Leaderboard

Popular Content

Showing content with the highest reputation on 01/22/24 in all areas

-

2 points

-

2 points

-

After a chat we had recently with someone who had built a lovely chalet bungalow, I checked on their planning app as I wanted to copy their materials statement. Let's just say what we saw was a teeny bit different size-wise.1 point

-

The copper flexys are handy sometimes. Our chinese friends offer convoluted stainless tube (similar to the tracpipe or the flexy solar stuff) in short lengths with flat faced ends for a few quid a touch, they're quite nice too. Same is used inside UVCs as the HE coil this kinda thing: https://www.aliexpress.com/item/1005002680190702.html1 point

-

So i've manage to get some stability since Saturday night. Basically I opened all the zones so all my thermostats are constantly on then using the high UFH temp I warmed up the house to a comfortable 21-23 deg in various rooms and then I crank the temperatures right down but everything is running constantly. Downstairs is running around 30 deg Upstairs is running at the lowest on mixer which is 40 deg All the rooms have been a stable temperature for 2 days with no drops. Now I know that temps have also increased so i've yet to test in sub zero temps but at least now i'm not experiencing low temps. So thank you everyone for the helpful comments Next I will be purchasing Salus auto balancing actuators to have optimum flow rates.1 point

-

1 point

-

If you added 100mm I doubt it would be noticed, I have yet to hear of any build being measured after completion (my roof was 100mm over the designed height but no one noticed 🤷♂️)1 point

-

True - my assumption was that it may be going through/been approved by planning without that in mind though...1 point

-

Managed to get everywhere completed now. Living Room (-2C Night) Before - Temp just before the heating comes on - 15.7C After - Temp just before the heating comes in on - 15.8C Bedroom (0C night) - Least accurate as the reading comes from TRV which on a night is behind curtain, though both values came from same device in same situation. Before - Temp just before the heating comes on - 13.7C After - Temp just before the heating comes in on - 14.8C Dining (0C night) Before - Temp just before the heating comes on - 14.8C After - Temp just before the heating comes in on - 15.1C Did some acoustic readings before and after for the 'roadside' windows, and achieved a 1dB drop on all 3 windows. The temperature readings are probably very finger in the air stuff, i've tried to marry up days with similar temperatures and the previous day where i was in all day to make it as good a comparison as I could. I noticed the newer uPVC windows i've got have a larger gap around the glass in some cases, but not always, so it could be difficult to say exactly what size backer rod would be perfect. I think for the majority the 10mm stuff has been idea, and even tight in some cases, but then on others i've had to double it up and 20mm would have been a better choice. All in all, i think for the small outlay in money and effort, its certainly worthwhile considering, especially if you are fitting new windows and have the beading off anyway.1 point

-

You can ease a bend into them, don’t try to bend the 15mm bit even with a spring or you can distort the end that’s going into the hep20. Gently bend the thinner section/s. If you have a small tube bender even better1 point

-

I wasn’t either ! . I had some flex’s disintegrate on my temp sink kitchen tap ( only 2 yrs old ) . I’d forgot about that . But Friday a friend said they got in their bath turned off the hot and heard a pop as the flexi split - naturally flooding their bathroom . So - Now I worry about flooding my nice new kitchen. Also you’re going to worry . Bet @Thorfun is worried also . Might have to start a new “ Worried and scared “ thread .1 point

-

1 point

-

Looks like a system flush/chemical clean and some corrosion inhibitor wouldn't go amiss. Wonder the system worked at all.1 point

-

1 point

-

If you are currently insured, talk to your supplier of insurance and they will do a temporary change of insurance during the work period. Then if the worst happens you are covered1 point

-

You don’t need to insure contractors but you do need to insure the building Your basic build insurance will cover the building fire and theft and your liability should anyone wander on and injure themselves Id definitely insurer the building against fire and flood1 point

-

Welcome. There are 3 main things to consider (4 if you consider safety). Will it affect any Fit payments. Will you need a new inverter. Will your DNO need notification for the increased generation capacity.1 point

-

My house is not the same design as yours at all, but myself, and my neighbours, have all had the same leaks. They happen when we have strong south westerlies (and they are strong down here). Leak leak in the same corner of all 3 of us was caused by the lift insulation moving, then somehow soaking up wind driven water. This caused damp patches on the bedroom ceilings. The other leak, similar to yours, is above the downstairs window, and can be a lot of water coming in, a constant drip for hours. This was caused by a crack in the render. This crack (in my house) was not that close to where the leak in the inside was (about 3m away). I 'temporarily' fixed with a squirt of sealant and it has held for several years now. Main thing I learnt was with a timber frame house, water paths can be very long and contorted. My neighbour was a bit miffed when he had new windows fitted and the leak did not go away. The give away to me was that the leak was higher up than the window frame, by about 40mm.1 point

-

Actually we put our conduit within the insulation under the screed so didn’t have to worry about depth of screed. sorry, forgot about that!1 point

-

@Gaf Can you post up a cross section of your house please? Take your name and address off it and I'll have a look. Kingspan Kooltherm is ridiculously expensive. It's 4 times dearer than PIR for the same U value and 7 times the price of mineral wool. It has a negligible performance increase for the same thickness vs other insulations. 100mm Kooltherm is the same as 105mm of PIR. There's two reason's the architect is suggesting it. The Kingspan salesman gave them a handy booklet that they were able to copy and paste a detail into your drawing because they were too lazy to cost and draw up a detail themselves. The Architect is getting commission from Kingspan for selling their product. Either way it's going to cost you thousands of euro.1 point

-

1 point

-

+1 I can't see the point in building a timber framed business unit.1 point

-

Sounds like one of your old slave ships from the 17th and 18th centuries. "Once she goes black, she ain't every coming back"1 point

-

1 point

-

IIRC Icynene is made from oil from the castor oil plant.1 point

-

Yes, most probably are, and bio based will be for specialist installations. And there there will be the clash about land usage. We had a spike in grain prices back in the mid 00s because some twat of an oil trader could not work a calculator when working out the consequences of adding 5% bioethanol to gasoline would actually mean. It is going to be either price or legislation that changes the market. But I would still use blown in cellulose.1 point

-

But a bit like EVs from the 1900's they were pushed out by cheaper, higher performing fossil fuel based products. I believe for now, PU based foam thermal insulation products are fossil fuel based, but the industry is having to re-look at alternatives.1 point

-

Not really, they have been about for decades. Was back in the 80s I was working with them. I think the very first polyurethanes where bio based, as where the first plastics (called cellulose for a reason) No idea. There are so many different blends from secondary re-processor that I can't keep up. It is one of the problems that makes comparisons so difficult. The base may come from 2 or 3 companies i.e. Bayer, but then it has other chemicals added before being shipped out i.e anti-oxidants, plasticisers, lubricants, fillers.1 point

-

Is this not at research stage (for use as a thermal insulation product), with work still to do? Is there a commercial product available. I remember reading about blends of veg oil in fossil fuel based PU foams, but then more of the blended product being needed due to the reduced performance of the veg oil.1 point

-

Putt my chef's hat on for a moment, if people can't cook, then the choice of hob is irrelevant. Those that can cook, prefer an induction hob. And don't fall for the nonsense about 'you need thick based pans on an induction hob to spread the heat', that is only said by people that can't cook.1 point

-

And the other comes from plants, possibly. We used to use a vegetable oil derived polyol, worked just the same as the others. If it can be made from oil, it can be made from plants, usually.1 point

-

Spray foam insualtion has one of the highest embedded carbon levels of any insualtion, cellulose has one of the lowest. Even though you need more of the cellulose, it's still way lower. Never mind one come from trees, and the other comes from an oil refinery.1 point

-

As with all things, none of them are bad, if done right. Personally, from my limited experience, the sound deadening qualities of cellulose would make it my choice. I think there are two ways that this gets installed, dry and wet. I think from memory that the wet method reduces the chance of slumping. There is also the bigger environmental picture. Cellulose is a recycled product, which may, or may not, be environmentally better (mineral wools have a very low embodied energy though). As for the 'off gassing' of polyurethane and phenolic based products, not a problem these days, 50 years ago maybe it was, but we survived the 1960s and 70s. If you are really irrationally worried about it, get rid of your sofa, mattress, car steering wheel, carpet underlay, then move up an isolated mountain, make sure that all combustion technology is banned within 500 km...1 point

-

Yes, pretty much. I did some work in a hotel once and there was at least one connector failing every month, sometimes every week, even more than one on the same day. I recommended replacing the lot, but the budget wouldn't stretch that far. Cheaper to repair the damage. Personally I no longer use or specify them, except the ones that are safely fitted inside a WC cistern. It's easy to avoid them - you can readily buy rigid copper tails to fit monobloc taps, and just use regular pipe connectors elsewhere. See also Faulty hoses dampening Australian households.1 point

-

No problems with blown Cellulose here, ~0.1 ACH with no membranes. Can't say I didn't use tapes though, as all windows were taped and all penetration in the external air tight layer (T&G Egger DHF board) were either gasketed or taped. I went with blown cellulose primarily for its air tightness and acoustic qualities. At the time I was making the decision there were also numerous comments going around about PUR/PIR type insulations off-gassing and I wasn't able to quantify any potential risk involved with that, so went with the cellulose and other natural materials as much as possible.1 point

-

I would say “if you have electricity, I cannot for the life of me see why you would want gas.” I think @ectoplasmosis summed it all up nicely. @ProDave we’ve got a couple of camping gas stoves for the power cut that hasn’t happened since we bought them. Tonight may be the night though, it’s blowing a hoolie out there.1 point

-

Cad work is done for now. Meeting with the architect next week to try and finalise most of the window sizes and some other details. Almost finished printing the parts for the model and made a start tonight glueing it together. I’m using PLA plastic for the prints and super glue to stick it together.1 point

-

It may not help in your circumstances, but Passivhaus design is one way of overcoming this economic dilemma. That is, if you increase insulation, and all the other factors, 'enough' (to require no more than 15 kWh/m² of floor area per year for heating and cooling, as calculated using the Passivhaus Planning Package), then you won't need to pay for a traditional central heating system. And that saving then pays, in theory, for the extra insulation and other measures required to achieve the standard. In other words, there could be a world where you and your identical brother spend identical amounts on the build, but you save on your fuel bill each year and he doesn't.1 point

-

There are dozens of things you could do to improve the efficiency of your build and, as you're finding, at some point you reach the point where you have to say "I'm just not going to do that". The key is to make sure you're doing the things that are most effective and being consistent with yourself, there's no point spending thousands extra on one aspect early on in the build and opting out of something else later on that was actually much more cost effective. I ended calculating a "pounds per W/K improvement" measure that I used to decide to make sure I was being consistent with myself across the project. If I was debating adding a new efficiency improvement (e.g. increasing insulation, introducing marmox thermoblocks on our masonry build, thermally broken lintels etc.) I would assess the impact of the money I was spending on the improvement to see if it was worthwhile. So in your example: A U-value of 0.14 over a 220sq m wall area, gives the heat loss through the wall as 30.8 W/K. A U-value of 0.11, gives you 24.2 W/K. So £6000 gives you 6.6 W/K improvement, meaning just over £900 per W/K. For info, my cut-off was somewhere around £350 per W/K (based on raw materials as we DIY'd a lot, I'm aware your figure is fully finished)1 point

-

It's interesting that payback period is one of those things so often raised as a problem when it's down to spending on the fabric of the building or the heating system, but never gets a look in when it comes to a bathroom, kitchen or some other internal home improvement. Yet from a daily living perspective it's worth so much more. Everyone who visits our house for the first time, especially in the winter remarks on how comfortable and warm it is - which I explain is because it is well insulated and doesn't have any draughts. Is that worth the just the extra £10k I decided to spend on insulation? Absolutely.1 point

-

Also have to concider location and building form factor, also some people live in colder locations, so payback is different. If you are doing UFH get yourself down to 0.1, to mitigate downwards heat loss. And the roof is generally quite cheap to get down to 0.1 also. All things house related are not about pay back period. If you built all houses based on payback we would all live in tents. You mean 0.14/0.151 point

-

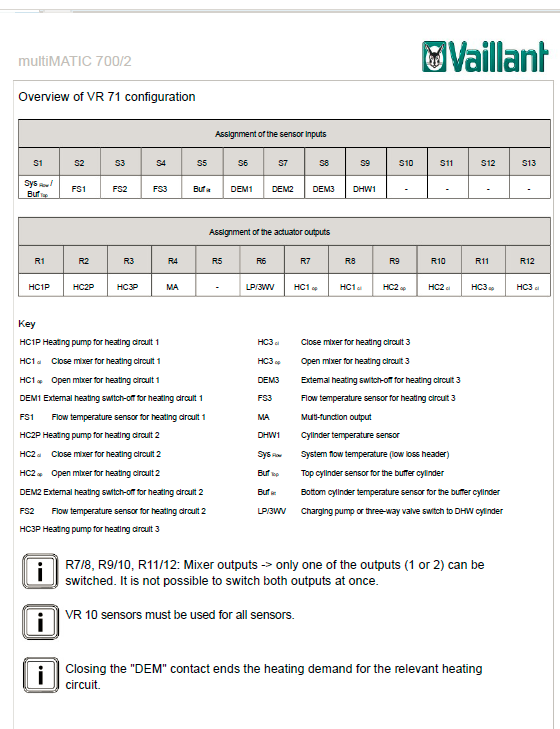

Here is the connection diagram for the Vaillant VR71 interface box. You can see that terminals S6, S7 and S8 are used for the heat demands for up to 3 different zones. Note 3 says they are contacts closed to stop heating, this is the reverse of the usual convention but it can anyway be changed to "closed for heat" in the installer menu. In my case the zones will be rads, UFH and a thermal store. Vaillant have signed off the schematics with the Honeywell external controls connected to S6, the existing UFH manifold controls to S7 and a timeswitch to S8 so I am 100% confident they are happy with external third party controls, and a simple contact closure from your Sunamp (of either sense) should work fine. I do not know whether the Sunamp should be treated as a separate zone or as a substitute for the usual HW cylinder. Your installers should agree a set of schematic diagrams with Vaillant for your Sunamp application, they will not support it unless the design is signed off like that. If you can get them to give you a copy and post it here we can tell you more.1 point

-

Make sure you rub them up and and down well with something like old nylon knickers (seriously). Makes it easier to bend.0 points

-

0 points

-

Just coming back to this topic because for the last year and a bit I've had to run my CH pump on speed 2 to stop the boiler short cycling - Previous 30 years it's always been fine on speed 1 but I made a lot of changes a year or so back doubled rad size and reconfigured pipework as well as changed all the lockshield valves and TRV's. I think I know why now - I pulled the pump apart at the weekend Took a bit of work to get it clean and all the impeller channels clear - I have a magnaclean unit in the circuit but it's after the pump and never seems to collect much magnatite0 points

-

0 points

-

Are there no actual roofers or roof surveyors on this forum that can give some actual opinions instead of randoms that have no useful technical information.0 points

-

Just imagine going to see an ancient Aunt and she starts rambling on about chemistry and how her house is insulated with Icynene, then noticing the castor oil plants in her living room, and her Palestinian husband. Or is it just me that has strange Aunts.0 points

-

I have rimless with no attenuation . It can splash a tiny bit - but no real issue when you consider all the piss and shit covering the floor anyway .0 points

-

0 points