Leaderboard

Popular Content

Showing content with the highest reputation on 09/25/19 in all areas

-

4 points

-

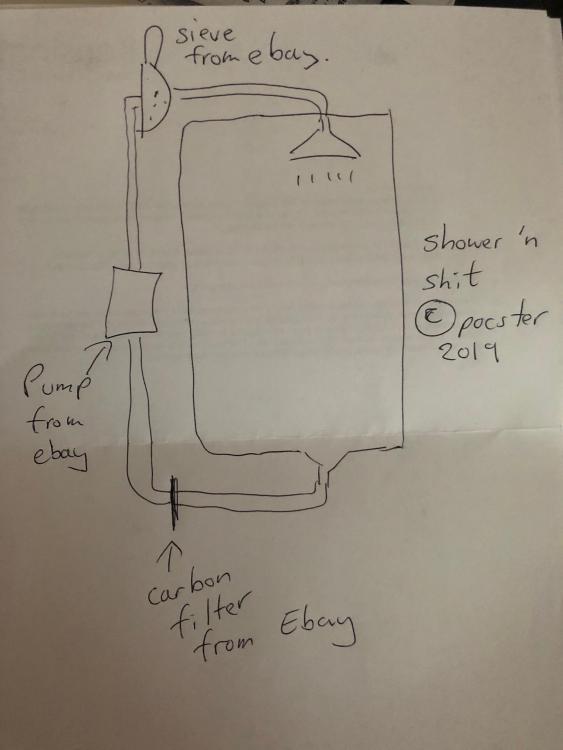

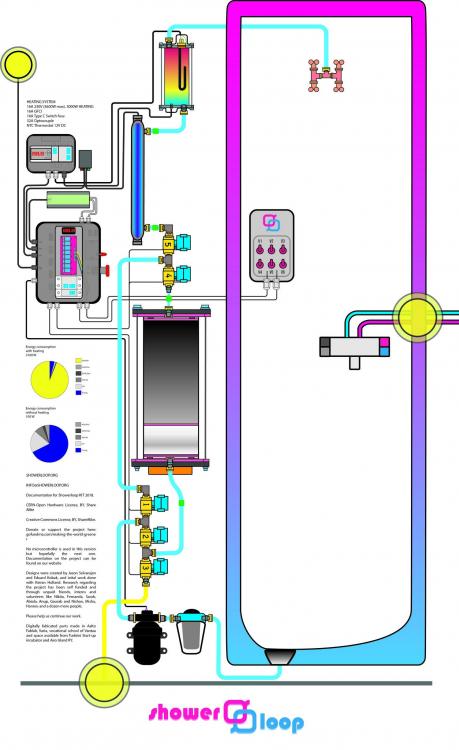

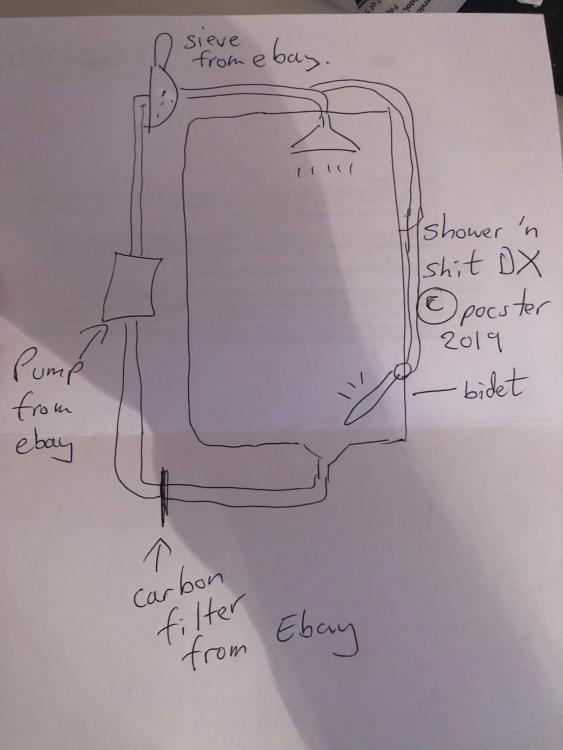

Looking at the official parts list it uses activated carbon, sand filter and UV - the spec is, shall we say, loose! Bacteria needs to be zapped with a specific wavelength of UV for about 10-15 seconds, i.e. the water must travel slowly enough through a UV tube that the water is being exposed for 15 seconds, that is a slow flow rate, or a big long UV unit. Now I am not an expert in these matters but know enough to know that you cannot cobble together some filters and a cheapo eBay UV filter and have water with no bacteria of viruses present, if it was that simple then people could have little boxes clean up all their water! The whole thing is going about an issue, that in my eyes isn't an issue, the wrong way. I honestly think that humanity is going about environmental issues the wrong way in many cases, the answer seems to be to generate vast amounts of carbon and pollution in order to solve something that didn't really need solved, or if it did, there is a better way. In reality it is back to the problem that creates pollution in the first time, greed. So people invent "green" solutions, that are actually just business plans! First thing would be to, encourage local businesses to setup and sell fruit and veg, meat, fish, general groceries, almost like a row of shops on a street would be a good idea! Then a street like this could exist every mile or so, then people like me would walk to these shops and pickup produce as they need it, but instead we drive cars once a week to the supermarket or if you plan like my wife every 2 days! Every night after work our dog gets a walk, if it is my wife and I we often pop into our local Co-Op and pickup bits and pieces, I am going to buy a little rucksack so that I can take it with me when we go and start buying more locally when out on foot. During the bad snow people were panicking about getting to the shops, I didn't see an issue, I just got on my boots and walked, 4 mile round trip for Asda or about 2 for Co-Op, nice walk in the snow and had what we wanted for dinner. But apparently the world had come to an end. I know not everyone can do this for distance or health issues but really, as a nation we have just become so lazy and everything is such a bloody rush.4 points

-

I'm sure there was a discussion year or two about something like this, or maybe I read it elsewhere. Just go for shower waste water heat recovery. While it doesn't save water, a properly installed system will return over 50% of the energy that would otherwise be lost straight down the drain. No moving parts to go wrong, and no need to bathe in your own crap. Win-win.4 points

-

Worth bearing in mind that there are pretty much always faecal bacteria in shower waste water, at least for those in the UK that rely on toilet paper for smearing the stuff around their backside. For those that use a bidet or shattaf this may be less of a problem. Not sure I'd like the idea of having diluted shit sprayed on my face, TBH...4 points

-

Hi, Quick update - my Structural Engineer says that securing the bottom fixed alu channel with M10 Type 316 SS bolts into tapped threaded RHS 8mm mild steel box section is fine. On the issue of frameless glass balustrading moving out of alignment over time, this should hopefully not be a problem with most of the dry-fixed systems where the rubber gasket can be removed and spacers adjusted. Some systems requires a tool for removal of the spacers (usually also required for installation) and others have spacers which are adjustable by means of, e.g. allen bolts. If I experience any problems I will do a subsequent post. David2 points

-

Just in case anyone thinks that this system is OK because of the UV disinfection unit, it's worth noting a couple of things. UV disinfection only works under a specific set of conditions. The UV tube has to have been on for a while to reach its specified output - when first turned on they tend not to emit anything like full power. They also have a life that is limited by the number of start cycles - they do not like being switched on and off regularly, and replacement tubes (which are needed annually anyway if just left on all the time) tend to be about £30 to £40 each. For UV treatment to work, the water has to be very clear, as bacteria and spores tend to stick to particulates and so avoid being exposed to UV as the water passes through the unit. The water also has to be very clear in order to pass enough UV to provide a fatal dose to the bacteria and spores in the time taken for the water to flow through the unit. Activated carbon filters are very prone to becoming a breeding ground for bacteria. Anyone that has taken apart a carbon pond filter will have seen first hand just how much slime builds up in them. Water from a shower is warm, so will promote bacterial growth within the carbon filter at a faster rate, and, because there is a very high probability of the water being too murky for UV sterilisation to work well, bacteria will be washed out of the carbon filter into the shower water. To make this system even partially safe it needs an effective way of disinfecting the water that sits in part of the unit, which means heating it to over about 65°C for long enough to kill off the bugs. The energy involved in doing that may well be greater than any energy saving, taking into account the running cost of the carbon filtration, pump, UV disinfection system etc. As previously mentioned by @jack, the best solution by far is to just fit an approved waste water heat recovery unit. The capital investment will probably be lower, and the running cost may well be lower, too, as the waste heat recovery units are virtually maintenance free.2 points

-

I’m starting to set out the waste pipes for a basement bathroom and was wondering what was best practice for such things. I had in mind something like this (see photo). My thinking was that if I shuttered around the pipes I could then have some flexibility fitting the sink, shower and bath. In my situation the toilet waste waste is in the middle so I was thinking of a boss on each side, rather than using a T piece, as in the example below. Once fitted and in their final position I’d then remove the temporary shuttering and concrete the pipes into place.1 point

-

Our service voids were 45mm x 45mm, I did consider going smaller to save on space or prehaps add 10mm onto the insulation, but in the end we decide to keep it simple and to what the electrician and joiner suggested.1 point

-

1 point

-

Well I think you all just pissed on the original posters fireworks. You bunch of meanies.1 point

-

Thank you everyone. Yetanuvver steep learning curve. I need to go away and translate all your responses. Like Arnie said ... "I will be back "1 point

-

1 point

-

1 point

-

My basin and semi sunken bath go into the same 50mm waste. Anti siphon trap on the basin. Connection to the bath via a 40mm flexible.1 point

-

1 point

-

All seems reasonable to me, essnetially you are creating a support column. You could even put in a single wide window with a suitable lintel above it and then the beam load comes down from above onto it - it all comes down to the structural design. We did something sort of like this, but we made it one big window and just used lintels to suit the job. Looking at what you are planning I would say BC will ask for a structural engineers calc/detail - so go for what you want and have a SE design it and make sure your builder reads and understands it while quoting as the lintel may end up quite beefy and or the use of steels - I'd use steels. Details you will need to spec up are the make up of the "column" you are creating which supports the beam above, and the insertion into it's side for the window lintel and making sure that the detail allows for adequate support from the column.1 point

-

What a bloody shame, yes living in an area where you are “watched” limits what fun you can have. It looks like a great project but only great if it’s possible. Well that’s option two, option one is to exhaust all other options...... I hope someone on here has some good advise for you.1 point

-

For what is worth I am converting an old milking parlour c.135m2 into a three bed holiday let. It is of varying ages varying from 100 to 20 years old. 200mm+ solid walls (some block on flat, she stone) built off an eight inch or so slab (no idea whether any reenforcement but no cracks in it). I am in the process of underpinning all round (~65m), 500mm deep, engineer spec. attached. I don't actually think it needs it as there is no sign of movement and no extra loads will be imposed (it has a slate roof, put on 20 years ago) but building control requirement. Not too onerous or prohibitively expensive to do. Might be worth another engineer opinion though. The trouble is, like me, you cannot pull down and rebuild as your right to conversion will be based on converting an existing agricultural building, I suspect. timber_structure_1.pdf1 point

-

1 point

-

On the subject of frameless glass, my main point would be to make 100% sure that you have every detail worked out, especially drainage (including how you handle any leakage into the channel supporting the glass). I overlooked these details on our (admittedly timberframe) build until too late, and it's added a lot of stress, delay and cost trying to sort something out.1 point

-

I wonder if you would be better looking into a replacement built in the same spirit. The advantages of self-build will be likely to outweigh the costs of pfaffing with a refurb. (Perhaps This has been covered previously.) You need to look at lifecycle costs in terms of ££ and CO2 eg electricity bills in those 2 dimensions over 25 years. eg look at the place built by @Crofter.1 point

-

I actually think the crucial sentence in that PDF is on the next page : "I presently know of no reason why electrical wiring installed in accordance with the Electrical Safety Code will not operate safely in buildings where the thermal insulation is of the Icynene type". I found a copy of the 2012 edition of the Canadian Electrical Safety Code online and from a cursory search it says: I haven't done a detailed look at their cable tables etc so I don't know if they specify in the same detail as BS7671, or if they leave it to the installer, but it's fairly clear they require precautions against overheating. And they probably did back in 1987 when that letter was written. Therefore I read the electrical inspector's letter as meaning "there's no reason why Icynene poses any specific issue beyond what you'd have to consider with any sort of thermal insulation". Not "Icynene magically absorbs and disperses heat from the cable even though its entire function is to do the opposite of that with all other heat sources". Somewhere along the way someone has misunderstood, or misrepresented the advice. Possibly if their recommended detail is that cables go in at first fix then you could (in some constructions) treat the cable as adjacent to a conductive surface at outside air temperature, rather than as being enclosed in insulation. I actually think that's marginal given the spray foam is likely to get most of the way round the cable, unless you had it in square ducting or whatever. But either way you'd definitely have to make some allowance to derate the cable from its free-air value. I think that's quite a charitable view. I'd be very surprised if many developed countries don't have similar regulations, albeit varyingly proscriptive/detailed. It's basic electrical science that one of the key factors in choosing a cable size is the heating effect of the current passing through and the effect of the resultant temperature on the adjacent building materials and the conductor/sheathing/electrical insulation of the cable itself. It's also basic physics that wrapping it in insulation vs hanging it in the open air will have different effects on that. In the nitty gritty of 7671 you're even supposed to allow for things like solar gain on cables if applicable. Hence, of course, why the regs here haven't changed significantly for a long time - the science of electrical heating is fairly well understood so there's not likely to be much need for change. Very good question. As far as I can see "thermal insulation" is not actually defined. That said the "reference methods" that are used for the quick-and-dirty tables of pre-calculated values @JSHarris mentioned tend to either specify the cable being at least partly in open air, or in "masonry, brickwork, concrete, plaster or the like (other than thermally insulating materials)" or in "thermally insulating wall / ceiling etc". So I'd say it's reasonable to use the non-insulated values for materials that are close to the performance of bog-standard old-fashioned masonry etc. Anything less conductive than that is probably outside the parameters those values were calculated for. So you'd either need to take the easy route and use the "thermally insulating" construction values, or if that produced a massively oversized cable or you had time to kill, work it out from first principles.1 point

-

Absolutely, which is why really it's a fallacy using UV as the means of "cleaning" the water. As said above, the spec is not even clear on the UV aspect, so you will get people getting an Alibaba $10.00 special and expect all is safe!1 point

-

V12 Boots are very good and pretty reasonable on price - try Granite Workwear1 point

-

Quite a few here use co at ruction trainers. Mine are by a brand called Tough Grit (someone is clearly a fan of the Two Ronnies crossword sketch), which is an own brand from a DIY shed I think. but others give theirs a harder life. F1 point

-

I'm not privy to the machinations within the IET that came up with these figures, I'm afraid! If the conditions in Table 52.2 aren't met then the earlier paragraphs apply, so the derating factor is 0.5, or the factors in Appendix 4 apply. Appendix 4 is several pages long, and includes calculations that should be used for different circumstances. It's a bit too long for me to copy and paste to a post here, I'm afraid. The general way the regs work is that they give a "quick and dirty" tabulated option that doesn't need calculations, plus a detailed option that requires a few sums in order to derive a valid answer. Most of the time electricians try and stick within the simplified tabulated guidance, as it makes life simple, but it is equally valid to calculate factors using the methods given in Appendix 4.1 point

-

It seems like a lot of difficult to recycle metal and plastics and other materials, maintenance and filters and fuss and money to save on some heating energy. I would just invest the money into some solar or ASHP etc. and just use that energy to heat my clean fresh water. We are getting good at heating with renewable sources etc. people have ASHP and Solar and all sorts so heating isn't the issue it once was. I know people who have basically unlimited free hot water now, they use tumble-dryers that cost them £0 to run from an energy standpoint and create only one off carbon emissions (i.e. production emissions from manufacture of the systems). Water is not such a huge issue, the water board clean water for us for less than a penny a litre, it leaves your plughole as grey water, it easily cleans up and helps the dirtier waste water in the system to become more dilute. I see this more and more, we are trying to solve environmental issues by using more and more resources. Frankly the whole climate change movement is targeting many of the wrong industries and environmentally "dirty" objects.1 point

-

From memory these don't meet WRAS or Building Regulations so it would have to be completely disconnected from the house supplies. The images on the site about using rainwater and solar heating it was a recipe for making some pretty nasty bacteria soup if you are not careful.1 point

-

IMO, certification is an irrelevance. The core issue is thermal performance. You need the correct mix of profiles to get your U-values and your thermal capacities right. In your design the U-values are a bit high, I feel, and you don't have enough thermal capacity within the warm environment. Block systems like this are common across the Mediterranean. They have a lot of advantages, but they are nowhere near passive class. You would still need 200mm PUR in the walls to get this. Ditto under the block floor. Look at the data sheets. My floor profile has 300 mm EPS underneath the slab floor, and the slab floor beams have roughly 17 tonnes of concrete inside the warm environment. The cellulosic filled twin-wall frame with outer stone skin only has a 0.12 U-value; the skin makes no material difference here, but it does dramatical improve the overall wall decrement delays. All of this makes the room environment extremely stable. I only have about ±½°C daily ripple on a flat internal temperature set point yet only being heated overnight. This wouldn't be the case with a lower decrement delay profile and thermal capacity: you would need to heat throughout the day in colder periods. There's nothing wrong in principle with a continuous control, except that using electric resistive heating on a flat or peak tariffs can get quite pricey. You would really need a high CoP rather than 1.0 such as a decent ASHP. You need to start with a simple thermal budget calculator such as JSHs and plug in the numbers to make them balance before making finalising you profile and material selections. PS. On rereading this whole thread, I realise that this last advice comes too late. Maybe you can tweak the outer in insulation skin. You certainly need to think about correctly sizing your heating. / cooling system because whist the house is better than min 2016 BReg standards, it isn't going to be passive-class. The floor performance is a weakness, and you will probably need some upper floor heating for winter months, even if a few small 1KW oil filled heaters on timers.1 point

-

Yes, definitely built and I'm definitely on the 'quite cool' side of the argument! Presumably using brick slips would achieve the same(ish) look but would mean having to use slips for the full thing?1 point

-

1 point

-

As part of the application, we had to provide a meter reading (because we have bivalent system), so I would assume that it will be backdated. If it takes this long to just register though, I shudder to think how long it takes for them to make payments. will keep you posted.1 point

-

1 point

-

That’s fine then - it’s venting the sewer. You may get some sink gurgling when a toilet in the extension is flushed but otherwise that is to regs. If it’s a problem then fit a couple of 32 or 40mm AAVs or anti siphon wastes to the basins.1 point

-

You won't need the trestles as well. Each lift is about 2'. I'll dig out a video with them in Edit. About 1:20 is them set up how I liked them but they are used throughout1 point

-

Knowing what size ASHP you’ll go with is a little coarse in deriving a size for PV, as a lot of people will oversize an ASHP so they run at half wallop ( modulated output to match demand ) so they run quieter and last longer. ?1 point

-

1 point

-

I think this has been discussed here before, but I can't find the thread. Any pantry built like this needs a well insulated door, and all walls that face into the thermal envelope, ceiling, floor, etc need to be well-insulated and sealed. If including vents to outside then the pantry door also needs to be airtight, so the easiest solution might be to just use a decent external door as the pantry door, as that will have the required seals and be reasonably good thermally. Another approach might be to just build the house with a "notch" in the external thermal envelope, that runs around where the pantry will go, with an uninsulated external wall over the notch. Whatever approach is used, it's worth remembering that the outside temperature will often be well above the temperature needed for a pantry for a fair part of the year, so the pantry may well end up warmer than the rest of the house at times. If I were going to do this, then I think I'd forget trying to put vents to outside, forget trying to use a thin wall to outside, and just build a well-insulated cupboard wherever I needed it to be, and fit it with a decent door, with an airtight sealing system (probably a suitably redecorated external door). I'd then just fit a small air-to-air heat pump in it, to keep it at a constant temperature. Doesn't need to be anything big, the sort of cooler units fitted to small delivery vans would be about the right size, might even be a bit too powerful. Failing that, a small monoblock ASHP, supplying chilled water to a cold shelf in the cupboard would probably do the job. Still cheaper and easier to just buy a larder fridge though...1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)