Leaderboard

Popular Content

Showing content with the highest reputation on 01/31/24 in all areas

-

Yes - I agree, I even advocated not doing this here I think, I won't be developing the hardware I will use COTS components everywhere I can, which I will double up on so I have spare of everything as I don't know how long even established brands will keep on keeping stuff available in a fast moving tech market, and document copiously both the system and the code if I need to develop any. I have wired the house traditionally and in places it will be used as such otherwise the switches just send momentary pulses, at 240V - so if needed be the momentary switches can be replaced by traditional rockers and the HA bridged out to control the lights, to the de-bounced inputs of the relevant PICO - its all node-red, local RPi install of mosquito and MYSQL for data logging - actually getting that stable has been one of the biggest challenges so far. DMX control of the lights via Whitewing will be the way forward although I have not purchased them yet as I don't actually know how many of the lights need dimming! I have struggled to keep it below 16 so I only need one unit but even then I will buy two with one as a spare! So I guess I would argue I have thought this through but I admit the risk you highlight but you must admit that any technology has a life (a carrying capacity) and so there are no guarantees anywhere here, only balances of risk.2 points

-

The overwhelming wisdom from responders must lead you to the obvious conclusion to go ASHP. Your misgivings about winter performance are correct though - lower temperatures do lower the COP - but even so you'd have £10,000+ in hand to pay for the slightly higher running cost. Anyway, there are many days when the ASHP runs cheaper than GSHP especially in the second half of winter so which is best is arguable. You mention UFH throughout. I'd consider fan coil units for bedrooms where the slow response of floors doesn't match the requirements of cool sleeping time but warm getting up time. When you put in the 6kW ASHP, as suggested, fear not for being underpowered, just add a mini-split to top up and do the aircon. Normal pipe sizes will work, heating will be free on many sunny days with a bit of PV, life will be good.2 points

-

2 points

-

A parge coat wouldn't need to be that thick. 3-5mm should be fine. Slop it on with a broom. If you are using insulated plasterboard then you'll still be chasing conduits into the blocks. These will need to be sealed too. I used airtight paint. 1 dilute coat at about 5:1 as a primer and 2 neat coats. Even so when I had my DIY blowerdoor running I could feel some leaks from the back of the conduit. The blue airtight sealer was used quite a bit even with 3 coats of airtight paint. Also note my detail allowing the conduit to run up to ceiling level and emerge under the A/T membrane ( not installed) into the ceiling service cavity. Also known as a Tony Tray. See @tonyshouse for details. He did a blog too. http://tonyshouse.readinguk.org/index.htm This will work ok if you can fit the hollow core planks yourself. In reality they'll be crowbarred into position by the delivery guys and it'll tear the membrane. Ours was in tatters so I cut it away and painstakingly sealed the house room by room, from the inside out. As a minimum use some heavy DPC type plastic with a bedding layer of wet mortar on top before dropping the hollow core to protect it. Realistically it's hard to do a good job on the corners and it's one of the reasons I'd prefer to follow the denby dale intermediate floor detail. Much more robust. I would mix standard 220mm timbers with metal web space joists only where they were needed for service's to save cash. The pozis could be deeper in rooms where you needed the service space. Alternative use standard 220mm joists throughout and install a metal drop ceiling for a service space under bathrooms etc. 16mm resilient bars underneath the joists and 2x layers of standard 12.5mm plasterboard +skim and mineral wool sound insulation in between would make a very quiet floor. Especially with carpet upstairs.2 points

-

Yep, you can just push them in and out once and they should snap off cleanly, no cutting needed1 point

-

No problem at all, standard practice when wiring industrial cabinets.1 point

-

Agreed. And I do enough of this at work to last me a lifetime. (And I have to train the next generation of engineers to look after it too - the design lifetime extends long after my retirement and the customer doesn't like budgeting for spares...). I'll stick to writing a few bits of software to glue things together. It's about all I get time for these days. If you want a demo, let me know. I have a few of them running linked as a bank now. They are proving to be very good pieces of equipment so far. If I can avoid it I will. It is one of two lanuages I have tried that I just don't like. I find many aspects of the language to be absurd, and my experience is that it is a terrible thing for teaching people to code. I am finding that the Pico code I write in C/C++ works reliably but the Micropython code suffers from marginal timing issues and general low level unreliability. Not a problem until I want something to run for weeks at a time. Aside from that, I agree that the Pico is an excellent microcontroller for general use, but it's a shame that theres no acceptable Javascript option yet, although the internet says it is being worked on - there's some merit in everything being in the same language because it makes my head hurt less. (Matlab, Ada and Perl in the office, JS and python at home if I'm not careful. I'm amazed anything works at all some days.)1 point

-

You need to set the architrave back from the face of the liner at least 6mm, modern hinges have a bigger barrel now, this will catch the architrave.1 point

-

Sure but the ASHP installers tend to err on the side of caution and don’t take MVHR into account. For example, our installer wanted to fit a much bigger heat pump than our heat loss calculations said. Get the insulation and airtightness detailed really well and your heating input needs will surprise you. Keeping your house cool on really hot days is likely more of a challenge than keeping it warm on really cold days.1 point

-

Hi Jonathan and Welcome to the forum. Building a house is tremendously exciting but also enormously complicated. Excellent looks like you turned up in the nick of time. My advice is. Digest the forum and build as close (or beyond) a passivhaus as possible. If done from the design stage it's not particularly expensive either but will need a little thinking. The forum will help. Post some de-identified drawings if you like. You'll have such low energy demand that your choice of heating systems is almost immaterial.1 point

-

Door liners fit any height and width door, all you change is the wall width. a lining kit will come either 2100 high or 2200 high and with a head that you cut to size so will fit any door from 838 to 762. make sure you pick done widths suitable for wheelchair access if you need it.1 point

-

Slow down. You ideally need heat loss calculations done. You can either have a go yourself (there’s a spreadsheet on here if you want to try that) or speak with Fleming Homes about doing the calcs. There’s a Glasgow company called Lùths Services who specialise in this area.1 point

-

slow down...... Get the Heat loss calculations for what you want to build and when you have this info, you can ask for quotes - otherwise its just speculation and your spending thousands boring bedrock when a £4K ASHP will (or wont work), and if it won't work then IMHO you need to change the spec, because it should.....1 point

-

No, just need to leave enough for door frame and architrave. You either want o leave a good 100mm of wall between architrave, or nothing.1 point

-

1 point

-

The kit is being supplied by Fleming Homes to our design. I have details of what the panels in their system claim to provide but as our design has lots of large windows, some large rooms, open spaces, a flat roof and large areas of roof terrace I've assumed the calculations could be relatively complex but will obviously need to be provided in the building warrant drawings. In the meantime I'll be absorbing as much info as I can. Tomorrow I'll be contacting some ASHP installers.👍1 point

-

You are ocd correct . Both doors must open the same way . I’ll be brave and cut the proper door tomorrow.1 point

-

I was just going to say that even if it was counter intuitive you'd soon get used to it, but yes - it is exactly the sort of thing that keeps me awake at night in the planning stages!!1 point

-

Who is providing the kit? We can probably pull some detail from their website.1 point

-

If you've paid a deposit to the kit designer, I assume you have a quote based on a fairly detailed spec. Fair chance you'll be able to do a pretty accurate heat loss calc off the spec/quote and know if an ASHP is in the running1 point

-

@MikeSharp01, I am also minded by this wonderful post by @Cooeyswell and to which Jan often refers: "Who the **** is going to fix this **** after your demise?". This is why I now try to avoid doing my own H/W design or firmware development these days. 🤥1 point

-

Airtightness is at least as important if not more important to building performance. Start reading up on that and decide where you want to get to.1 point

-

1 point

-

You'll be amazed at the widespread indifference to energy efficiency within the construction industry.1 point

-

In hindsight, Cosy worked well but ended up costing £30 more than just being on Octopus Tracker for 3 months, before even factoring in battery inefficiencies. So I'm just on Tracker now. Obviously tracker won't stay cheaper forever, but at present with low rates on Tracker there just isn't a use case for Cosy to me. It still compares well against standard variable, of course. Flux was a different beast, over £200 better being on that over summer compared to Tracker with fixed export at 15p, so I'll switch back to that again in the spring depending on where export rates go.1 point

-

I started in the same place a few years ago, then realised I really wasn't getting what I expected. After that I learnt and started to drive what my expectation were. I actively reviewed and commented on every document, as would as a client within an engineering project. Learn and fully understand things like kW is and the difference to a kWh - sounds easy, but you would be surprised how many mix up the units. Also understand U values and R values and the difference.1 point

-

As the client, the level of insulation and air tightness is up to you. Get your head round your energy saving options and tell your architect what you want- build to passive house or building regs or somewhere in between, but it's your call1 point

-

Thanks Mike and Jack. For @dpmiller, I note that the board that Mike references uses HLS8L-DC5V-S-C relays which are rated to 10A at up to 30 VDC. Perhaps the main difference between the Pico and ESP32-based boards is that on the ESP-based boards you have a range of options such as Tasmota, ESPEasy (as well full Arduino Runtime and JS, Python and Lua runtimes for higher level scripting) on the Pico for are pretty much constrained to doing your own custom MicroPython firmware development. So for the Pico you have to do firmware development whereas on the ESP you can avoid the need for custom firmware development entirely by using standard OS firmware such as Tasmota which offers and MQTT interface to these type of I/O boards, (as well as having a wider choice of languages/frameworks if you want to go down the custom route). I am comfortable with using custom firmware (I helped develop the Lua runtime for the ESPs, after all) but doing to means that I need to think about long term support options whereas both my son and son-in-law already use Tasmota devices in their own Home Assistant implementations. Here is one example of an equivalent ESP-based 4 channel board that I am considering, and you are spoilt for choice in this space.1 point

-

Well that's a weird thing as at least some of those are covered by BC already. As there are no hard-and-fast targets written there, maybe one or two pages of eco-waffle? Most people on BH are far ahead of the curve on these items, so I'm thinking probably you will be too.1 point

-

Time for a chat with your architect I think. You need them to accept what you have established, or prove otherwise. Also for a clear understanding that you want expertise, not bad info from sales pitches they have heard. That applies to the rest of the project too, for example insulation and airtightness. Looking forward to hearing of your progress.1 point

-

There is no way the hollwcore slabs will sit on 50mm of 100mm blockwork, they aren't made to that level of prcision. 100mm blockwork is ok to support them, although we have 140mm blockwork because, I think, we have some very big slabs. Our SE specified this. You definetley need an SE. They cost far less than an architect and give very good value. For airtightness around the slabs on a cavity wall there are three things that we did, but you can choose from the list: 1. Get the ends of the slabs filled with concrete at the factory. This is the minimum I think should be done and is common practice in Ireland where airtightness building regs are stricter than GB. The ends are not always completely airtight however. 2. Put a bed of mortar under the slabs. This closes most of the gap ready for airtight paint later. 3. Wrap the slab ends in solitex, with mortar bed in place to provide a slip plane. We did this. Probably overkill and it can't be left to the trades on site to get this right. Any service voids at the boundary will leave a gap into cavity to be closed. The filled ends are not complete (on ours they forgot to fill one of the slabs) but better than nothing for very little cost. Mortar on wrapped ends: Service void:1 point

-

we put ufh in the bathrooms to warm the tiled floor (a comfort thing), with rads in bedrooms.1 point

-

The other thing to question and research is whether you need UFH upstairs. It’s a big expense. For example we don’t have any heating at all upstairs, apart from an oil filled rad in the bathroom, as do many others on here. We have wired for some electric panel heaters just in case I am wrong about the need for heating. However the house has been up for 9 months and the heating has only been installed for a few weeks and upstairs has been fine.1 point

-

Probably the only 'safe' (in the sense that installers are unlikely to object) tank is one where the coil is at least 3 sq m and the size is at least 45l* (greater of number of bedrooms +1 or actual occupancy). Unfortunately you may also get installers who insist on 28mm primaries to the tank, or using a pre-plumbed tank, so even this is not absolutely guaranteed (incidentally I would run a mile from any installer that wanted to use a pre plumbed tank unless it makes sense in terms of the layout of your house. if they are shoehorning a pre plumbed tank in where it doesn't fit its because they use rookie plumbers and there is less chance of cock-up with a pre-plumbed cylinder ). If you want to get a feel for it you could play with the simulation in the DHW tab in the attached workbook With all the usual warnings that its a theoretical simulation only etc... WC Simulation.xls One of the more rational reasons for large coil size is the risk of cycling towards the end of the heating period if the coil is too small. This is of course a particular problem if you have a high capacity, oversized, heat pump that doesn't modulate down well (as fitted by a fair few installers). Cycling will extend the reheat time quite dramatically. You say you are looking at around 6kW however - at that level you are very unlikely to have a problem with a 'Vaillant' coil size in practice, but of course that wont necessarily convince an installer.1 point

-

It really will. There are many people on here with ASHPs and they are perfectly fine. Our previous house was over 300m2 and wasn’t particularly well insulated or airtight and it was sufficiently warm with more than enough hot water. The house you are building is similar in size to the house we’ve built. It’s very well insulated and very airtight. I can heat the place with a couple of oil filled rads and have done up to the ASHP being installed. You’re being given duff information on ASHPs I’m afraid. You shouldn’t need to spend anywhere near what your quoting for heating and hot water. Do you have details on insulation and airtightness targets.1 point

-

I have a couple of these I intend to use to control 24v which will then use WAGO 24V relays to control the bigger loads. https://thepihut.com/products/industrial-8-channel-relay-module-for-raspberry-pi-pico?variant=40605655367875¤cy=GBP&utm_medium=product_sync&utm_source=google&utm_content=sag_organic&utm_campaign=sag_organic&gad_source=1&gclid=Cj0KCQiA2eKtBhDcARIsAEGTG40_R-cXtRgFbkA_bCKbAX7r1NvSWOReNEeHk8qOv5Sf7LZeswKMf6gaAiS6EALw_wcB As it takes a PICO directly, which you can of course bridge out on the Gpio pins, you have a smart relay board to boot.1 point

-

You're probably not far off on the kit cost (especially if you want a lot of centrally controlled dimming), but we didn't have any professional services costs. I did the design with the electrician (who admittedly has an electronics engineering background), he did the installation, and I handled the programming. The programming really isn't difficult if you're of a reasonable technical bent. There's lots of support on Google groups and various forums, too. I'm not sure whether I'd use Loxone again. The upside is that the system is extremely easy to program, and it can be used with a wide range of other protocols. It also virtually self-documents itself as you program it. The downside is that it's very expensive if you want to use their proprietary modules like dimmers. I'd be tempted to just use the miniserver (the Loxone core controller) and have it coordinate everything else via DMX, KNX, and IP based protocols. Also, while it would be a hassle to swap in a different solution if Loxone went bust, it's still just inputs and outputs at the end of the day. I'm sure a lot of what's there could be replaced with equivalents from a different system.1 point

-

Thanks, we're still gathering all the info we can. She wanted an outside sink as well.😄1 point

-

A 210 l tank full will take about 9 kWh to heat. That's 1.5 hrs with a 6kW HP. No amount of coil area is going to reduce it below that. So it is probably not the rate limiting step unless you have say a 10 - 12kW unit and are desperate to get the recovery time as low as possible. But a 12 kW one will generate HW continuously at over 5 litres/min which is rather better than an electric shower. So timing it for when you are actually using the HW might mean it does not deplete the stored water at all.1 point

-

☺️https://www.selfmade.com/en-gb/p/prym-snap-button-w-cape-15mm-silver-10pc-669344/45053 like this, you can get heavy duty ones for heavy fabric and leather with pliers1 point

-

Pre-cast houses put up in the fifties were done on a budget and at speed and not really designed with longevity in mind. I have a plot that had a pre-fab bungalow and the condition of the foundations are not in the best of shape and it was always the intention to get them removed when I commence the groundworks. Personally, I would not take any chances and best to budget for it’s removal and start from a correctly specified base.1 point

-

1 point

-

They don't normally work properly at all. Is the rock hot? Otherwise you are taking heat out of the rock, but it can't replace it quickly and you run out of energy. Near me, a development with 12 borehole systems 90m into clay has had at least 4 replaced by air source, because they weren't working. All agreements to replace were private, so there may be more. There used to be a lot of cowboys in ground source. Most have gone, and so those left are perhaps giving you great advice. Anybody near you with GSHP so you ca see how well it works? what guarantees will you get? what happens if it doesn't work well Trench type is actually air source. The ground warms in the summer from the sun and air, and stores it for winter. you only need 1m or so. A borehole needs the heat to be replenished from hot rock, or from water flowing past, eg in sand or fissured rock. That's what we'd expect. For a 200m2 house you'd probably pay about £10,000 for the ashp and internal gubbins (excluding the plumbing around the house which applies to any system). I'm guessing the gshp will be many times that cost. ??? there is no limit to the energy available in the air. Unless you are in the arctic Id expect air source to be a better bet.1 point

-

1 point

-

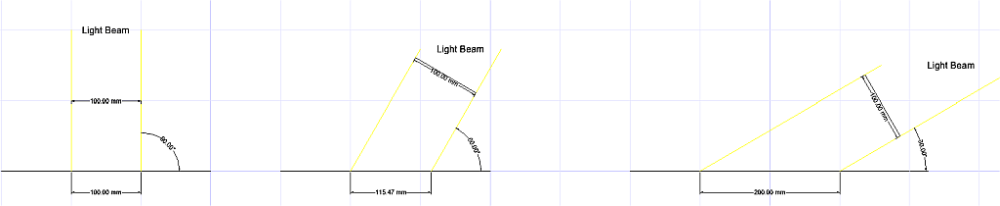

Trigonometry, Power and Specific Heat Capacity. To keep things simple, assume the same light beam, with a power of 200 W.m-2, and using the sketch above. When the sun is at 90° to a surface, the area will be 100 mm by 100 mm, so 10,000 mm2, or in proper language 0.01 m2. The power per square meter is therefore 200 [W.m-2] x 0.01 [m2] = 2 W Angle the beam over by 30°, the area changes to 115.47 mm by 115.47 mm, so 0.0133 m2, 33% greater area, at 60° it is 200 mm by 200 mm, 0.04 m2, 4 times greater area. So it goes from 2 W of power, though 1.5 W at 30° to 0.5 W at 60°. If your wall was granite (or most stone/brick/cement) it has a specific heat capacity of around 0.8 kJ.kg-1.K-1. Now a W is a J.s-1, a small amount really. The density is around 2500 kg.m-3. Taking an area of 1 m2, but just the first 10mm of wall depth that is facing the sun, this will have a mass of 2500 [kg] / (1 [m] x 0.01 [m]) = 25 kg. So to heat up 25 kg of wall, by 1 K will take: 0.8 [kJ.kg-1.K-1] x 25 [kg] = 20 kJ of energy. At a power input of 200 W.m-2 (200 J.s-1), and not taking any losses into account (which will be quite a large fraction) to increase the temperature by 1 K will take: 20,000 [J] / 200 [J.s-1] = 100 s. At 30° light beam angle, 133 s, and at 60°, 400 s.1 point

-

The issue there is that you'll be accessing a smaller "pool" of groundwater and might suffer from repletion issues. Out of interest how come ground source instead of air source? Don't hear of many being installed for domestic projects these days, don't normally compete in terms of cost.1 point

-

Bit more progress. We are now fully plastered and I’ve done about 60% of the painting. Heating has finished the floor drying mode which resulted in one relatively short minor crack in the floor. Worktop was installed today. It’s big a very white. Nice job by the fitters. We have a slight problem in that the sink is a little too deep (by mm) so it’s fouling the drawer beneath stopping it from fitting. I can check a bit out of it but the kitchen company has agreed to make up a new drawer carcass and I’ll swap the front over. Also a bit of a palaver fitting the extract duct for the hob.1 point

-

+1 to trend's high tooth fine blades. Got one for doing kitchen panels, perfect cuts with no tear out.1 point

-

I agree but not to the extent of diminishing what can be built on the site.1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)