Leaderboard

Popular Content

Showing content with the highest reputation on 07/27/23 in all areas

-

Not seeing any reason for a larger cill, that’s the correct size stub cill and unless the unit is goosed, I’m not really seeing any reason to replace the unit either?2 points

-

2 points

-

Right, what is enforceable is the Requirements of Part C - Site Preparation and Resistance to Contaminants and Moisture. In particular C2 Resistance to Moisture. C2 states: The walls floors and roof of the building shall adequately protect the building and people who use the building from harmful effects caused by; a) ground moisture, b) precipitation including wind driven spray, c) interstitial and surface condensation; and d) spillage of water from or associated with sanitary fittings or fixed appliances. OK so it is only paragraph b) that is an issue here. Section 6 of the Approved Document applies to roofs. It gives three concerns : precipitation from the outside, interstitial condensation, risk of condensation on the underside of the roof covering. Here we are considering slates so interstitial condesation is not an issue and if the roof is a traditional cold one with adequate ventilation then there is little risk of condensation on the underside. What is left is keeping the rain and snow out. Paragraph 6.3 states: Roofing can be designed can be designed to protect a building from precipitation either by holding the precipitation at the face of the roof or by stopping it from penetrating beyond the back of the roofing system. Paragraph 6.4 states: Any roof will meet the requirement if: (b) it has overlapping dry joints, is impervious or weather resisting, and is backed by a material which will direct precipitation which enters the roof towards the outer face (as with roofing felt). Finally Paragraph 6.6 states: Roofing systems may be: (b) weather resisting including natural stone, or slate, cement based products, fired clay or wood. Sorry it's long winded but that is what the LABC should consider. So they cannot insist on BS 5534 being used but they are using it as a reference to base their judgement on whether you satisfy the above. However, the Approved Document right at the start states: "Approved Documents are intended to provide guidance on some of the more common building situations. However, there may well be alternative ways of achieving compliance with the requirements. Thus there is no obligation to adopt any particular solution contained within an Approved Document if you prefer to meet the relevant requirement in some other way." (Bold in document). Consequently you can refer to other guidance particularly specialist historic building documentation to support your arguement. Certainly a SPAB document is appropriate in the circumstances and they ought to listen to reason. I would also pay particular attention to the underlay or consider a product such as Isoline by Onduline which is used for slates/tiles below the recommended pitch. It's a polite but firm approach challenging their position, explaining the age and appearance of the building and how you have reached out for further advice. It's all about appearing to concede whilst not!2 points

-

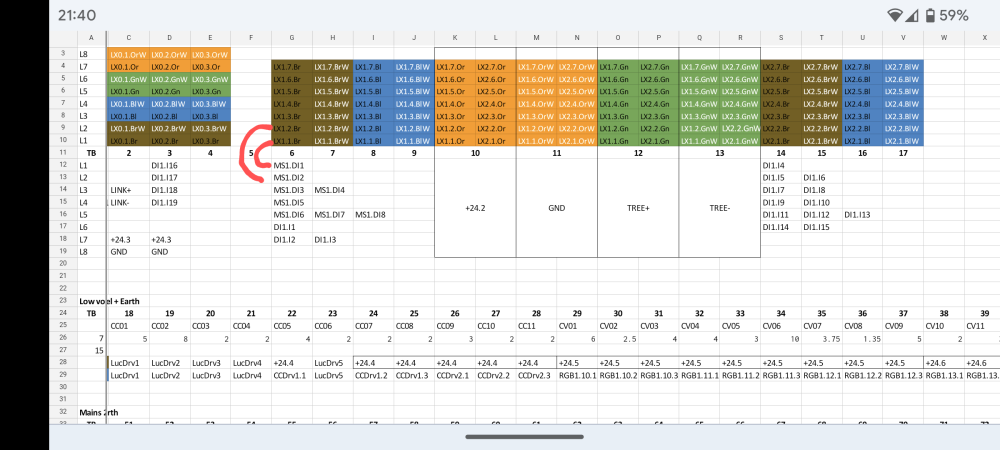

Yah I've seen many folks ruminate on benefits of 110 blocks but not heard many solid case studies from anyone that actually did it 😅 It seems with 2 enclosures you'll be lacing all the interconnects between them onsite rather than on the bench, so if you have time to do that what not lace it directly from the 110 to the Loxone extension device or whatever and skip the middle terminal block. Maybe a few of the interconnected blocks to act as distribution for power and Tree to keep it all neat. I think it all depends on intended install (and maintenance) workflow, on bench vs in-situ1 point

-

Are you employing an architect or other designer to specify the details of the building and get the building regs approval or are you doing it all yourself? By far the best approach is insulate the hell out of the building and make it air tight. If you are needing to add things like solar PV just to get a SAP pass, then the building itself is not really good enough.1 point

-

Yes The interconnected ones have the black border around the connected terminals. I could make that more clear if documenting it for someone else, but this was enough for me to follow so far 😄1 point

-

1 point

-

You need to make a doc (spreadsheet) of all the things in the cabinet and what they all need to connect to. Methodically work through all incoming cables, and all devices, to make a mapping Any device that needs connected to many outgoing cores (power lines, Tree, etc) you can use interconnected blocks for, everything else is probably and individual blocks. I find it best to arrange the blocks according to the external wiring, to avoid lots of mess with CAT6 wires all over the place. The internal hookup wires can be routed flexibly according to external needs. In the extreme this means you can do everything with non-inconnected blocks: one per cat6 cable, and do interconnects manually by daisychaining jumps between the terminals as needed. Mine tend to be more of a hybrid, with orange and green pairs going to interconnected blocks, and the browns and blues going to individual terminals. HTH Maybe I can make a photo...1 point

-

Build them in as you go and lap dpc over them then cover them in sand to catch anything that falls.1 point

-

No It’s a crap way of doing Building in as you go is much more solid If they don’t want to do them now They won’t want them at the end of the job1 point

-

I fitted an anti flood valve to stop this happening It also stops rats entering the void1 point

-

I remember debating about my air valves and other multiple things on ceilings like smoke and co2 detectors being independent and stressing about how it might look etc. Some wise head on here, maybe @Nickfromwales told me, after a while you won't even look at them never mind notice they are there, how true that is.1 point

-

1 point

-

Have a butchers at this https://www.pbctoday.co.uk/news/planning-construction-news/the-importance-of-consistency-in-planning-decisions/37423/1 point

-

Ig sounds as if your officer is simply out of their depth and doesn't understand the role. There is a shortage, but that shouldn't be your problem. Sometimes a junior officer can be reluctant to back down, where an experienced one is pragmatic. Contacting the supervisor for a quiet word is correct. I'd also contact your Councillor. Officers have to respond to them. Its wierd that an elected Councillor with no planning skills can do this, but it works. The council doesn't want appeals, hence a firm approach by your team can make it clear you've got good grounds so accept now. A planning consultant can help as they know the precedents. I'm assuming your submission actually is reasonable. Again a planning consultant will have an unbiased view.1 point

-

Any good track shop will have the dimensions just from your machine make and model. Look online they normally have a drop down menu for different makes.1 point

-

If you can let me have details of your contacts there @JamesPa I will send them the following: <Government's Air source heat pump (ASHP) grant system only benefits the closed shop industry. It costs more to the end client and taxpayer, and is a hindrance to the UK reducing emissions. I have been trying to install a heat pump in our barn conversion in place of the existing oil boiler. I have contacted numerous installation companies as well as two utilities that offer heat pumps, Good Energy (who have quoted) and Octopus (who say our installation is too complicated for them). 1st problem: the house is large and has solid stone walls and so needs a large (12kW) heat pump. These are bigger than the 0.6 cu m limit under Permitted Develpment (PD) so it needs formal Planning Permission. This costs £270 and will put a minimum delay of 10 weeks into the project. Some planning authorities also use this to impose impractical noise limitations far more stringent than required under PD. 2nd problem: the existing hot water tank has a heating coil that is "too small". All the installers insist I will need to replace the current tank which will mean dismantling the airing cupboard to get it out and ripping up the landing floor to fit new pipework, at an extra cost of £2k or more. I am a Chartered Engineer and have proposed three different technical workarounds: an extra pump, a separate heat exchanger or an extra plain tank. None of the installers will listen. 3rd problem: the government's Boiler Upgrade Scheme offers a grant of £5000 to fit a heat pump, but this is only available if you use an installer registered with the Microgeneration Certification Scheme (MCS). In addition, the fitting of heat pumps is only ever exempt from Planning Permission under the Permitted Development rules if you use an MCS installer. This requirement has nothing to do with Planning or the environment but was written in by MCS themselves. So the MCS installers are a cartel which has little incentive to compete on price and will not entertain ideas that would reduce the installation cost (see 2. above). In practice the £5000 grant is spent on the additional paperwork and the over-specified systems that risk averse MCS installers like to fit, and does not benefit the consumer. 4th problem: ordinary plumbers that are used to fitting gas boilers are kept out of the marketplace. The additional costs of registering with the MCS scheme and completing the resulting paperwork (anecdotally over £1000 per job) dissuades them from entering the heat pump business, so perpetuating it as a closed shop. 5th problem: householders cannot easily do the work themselves. If they fit even the smallest heat pumps it requires Planning Permission. The major heat pump manufacturers only offer extended warranty terms if they are fitted by an approved installer (in practice, an MCS registered firm). So by keeping out the ordinary plumbers, and houselholders who are competent to fit their own systems, it is a nice business for MCS companies. But there are far too few of them to meet the target of xxx installations per year so the requirement to use them needs to be abolished if we are to get anywhere close to meeting those targets.>1 point

-

I would use mineral wool between the studs. (As a second to blown cellulose) Almost zero waste,all offcuts can be tucked in somewhere. It can move with the timber as it expands and contracts. Better for fire protection, sound protection, decrement delay. Easy and fast to fit well. Get a bread knife and cut it slightly large and it tucks in perfectly. For a 140mm stud wall with a continuous internal of PIR like @Thorfun just bump that layer by 10mm and you are at the same U value. @saveasteading did you consider Using something like a mineral wool full fill batt and a 22mm insulated plasterboard for less labour overall?1 point

-

From my reading of that quote the biggest chunk is contestable works, which means you can get your own contractors to quote for that bit (others will tell me if I am wrong!!).1 point

-

The Guardian responded within the hour: Thanks for your email. I know that our consumer desk are currently working on various angles related to heat pump installation and the current difficulties surrounding it, so I've passed your email on to them and someone may be in touch with you down the line if they're able to use this information. If anyone has any stories to tell it looks like the consumer team are on the case.1 point

-

As above, lift the tarmac and put down concrete or screed, depending on the thickness. Anything else will fail.1 point

-

It's easy, not much more challenging than wiring a plug. I did my own.1 point

-

Any competent electrician can fit a diverter so just get that done when the tank is installed.1 point

-

You’ll need to lift it and put a concrete slab down if you want something strong. Not sure what kind of weights you are lifting with a jack are but just putting a 5m sheet of metal under the jack will solve that issue. For spillages there is not much aside from painting/expoxy but you’ll need to keep reapplying every now again as it wears. It also depends on the size of the aggregate in the tarmac - smaller the better for painting etc1 point

-

I’d ask to speak to their supervisor but not in a confrontational way, just for a second opinion. I don’t think going to appeal is a bad route, I’ve seen plenty successful appeals.1 point

-

The sill is there to prevent repetitive drips onto the wall face, which might leave unsightly stains. As there’s a stone sill below it, why do you need another one? Nb: The upvc sill has a little gap above it, which will allow an air path to the edge of the sealed double glazing units, keeping them at low humidity which ensures a long life.1 point

-

My tuppence worth. I agree with @kommando. I have restricted access, albeit only 80 metres worth. And could not have a crane on site too. My frame builder, which I chose to be local, simply had the frame designer design smaller panels, which were made in the factory and brought to site on a smaller lorry and then handballed in to position with dollies and few burly lads. It went up easily.1 point

-

Yes. No, if used carefully No idea. One of my tracks survived long enough with a couple of guides missing for me to get someone to change the track for me (because I'm not the HeMan @Russell griffiths is ..... bear in mind he grew up knowing how to change a track before he could change his trousers)1 point

-

Happy to report that the pdf bought from UK Planning Maps passed validation by ####### District Council yesterday. The online markup for the site boundary worked OK for me after a bit of practice despite what one of the reviews says. The hard copies turned up from Kirkwall 48 hours later, not really necessary but bought as an insurance, printed on good stiff paper and not creased in transit. I edited the file to add the proposed heat pump (a tiny rectangle 3 x 9 pixels!) using IrfanView, which is a free download, to convert to .bmp and using MS Paint to edit, then the reverse. Some advice on the website on how to do this would be helpful. Conclusion: does what it says on the tin!1 point

-

See how it goes, Think ours is 63%. Next time someone has a shower see if the boost still comes on.1 point

-

Over 1 year since my last update and some 2.5 years since we started this process - UK Power have today finally removed the overheads! I'm not sure if this length of time is normal (covid, etc) but I thought it worth an update for anyone about to embark on something similar.1 point

-

My cabinet is a mess, as I arranged terminals purely for what was convenient for internal cabinet lacing, which left the cat6 side a complete jungle of wires. The screenshot above is for another I'll be installing in the next few weeks. Learning from my own, I'm arranging it to optimise more for consistent layout on the cat6 side. Even connecting up unused cores, just so they're all accounted for I'll let you know how that goes and post photos if it's something I feel a bit more proud of 😂0 points

-

0 points

-

I realise this is an old post but having just received a quote for a new supply from SSE thought I'd share. From the quote, SSE are saying that we can't take a supply off an existing pole near our property as "LV POC off this PMT exceeds volt drop limits with new load". So they're proposing to run 430-475m from a pole a lot further away. It's all a bit unclear whether they're using HV or LV. The written quote says 430m of LV and the drawings say 475m of 300mm XLPE HV. Breakdown of Charges Description of connection charges Connections: 1 Domestic Lay approximately 430m of LV cable.£169,891.38 Total connection charges £169,891.38 Description of non-contestable charges HV pole termination at WHIW E4L5 200 for new s/s tee'd from White House PMT. POC and Network Assessment, Design Approval (where relevant) £185.00 Final connection £7,831.11 Inspection & Monitoring £2.00 Total non-contestable charges £8,018.11 Total charge to applicant £177,909.49 Seeing how cheap it is, I might just get two! Back to the drawing board....0 points