Leaderboard

Popular Content

Showing content with the highest reputation on 10/16/20 in all areas

-

Hi, as a new member, I'm just introducing myself to the forum. I've done a bit of lurking on the forums on the odd occasion as threads have come up in search results for me over the last year or so and I finally thought it was time to actually join up. I've been building a house on my own. It's part renovation/conversion, part new build with a total area just over 200sqm. The renovation/conversion is 1920s brick & brick, and some brick & block, or shall I say what was actually left of it once we scratched beneath the surface of the structure - all soon to be covered in woodfibre EWI & lime render. The new build part is mostly timber frame but a bit of a hybrid with a substantial steel structure amongst the glulams. The timber frame is all filled in and wrapped in sheeps wool and to be finished off with timber cladding. It's all built as a fully breathable wall system. Roof is now on and I've just ordered the windows for delivery early December all being well. I've never done this kind of thing before so it's been a major steep learning curve every single step of the way. It's been gruelling, interesting, and a but if a pig of a project because it has two curved & vaulted roofs with some flat roof in between. The architects detail drawings were all rubbish so I've had to work a lot of it out myself. Oh, and it's been fun too in parts ? Covid has, like for many, taken its toll in terms of progress so I'm well behind on my timeline, (the rain and storms last winter didn't help much either) but I've at least just installed the roof before winter and now getting the cladding on too. Much to do still but I've attached some pictures of the build.5 points

-

Following on from the last entry we had our final inspection and were on the cusp of getting our completion certificate. A few final documents were uploaded and a certificate was received from building control. We had built a house. A few final jobs were completed following the last blog entry. I order 20 tonnes of gravel from a quarry on Skye and then barrowed it down the access and spread it around the house. I also had enough to put some at the top of the access as well and fill a couple of bulk bags. The last job for the joiner was fitting the downpipes. We used the cast iron effect ones as these provide a bit more of a decorative look compared to the standard glossy pipes. We seeded the ground at the start of lockdown and now after a summer of growing the grass is coming on nicely. The grass seed cost very little money. It cost us around £15 to do all around the house. We are pleased with how the house fits into its surroundings. Our pallet wood shelter was finished and I’m currently building up the wood stocks. I am also storing fresh cut wood for the future years. These old CUPA slates crates are useful for this. As we are now heading into colder times of the year, we have had an opportunity to have a few burns from the stove. I’m really pleased with how well it is performing. The stove is bang in the middle of house surrounded by thick concrete block with a lime render. It heats the entire house and the increase in room temperature can be felt twelve hours or so after the last log goes on. I wouldn’t however recommend fitting a stove in a self-build unless you put some serious planning into how you will actually use it. Even a small stove could easily over power the heating need for a living room. Solar gains produce our base heating, keeping the temperatures to around 20c and the daily electricity usage at 10kw. We don’t have any underflooring heating or radiators. If we reach a long cold spot and need a quick boost, I plan to wheel out an oil electric heater or use the towel heaters. . What’s next. I need to crunch the final numbers. I also need to put a final layer on the access road but might put this off until the winter. Thanks for reading.2 points

-

Excited is not the word! Secured an Internorm front door ex-display with fingerprint sensor, all instruction manual etc absolutely dirt cheap and I'm so bl**dy excited. Do you all like it? Inside it has a mirror inside. Just need to get a new barrel/lock which I'm hoping I can get whoever supplies our Internorm windows to throw in as part of my negotiation.1 point

-

I agree, even some insulation is better than none on your solid walls, foam on plasterboard internally or external wall insulation. Nows the time to get it done well. Most here double or triple building regs insulation wise. The old adage here is you only buy insulation once, fuel for heating you pay for continuously and it goes up in price regularly.1 point

-

In our kitchen design, we have the main sink a fair distance (3m) from the hob and prep area. This is entirely deliberate. So I could do with some wort of prep/workstation sink on the island beside the hob for filling pots, rinsing veg etc. Doesn't really seem to be a thing here... seems to be a thing in commercial kitchens and bars or in USA. Love the idea of the chopping board sitting on top of an under-mount sink, with a draining rack and tap with a hose style outlet. Would be right beside the induction hob, maybe 600mm gap at the most. Anybody done something like this before? (obviously about half or a third the size of this!!)1 point

-

It's a mechanical problem then. the basis of all electric showers is the heating power remains constant and you adjust the temperatue by adjusting the water flow rate. Running briefly hot then going cold is usually a sign of too little flow, it overheats and shuts off the heater. Some showers have a little toothed belt to connect between the knob and the actual flow control, check that has not snapped. Can you post a picture of the mechanical bits around the temperature knob?1 point

-

got test results back ==water is fine however although the lab complies with all required codes I still might have to get the council to do a test -- why ,because I do not have the qualifications to take the samples !! anyway water is fine which what we needed to know for now last email from head of planning was to say that due to covid he can give me no time scale as to when a planning application or site visit can happen my spies tell me it could be next year before they are working normal --and that is measured on a glacial time scale1 point

-

You would be better off taking £10,000 from your ufh budget and spend it on upgrading your insulation, even your loft conversion with current building regs insulation is poor. Upgrade it now while the house is a wreck.1 point

-

Google found this which might be useful.. http://www.structuraltimber.co.uk/assets/Links/STA_Cavity_Barriers_Technical_Document_FINAL.pdf And nhbc has some info on installation in S8.. http://nhbccampaigns.co.uk/landingpages/techzone/previous_versions/2008/Part6/section2/sitework.htm1 point

-

I got an updated quote for 50mm which is £15 per m2, which seems pretty decent1 point

-

In that case I would put one of these in the ceiling with a short duct off the back through the wall. https://www.airflow.com/Product-Detail/mixed_flow_fan1/iCON-60-Fans/72591701/iCON-601 point

-

I know this can be an issue. One plus of this fan we found in our last house was that it opens and closes up after use. It was a replacement for a previous fan and we really noticed a difference.1 point

-

Think that means 12mm binder over floorboards, then decoupling membrane. @Godley? If the 12mm ply is over properly fixed floorboards and that has been screwed and glued then you can tile straight onto that as long as you fully bed the ply and butter the backs of the tiles.1 point

-

We have used granite to cut down on maintenance. If you contact your local merchant they have off cuts which are usually a lot cheaper and work out quite good value1 point

-

I think you need to go back to the drawing board, It looks like you are trying to build a sauna, if you insulate it properly and air seal it you will not need heating in the loft, it will be unbearable up there and you will need the windows open. I have a mezzanine area with no heating apart from what rises naturally and we are wondering how to keep it cool.1 point

-

So we have been doing some searching into finding the smallest and most inconspicuous looking extractor. In the end we wondered if something like this would be suitable to go into the ceiling. It wouldn't be exactly over the hob, probably only over a quarter of it because the hob is part way between the pitched ceiling and flat ceiling but this extractor is very slim and only 300*350 and just in case we do decide we need to cook greasy food we have an extractor (although our hob is bigger I see no reason to go for the larger measurements). I'm hoping this would be fairly inconspicuous. https://luxairhoods.com/ceiling-cooker-hoods-slimline/powerful-slimline-ceiling-cooker-hood-white1 point

-

12mm directly on joists doesnt meet building regs let alone the stiffness needed to stop tiles cracking... https://ukbathroomguru.com/screwing-down-structural-plywood-to-joists/ https://www.diynot.com/diy/threads/minimum-thickness-of-ply-subfloor.511459/1 point

-

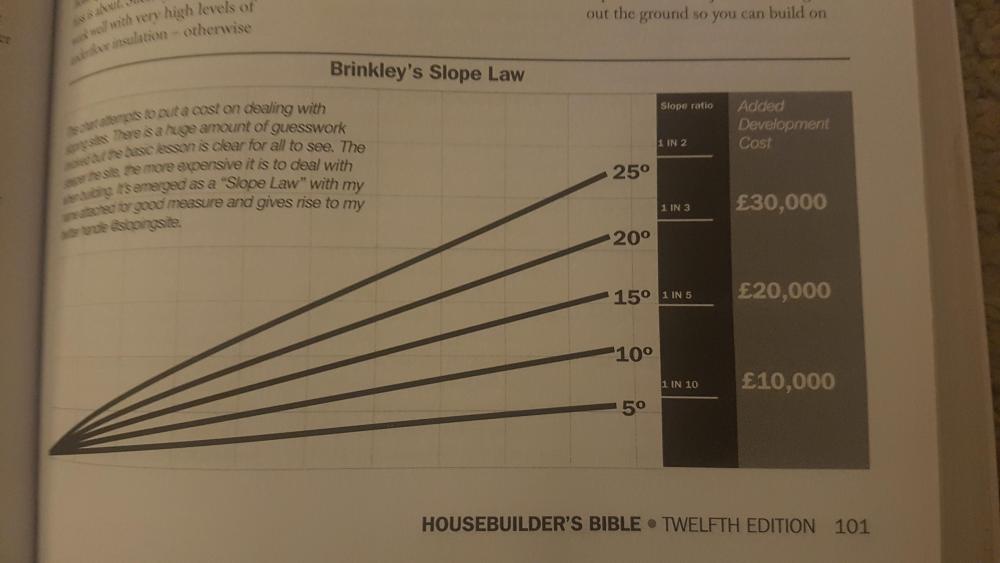

Here is the @Thedreamer referance, and suggest getting the book. We have a sloping garden plot which we got planning for, which is off the above chart. We knew that the slope was always going to be the unknown, and a big cost without knowing the full extent of it. However we have tried to minimise the area of the basement that is getting cut into the slope. We probably won't know the cost to do the ground works until we are sat on the block and beam at 'ground level. Though we are getting some ground investigation work done and a structural engineer to design the retaining walls (Looking at £5k for both these things) Once these specs are know we are going get ground workers to quote on the work. Only then will we have an informed idea of cost. My hope is that because my site is dense sand I will able to use a raft and solid retaining walls. If I have to use piles then I am a bit stuffed as they are expensive. How steep is the slope and what are the ground conditions? E.g. clay is bad and you will need some expensive foundations. Maybe the plot is still on the market is because it's not a financially feasible site for them?1 point

-

House looks brill, agree with your bill approach, wait till he comes asking and have a chat, I would probably end up paying it just to stop bad feeling, even although he let you down.1 point

-

You need to have a proper look at this if your water table is high. We are building on the Fen outside Huntingdon and have set our FFL at 600mm AGL for planning - it looks like we are going to drop them in at 0.00 AOD - yep that is Sea level which is 800mm above current chopped up ground level. Spent the whole morning walking around site with the laser level sorting that out! Still hearing the beeping now (set out the concrete levels in my foundation too - beep beep beep!)1 point

-

1 point

-

I've honestly never had a cracked tile and I can think of at least 5 floors I've done that way. I screwed down the OSB every 400mm so maybe that helped. I just always assumed using flexible adhesive was the key but I'm always happy to learn1 point

-

Run ducts and pull cables in later if possible. If you pull cables in now you'll need to run 10mm2 to be sure you have sufficient capacity. Also you'll need to run the duct / cables to where you can glean, retrospectively, the required amount of current. This is usually from the meter, or cutting into the CU tails at the CU. Thought, and proper planning required here1 point

-

1 point

-

There seems to be over 30% premium for - well, 'Premium' - ducting https://www.bpcventilation.com/quietvent-radial-pipe-75mm-x-50m over standard https://www.bpcventilation.com/basic-radial-duct Probably for the piece of mind I'll go with antibacterial etc for supply, but do all the perks matetr for extract ducts, if I'll never breathe the air carried by those. Or is it actually the opposite, because they suck out all the bad stuff from a house, they're more likely to be at risk of fungal/bacterial/dust growth inside them, with risk of making its way back to the rooms?1 point

-

Hello Christine, after the network provider's usual ineptitude they were removed. I had to push them for timelines now and again and waiting for their budgets to be approved. We came back after one summer break (must have been last summer) to find they were gone. No idea how they did it as I was not consulted for access etc (poles were just over the fence line) and no damage done to garden or house. In my case I did not push them after my scaffolding went up (I didn't want them interfering with the build!) and that must have been up for 2years at least...). I think that once they know you want to get rid of them and that there is no wayleave agreement, they really need to get the ball rolling. I think if prospective buyers know that they will be removed (in writing) then that would placate most. SP = Scottish power? Try Carol Davies. Wayleave Officer at SP. I don't have her phone, but she's on LinkedIn.1 point

-

Can we play guess the price? Me first RRP £4,500 You paid £1,700 Let me know if I am close.1 point

-

Ok so how long are the loops ..?? 4 way would indicate 400m of pipes max so that’s about 60 litres of content. If you then think you want to add probably 15 litres of antifreeze, you need to empty one loop entirely - not easy ..! Have you got a submersible pump ..?? A bucket and a couple of hoses and you could circulate the contents of each loop, and bin the first couple of litres into a separate bucket as you add the antifreeze into the pump bucket.1 point

-

pity my hill faces s/w ==or that could have a been a good usage -- select country jewish cemetry0 points

-

aty leats yuo have a house Ican,t even get started at this rate i think i should ask planning to include a mausoleum in the grounds --in case i never get it finished +build that first0 points

-

0 points

-

0 points

-

0 points

-

It’s like watching your first born take their first steps ?. Such an emotional time for BH as the father.0 points