Leaderboard

Popular Content

Showing content with the highest reputation on 05/14/23 in all areas

-

The lintol over the bay is very likely to be timber (known as a bresummer) and has probably deflected substantially,if not failed completely. I would factor in replacement when calculating how much you’re prepared to pay for the property.3 points

-

Tesla batteries use the less common Lithium NMC, majority of DC batteries use Lithium Ferrous Phosphate, each have their advantages, NMC is better in low temperatures hence why powerwalls are generally seen externally on marketing material. LFP is safer and generally more efficient at lower SOC. from google When it comes to safety, LFP batteries beat NMCs due to their stable lithium chemistry. Even at higher temperatures, the Lithium Iron Phosphate chemistry is more stable than Nickel Manganese Cobalt. if it’s going inside I would rule Tesla out myself. I’ve got an ac coupled setup with pylontech batteries, I’ve written a blog about my experiences so far, on the forum, I can link it if you can’t find it2 points

-

I have both Tesla and SE dc battery . Tesla is an expensive option in comparison ( wasn’t many other choices when I first got it ) . It is very good imho for the money - not just capacity but construction and the software . SE battery more primitive I guess BUT doesn’t require any DNO Stuff . Together with lots of fiddling ( trial and error ) is pretty darn good with pw I think you need to accept the issues / limitations of dc over ac and how much control you want /need . I ( because I’m sad ) alter my setup practically everyday to suit / get the best results for me . Also ( important for me ) SE and Tesla designed to be happy outside .2 points

-

2 points

-

Must have been a poor installer? I’ve fitted loads of Ideal logics, mostly combis, great little boilers. If you have attic space, then I’d look at putting the combi in the attic and as central as possible. Leaks come from old knackered plumbing or equipment, or poor workmanship. Don’t write off anything going up there, as it’s a neat solution we often went to, to preserve space in smaller homes.2 points

-

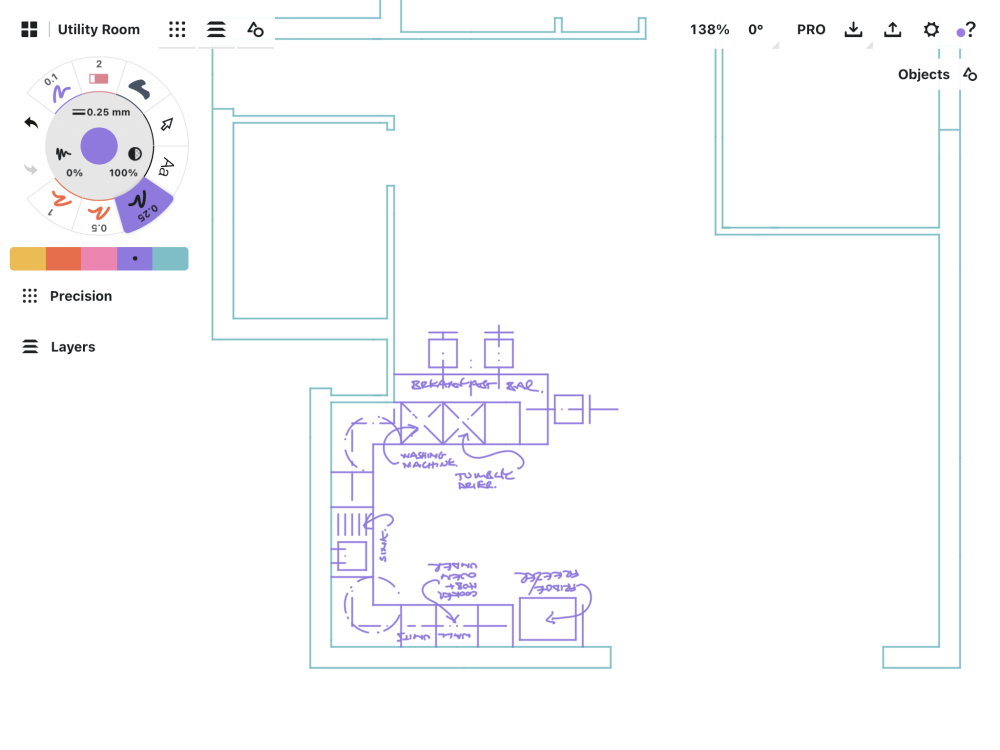

Thank you soooooo much @joe90. I wouldn’t have turned to people here if I didn’t trust their opinions. For years I’ve used forums for their wisdom and wealth and generosity of knowledge. My work is all about evidence based practice but my customers come first and they have to be onboard plans when they involve any long term issues. i totally agree, both the Architect and the Project manager unfortunately just wanted to give me the biggest space ignoring my request of having a functional utility that was designed to function well with my needs. I am hoping by tonight I would be able to share my new visions of this area’s layout and see if it can be translated into reality. Luckily the builders are ok with me stalling for the next 2 days till I make up my mind. I am praying for the miracle of clarity.2 points

-

I completely agree. I tend to only refer to professionals for things like S.E.s, electricians, plumbers etc where knowledge of regs and complicated calculations are needed or insurance, other things (IMO) are on a more “practical “ level, “well I did this and it works well for me”. When I was working as a builder I was often asked what I would do, and I didn’t mind giving my opinion but always with the caveat that I didn’t have to live there and there is no right and wrong only opinion. With this thread (IMO) the architect/project manager did not follow the customers request (and I would be asking fir an answer from them) however whatever @Sophiae decides is what would work best for them and we are here to offer our opinions (on what would work best for us.) 👍2 points

-

Actually a super team of multiple diciplines, but nearly always with a practical attitude...and understanding that cost matters. But we often end up saying to get a professional because site specifics mattter. You do that with ideas and knowledge.2 points

-

2 points

-

Not trying to be clever or anything, just make sure I was not totally off track when I suggested this. I did not add any detail as I am basically a lazy bastard, and there are others that are much better at calculating this.2 points

-

I believe supply of all batteries and prices are more abundant now . So it’s a better market to buy than perhaps 12 months ago . I got SE because wait time ( at the point of order ) for a PW was 18 months and DNO said no anyway . I still argue even now with DNO because I’m like that 😁1 point

-

Tesla has its own heating / cooling so performs the same in all weathers . My SE in winter ( never had any problems in summer ) can struggle to fully charge if temperatures are too low . So in a *perfect* world I’d want a dc battery under cover and out of the weather . Not feasible for me . Tesla can be a ‘set and forget ‘ option if you want musk’s algorithm to do its thing 😁1 point

-

1 point

-

you can get hybrid battery inverters that will do the pv and battery but I'd already purchased the Solaredge inverter with the PV system. there are many on here, @Nickfromwales is one, who would recommend you go for a DC battery system especially if EPS is not required. @pocster is also having fun with a Solaredge battery and Powerwall combined system. I believe he's thinking of a second SE battery so might be worth getting their opinions as well. if the wait for the PW2 wasn't 18 months when I was looking to get a battery system installed I'd have simply gone with that. but it was and I didn't want to wait so went the route I did. but it's a much larger field of options and probably more joining the arena all the time, it's more than my little brain can cope with!1 point

-

honestly don't know. my installers did the G99 application and I've not worried about it all since then but I presume so as I have a 10.5kWp array with a 10kW inverter. I started a whole thread on the subject of placement. in the end I put the inverter and batteries in the basement next to the CU. happy reading. 😉1 point

-

Agree with the comments above, a poor installer can make anything look like a bag of nails. spend time looking for a decent installer, finding recommendations etc put together a specification so that you know the quotes will all be on the same scope of works.1 point

-

If you have enough solar power to charge your battery it's probably not the middle of winter. Most of the rest of the time, my LG Therma V uses most power when heating the hot water. So when I have spare solar power I heat my hot water using the immersion heater (3kW). That's wasteful of energy but means that the electricity is all free, rather than topped-up from the mains.1 point

-

Structural engineer (and self builder) here: 38x140 C16 studs @ 600mm centres are pretty much the standard for external walls for most building I engineer. I would only expect closer centres if the walls are > 3.2m tall (uninterrupted by floors or ceilings) or in high wind areas, etc.. It's a bit more complicated with 38x89 C16 studs as these require closer centres (e.g. 400mm, or even 300mm) more often. This usually applies to internal walls, however there are a number of companies which use this size for external walls. In any case, I wouldn't be too worried about the performance of domestic height walls as the limiting factor is not usually the deflection but rather the compression of the timber rail under the load from the stud (crushing force). I would generally trust the engineer's design on these. Regarding floors, I second what most people say in the other comments. Typically floors are designed at 600mm or 400mm centres with the most economical design which works within the maximum deflections allowed. Based on designing i-joists (I don't design metal web joists which are always done by a specialist designer) there are usually 2 almost equivalent solutions: with a wider flange joist at 600mm centres and a narrower one at 400mm centres, these would give similar deflection and very little difference in cost. If not happy with the centres specified, I would try to engage with the timber frame company, ask about the deflections allowed and how much would it cost to reduce these. Often to up-spec a floor is a good investment in the overall quality and feel of the building. Keep in mind that (for a series of factors) in the UK we have some of the worst performing floors in Europe, I would always try to not have to deal with squeaky or bouncy floors in the future.1 point

-

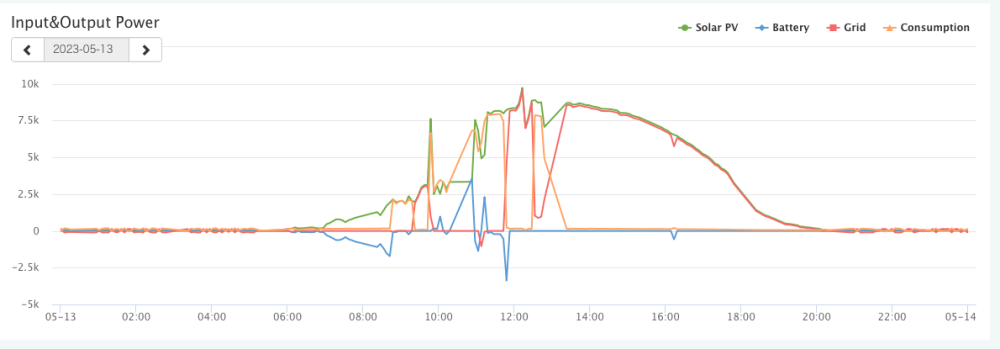

I had to cut back on spending so I only bought a single SPOD and 2 x 3.2kWh Greenlinx batteries but I have it in mind to expand that when I have some extra money. having 2 x SPODs and enough batteries would give you 7kW discharge rate. the export is not capped nor dependent on the battery system. this image shows today where I was exporting 8kW to the grid after the car had finished charging. I find the system pretty good to be honest. like I said, I'm a bit miffed that I can only have 13A max as an emergency backup supply but we have very few power cuts and if we do at least that'll be enough to keep the lights on. afaik the SPOD isn't limited to Greenlinx batteries. I bought directly from Big Green Beard and they also offer other batteries but the Greenlinx ones are the ones they recommended to me. I believe that max 2 x SPODs can be chained but a call to Infinity Innovations should clear that up for you. I had this data sheet sent to me which might help. Squirrel Pod Information-1.pdf1 point

-

You could just time how long it takes to fill a 5 litre container with the kitchen sink cold tap on full.1 point

-

Do you mind saying what you now hope to do? I mean what will you propose to the builder for his reaction? Keeping us informed we can perhaps point out any secondary effects of your intended changes....eg foundations, walls, floor support. Re using forums: it is OK but beware some have poor standards or poor control of troublemakers (through ignorance or malice). You are safe here but we can only deal with what you tell us as we don't have all the background.1 point

-

OK that looks good. I'd say it was clayey with stone. But it looks really strong, with those teeth marks in the bottom. The vertical sides are a good sign too.1 point

-

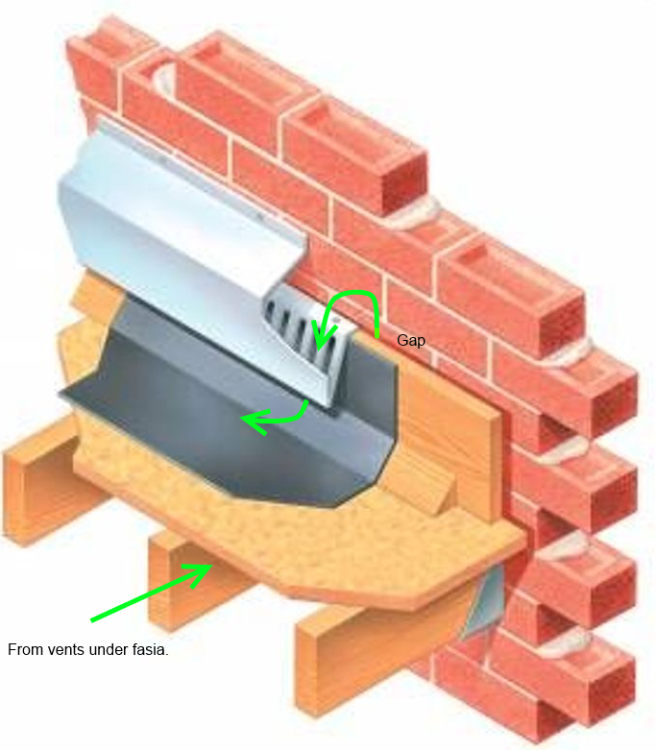

I went thermally broken because, if I recall correctly, it makes as big a difference as upgrading from double to triple glazing but significantly less extra cost. I went with Keystone which need cavity trays either way. I believe some Catnic lintels don't need cavity trays. Also, I heard windows under eaves often don't get fitted with cavity trays. I have cavity trays all round. It's also worth remembering how much harder the inner leaf part works than the outer. The outer leaf may only be carrying a small triangle of bricks whereas the inner leaf could have to support floor loads or roof loads.1 point

-

1 point

-

Photo would be good. Also, if safe in the hole, do some simple tests. Push your thumb into the side of the hole. What effect is there? Take a broom or rake and push the handle down into the base. How far does it go? Take a lump from the bottom. How easily does it fall apart in your hands, and what do you see? Photos of anything of note.1 point

-

I disagree, we tend to have better advice than your project manager/architect team. Lots of different opinions but nearly all based on actually doing stuff, not theory from a “professional”.1 point

-

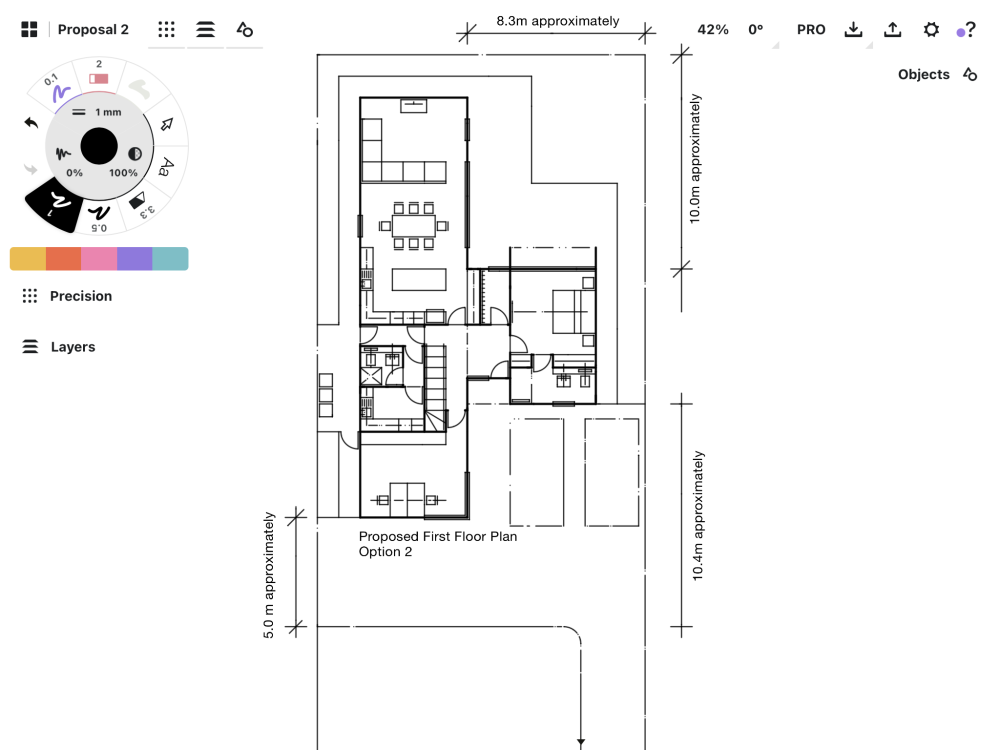

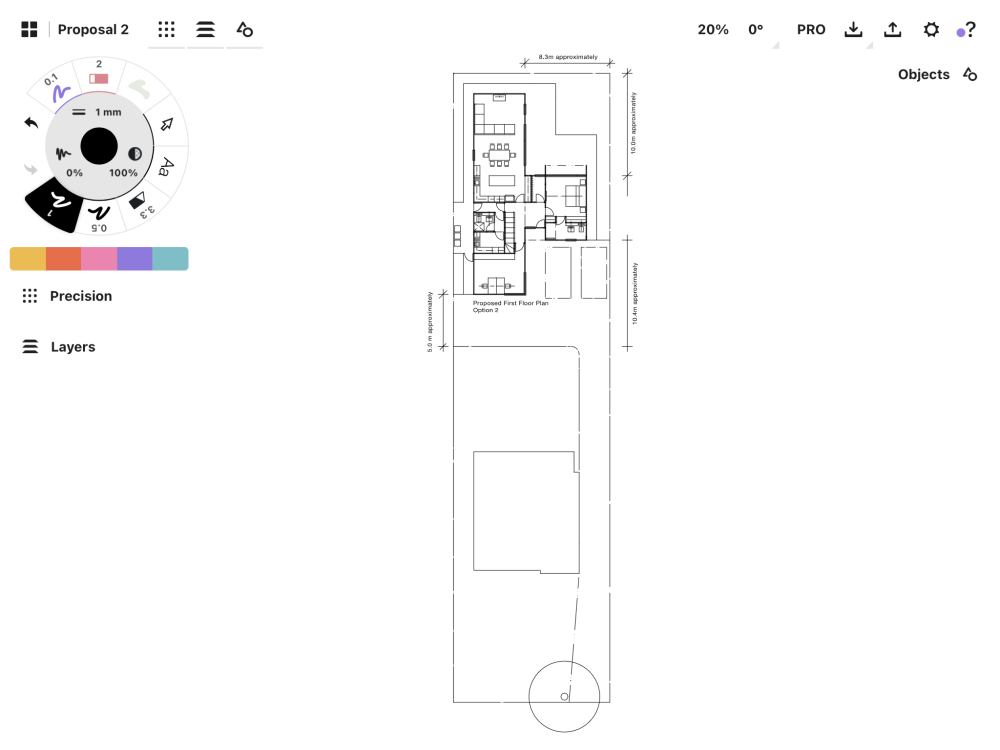

Have been up all night working on choice number 2. I’ll send you my sketch if you don’t mind.1 point

-

be careful of using a 'hybrid' method with insulation below. very much harder so seal the roof structure to make it airtight.1 point

-

Thank you! I’m genuinely so excited to see it! Already loving what you’ve come up with1 point

-

1 point

-

what we did on our 7m bifold, we hard a normal 170mm cill on it which provides the drip detail for the doors then slabbed over the cill with porcelain, we put pea gravel under the cill to support and provide drainage. No need for any linear drains and nothing to worry about with splashing etc. Had no problems with it at all, the frame free drains as it should.1 point

-

A quick site visit yesterday morning prior to commencing works in early June, we’re going to rip it out and install fresh…1 point

-

Just tiled my bathroom and debated if I should do walls or floors first. In the end I did this... I fixed a batten to the wall about 3/4s of a tile up from the floor around the room. Used laser level to set this. Tiled the walls from the batten up to the ceiling. Tiled the floor. When set, removed batten and cut bottom row of tiles to fit on wall. The batten wasn't exactly 3/4s of a tile up... Before I started I drew pencil marks and lines on the wall so I could be sure that things like the shower outlets and mixer wouldn't require holes to be drilled very close to the edge of a tile. Also to ensure I wouldn't need to cut very narrow strips of tile anywhere (eg at the ceiling). I also checked for the same issues horizontally.1 point

-

You have two choices if the wall isn’t structural. 1. move the wall between the utility and kitchen out to give you the space you need or 2. forget about building the wall (as long as it’s not structural) and incorporating the washing machine and tumble drier into the kitchen layout.1 point

-

1 point

-

No, AFAIK A2W units are rated on the output power too, the electrical input is of the order of 1/3 of the output (for a CoP of 3).1 point

-

That is like a cupboard squeezed in a leftover space. You could stack washer and drier at the far end, and the remaining area is then just space for handling washing. We have just built a utility room combined with plant room and are stacking. We decided not to buy appliances that would combine with a special stacking device, because it limits choice now, and in the future. So we are just building a worktop over the washing machine and the drier will sit on that. option 2, haul in the architect (small a for the moment) and demand a solution. option 3. don't build that wall and the sinks etc can go in that space. You have then gained a corner where the door was, and can put in more units with washing machine and drier. option 4, bring the wall into the kitchen to create 1.5m, and lose some of the generous circulation area. You still might put the appliances at the end so the doors can open without blocking the area. The foundations and floors may need revamping if the wall is structural. I notice that the architect hasn't even shown a washing machine. Needs embarrassing at the very least. The word architect cannot be used unless they are registered. Are they?1 point

-

In my book (white male, <50 years old), you have this the wrong way around. Wired switches are always going to be more reliable and long lasting than wireless, however something digital ("smart") will allow a pair of wires to each switch to have infinite uses, and be software reprogrammable if needs change, without need for a wire per light Like others here I use Loxone, but other options like Rako exist. All that said Lutron have gone wireless only and it is the trend with other tech (ZigBee Zwave Bluetooth and Matter) so maybe I'm the luddite. I just hate wireless tech when a wired option is possible1 point

-

Not or, as some becomes roots and leaves, of which some will rot to become soil, some CO2. What is burned becomes a mixture of water vapour, CO, CO2, NOX ect. The problem is that it can take decades for a tree to grow, but only a few hours, at best, to be released back into the atmosphere.1 point

-

At (early) primary school our kids did 'science' including growing seeds. Their teacher thought that the substance of the tree came from the ground. Burnt timber doesn't just become carbon and a few trace elements though, and the smoke, ash, resins etc are going to take a long time to become air again.1 point

-

If your not in a rush I’ve four to do in about a week I can post some pics As T says Making a template out of card would be easy1 point

-

+1. Perhaps make one out of paper or card first to see how it would go. Too easy to cut off a bit of lead then wish you hadn't.1 point

-

Generally on waste. I was in a contractors' discussion group once (before it became a 'thing') where we swapped ideas, even when we were in competition. A few points arising. This is for new build not demo. 1. Skips cost about £2,000 each. £250 for the hire and the rest for the stuff you should not have bought' only to throw it in a skip. 2. Subcontractors and trades don't care when it is your material. 3. Site managers only care when they are completely bought into the principle, which is rare. 4. Cautious or non-joined-up design causes more waste (material used needlessly) than disposed of waste. Some designers will be interested while others don't like to be told to try again. 5. The chairperson offered a site visit, and reported back that he could not improve on our methods or quantity. 1. Air is very expensive. All boxes to be flattened and stored separately. Timber ditto. There should be no useful stuff in the skip. Bricks and blocks used or expensive hardcore. 2. They have to be made to care, knowing you are watching. using aggregate bags by material instead of skips makes it obvious and big stuff doesn't fit. (example tile battten offuts taken back up to use or cut to fit a hipp bag...maight as well use them...10% improvement on batten purchasing.) Tell them there is hardly any spare material so don't waste it. Emptying and refilling concentrates the mind and saves half a skip. 3.We (the group) devised a form where the site manager had to list the approx contents of the skip, and report on what we could do better . It was easier to do better than fill in the form. Some were known to use diggers to squash the contents, ie achieving reduced number of skips but not of waste. A competitor said his managers starting using grab lorries to keep the number of skips down. 4. Understand costs. tell the designer what it really costs to, for example, use a 600mm tench instead of 450mm. 5. Yes, he was the well meaning expert for a waste quango, but was learning from us contractors. Other contractors perhaps cared less. The above can be worth about 20% of a project cost. especially number 4, which is the invisible one.1 point

-

The pipe will leave in line with the valve and water meter so just about horizontal in the first picture. I would expect it to be 25mm mdpe Dig down on that line at the edge of your property and hopefully you will find mdpe. Worst case there is a joint to something smaller under the pavement. If you do need to dig up the pavement you need a road opening licence from your council and you must employ a contractor with a minor streetworks permit. Dig in your own garden as close to the pavement as possible to see what you have.1 point

-

And your designers. I would have to rummage a long way back, but i recall that the big contractors had targets of something like 10 skips per 1,000m2.* (Ours was 2.) That involved everyone through technical design, ordering, and use as well as site manager ordering reuse of ends etc. But on top of this came simply using less in the first place. Efficient use of all structural elements, no overdesign, no overdig, natural drainage...all sorts. We reckoned 25% less material used, let alone waste. So my view was that hemp etc were easy ways to seem green, while not addressing the less blingy aspects of waste.....use less. It also saves stacks of your money. What i don't understand is that straw is not used in the same way as osb. Or in blocks. There is so much as a waste product. I think sawdust is still added to concrete blocks as a filler. * that became zero to landfill, so a good thing. They way they managed that with mixed rubbish was to classify it as non recycable. Less to recycling would be even better.1 point

-

Hi Deejay, I have excavated a slightly larger tree for a friend and they leave a massive hole that will need to be back filled and compacted so I would not recommend this. If it were me I would be looking at getting in a reputable tree surgeon and grinding out only what you need to get a lintel or ground beam over it. The stump will eventually rot and it is likely that some minor settlement will occur so a lintel will allow for that, the second option is to stump grind all the way though but I estimate from the diameter of the stump that it could be 5-6 feet down.1 point

-

The thing about a practical SE is that they are quite likely to say that the dead tree is irrelevant, where a bco might not. I see where the worry about engaging an SE comes from..the nhbc implies that you need an SE for deep founds and that an SE will design piles. Not so. An SE will specify only what is required, and that is probably mid depth standard footings.1 point

-

My deck is 4m deep (back wall of house to edge of deck) - does that excuse me from railing?1 point

-

1 point

-

so I've gone against the advice and have installed them in the basement. After speaking to the suppliers who've stated they have never had a battery catch fire and have also said that I can fit a DC breaker (80V/125A) which will reduce the risk of cable fire I am confident that they're safe in the basement. there's probably more chance of our washing machine causing a fire!** so, today I fitted the Squirrel Pod and the 2 x 3.2kWh batteries and it looks very nice and neat with plenty of space below for more batteries should the need arise. now just waiting on the Solar PV inverter to be installed and commissioned next week and then I can get the electrician back in to wire the batteries up and can start making use of our free energy! ** I have no data to back that statement up1 point