Leaderboard

Popular Content

Showing content with the highest reputation on 09/14/23 in all areas

-

That’s good What you need to realize is I’m not a builder I’m a self builder that takes the term literally I’ve loaded every block and brick Even though I’ve people who could do this for me But it sort of defeats the object Shopping around and doing as much of the labour yourself isn’t beyond most keen DIYers Which in most cases can cut your turnkey build cost in half2 points

-

A larger diameter thicker blade would be horrendous to use, the rim weight would act like a big gyroscope and the blade clamp wouldn’t be able to hold onto the disc when you released the trigger.2 points

-

2 points

-

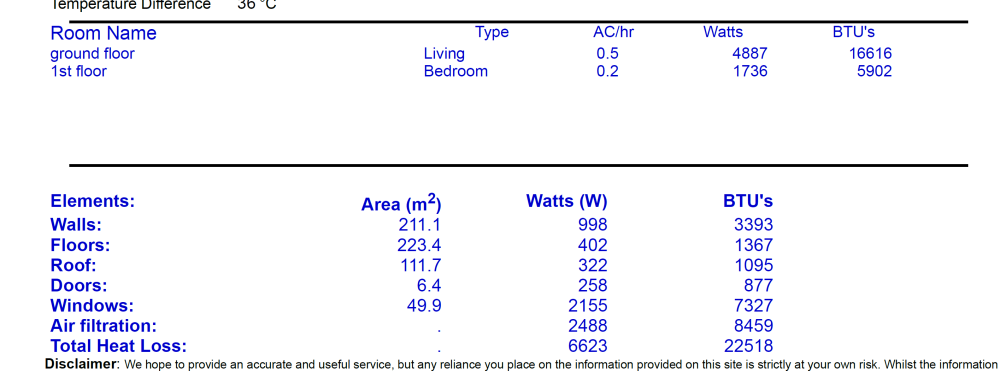

Even if your airtight test shows you have a leakage rate of that, that isn't the figure you would used in a heat loss calculation. The 50Pa used during the test is the equivalent of extremely high winds, on all sides of the house - so you have to have the lowest temp and extremely high winds from all directions at the same time, which is rare or impossible. You would be fine using 0.5. It's only really going to be that if you have mechanical ventilation running 24/7. Otherwise the infiltration would less than 0.2. If you have a SAP report the infiltration rate will be in there.2 points

-

spelcheque striques agen. As all loads know to disperse at exactly 45° (symbol cut and pasted from above) the wheels will be far enough not to load the wall at all, and only a problem if the car users are very heavy indeed. You can scrape a footing and build straight on to of it to hold back 450mm, for more you might want a wall with some structure, but in your circumstances i think I would simply lean it back towards the cars, or make it thick.1 point

-

Don't get me started again @SteamyTea Like that poor fella who was asked to spend a load of cash because he had a flawed Air test. He had some of his uncontrolled air losses taped off for his air test. It might well have been what was required for the test, but it didn't make his result scientifically correct. Luckily, the BCO understood that the test, although carried out correctly, was flawed. Science, i think i went once, and sometimes, logic beats science.1 point

-

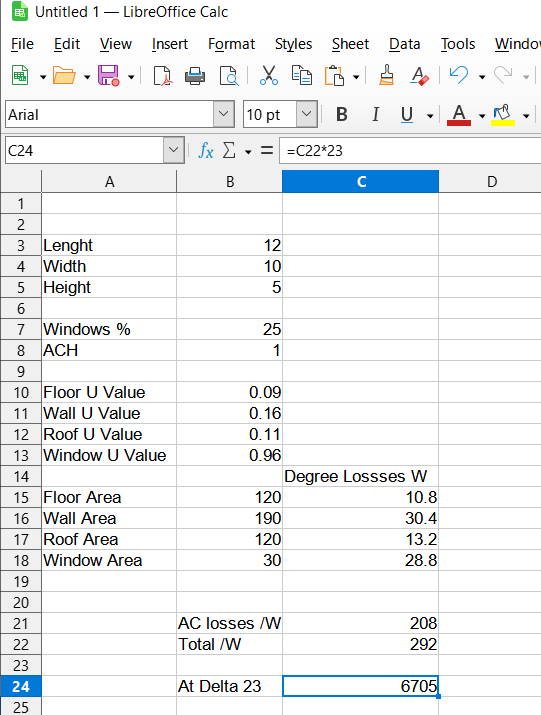

Shows I can bull shit with the best of them still. I was thinking that it may be worthwhile knocking up a very simple spreadsheet that does a sanity check. Or if there is a clever person on here, a web based one.1 point

-

I think you have, 50 kWh would be more like it, though that would be a very large, and heavy, set of lead acid batteries for a fork truck. Maybe they said 50 Ah. Lead acids used to be the cheapest mass energy storage, though I suspect second use lithium's are cheaper now. Lead acids take looking after, but nothing wrong with them.1 point

-

Probably an 8 kW model is needed. Most of the time it will be fine as it will not be -2⁰C outside, more like 5 to 10⁰C, then the heating is off. Are you fitting MVHR, if so, your air change losses will be quite low, as long as you get your airtightness good. As others have said, how often will you really be running 4 showers at the same time? At 10 litres a minute, with 4 showers running, a 300 litre cylinder would be empty in about 10 minutes. Actually if it was stored evenly at shower temperature, the 7.5 minutes.1 point

-

im looking at a 9kw panasonic aquera as running it at 4-6kw is its most efficient apparently.1 point

-

You might want to go a bit larger, as you want it running less than 24/7 on heating on coldest day as it'll also need some time to do the DHW reheat. Also going larger means the DHW reheat is faster, meaning you can get away with a smaller tank. Spot on. You increase the stored energy by storing more volume, or higher temp, or both. Generally a larger volume at lower temp is more efficient (better COP to heat it, and lower standing losses due to lower delta T and the better surface area to volume ratio on the tank. I think 😅)1 point

-

1 point

-

An extra 208x2x23=9.568kW surely? ACH assumptions make a huge difference to heat loss calculations, particularly in well insulated large houses. @SteamyTea's worked example shows that clearly, 84W for fabric and 208W for 1ACH. As mentioned above, it's the realistic value you want to use not the @50Pa result.1 point

-

Haha - I think that's far enough and not even in the realms of OCD to be honest! But either way, it's available in grey too so all is good1 point

-

our target was 1ACH. our house is much more complicated that a basic rectangle and we spent a lot of time taping windows and membrane around attic trusses and fitting Tony trays etc. we ended up with a score of 0.98ACH@50Pa and were very happy. we know we could've got it lower if we had the time (and a diy blower to keep testing with) but as we'd already hit my target i was happy to leave it there. so 1ACH is very achievable doing it DIY.1 point

-

1 point

-

Dig the foam out 5-10mm and use a couple of layers of Easyfill 20 - one to bulk it out and the next to smooth over.1 point

-

It says it is compatible for lead 👍, however being OCD I would use grey to blend with the lead and the stone.1 point

-

Yes building with blocks and a tiled roof. So assume 300mm with reinforcement would be better. I’m no expert though1 point

-

G99 you can have any size system you like, the inverter is just set to match the allowable by DNO.1 point

-

The air changes per hour will make a huge difference and you should be nowhere near 3 in a new build. Try 1 as a conservative starting point.1 point

-

What calculation software did you use? Was it Jeremy's spreadsheet on this forum? I have broadly similar insulation values to you but only a 150 square metre house, and my max heat loss is about 2200W with inside at 20 degrees and outside at -101 point

-

Well, when there's a vertical load the rule of thumb difference in height allowable is 4 x thickness of wall - 750mm would suggest 187.5mm. However, this is a pure retianing wall with no vertical load, only a horizontal one, however unless a really heavy truck was to be parked alongside the wall I would have thought a total of 100mm block plus 150mm stone = 250mm would do. If you wanted more certainty without involving a structural engineer then how about a strip of horizontal mesh in the foundation with vertical bars at intervals. Make the vertical rods L shaped and wire the "foot" to the mesh. When set, use 225mm hollow concrete blocks with the vertical rods threaded up the voids and backfill the voids with concrete. Face with stone. I can't see that being pushed over easily.1 point

-

As a general rule, if a wall is, or is in part, retaining, then the width of the footing should should be equal to the height of the retaining portion of the wall. In your case, about 600-700mm? In these cases the footing acts more like a beam, so depth is less important as the load is spread out over the soil, rather than down through it. I'd dig down deep enough to firm ground, the full width of the path, and pour 25nm concrete to the depth that allow you to pave directly on top with about 30mm mortar. You'd want a wee bit of steel in there as well. Even just dowels for the first course. Our retaining wall founds are only 250mm thick and about the same under the surface. But they are 1200-1700mm wide with a fair bit of steel. In fact, one is at FGL and forms the base of a "shed". This wall is 100mm RC tied in to the slab, bricks and block used as shuttering.1 point

-

Sorry steamy I only have an iPad which does not have those “things”, I am sure people know what I mean 🤷♂️1 point

-

Perhaps I am getting lazy in my old age but do you need to park close to that wall?, my immediate thought was to slope the ground at 45’ (do you still have your digger?) use the stone as a rockery on the slope 🤷♂️1 point

-

Am I missing something here. It is not just a foundation for a wall. That is easy. Just dig until you hit hard undisturbed ground, no calculation will tell you what you will find when you dig. Bit this is not any old wall, it is a retaining wall, if I am reading it right to keep your driveway from sliding down into the piggery? If so I have not seen discussion of the height of what it has to retain and the forces trying to overturn the retaining wall.1 point

-

1 point

-

You'll likely get those on single phase easily as they don't all hit max generation at once and you'll do well to get 3kw out of the NE array. If you put each array into PVGIS separately, download the hourly figures for each of the 3 arrays then use Excel to combine the 3 data sets, you'll be able to see what your max DC generation is. You'll then be able to size your inverter. One of our 2 systems has 8.5kw of panels spread over 3 compass points and the calculated max output is 5.4kw You've already mentioned Solaredge and their inverters will handle way more input than the inverters rating, so you can have a seemingly large array hooked up to seemingly small inverter. What's the peak demand that you need for the house?1 point

-

If anyone remembers slide rules: digits were shown as an answer, but we had to know ourselves where the decimal point went. In a complex sum, it required a bit of working out. But with this sort of calculation, it is common sense. What sort of number do I expect to see? 7mm or 70mm or 700mm or 7m? The answer here is fairly obvious and it usually is. Assuming the calcs are right and the fundamental principle is valid.* For example, I offer each school client a practical maths class. the first challenge is how much concrete do i need to order for he floor slab. H x L x th. decimal places are always the biggest challenge. So I help by asking how many concrete lorries feels right? for example is it 3 or 30 or 300? some kids immediately feel what is right, but others don't. It's the way our brains are wired i guess. Now, from a quick look at your link... *Rankine's formula doesn't, as I recall, apply to foundation depths. But he did a lot of stuff so..@Gus Potterhelp please. There is no such thing as The Institute for Civil Engineers, not in UK and Commonwealth anyway, It is the Institution of Civil Engineers, and these are not they. Who knows who wrote this googled page? So to your wall. I wouldn't calculate this, as its not exactly a motorway where disaster could result. 700mm seems very deep to me. 450? /500? just do what feels right. If it fails it will be by falling over, not settling.1 point

-

I don't know anything about foundations, but I was curious ... as I recall, one way to answer this question is to do dimensional analysis on the equation. Working through the dimensions on the RHS should give a dimension of L (depth of the foundation), but it doesn't so I'm wondering if there's something wrong with the equation .. here is the dimensional analysis: p has dimensions force per unit area, and force=mass*acceleration, so p has dimensions M LT-2L-2 w is density which has dimensions ML-3 The expression in the bracket is dimensionless. So the RHS has dimensions (M LT-2L-2)/(ML-3). If you cancel that through, you end up with dimensions for the RHS of L2T-2, but it should have dimensions just L for the depth. So we need to get LT-2 out of the RHS. LT-2 are the dimensions of acceleration, so the dimensions would come out right if p was in kg/m2 rather than N/m2. So I would say that if you put in a number for p in kg/m2, your answer will be in m. Willing to have my maths homework corrected if I got this wrong 🙂1 point

-

We liked the idea of a raised washing mashine until we saw our friends intsallation with a peice of pipe insulation wedged between their washer and dryer to stop them acting like giant castanets. I think if done right and raised like @Buzz then it can be very nice. But it can be done badly which is not so great. If I remember correctly I think some of the German Kitchen manufacturers install a steel frame to support the appliances of the ground. Which is probably the way to go.1 point

-

Can you qualify "better mechanical strength"? Isn't lambda only a very small part of the overall calculation for sap? The EPS Vs XPS argument is mostly predicated on manufacturer sponsored research. Not going into that rabbit hole but generally speaking "facts" like the ones started do not paint the whole picture.1 point

-

I have just had some horizontal lead flashing done on brick. They used Flashpoint sealant in the gap at the top of the lead. Looked fine to me!1 point

-

1 point

-

With the greatest of respect though -and please correct me if I'm wrong-but I believe you are undertaking some of the work yourself? Thus giving you a greater saving on psqm cost. Most self-builders will be in the same boat as me, not able to do any work Inc project management so will need to assume full builder fees.1 point

-

0 points

-

0 points

-

I ‘read’ porn hub - not sure how helpful that is here . But a literary masterpiece!!0 points

-

0 points

-

That debris appears to be the inner part of the pipe that has just dissolved away! The bit that worries me is about 2/3 of the downstairs is cast into screed under tiles. If the issue was simply abrasion of the pipes from the outside, i'd be reasonably confident the slab pipes would be OK. But if the pipes are corroding from the inside, it's only a matter of time before they go. My choices are to abandon UFH entirely and fit rads throughout or to rip out room at a time and replace, which I can do in the upper floors but the cast in sections are done for.0 points

-

0 points

-

0 points

-

Until you have visitors, who will inexplicably park on lawns/middle of roads/millimetres from the edge of your retaining wall...0 points

-

As soon as I pressed that reply button I thought - I've seen that ..................0 points

-

Ha, my first house (a wreck) still had lead covered cables buried in the plaster. The electric had been disconnected so when the DNO came to re connect it he tested the wiring and nearly had a fit, “I am not connecting that it’s fecking dangerous”, he pulled the main fuse (but left it there). To work on the house I put the main fuse back in, went upstairs and leant on the damp wallpaper and got a right tingle. I quickly rigged a temp power and lighting ring 😱0 points

-

Was a wee delay in getting the ceiling sheets up, but was on site with the boys putting the sheets up today. They're good joiners and put resilience bars on most of the jobs they do (mix of commercial and residential). "So it's 25mm screws you're using?" "No, we just use 32s" "But you're 16mm for your resilience bars and 15mm sheets, so you'll be going into the joist" "It's only a mil and you'll hardly get any biting across the full place" "Are you not kinda missing the point of resilience bars?" Lunch called early while I ran for some collated 25s. And just the latest in a long line of how decent trades would miss the important details if left to their own devices.0 points