have a photo of the whole wall, for context, please? That is a very local bit of movement. The concrete raises questions too. I am not one for underpinning as a first thought. I like to see another season for the ground to recover. But insurers may need to be informed, if only for the record.1 point

-

1 point

-

Don't underestimate glue. We used Adiseal in a couple of places for runs of stud walling that we were unsure of the exact location of the under floor pipes. Adiseal brands Denmans As test, we stuck a 1 foot piece of CLS to the screed flooring, left it a few days, to cure. Hit it with a hammer, and it didn't move. So got a sledge hammer, and hit it. the wood broke, It left 1/8" of wood stuck to the floor. Concluding the glue was stronger than the wood. you could use in conjunction with the screws.1 point

-

Fit LVT in the bathrooms and there should not be an issue with cold feet. Only a problem if you have ceramic tiles.1 point

-

It might be worth looking at the deeds to see if your boundary is actually 1 m away from the wall...1 point

-

With the boundary being the wall of your garage, it seems odd that you would have an outward-opening window there, as you would be opening into your neighbour's "airspace" for want of a better term.1 point

-

Why not just use the circulation pump within the ASHP, or doesn't it come with one? If you have a radiator or UFH heating loop without actuators do you need a bypass? Your flow rate is basically double mine - at 6kW, so sounds right. If you use an 8m pump, you have room to change speeds to get the flow rate you need, but heat pumps should have all you need and that should auto modulate to maintain delta T target.1 point

-

Good Closed cell foam to top up the cavity. It'll do a cracker job of improving your airtightness too. Blow in another 300mm of cellulose. It'll help with airtighess much more than mineral wool, you'll get better coverage around roof timbers etc and it involves none of the human suffering. Consider good quality uPVC. Better performance and less cost. Think about ventilation. Depending on access a central MVHR would be ideal but dMVHR/DCV/MEV/PIV would all work.1 point

-

1 point

-

Few buildings are level. You might be surprised how out of level, but nobody notices. I know an indoor tennis court with 50mm difference in the court length. (It wasn't my project) Only i and the manager know.....players haven't noticed. I doubt anyone will notice in a domestic room.... otherwise why do kitchen cabinets and washing machines need adjustable feet?1 point

-

starting to feel sorry for this builder. Next will be he's built the extension square and it doesnt match the existing which is a banana. I want money off!1 point

-

1 point

-

As others have mentioned, go against the Planning conditions could result in Enforcement Action and/or a stop notice being issued. You can try to vary the condition but working days/hours is pretty standard amongst LPA’s so don’t expect them to budge. Planning cannot tie you in, nor can they control the self-build element or involvement. So you and other contractors need to adhere to the approval and conditions.1 point

-

If his screed is level then you can have no complaint, you have a problem with your existing house, the new extension is not the problem. However if its actually your existing house that's level and the new bit is out, then you have grounds to complain1 point

-

the official Gyproc screws were better but the new Dewalt Drywall screwdriver makes it a doddle.1 point

-

I've been following this in the forum because we've been planning to get a Zappi for a while. I believe the Zappi is about to be added to the compatibility list for intelligent octopus. I believe they're in final testing. That's only for the 6 hours of cheap charging though. I don't know what that means for charging the car using solar.1 point

-

1 point

-

I've not seen the Tiger Claw so would assume much superior to this, but I'm only doing this once😂 https://www.amazon.co.uk/dp/B07K6MTSKT?ref_=cm_sw_r_apann_dp_ANBM4JX1D0QKZ60ZD3CT The Screwfix link is more a k rend float? I'm hoping this will be smoother,my K rend float would destroy polystyrene.1 point

-

I assume you know this but mention for the benefit of other readers, DC from the panels is lethal. At the very least leave each string of panels incomplete, i.e at least one dc plug and socket not connected so there is no potential on the cables while wiring the dc isolators and making the connection to the inverters.1 point

-

If he does the work to the standard you expect then pay him the rate you agreed - it makes no odds to you if he's got someone else to do it or done it himself, or made more or made less on it.1 point

-

Oddly my spread asks for the orange stuff. Maybe it's just cheaper than buying glasses.0 points

-

0 points

-

0 points

-

But ! You are now a Dewalt man ! . So you must honour the sanctum of the black n gold . There are multiple tasks you must perform before you are encapsulated in the clan0 points

-

0 points

-

It’s all the same regardless of colour Scrim is what was use prior to fibre tape The name just stuck No pun intended 😁0 points

-

0 points

-

0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)