Leaderboard

Popular Content

Showing content with the highest reputation on 10/31/20 in all areas

-

https://www.jtmplumbing.co.uk/search/manifold#sort9 JTM offer a good variety keenly priced!2 points

-

Can you take a photo @zoothorn of this controller please on the inside unit or the thermostat and post it here ..? Can everyone bear in mind this is NOT a monoblock ASHP but a split unit so in the house there is a unit that will make more noise than just a circulation pump. You can’t compare the two as being as silent as each other.1 point

-

1 point

-

If the pipe failed anywhere they’d look to point the finger of blame anywhere. Being sure the Hepworth insets fully seat and seal into an alien manifold is another consideration. I won’t be mixing and matching for anybody if I am going to be liable for a catastrophic failure. Water causes a LOT of damage, and that’s if you’re home to stop it. If not, it’s humping out until you discover it. Save a couple of hundred quid elsewhere.......?1 point

-

1 point

-

I've found in the past that type of hygrometer gives readings that vary quite a lot depending on the type of surface they're on. If it's on an absorbent surface the readings are lower.1 point

-

In case anyone has a similar issue. I hired a one man tower and set it up. Scrubbed off the dirt with water and Fairy Liquid. You could still see the stains. I sprayed it with Cillit Bang Black Mould Remover, left it for a few minutes and rinsed it off. Worked a treat. You can only very faintly see where the stain was, if I had left it on longer it would have been better, but I wasn't really enjoying being up the tower. I now plan to use this on my garden walls where I have some areas of staining.1 point

-

1 point

-

You could do that, but bear in mind that the longer the sample period the bigger the jump is expected to be and so it makes it easier to detect and easier to avoid false positives. If your window is small the threshold would likely have to reduce and you may find it triggers when it shouldn't. As @SteamyTeasaid trial and error will guide it well, and to be honest I only went with 5 minutes because that's how regularly the script wakes up to take temperature measurements for plotting so I just piggybacked on the back that. That said, I do find a shower gives a 5-10% rise in that timeframe and so it stands out from the noise (natural variations) quite well.1 point

-

Why would you need a warranty, what bit for?? or are you talking about if it caused a flood.1 point

-

https://www.jtmplumbing.co.uk/pipe-fittings-c433/hep2o-brass-manifolds-c661/hep2o-four-port-valved-manifold-15-tm-tf-fp-p21691 Remember you can’t mix JG Speedfit manifolds with Hepworth pipe. Has to be like for like for manufacturers warranty to remain intact.1 point

-

I’ve looked on line all week, best price is the plumbers merchants at £42 for a 4 port, you can find them cheaper but not come with no fittings, so the time you add 4 fittings your back to £42.1 point

-

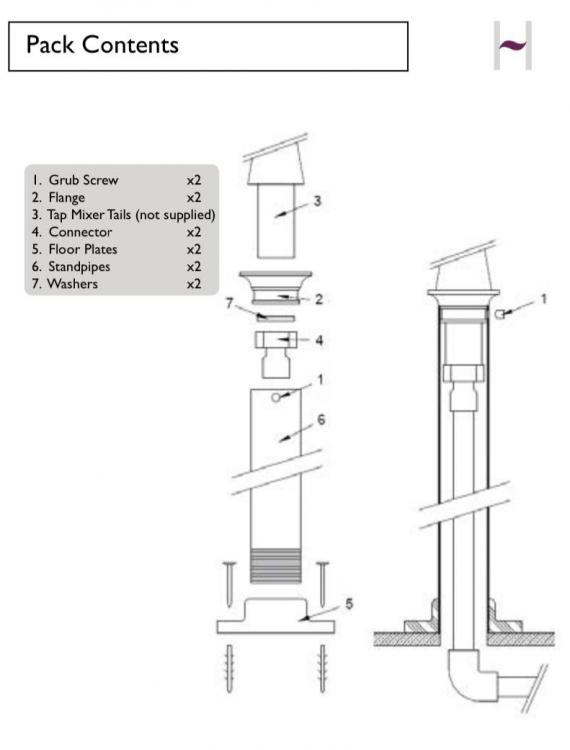

No... That screws onto the bottom of the tap, and will go all the way to the top tight under the tap itself leaving a piece of thread that the tap connector screws onto.1 point

-

This is why I think you’ve got half a set ... Just get a couple of these and see if they fit through the shrouds - think they will. https://www.screwfix.com/p/hep2o-plastic-push-fit-straight-tap-connector-15mm-x/7367f1 point

-

1 point

-

1 point

-

1 point

-

Yes although I have seen a slimline tap connector. Pretty sure it’s Hep2O but need to find the latest catalog1 point

-

And I will bet a standard tap connector will be too fat to go down the tube hence it will need the special one that should have come with the kit.1 point

-

1 point

-

@pocster Someone has sold you half a kit. Remove ALL the fittings from the bottom of the tap. That’s the nut and the washers, leave the thread clear. Then the chrome bit you have released with the removing the grub screw fits tight onto the bottom of the tap. This then should have a 3/4” tap connector onto the bottom of the thread of the tap remaining which should allow you to connect a pipe into it which should be part of the kit. If not, you will need something like a 3/4” female to 15mm copper adapter that has a diameter of less than the inside of the shroud.1 point

-

1 point

-

Okay, another try. With that end off, screw the "end" onto the tap. How much tap thread sticks out the other end? Is there enough thread to get a tap connector on? And if so will a tap connector fit down inside the tube?1 point

-

I think there's been a misunderstanding along the way somewhere. A new pump (or radiator, or any other invasive bit of work) could indeed result in pressure loss for a period whilst you bleed out any air that was inevitably introduced (from the work itself and the fresh water added afterwards). However, a new pump would *not* cause the PRV to pass water. That is, or represents the existence of, a fault and so I would be getting the installers (of the system) to come and take a look at that.1 point

-

Lintel schedule should be on the plans. I use Condell for them and send a list and get them all together on one order - usually get best price and merchant can’t match it. Plans get marked up and they then get sprayed with a number and the blockwork next to the opening gets the same treatment so there is no mix up as to what goes where.1 point

-

1 point

-

1 point

-

@pocster you nugget..!! undo the grub screw ..!!! All the fittings are inside the shroud ....!!!!!1 point

-

1 point

-

The mantra here (and the same applies to your garden room) is you only buy insulation once, fuel (electricity) you keep on buying and it’s price will not go down, I,m with @Nickfromwales above, get it built properly and your heating/cooling Spend will be minimal.1 point

-

Perhaps it's time just to bite the bullet and pay a different, competent plumber to come and sort the niggles if you are convinced the supplier can help no more and are not prepared to fight with them?1 point

-

£100 worth of bits there in his home built system and you can hire the real deal for £50 for a weekend and it will be much more powerful. Also as you’re on a single pipe system you’ll only get the crud out of the pipes not the rads as it will follow path of least resistance.1 point

-

1 point

-

Whoa there fella!! Ground source for a garden room is a little OTT Change of £500 Link Change of £900 Link So +1 to @ProDave. Don't fit any screed, just put EPS 100 down and finish it 44mm short of your floor covering. Then lay 2 layers of 22mm P5 T&G boards on top of the insulation and that's you done and dusted I use that method for garage conversions mostly, and with excellent results. Don't forget the DPM!1 point

-

Hot manifold adjacent to the water heater is best practice, and implementation of an HRC ( hot return circuit ) is always gauged on the dwelling. It depends on how far away your basin and sink taps are from the manifold tbh. You could shift the hpt manifold to a strategic centralised location and just have the ( HRC ) running between the UVC and the manifold and then leave as is.. Two current jobs for eg's; HRC to hot manifold at the hot water device, kitchen sink as last point of draw off on the manifold to promote flow across the whole manifold ( pre-heat ), HRC pump only pulling back from the kitchen sink therefore the whole hot manifold is warmed routinely hugely reducing waiting times at the other reasonably close outlets. Timer to be fitted for the HRC pump so that operation is in line with activity / occupancy.. HRC to hot manifold at the hot water device, HRC pump pulling back from the 2 upstairs bathrooms ( wash hand basins only ), manifold 'warmed' / 'pre-heated' as above, micro-PIR's to be fitted under each of the 2 wall-hung vanity units to trigger the HRC pump. Same PIR's to be used to also bring on ( automatically ) the night-time 'pee lights' under the vanity. Manual lighting circuit will be set to bring pee & other low-level lights on constantly for chilling in the bath ( so no overhead spots need to be on, and no disco lights from the PIR ). Timer to isolate pee lights during daylight hours if necessary. All depends on the layout of the house, so if you add distances to the basins / sinks from the UVC I can recommend something for you.1 point

-

Ditra has a proven track record. We used it a few weeks ago (about 2.8 rolls), I would use it again, shop around for a good price - try CTD. I am not sure about the thin rubber / fleece decoupling matting. The shape of the Ditra offers a good mechanical fixing. We used also used Kerakoll Fugabella grout for our main floor area - the tiler said it was the best non epoxy grout you can get.1 point

-

Don’t forget the big plastic storage tank that you’ll need in the attic to give you any kind of “reasonable” hot water pressure. Then the grief of getting mixer taps / showers etc that can deal with mixed ( unbalanced ) hot and cold supplies........ Then adding noisy pumps and complex plumbing arrangements to suit if you want a nice powerful shower....... C’mon grandad, it’s almost 2021!! ?1 point

-

I did a halfway house. Kitchen and utility each have their own feeds with local isolators. Where I used a "manifold" was for the 2 adjacent bathrooms. This gives me isolation for each in one place. And to keep pipework runs short, particularly hot water, the manifold is placed under the floor of the main bathroom accessed through a small trap door in the ceiling of the utility room. to save cost I "made my own"1 point

-

If the OP has 16 x cold feeds ( assuming 3 x WC’s / 2 x cold mains appliances ) that’s 11 outlets requiring cold supplies ( so also assuming 11 hot supplies ) then the cold supply would need to get to at least the first two bathrooms in a minimum poor size of 22mm. Same for the hot, but the hot more like starting off in 28mm, then picking up the first bathroom, and then 22mm from there forward, and then reducing to 15mm as seen fit. Really if a bathroom is the last item then you can’t drop to 15mm until you’ve picked up the shower & bath. So, a minimum of 26 x T connections if you don’t adopt a radial manifold setup and fingers crossed after you’ve tested initially and boarded up. Another benefit is that for a new / self builder, you can just bring on items as work progresses, so no need to keep draining down / connecting / re-pressurising each time you add a new item. And, the party piece is hot return and flow rates. With a large single bore series setup you’ll be waiting for a very long time to get hot water out of basin sinks in particular as they are low flow / high frequency use and by the time hot had got there you’d have got fed up waiting. Pressure and flow rates are as uniform as you can get too, so question has to be.....why wouldn’t you do it? Not having isolations on the end of every run / at each outlet is a no-brainer, as most modern bathrooms won’t have somewhere for such valves to be easily / practically accessed, particularly for baths and showers etc. Regular ( series ) 0 Manifold ( radial ) 1 ( well 4 actually ).1 point

-

Major benefit which you are forgetting @SuperJohnG is elimination of joints within the structure of the building. Ever piece of pipe is a full run with only joints at either end. Also whatever the technical term is but I can flush loo and it doesn't affect shower when running.1 point

-

What about getting and SE in right at the beginning even before you ask a builder, employ a QS, get an Architect. SE's know a lot more about this process than the common perception that they just just "provide calcs" A few rakes about on build hub say etc will get you on the ball re your budget. Work out if you have the money, can borrow it etc first . Much of the cost lies in the ground. Then spend £300 - 500 quid on getting an SE. Yes..you maybe don't want to put your money where you mouth is at the moment but it's a bit like site investigation.. if you skimp on this you end up paying for it later and often more. This is a known statistical fact in the industry and you are more vulnerable to this as a domestic client. Maybe it's worth getting and SE in early who will take you under their wing and guide you. A good one (SE) who has experience will do a desk stop study on the QT before they meet you and this can really go along way towards identifying real potential issues that need investigated/ designed around. This will also help you get provisional prices from builders by way say of an A4 spec on a page or two and you can access their contact list. They will also help you prepare a brief for the Architect. Also a lot of "SE's" are pretty good Arctitectural designers themselves so you may not need an Architect at all. You get two birds for one stone. You'll need an SE for a lot of basements so I think you could be missing trick and often wasting your money. It will do you no harm to just ask an SE right at the start?1 point

-

I’m still thinking about this and wonder if we are overly worried about how long it takes to get hot water to a tap. Things ive thought about. 90% of the time I need a wee I’m out around our land and wee in the bushes, so never wash my hands. I asked the wife wife if she waits for the hot to come through when she has been to the toilet, she said no she uses soap and cold water. If if I go to have a shower I turn on the mixer and then get undressed, so the hot is there by the time I step in. If if I want a bucket of hot to wash something in the garden I place a bucket in the sink and let it run, it takes a minute to fill a bucket and I don’t want it all hot so what’s the problem there. I think with building a new house we want everything perfect, instant hot water taps and stuff, what happened to just flicking the kettle on I think it’s all getting a bit carried away.1 point

-

Hello fellow self-builders! Having lived in the South East (nr Reading) for over 30 years in various cookie-cutter boxes of varying quality, after a 2 year hunt we have found a building plot on which we are going to build what we intend to be our "forever house". We are currently in the purchase of the land stage, so fingers are still crossed as we wait for all the legal and financial stuff to conclude, hopefully next month. The plot comes with OPP for an eco-designed house (architects were ARCO2 in Bodmin) which we intend to make minor tweaks to as we apply for DPP and Building Regs approval to proceed. Our intention is to perform as much of the labouring ourselves, both being practical minded, in order to be able to spend more on the materials. Personally, when younger, I helped my parents build a major extension to one property and renovate two others, I have renovated and rebuilt two classic cars, and undertaken re-wiring and re-plumbing in our current property - I'm reasonably confident in doing the work. On the Quality/Time/Cost triad, Time is the one that will be most variable :-) I'll probably be using these forums to seek input on the steps and order of tasks for project planning purposes (if anyone has a good starting template I would be very interested!), to discuss various material choices (e.g. raft v strip foundation, ICF v timber frame etc.), and delve into the variety of construction experience that exists here, so on the basis that there are no stupid questions ..... :-) Cheers Stuart1 point

-

0 points

-

0 points

-

Really? If an installer doesn’t check all in line flow valves are open then that’s now the fault of a bit of kit is it? No, it’s not. ?? Not checking pump / gate valves are open is 1st year apprentice error. I’ve not had one yet which has caused any issues.0 points

-

God damn.....again the forum strikes.and gives me a reason to make something better. I now see the added value.....maybe.0 points

-

All the money @nod has and he still takes photos on a Nokia 33100 points

.jpeg.ab26ea7722918b3b2d9fc8b252fe99e1.thumb.jpeg.bbe90caa417d9ffc31454ce90532e472.jpeg)