Leaderboard

Popular Content

Showing content with the highest reputation on 04/10/23 in all areas

-

My take is he is worried the works next door might be putting his own home in danger if they are being done wrong. If only he would post the pictures for us all to see, we could either re assure him it is all normal and nothing to worry about, or tell him yes you do have a bunch of cowboys working there and give him some advice.2 points

-

Look at the above picture from the ecological building systems website. It's a good system in my opinion. The thermal resistance of a material is mute until you make sure you can install it properly. The above system makes sure no wind can blow through or around the insulation. PIR will perform worse than the cheapest mineral wool if it's not installed well and the mineral wool is. I would put. Breather membrane draped between joists. Stapled square to the bottom of the joists with all joints taped and returned to the external walls and sealed here too. Good performance mineral wool fitted between the joists. T*G chipboard glued and screwed over the top. If you have space put a layer of PIR over the top of the joists under the chipboard. This will need to be between battens and all joints foamed and taped.2 points

-

Usually the cavity is filled below DPC so there is no "cavity" there. As there will be a cold bridge from the beams out through the wall, I would perhaps mitigate this a bit by not taking the UFH all the way to the edge of the floor, as another way of giving the heat further to travel to get out of the house.2 points

-

If we remember back to the early pandemic days, when there was a lack of face masks, it was suggested that the best material to use was T-Shirt fabric. Should not be too hard to make up some washable bags. I think I will design a vacuum cleaner. Shall call it the Daniels, already got an endorsement from Donald Trump, he said 'Daniels sucks'.2 points

-

My opinions: Beam and lock preferable to void formers. Above void formers need a structural (ie expensive) slab. perhaps 200 thick and with 2 layers of heavy reinforcement. If the ground heaves it crushes the former, but if it shrinks it then leaves a gap....so might as well have used B and B. If you need fibres in the screed and it is only for crack control, then use plastic fibres, which add typically £100 to the job, as compared with very much more for metal fibres. From my experience, Engineers (I am one) and Architects have been sold 'a solution' by void former suppliers but don't always know the cost implications. I am more used to severe shrinkage clay, so it should work for you with your lovely 'medium shrinkage'.1 point

-

Marazzi do a 6mm thick large format porcelain tile in this style. It’s called Grande marble look, I think, and the particular black marble with the amber/rusty veining is called Saint Laurent: https://www.marazzitile.co.uk/collections/grande_marble_look/ I bought these tiles in the giant size. They were 1600 by 3200 in size. People on here said we couldn’t achieve what we wanted to with these tiles. But we did! I need to update that thread.1 point

-

I can't remember the science, but the act of it rotting takes one of N, P or K out of the soil around it. But if it is in the compost, that happens benignly and it is all useable and useful compost next year.1 point

-

1 point

-

Now that did cross my mind. It started with no foundations then too much foundation.1 point

-

I bought an Italian made vacuum fir the workshop over 40 years ago, very basic, motor, cloth bad and paper bag over it, treated badly repeatedly now held together with gaffe tape and only just started making bad noises (I think the brushes may be going). Very good value for money I recon 😎.1 point

-

I’ve used an online free tool called source4me in the past & found it to be pretty good.1 point

-

1 point

-

Lay it on the surface to kill weed seedlings, and to keep the ground moist. Any thickness helps but 50mm is often recommended. If you dug it in , it would rot in the ground and reduce nutrients. Or mix it in with compost for next year1 point

-

Well that is my "summer" programmer now on the wall and the one with winter times set, put away for 6 months. I will see how it works now it is automated. Of course the theory works well on a sunny day. A lot is talked about "weather compensation" but for me, proper weather compensation would be turning the heating on and off to properly match available PV generation.1 point

-

Can't think why not. Evan 25mm of PU or EXP would help. May need to drill some ventilation holes, or pull the plasterboard off and get more thickness. Get a multitool and you can trim it all easily.1 point

-

If you do return it, just say it leaks. Don't try arguing the perfection or otherwise of a soldered joint and say it might leak one day.1 point

-

The BM will know the ratio to order. I would have to find my wee black book. 'sand and cement for 226m2 of brick' / 100mm block or whatever. you will have waste through spillage and spreading on the ground.1 point

-

Easy enough in our case. The builder ordered a 25t lorry of sand, tipped out at random on the site and a 2t pallet of cement. And a few bags of lime. Reorder as soon as it got slack. Plenty of suppliers who will do both next day near us. One of the advantages of building with common materials I suppose. A more useful reply..... 226m² at 25mm is 5.65m³ . Add 1/3 wastage (plastering is messy) and you get to about 7.5m3. At 3:0.25:1 sand lime cement. This breaks down to 5.3m³ sand is about 8t 0.44m³ of lime is about 1.1t 1.76m3 of cement is about 2.7t of cement. Otherwise ask @nod for someone who actually knows!1 point

-

Would that have been their notebooks, blood stained truncheon, camera memory cards and morals.1 point

-

Back to using containers. I'm not against this, and adapted a couple for storing sports equiment, just by putting a slab down, and cladding with battens. but it is horribly hot/cold depending on the weather. It is that these are designed for slinging about on lorries and ships, and any cutting of holes requires stiffening and framing. Where I have seen them used as 'sustainable' (often a glowing article in the Architectural Press) it has been just a gimmick and ends up costing a lot more than a proper building. It is a different matter if you can buy one cheap at 'end of life' and use it as a store......but they get so hot and cold.1 point

-

1 point

-

My experience as well. Also, the north east facing painted windows 'weather' better than the south west facing ones. Less UV, rain, salt and windspeed.1 point

-

Stick a directional cowl on it and simply point it away from the bits you don't want the extract getting to.1 point

-

What you doing to generate so much steam you are even thinking about it? Our kitchen fan is just a recirculating one and we don't have any steam buildup inside the kitchen1 point

-

Have you got any photos of this? I will need lights in the near future for vaulted ceilings. My photo collection is on my main computer, which is currently in storage, however it was something like this (but more atmospheric): https://www.lightingstyles.co.uk/simple-adjustable-low-voltage-tension-wire-lamp1 point

-

Yes, really. I shall stand firm, sorry! A shipping container will deter all but the most determined of fcuktard, and if anyone who is beyond their pay-grade is interested, then the bounty would have to be of interest. Your average scrote won’t look twice at a steel container, and will actively seek wooden sheds or structures with windows. So, “No”.1 point

-

Forget ceiling downlights - there are more interesting ways to light a room, especially a room with a vaulted ceiling. The last one I built included spotlights suspended from tension wires hung from gable to gable, for example, as well as wall lights.1 point

-

If you want something that's Henry-like then the Wickes one is great for the money https://www.wickes.co.uk/Wickes-Wet+Dry-Vacuum-Cleaner-With-Blower-20L---1250W/p/215735 Light, easy to move. Used them for everything.1 point

-

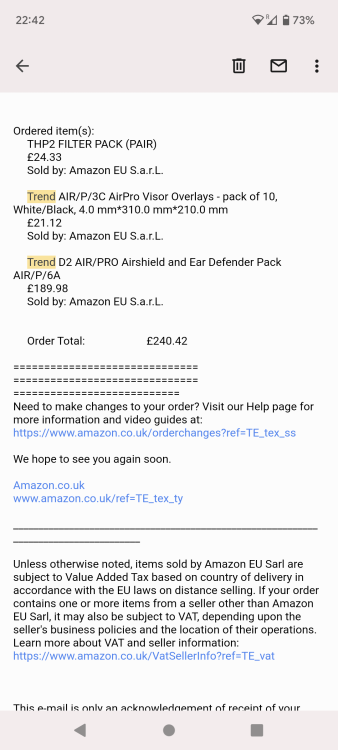

Sorry must have sent wrong link above. https://www.amazon.co.uk/Trend-D2-AIR-PRO-Airshield/dp/B096M7LSM9 They can be had for sub £200 Inc the VAT when on offer - try a camel camel camel alert on Amazon. Full face mask, ear defenders, and air fed via filter. Honestly life changing vs mask and glasses or mask.and goggles - you can see what the chuff you're doing even if breathing heavily into an otherwise cold mask after eating garlic for breakfast and even your hair stays free of wood chip etc. It's now something I pickup even if "it's only a little dust" as convenient vs the face nappy style mask; as pleasant rather than unpleasant. Try one if you ever have the chance. You'll not be disappointed!1 point

-

Heat pump efficiency is fundamentally / intrinsically linked to the supply temperature from the heat pump. You minimise the flow temperature needed (for heating a space, or for heating hot water) by reducing the "deltaT" between supply and return that is going to the heating system or heat exchanger for hot water. 5C is common. 3C yields improved efficiency in most scenarios. 8C is a tolerable compromise. 10C is about the upper limit and only tolerated by some heat pumps. Go do the math on pipe velocities and pressure drops. You'll find that you need 28 mm or even 35 mm primary pipework when operating at > 6 kW or so. You can't run 22 mm primaries on anything but the smallest heat pumps. You'll therefore need to replace the primaries running to the cylinders if you're wanting to heat the cylinder at any respectable power level. There is absolutely a fundamental / intrinsic problem with turndown. Compressors are available in various flavours. Rotaries and scrolls are the most common in resi sized units. 1) Compressors leak. If you run them at their rated outputs / rated speeds the gases don't have time to leak before they are compressed and shoved on their way. If you run them too slow then too much gas leaks past the internals of the compressor during compression. 2) Compressors need to last. If you run them at their rated outputs then the bearing loads will be balanced/neutral. If you run them below their rated outputs/speeds then the bearing loads (due to gas pressure, centripetal forces, etc) change and you'll increase load on bearings / shorten life 3) Motors are not efficient throughout their entire operating range. Nor can they cool themselves when running at low speeds etc. So in the real world you're limited to say 30 revs/sec to 120 revs/sec on a compressor before either the efficiency falls off too far for it to be worthwhile running at those speeds OR the bearing loads all go to heck and you destroy the compressor. So whilst you can turn down the units, even with today's tech, you'd be daft to do so. Nope. You won't find it written down because it stinks. DuPont have patents on the environmentally nasty gases. DuPont support the compressor vendors designing their compressors to use the nasty gases. DuPont lobby the regulators to make using noddy basic hydrocarbons difficult. So do the unions. (the F-Gas registration bodies etc) in much the same way as the natural gas lobby. Greenpeace had great success with fridges in the 90s; banishing F-Gas in favour of butane by doing some great demonstrators. DuPont didn't care because fridges were cheap junk. Is R290 a problem? Not in the grand scheme of things. The EU is about to allow 0.9 kg of R290 in split systems in the coming years. At that point expect to see a bunch of R290 splits not just the (low capacity) air to air units of today. For now it's just monoblocs (R290 outdoors is fine) and low-charge water to water units indoors (where volume of R290 is already below the limit where room size matters) The refrigerant cycle doesn't respond as quickly as dialling a flame up and down so cannot load follow. You also need to consider defrosting in cooler weather. A 25 kW+ unit wouldn't be able to turn down far enough to run a small basin tap. And efficiency would be pants if running at high delivery temperatures all the time Not viable. You run with a tank. CO2 is a very different beast. CO2 needs a high temperature drop (e.g. 60/30C) to work effectively; where a typical heat pump would be running 47.5/42.5 to deliver the same heat output from a radiator. It has potential for DHW heating. It has potential in district heating schemes too small to be worth the hassle of ammonia. Propane kicks it to the kerb in domestic applications. It is probably difficult to understand because it's such a dumb thing to do. Normal heat pump Step 1: compress gas Step 2: take off some heat (condense) Step 3: expand to a lower pressure (and temperature) Step 4: take some heat from outside (evaporate) Step 5: go back to Step 1 Samsung: Step 1a: compress all the gas Step 1b: "throw away" all the work that you put into compressing some of the gas by skipping to step 3 Step 2: take off some heat from the gas that is left (condense) Step 3: expand to a lower pressure (and temperature) Step 4: take some heat from outside (evaporate) Step 5: go back to Step 1 Say your compressor runs at COP 4 to produce 4-8 kW for arguments take; using 1-2 kW of electricity Samsung still put 1 kW into the compressor, but then waste that work by skipping the condense stage using hot gas bypass, so that they can give less than 4 kW output It's a dumb thing to be doing. They used to do this on old, fixed speed, compressors when they needed to do precise control of air temperature regardless of energy efficiency. Samsung have implemented in their new heat pumps so that idiots can plumb them into heating systems with a flowrate that's too low for the heat pump without tripping the unit out. Before "you're being bumd; increase the flowrate else I refuse to operate" and Now "sure I'll operate with a terrible COP at below the minimum compressor output if you want me to" Samsung do not provide modulation information OR part load performance information for their heat pumps. There's a reason that they don't want you to know. Misti provide some information. Also Vaillant. (example for 7 kW attached - and you can see the compressor led dropoff in COP at lower frequencies in spite of the oversized evaporator/condenser at lower outputs) A 2:1 ratio between "max output at minimum ambient" and "min output at max ambient" is par for the course / what to plan for. I think the 8 kW Samsung starts to do hot gas bypass at ~3.5 kW. Just below the minimum output is that the EU efficiency test uses to calculate the unit's performance. 😉 Defrost pretty much kills that proposal. You need 100+ litres to stand a chance of supplying hot water through a defrost cycle. The good ways to do this are: - Replumb and new cylinder (folks to stop being sissies about replastering/redecoration it really isn't that hard) - Split system and new cylinder (easier once the EU changes rules and we have almost 1 kg of propane to play with and reduces need to lift floors) - Separates (one heat pump for space heat, plus A N Other solution for hot water including a standalone cylinder with it's own heat pump pulling heat from cold roof etc plus option for solar diversion) - You can get A2W and W2W separates (the latter use a low grade input from your space heating circuit aka the existing primaries) easily - e.g. https://www.electricpoint.com/dimplex-edel-hot-water-cylinder-heat-pump-270l-edl270uk-630rf.html - There are also combined heat pump / cylinder / mvhr assemblies from Europe if you've got a wall spare and a low energy build: - Indoor phase change (sunamp etc) to avoid many of the installation constraints surrounding unvented cylinders and eat the reduced efficiency caused by running at max temperature all the time - Barge pole not touch would not I etc though on that. Clagging a plate heat exchanger onto an existing cylinder to avoid some paint/plastering; given that you're then still ripping up all your floorboards etc to run dirty great primaries to serve it and indeed the heating system; does not appear to achieve anything whatsoever sorry. HeatPumpPerformanceData.pdf1 point

-

Based on slightly better than Building Regs level performance data, the proposed 16kW ASHP seems about right for a 420m² house. Of note is the caveat on your "Building fabric summary" image in your first post "*These costs are based on an air source heat pump providing the space heating.". So the 6332kWh annual figure quoted is the electricity to run the heat pump, equates to 21,044kWh of annual energy loss through the fabric and ventilation. You therefore have a 50.1kWh/m² annual energy loss. Is this planned to be a long term home? If so you are saddled with these energy losses for the time you own the home. I personally would be looking for cost effective ways of reducing this figure. 15kWh/m² annual energy loss is an achievable target. Going for the 0.12 U Value wall option for instance. The stated air tightness target of 5m³/h.m²@50Pa is really quite poor. Your EC shouldn't be suggesting an MVHR system at that level as it will bring no benefit, just cost a load to Install, run and maintain. MVHR's come into their own at 3m³/h.m²@50Pa, and are best at 1m³/h.m²@50Pa or lower. If this is your long term home I'd suggest targeting 1m³/h.m²@50Pa. You describe the property as having some large double volume areas, in those circumstances you'll find that good air tightness considerably lowers your energy losses. If you are to target 1m³/h.m²@50Pa air tightness, then I'd research your chosen ICF. I've not looked into ICF much but the feedback I've picked up from this site, on wood-concrete ICF blocks, is that there is a lot of work involved in getting good airtightness from them. Maybe there are alternate ICF solutions that will make the job easier. If you can target better energy performance from the fabric of the building, then rather than the space heating requirement driving ASHP it will become DHW. You've specified a 400l UVC, I'd say that's the minimum size you should go with for the size of property, or perhaps a 500l. If you are heating the hot water via an ASHP you need to be able to store the water at 50°C or less to keep the ASHP efficiency at a reasonable level, so you need a greater volume of 50°C water than if you were heating it to 65°C. With large UVC's, you then need to watch your re-heat times. ie. you may get your space heating down to just a 6kW requirement, but you may still want to specify a 9kW - 12kW ASHP for better UVC reheat times. My own property is a similar size to yours, my heat loss is calculated at 15kWh/m² per annum, but has come in at around 12.75kWh/m². At today's prices that's around £535 per year for space heating which is a £1,700 per annum saving on your current performance targets. Index linked over 20 years gives a reasonable budget for performance improvements at the build stage.1 point

-

if it goes under the bottom of the door frame it will be a bugger to change, id be tempted to get a 'magic man' to come and fix it. or put an over sill ontop of it.1 point

-

Card processing is an area I know, and for the situation of taking a deposit on a larger order, these fees are negligible. Taking a pay-as-you-go card processor as an example (i.e. the most expensive fees on offer) a £100 payment by card has £1.60 in fees. If you're doing volume you can quickly negotiate these down. If a company wouldn't accept a small fee + accounting overhead to secure an order worth thousands, I'd be concerned they weren't credit-worthy enough to be accepted by any card processor. Or their order books are so full they can be choosy. Which when I come to order windows is the argument I expect they will make... I'm sorry for everyone caught up in this liquidation. I've been caught in a couple (losing 4-digit amounts each time) and it's an absolute emotional rollercoster. After the shock and anger came an "I feel so f*****g stupid" phase which was the worst. Stay strong.1 point

-

Just to re-update this - a few more years down the line! I went with Pylontech US3000 Lithium units, initially 3 of them and then added 2 more. They are absolutely great - zero maintenance, zero hassle. With a 6kw PV bank I'm sorted for the vast majority of the year with a generator being required for a top-up 6 times this winter. I expect that when I get round to moving the PV array to the roof and doubling it's size I won't need the gen at all. I'd have no need for the generator if I hadn't ditched my wind-turbine but I don't miss that howling beast when it's windy (there was no easy way of making it play with lithium/Victron). My time with flooded lead acid batteries was educational but I do not miss it! Less of my clothing has small acid burns and the monthly maintenance schedule has become an occasional glance at the Victron App.1 point

-

This is the first energy report I've ever read and I reckon that 90%+ is generic filler content like "What is a heat pump". Does anyone have a copy of a good energy report that I can look at for comparison? I've attached my EC's report if anyone wants to have a look Grey Cottage Renewable Energy Feasibility Study v1 .pdf1 point

-

1 point

-

It's unclear what stage your build is at, but if you haven't set an airtightness goal and figured out how (hint: written into contracts) you'll get the designer and builder to work to achieve it, then I think doing that is probably a higher priority than choosing the specific heat pump make model This is a good idea, but learn from my mistakes: - MCS tradesmen (and builders in general) are not trained / experienced in FCU install so you need to find a unicorn, or do a lot of the design and install detailing yourself. - remember the whole system will need insulating against condensation if you run cold water for FCU through it. This includes all pumps, filters, valves, etc - typically a FCU will be much lower kW output than a UFH circuit on a house your size, and you often don't want all FCU running at once (e.g. if some bedrooms are overheating but others aren't you don't want to turn them into a refrigerator) so you'll almost certainly need a buffer tank / volumizer on the FCU circuit even if you don't have one (and it's more efficient not to) on the UFH circuit. - installing ducts and plenums for hidden FCU as retrofit is a miserable job so get them put in in the build.1 point

-

It's down to how good the subfloor is tbh. I always set them into a lattice of Sikaflex EBT and drill and countersink every single hole position. A solid deck of 18mm plywood D4 expanding wood glue ready for fitting the 9mm fillet of ply used to raise the tray accordingly, The tray set into SF and screwed at every hole marker ( the little pillars seen in the GRP from underneath ). See the little circles in the pic above You don't need mastic on the ring TBH ( DONT USE SILICONE WITH GRP EVER ) but I do use EBT regardless as I know it's bombproof then. The reason that Impey don't show that is because they assume you'll be covering the whole thing with they're waterproof decoupling membrane which terminates into the mouth of the waste, therefore after / past that ring and below the surface of the tray, negating the requirement of any sealant anywhere as the water ( in theory ) cannot ever get there anyway. Problems arise if you stray away from the Impey family of products so are you using their membrane?1 point

-

.....also keeps us interested and the OP (and others) can learn other stuff, eg planning and structure came up here. As long as we don't get whimsical when there is a serious problem...ahhh but I digress from the current discussion Out.0 points

-

Don't assume "April showers" means rain. I worked for someone not far from here that remembered it snowing in mid summers day many years ago.0 points

-

Well I am going to say it if others won’t! “Is @greenbanana just a nosy neighbour looking for trouble? 🤷♂️0 points