Leaderboard

Popular Content

Showing content with the highest reputation on 01/31/19 in all areas

-

That's the Geberit wall drain in. Push the brushed st/st plate in, bring it down onto 8mm packs, take the plate off and lock in place with the Allen key. Push plate back in. The brushed finish doesn't really match the chromed mixer, riser rail, flush plate etc but hey ho. Tbh the simple look belies the work that went into this and what's hidden in the wall & floor: Geberit never cease to amaze me. I invariably look at the instructions and first think WTF? Then I figure it out and think how bloody clever albeit simple. It's just good design.4 points

-

https://mobile.twitter.com/OrachaelO/status/1090728910940237829 nice story about a successful refurbishment but with a surprising twist at the end...never heard anything like it in my life...enjoy!4 points

-

To self manage a build takes hundreds of hours of preparation by reading, researching, speaking to others, visiting builds, exhibitions, etc. But for me the journey is the destination and I immensely enjoy doing all of that. Personally, I would not want to skip any of it by handing it over to someone else and paying a much larger bill. But then I also have full control over my time so can devote those hundreds of hours by choice.3 points

-

Since the last blog entry we've been working away at co-coordinating the paperwork for the building warrant . But progress is slowly being made. Last week we heard we've been lucky enough to get a 50% grant towards our grid connection costs, which is a big help. Anyone else who's thinking of applying, feel free to get in touch if you want to know more about it. I think you need to sit within SSE's (North Scotland) area. As part of our build we're removing quite a few conifers, the condition being that we replant with a load of native trees. One of the constraints on this is that the conifers sit quite close to a HV line, in particular within what the DNO call the red zone (where if the tree went the wrong way it would hit the line). For a while it was a bit difficult trying to figure out how we'd get these down, but in the end we were lucky enough to take advantage of a line shutdown by the DNO a couple of weeks ago. So now most of the conifers are down (only a few remaining), we just need to get them extracted. In other tree related news, we also arranged to mill a few of the hardwoods that were felled a year or so ago. Pretty pleased with the results, these will now air-dry and then probably need putting in a kiln just before we use them. Action shot of SWMBO taking it out on a tree: The aftermath: Logs ready to mill: And some of the results:2 points

-

2 points

-

When people say “thermal mass” just read “heat capacity”. Saves on the blood pressure. My guess would be that the house @PeterStarck is talking about was not, by the standards of this forum, well insulated. Sort of a re-run of the 1970's mass&glass vs light&tight controversy when now we know the truth (?) mass&tight (with maybe a bit of glass). Still, going back to the OP's question, the tight bit is more important than the mass bit; the mass only helps if you have some intermittent form of heating like sunlight or E7 electricity. If the heat source is directly and easily controllable all the time the mass matters a lot less.2 points

-

For a cheap, easy and quick to install small retaining wall it's hard to beat stone-filled gabions. If the wall isn't going to be seen then the baskets can just be filled with rubble.2 points

-

I can send you a piece of string to provide the answer to that one ?.2 points

-

Definitely. Can’t be too sure eh ? ?? 15-20 years and @Onoff may be free to tile it for you......... Disclaimer :- “may”2 points

-

2 points

-

Again looks better in real life: Been messing around with the angle of the LED strip to light the mosaics. Hoping to fit the end panel on the bath once and for all next. I'll white silicone the joints around the removeable panels then grout the rest. Tbh......could I just white silicone all the joints instead of grout at least on the long side and end and just grout the top?2 points

-

This thread was originally posted in the other place, and is a team effort to collect together as many acronyms and abbreviations used in the building trade as we could. If you know of any abbreviations missing, or think there should be a correction to the list, then post them as a reply to this topic and one of the moderators can edit the original list to keep it all up together. AAV = Air Admittance Valve. (Sometimes referred to as a Durgo Valve.) AAV (alternative) = Automatic Air Vent. ACH = Air Change [per] Hour AIUI = "As I understand It". AONB = Area [of] Outstanding Natural Beauty Article 4 Direction = Removes Permitted Development (PD) rights. (See: http://www.brighton-...cle-4-direction ) ASHP = Air Source Heat Pump (And see also: http://www.planningp...ects/heatpumps/ ) BC / BCO / BI = Building Control / Building Control Officer / Building Inspector (Often prefixed with LA = Local Authority, as in LABCO.) BR = Building Regulations (Regs) CIL = Community Infrastructure Levy (= a charge levied by a LA based on the sq.m of a property. Note: self-builds are exempt.) CO = Conservation Officer. (Now often designated: Heritage Officers. Specialized - although often not particularly qualified - planning officers working in a local authority Conservation/Heritage department. Have the power to over-rule BC where the Regs are concerned if a proposal is considered likely to impact on the "historic character" of a building, whether Listed or not, or in a Conservation Area.) {Listed Building, see: http://www.planningp...ing_consent.pdf } {Conservation Area, see: http://www.planningp...ns/conservation } CU = Consumer Unit CCU = Cooker Connection Unit CWS = Cold Water Storage [tank]. (Large plastic tank often in attic.) CYL Stat = hot water cylinder thermostat for control of DHW temperature. DeltaT = ΔT (Greek symbol Δ =delta in Greek alphabet) Temperature difference. (In the building context usually referring to the difference in temperature across a wall when discussing the effectiveness of insulation.) DG = Double Glazing (Sometimes referred to in shorthand as 2g = double glazed; 3g = triple glazed. Also expressed as 'd/g') DCW = Domestic Cold Water DHW = Domestic Hot Water DNO = Distribution Network Operator (electricity supply) DPC = Damp Proof Course DPM = Damp Proof Membrane EA = Environment Agency EDPM = Roofing membrane. (EPDM rubber (ethylene propylene diene monomer (M-class) rubber), a type of synthetic rubber,) EPC = Energy Performance Certificate (See: https://www.gov.uk/b...ce-certificates ) EPS = Expanded Polystyrene Insulation EV - Expansion Vessel EWI = External Wall Insulation F&E = Feed and Expansion tank. (Small plastic tank often found in attic alongside CWS.) FCU = Fused Connection Unit FWIW = "for what its worth". (As in: "That's my opinion FWIW.") FYI = For Your Information. (Now often seen in formal letters since they took the form of emails, and especially in the header of an email forwarded to keep someone "in the loop".) GCN = Great Crested Newt GSHP - Ground Source Heat Pump HC or VHC = heat capacity/volumetric heat capacity ICF= Insulated Concrete Formwork IGU = Insulated Glazed Unit (industry term for double or triple glazing) IMHO = "in my honest opinion." (Alternative: "in my humble opinion.") IIRC = "If I remember correctly." IWI = Internal Wall Insulation KISS = Keep It Simple Stupid. (Usually expressed as: "Stick to the KISS principle.") LA = Local Authority LBC = Listed Building Consent. (Needed to carry out work on any Listed building, whether domestic or commercial, privately or publicly owned, which is protected by law because of its historic significance, whether by age or architectural importance attested to by English Heritage.) (See also: Listed Building, above.) LPA = Local Planning Authority LPG = Liquefied Petroleum Gas M&E = Mechanical and Electrical MCB = Miniature Circuit Breaker MDPE = Medium-density polyethylene also referred to as Alkathene. Pipe used to carry mains water and gas, usually buried underground. MI = Manufacturers Instructions MVHR = Mechanical Ventilation [with] Heat Recovery. NPPF = National Planning Policy Framework OEM = Original Equipment Manufacturer OLIVE = Compressible copper ring accompanying threaded plumbing fittings that compresses around the pipe when the fitting is tightened to form a watertight seal. Often reinforced with PTFE tape [see below]. OSB = Orientated strand board Party wall = An internal wall common to two properties. (Not always a contentious issue, but see: http://www.planningp...on/partywallact ) PDR = Permitted Development Rights. (Sometimes just 'PD'. See: http://www.planningp...ssion/permitted ) PGM room stat = Programmable room thermostat: selects both operating times and temperatures. PI = Professional Indemnity (Insurance) PINS = Planning Inspectorate PME = Protective multiple earthing PIR = Rigid Polyisocyanurate Insulation PoE (or POE) = Power over Ethernet. Enables power to be provided to the device (phone or a network camera) using the same cable as that used for network connection. PRV = Pressure Relief Valve PRedV - Pressure Reducing Valve PHE - Plate Heat Exchanger PTFE (tape) = (polytetrafluoroethylene) Tape used to seal threads and joints (e.g. around olives in compressions fittings) in plumbing. Also known as Teflon tape outside the UK PUR = Rigid Polyurethane Insulation PV = Photovoltaics e.g. Roof Solar panels R-value = Thermal resistance [insulation] (the higher the better) RCD = Residual Current Device RCBO = Residual Current circuit Breaker with Overcurrent protection RDF = Refuse Derived Fuel RTFM = Read The Flipping Manual. (The polite version; the less inhibited version is usually expressed with the 'F' meaning what you think it means.) SAP = Standard Assessment Procedure (See: https://www.gov.uk/s...sment-procedure ) (See also: https://www.bre.co.u...P-2012_9-92.pdf ) ( https://www.gov.uk/g...t_file_2012.pdf ) SAPV - SunAmpPV SE = Structural Engineer SEPA = Scottish Environmental Protection Agency SFCU = Switched Fused Connection Unit SHC = Specific Heat Capacity (heat is another word for energy, don't confuse with temperature) SIPs = Structural Insulated Panels SSSI = Site of Special Scientific Interest Stat = Thermostat. (Room stat = wall mounted thermostat/central heating control.) SUDs = SUSTAINABLE URBAN DRAINAGE [system] SVP = soil vent pipe. SWA = Steel Wire Armoured (cable) SWMBO = She Who Must Be Obeyed (Attributed to "Rumpole of The [Old] Bailey", who used the phrase when referring to his wife, but actually from Rider Haggard's "She": https://www.youtube....h?v=bS5YmETSVCI ) TAF = Temporary Amphibian Fence TBH = "to be honest" (As in: "TBH I don't know.") TBF= "to be fair" (As in: "TBF to the builder, he hadn't a clue.) T&E = Twin and Earth (cable) TF = Timber Frame (form of house construction) T&G = Tongue and groove. (Often given in lower-case: t&g.) T&PV = Temperature & Pressure [relief] Valve TS = Thermal Store UFH = Under Floor Heating. (Also expressed as 'Underfloor Heating' but usually still given as UFH.) U-value = Rate of transfer of heat [insulation] (get it as low as possible, below 0.15 if you can) UVC = Unvented Cylinder VCL = Vapour Control Layer WUFI = "Wärme und Feuchte instationär" - Heat and Moisture transfer analysis XPS = Extruded Polystyrene Insulation ZV = Zone valve, motorised or other. (Directs heating medium to wherever needed according to programmed requirements.) UNITS OF MEASUREMENT L x W x H = Length times width times height. (But note that when giving dimensions for windows and doors ALWAYS follow the convention of width first, following by the height.) J = joule (not Joule) W = watt h = hour s= second k = kilo (thousand) kW = kilowatt kWh = kilowatt hour kWp = kilowatt peak (Solar installations - literally peak output.) m = metre (not meter) m2 = square metre (not metre squared) t = time T = temperature °C = Celsius or Centigrade K = kelvin (not °K or degrees Kelvin) k or k often means conductivity R = resistivity U = 1/R g = gram kg = kilogram (the odd SI unit, use it) J/(kg.K) = J/(kg.K) = J.kg-1.K-1 W/(m2.K) = W/m2.K = W.m-2.K-1 f(x) = function of x. (Common usage in thermal and stress calculations as well as statistics.) e = Exponent (1+1/1!+1/2!+1/3!+1/4!...) how things heat up and cool down, how fast things grow, π = pi ratio of a circles diameter to its circumference1 point

-

1 point

-

OSB does vary, and I should have been more specific. Don't use OSB/3 or /4 for sarking, as it's not anywhere near as vapour permeable as OSB/1 or /2.1 point

-

i would put the membrane directly on top of the sarking boards and then your counter batten but it works both ways, many ways to skin a cat i just like the look of the membrane on top of the sarking with lapped and taped joins i had the siga rep down this week and we were talking about this very thing.1 point

-

Yes, OSB is sufficiently vapour permeable to be used on the outside. Our roof build up (warm roof, with rooms in the roof space) is, from the inside out: 12.5mm plasterboard 50mm service void (50 x 50 battens) VCL membrane 402mm deep I beam rafters, with pumped cellulose insulation between them. 22mm OSB sarking boards 50 x 25 counterbattens nailed along the line of the rafters to give a ventilated space Non-tenting vapour permeable roofing membrane 50 x 25 slate battens Slates or in-roof PV panel trays1 point

-

We have 22mm OSB sarking boards nailed to the outside of our rafters, then 50 x 25 counterbattens nailed along the lines of the rafters, then a layer of roofing membrane, then 50 x 25 battens for the slates. Works very well, as it stiffens up the roof and makes it easier to work on. It also improves airtightness a fair bit and decreases "wind wash" through the insulation. We have no gap between the sarking and the cellulose insulation, as the OSB is sufficiently vapour permeable to not need it..1 point

-

I think I'd just use the ASHP, perhaps with a duct cooler as well. Buying the Genvex MVHR was very much a hasty (and expensive) change of plan, following on from discovering that the temperature in the area we excavated out of the hillside got very hot in summer, when we were doing the ground works. As the house foundations and frame were all on order by then, I couldn't easily change the design, plus, as you say, opening the windows when it's hotter outside just heats the house up. The running cost for the cooling is always free in practice, as we always have an excess of PV generation whenever we need it.1 point

-

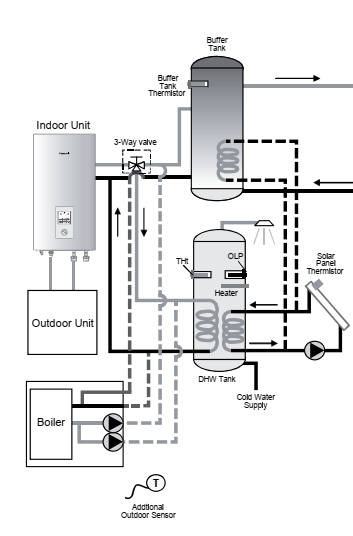

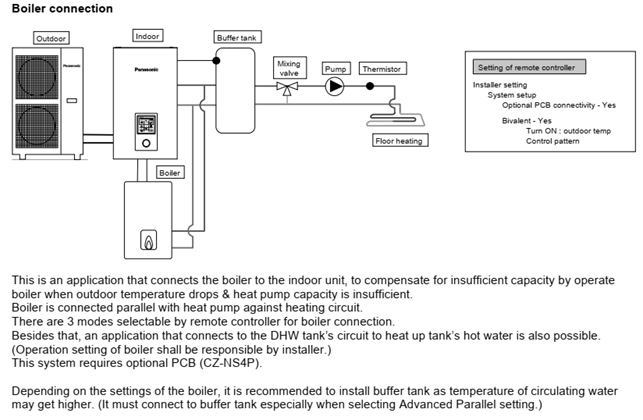

My ASHP will allow it (though mine isn't wired up for it yet). Two diagrams form the service manual showing how to do it. On the first one the 3-way valve is for the ASHP to set Heating/DHW. Mine is rigged for heating/cooling using 2 x pre-UniQ SunAMp PCM34 units as the Heating buffer and DHW pre-heat. I am considering as re-plumb/wire as the ASHP has been running for up to 8 hours a day to re-heat the units, It only takes a 2-3 hours if there is no concurrent heating demand otherwise it runs until the heating demand is satisfied (pushing about 34oC the PCM temperature), then quite quickly climbs to the 44oC cut off. The units require 45oC but stop the call at about 43oC. This re-heat is elongated if my mother has a shower (not short) as this also depletes the PCM34 units. SO I may consider plumbing the boiler heating circuit into the PCM34 units, currently it only supplies the PCM58 units with 65oC water.1 point

-

Yes thanks. The position of the house is fixed as is the design. 350 days of the year there should be any issues. Just trying to mitigate the other couple of weeks and the risk of changes in weather patterns affecting us in the future!1 point

-

@TFnovice, just a side note on overheating for well insulated houses. The best mitigant for this is not active ASHP cooling, openable windows, or even shutters but by good house design. Depending on the constraints on your site it may be possible to orient your house, and especially the glazing, and and add shading overhangs and other features that reduce summer overheating dramatically. For example, in the case of Ben Adam Smith of the House Planning Help podcast, his forecast rate of summer overheating by these design measures for his own house was zero percent. In reality, of course, its impossible to fully avoid overheating. However, if your house is also modelled using PHPP then you can see the effect of design changes. Personally, when I chose my architect, was careful to choose one that was familiar with both PHPP and these concepts. Many people who aspire to a (near-ish) passive house don't realise that, with a highly insulated house, space heating becomes easy and it is overheating that becomes the more major concern. Unfortunately, often they discover this only after they take-up occupation. Hope that's helpful.1 point

-

Hi Sue I would be interested in a visit on the same day. Please do keep me in the loop. I am going to check that Durisol has one; just interested to know.1 point

-

Tony on greenbuildingforum built a well insulated high density block house, he also had a website/blog - Tony's house reading iirc (the 'Tony tray' is worth looking at). As others have mentioned a good result can be achieved using any of these methods, which is most appropriate will be specific to your circumstances. Site access and the availability of trades will be key. As far as I can see attention to detail is vital to achieve good air tightness and insulation performance, for this reason I would avoid rigid insulation internally as gap filling would be difficult. Sheathing a building with eps sheets or blown insulation sounds fairly simple to get right.1 point

-

1 point

-

It did actually happen to an unfortunate lady a few years back. Good you got acquitted on everything!1 point

-

1 point

-

1 point

-

You shouldn't use solvent weld soil pipe underground, I believe, as underground soil pipes are subject to a degree of slight movement that can stress a solvent weld joint and cause it to crack. I believe the rule is to always use push-fit soil pipes underground. As for the colour, then the brown/orange underground pipe isn't UV resistant, so isn't supposed to be used above ground as the outer surface will degrade. Black, grey or white soil pipe is UV resistant so can be used above ground.1 point

-

Your buildup is pretty much exactly what I'll have for the gable walls, but mine will be a bit thicker. Biggest difference is I'm thinking I'll put the vapour barrier behind the PIR to protect it. Outside in: TF200 9mm OSB3 235mm rockwool insulation between 235mm JJI I-beam studs. Polythene vapour barrier. 90mm PIR. Battened service cavity. I don't see any problem with mixing insulation types so long as, as we have, the more vapour-open stuff is on the outside.1 point

-

Yes, it's mandatory that you provide a site toilet and clean water for hand washing. If managing the site you may also be expected to provide other H&S elements as well. I provided an eye wash station, first aid kit and a plastic box of gloves, safety glasses and a couple of helmets in our garage as soon as it went up, not that anyone used any of the provided PPE, or their own come to that...1 point

-

They started off by having the 3mm gap and filling it with PU glue but then changed to butt joints. They didn't tape the joints. Yes very difficult to quantify. All I can say is that ours was trimmed back and that Icynene is very different from other types of spray foams I have seen. When cured it is very flexible, rubbery and doesn't crack. A potential problem with Icynene is that it doesn't stick to cold surfaces very well and is therefore best sprayed when the surface temperature isn't too cold. A friend had the walls of an outbuilding sprayed in the winter and the Icynene pulled away from the corners.1 point

-

My wife puts it pithily.... A self builder is not a repeat customer. Trades prefer working for them. Self builds are one off. (Unless you are called @Stones)1 point

-

I agree wholeheartedly with @vivienz I opted to use a very non-local (at the time) contractor for our foundation and house build; they were based in Tipperary at the time and the team, and the whole house and garage, came over on the ferry to build our house. Best decision I made in the whole build, as not only did they do a cracking job, but the guys had nothing else to do whilst they were over here except build our house. Having contractors not turn up for a few days, because they've got another job on, seems commonplace. By using a contractor that's coming from a fair way away you remove that issue.1 point

-

When I looked into fitting a system self-install was not an option. There was no reason why a competent person couldn't install a sprinkler system, other than the fact that to get accepted either as part of a mandatory requirement, or by an insurer, meant having to have the system certified. I couldn't find any way around this. There was also the problem that, when I was looking, none of the suppliers would just sell the kit, they all wanted to undertake the installation as well. Mist systems seemed to me to be a lot better than conventional sprinklers, primarily because they seem just as effective and cause a lot less water damage. I believe that water damage from a faulty installation causing inadvertent operation may be one reason insurers want these things to be certified.1 point

-

This was introduced under a Private Members Bill type procedure in about 2007-2013 by an MLA called Ann Jones. Fire deaths And injuries in Wales were averaging 17 and 502. Clearly at that rate it will take two or three decades to save even 5 lives per year, assuming sprinklers save all the pot Niall lives they can (which they probably will given the record), as in this country we only renew at most 1-2% of housing stock per year. I expect that for te first 25 years at least there will be no detectable change, There was a Report from BRE pointing out that it was not cost effective at iirc 6.7m per life saved, but the decision was presumably made on principle and influenced by Fire Brigades who usually support the measure. See this piece from Wales Online https://www.walesonline.co.uk/news/wales-news/new-homes-fitted-automatic-fire-2051716 I am not sure how that perception changes after Grenfell. There is a fairly recent monitoring report presentation here, which has an installation cost table on page 67 http://www.cewales.org.uk/files/8614/8163/8572/Llandudno_Sprinkler_complete_presentation.pdf Personally I think there should be potential significantly to reduce the cost of these systems by perhaps 50% or more over time, so I am agnostic about the measure (though quite happy for somewhere to be running a long term experiment). At say 1-2k per house I would be a strong supporter. At 3-4K, not so much ... spend the money on a different Ill in society, such as impact of drones, insulation/ventilation programmes, or houses on corners that get lorries in the front room depending on research. F1 point

-

Just to the most you'll ever see, so if 23 was producing the desired output then you're done. TBH after 2 years I doubt if it'll make a blind bit of difference as that's pretty much 'cured' now for sure.1 point

-

Just received the credit to my account, nothing to do with VAT reclaim process - give it a whirl! You don’t ask, you don’t get ?1 point

-

So you’re using about £200 in winter, that may even out in the summer so may not be far off. What is the spec of the ASHP and what is it programmed to do..?? If it’s 2-3 hours morning and evening then you may be disappointed. Get E7 and run the ASHP overnight to do the heating and then use ASHP and immersion timers to do the tank. Get as much on E7 as possible. What was the final EPC/SAP..??1 point

-

Have done three small prints so far. Main issue/difficult I'm finding with the A8 is levelling the bed.... To get the first few layers to stick to the bed the nozzle has to skim over the bed the thickness of a sheet of paper above it. So the bed has to be level to that accuracy. However the printer mechanics make this quite difficult to set up. It's adjusted using M3 bolts and wing nuts but the whole thing isn't very rigid, move the printer and it twists enough to make the gap too big or two small requiring readjustment. I've got a bit of 25mm MDF on the way to bolt it to. I've seen references to auto levelling add-ons but not investigated that yet.1 point

-

Thanks Peter, and did you butt the joints up tight or follow the MI's and keep a 3mm expansion gap. Im assuming you didn't bother to tape the joints. Yes I think the thickness is important, in this demo example spray foam has been used to prove how well it performs at creating an airtight layer, coming in at 1.246m3/h.m2. The foam is moderately thick, they've used decent backing/sarking throughout and the foam hasn't been trimmed in places which seems to help by not disturbing the joints between foam and rafter. In a recent email Icynene said to me, "we regularly achieve figures better that 1.5m3/hr/m2". If I convert this to AC/H for my whole house the result is understandably poor. Therefore I need to balance the relatively poor airtightness of the roof compared with the good airtightness of the ICF (hoping for something less 0.5m3/h.m2 here, excluding openings) Its hard to quantify how much effect the following have in creating an airtight layer with spray foam: Thickness of foam Whether its trimmed back Type of sarking or backing material Brand of foam I'm finding it all a bit ambiguous and wondering whether taking the membrane route may be a safer option for a guaranteed <0.6AC/H1 point

-

Getting 20 quotes is time wasting - for you and them. Between 3 and 5 is fine. Having good people you can trust is worth more than a cheap price and nightmare work / workers.1 point