Leaderboard

Popular Content

Showing content with the highest reputation on 03/07/20 in all areas

-

I don't like the design of that one little bit. I would have expected there to be some form of gutter around the perimeter of that, with that able to drain somewhere safe, to give a safe exit for any water that does make it past the seals. No doubt they will remove the glass, re seal everything and put it back, and then all will be well. Until next time...... When it is off, make sure every single fixing screw hole is well sealed, that will be where it is getting into the building. And since the framework does look to be larger than the upstand, I would talk to them about the idea of drilling safe weep holes to allow any seepage out onto the roof.4 points

-

Here goes the next stage. Building the reinforced concrete ring beam. The plan is to build the steel cages off site in a shed due to awful weather, then deliver to the site. Lots of things arriving on site! The yellow plastic takes the place of traditional shuttering. Apparently this is faster and therefore cheaper. This will help pay for the huge amount of claymaster I need. It's still a little wet out here so digging might get interesting. We're armed with pumps and a couple of diggers so what could possibly go wrong? It took a couple of hours on Monday morning to measure out the site accurately, then the team got on with digging and cutting the piles to the right height. The cages started to arrive on Tuesday and installation was swift. The kitchen and family room cages nearly complete. The building inspector was happy with the progress on Wednesday so on with the show! With a bit of luck the concrete arrives on Friday. Then we can open the first of the four bottles of Cava allocated to the significant milestones.2 points

-

Second update: water poured all over the roof light this morning. First in the area nearest to the problem on the inside. Nothing dripping through for 5 mins. But then we moved to the higher end of the roof light (it’s on a slope to allow the water to run off). Almost immediately the drips started. And continued for a few minutes after we turned the water off. So we have found the problem. Now to contact the roof light people. we can’t see any solution other than to break the seal, crane out the glass, check the frame and (assuming we are tight) remove it and then check the upstands. Looks like the mastic may have failed at a different point but that the water might have run round within the frame to the low point where it then descended thorough into the roof void. so happy we have found the leak. Now the next bit begins.....2 points

-

So I took the plunge and purchased a FLIR One camera for my phone to investigate heat loss my suspicions were correct see image below. The rather yellow end of the house is our lounge and master bedroom. Clearly losing more heat than the rest of the building from inside I can also see some areas where the insulation is missing so next job is to pull the plasterboard off and reinsulate. If we can bear the mess! The original stone millions around the windows are like fridges too so may need to switch those for something with a bit less cold bridging going on.2 points

-

Well done. Pop along to the Horse & Groom for a celebratory pint!1 point

-

We did. I haven't sorted out all the photos so no new entry yet. The weather was perfect for the pour.1 point

-

I agree, it doesn't look right. Also has the roofer considered the distance from the bottom of the window to the top of the tile that sits under the window - it doesn't look right to me. Download the Velux fitting instructions and you will see what I mean - IIRC the bottom tile position in relation to the bottom of the window is more critical than the top (to get the window and flashing to fit correctly)1 point

-

+1 to the above ^^^ I'd very definitely want to see weep holes to drain what amounts to a gutter all around the periphery. Sooner or later the edge sealant will fail again, for sure.1 point

-

If it's a developer house then you can almost guarantee the most important thing, the insulation levels and air tightness will not be as good as they could be, so right from the start you have that disadvantage. That would be where I would direct my questions.1 point

-

Not quite. Outside to in: Stone wall gap 100mm (or more) frame filled with insulation air tight membrane taped at all joints 25mm battens following frame studs to create a service void for cables etc Plasterboard. That will give you an air tight structure I doubt insulating outside will stop all the damp, this house will have no foundations as such and no damp proof course.1 point

-

1 point

-

welome, glad to see someone down this end of the country1 point

-

We started out saying "Passivhaus principles" at the (para 55/79) planning stage, mainly so that Passivhaus certification didn't become a planning condition, but we went for it and got certification. I guess certification per se isn't a pre-requisite, but going for the appropriate level of airtightness is worth it and aiming for the official badge does give a reason not to back off. Based on one year's experience, when we sign up for economy 7, we should be able to heat our 3,800 sq m house for around £100 a year using an ASHP to provide ufh. We are mostly single story with a partial basement floor (living space). So it does work!1 point

-

We have what is apparently known as 1 and 3/4 storeys. Not quite 2 but, the headroom is a bit better than 1.5. Architect reckoned it would be more acceptable to planning that way, so you could consider that if you can't get 2.1 point

-

1 point

-

Hi and welcome. You might find planning won't allow full 2 storey, they won't here, but at least worth asking them. Otherwise stretch the definition of 1.5 storey as far as they will allow. Most of us found ASHP's make better sense. they are so simple and easy to fit. There is a LOT of extra work and cost (and ongoing cost) for a GSHP and it is doubtful the small improvement in eficciency is worth all the extra work and cost. Even having my own digger at the time I decided GSHP did not make sense. If you are getting close to passive house levels of insulation and air tightness then like many of us, you won't need any heating upstairs. Ours is a bespoke build pretty close to passive house standard, quote well air tight and mvhr fitted. Not only will mvhr reduce your heating costs it will also give you very good air quality inside. I had a minor falling out with Scotframe as I wanted better levels of insulation than they offered. And as soon as I mooted the possibility of having one of their builds and adding extra insulation to get to the level I wanted, they halted the discussion.1 point

-

You should find the joists / rafters above and screw a batten into those, to which you can fix your curtain rail.1 point

-

1 point

-

You could try just painting the wall above with StormDry, which is supposed to last 25 years.1 point

-

Have you tried Glasgow Brickyard in Blochairn? They have a brick matching service.1 point

-

This is an all too familiar story. Keep persevering you'll get there! As already posted I would suggest you become a pita....you ring them up and find out: What specifically is outstanding? When is it being done? Why can't we do this today? I'll be ringing again later to confirm that this has happened etc etc Sounds basic I know but it is effective. In the past I've even contacted the other party's solicitor's as it's all too easy for them to be ambiguous on what they are waiting for from the other solicitor. Good luck1 point

-

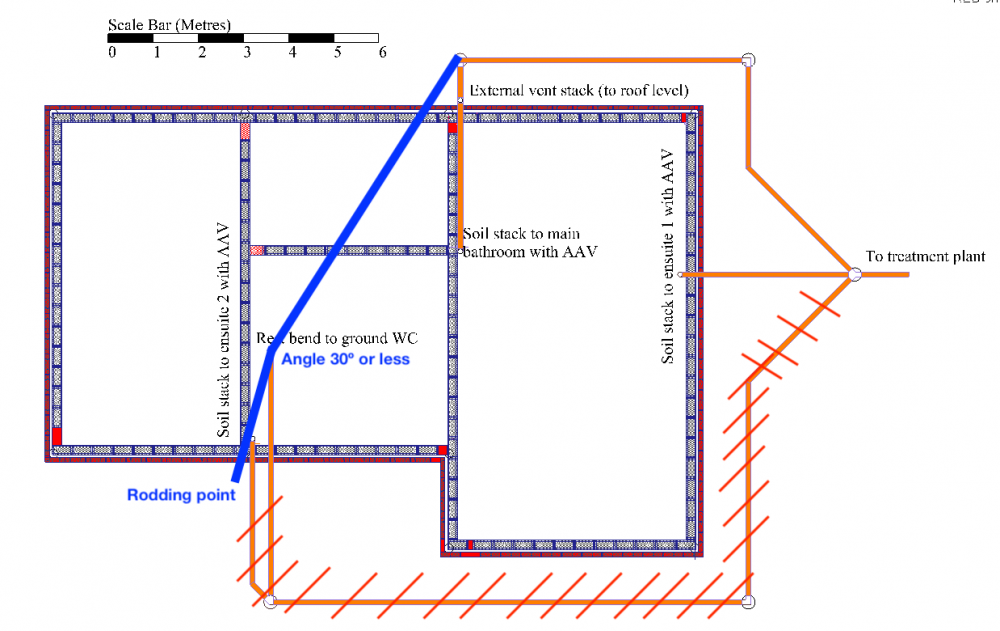

Move the main chamber where the branches collect to the right and use long radius , roddable 45 degree bends and you can loose the chamber(s) at the corner of the property as well. Bends are cheaper than chambers as well?1 point

-

Oh I am an amateur, but I would think you can greatly simplify that. Here's a first idea. With a bit more thought, and close reading of the Part H constraints, I think you could simplify it further. I got mine down from 8 ICs, as originally proposed by my drains engineer, to 2x 450mm ones and 1x 300mm one. Obviously, check the above against Part H, especially for the distances allowed between ICs and whether it is permitted to have two soil stacks on a single drain as I have tentatively suggested. And for falls.1 point

-

Actually, I've had a couple of really good solicitors in the past, but they stand out amongst a lot of pretty poor ones. I had an on-going issue a few years ago - I got through 5 different solicitors, who were just indifferent and uninterested or incapable. The last one ignored much of what I had told him, and I had to re-write several letters for him to send out, because they just didn't cover the issue. Finally, he sent me a bill - I sent him a cheque for half the amount, telling him how disappointed in his work I was, and that I considered the account settled in full. Never heard back from him. But yes, my opinion of solicitors continues to decline. Some people would tell you I am already.1 point

-

Tbh Roundtuit, I couldn't contemplate/ face this prospect of undoing, & especially putting up a sheet it'll be a n'mare job never having done before. I paid the builder to pB & loft-fluff the upper room, & its done now (he only mentioned 'visqueen' with regard to the walls too).. besides its as per the rest of my rooms, & there's no problems here without a vcl. I know its not the perfect job, & falls short of the top bullet-proof quality you guys do.. but it'll have to suffice for me. Matey above on his hop-up & t-things isn't going placcy sheet.. & he's far more pro than muggins here. Thanks, zoot.1 point

-

I have just fitted all my windows and it did take an age to get the right spec for each room, as far as I’m aware there is nothing to say that any window needs to open unless it is for fire escape purpose if you are using it for this purpose make sure you specify this to get the correct openings also check glass specifications in case you need toughened or laminated we have a bungalow and decided to go laminated all round as the extra cost was very little. We have 7016 outside and also inside. They look excellent. Be aware some internorm windows have a white section in the inner part that you see when they are open even if you have a colour inside and out. I think it was their upvc version.1 point

-

1 point

-

Try this: https://brickhunter.com/bricks?filter[colour]=grey&filter[material]=concrete1 point

-

The Apollo Gem is another one with a wireless sensor: https://www.apollosolarelectric.co.uk/products/ Has a 30m to 40m indoor wireless range, according to the spec.1 point

-

It’s annoying isn’t it. We came across hundreds of trees that we felled that all had a metal bar in the centre, turned out somebody thought it would be a good idea to use a piece of 1/2 inch re bar as tree stakes when they planted them.0 points

This leaderboard is set to London/GMT+01:00

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)