Leaderboard

Popular Content

Showing content with the highest reputation on 06/17/18 in all areas

-

Go to bed happy. Wake up next morning and go and have a look. Pick your heart up of the floor when you realise it should have been done by your bro in law. Go and get tools and start scraping.5 points

-

After youve spunked all your cash on the various potions, and devices with which to apply them, your have paid the spread. A 4' blade needs some serious skill, and I just about have the wrists for my 18" Ox for flattening off over old plaster etc. No xmas card for you this December ! Dead man walking The last customer who said exactly that asked to borrow my step ladder to skim his bathroom ceiling. When I came in the following morning, the ceiling was destroyed, his clothes were rolled up in the corner covered in plaster and about 8 litres of sweat, and my lightweight aluminium step ladder had to go in the skip as it weighed about 60kg with all the plaster that was on it. Took about 4 hours to clean the floor and walls too. My mate came in that evening and skimmed it for £80. Was like a sheet of glass. Disclaimer : After all this has been said, I really need you to cock it up or I'm going to put 2 stone on from all the humble pie and custard.4 points

-

It appears Nick followed me: "Ffs! Mate, Sorry about this but by the sounds of things you haven’t got a clue. Just pay a spread to come in and sort it, small job like that won’t cost a fortune! And from the look of your job you are fussy and particular so why balls it all up now?"3 points

-

3 points

-

thought I'd close this one off... the heating system is now in and complete. Mains gas boiler feeds a 90l buffer that then feeds two Wunda manifolds - ufh down stairs & rads upstairs. All individual room stats. A bit of cable management needs to happen but otherwise I'm pleased. Its taken Q a bit of work but all good learning. Its a @Nickfromwales design2 points

-

2 points

-

Ill nip to the offy's for another 8 ace then, and we'll see how this unfolds2 points

-

Big bonus is they're even funnier over there than you lot: "Mate, there’s good advice from two who know their stuff.Listen.Be a shame to bodge it all and miss the chance to bang her sister!" ?2 points

-

I think he should go outside and cut some nice hazel and hand split it then replace all this nasty board with some nice lath .... Then lime plaster it, horsehair in the backing coat of course ......2 points

-

or......better to have tiled and made the plasterer cups of tea..... FFS indeed. Please dont f.uck this up at the last minute !!!!!!!!!!!2 points

-

Don’t need to juggle chainsaws to find out what will happen2 points

-

I tried it once on a small wall up stairs in my last house. Scratch coat was decent but the skim wasnt. Let's just say it wasn't long before it got boarded over and hid. It's a real skill that takes years to perfect. Plasterers just make it look easy when it's really really not.2 points

-

2 points

-

I’d want that lot fixed by the architect and without a bill for the work ... it’s laziness and smacks of a standard set of annotations that are used regardless of what has been drawn.2 points

-

With one week to spare we have moved in?. Not finished as no doors or skirting finished etc.2 points

-

It's like CAD come to life! ? A few cable ties wouldn't go amiss...just make sure you get them all the same way around...1 point

-

You have to keep that T&PRV on the buffer so you're covered for the terminal failure scenario, which is all the isolations shut off and the immersion heater on and its stat to have failed. Its that situation that dictates the T&PRV's location ( and the fact that its factory fitted with half a tub of thread lock so its near impossible to remove ). Just put a 15L container under it and you'll be fine as the PRV on the boiler should be a lower setting. The buffer one is 5 bar IIRC and the boiler one will be 3 bar.1 point

-

Yeh and he even corrected my error with a certain isolator I fitted ... and I’ve drawn the schematic three times and put the valve in the right place every time ...1 point

-

Yep - but we will still stand back and look on in awe at the tidiness of the job and it's so much better than the one the gentlemen numpties who did the original @newhome system managed.1 point

-

bugger. This is the second one on the heating system (1st one is in the system boiler) - just added it because I thought it would give a bit more slack. If I shut off the valve then the system boilers own ev will still be plumbed in. So the 24kw system boilers ev does the UFH (~100l) and this one does the rads. Once we move in - I may go back and tweak this so my fellow Welshman can up the mark to 10/101 point

-

It's the pressurised volume rule - the heat exchanger coil is the only pressurised part and will be under the volume limit to require a G3 sign off, as I understand it. The bulk of the water in the thermal store will be unpressurised and vented via the header.1 point

-

Thank goodness that rats and mice have blunt teeth and no desire to knaw through things1 point

-

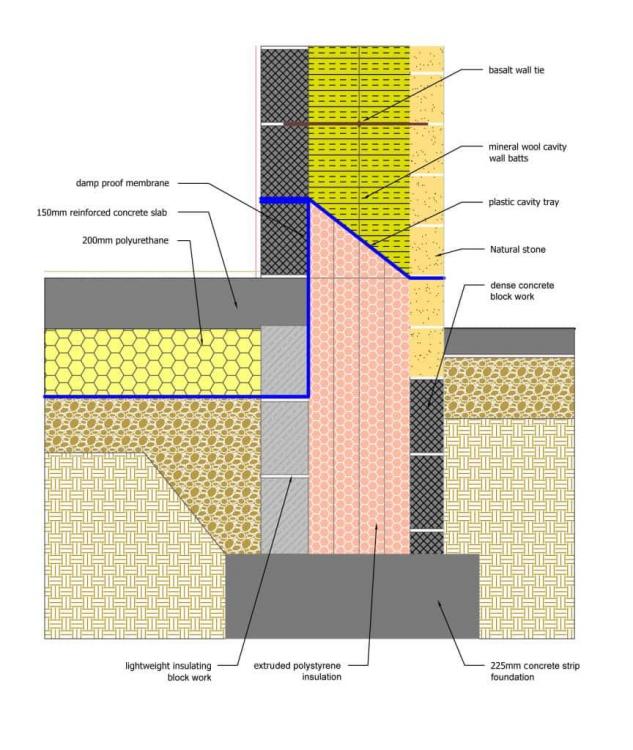

As per Steamy,s post above, yes our site is very flat, thick yellow clay and very boggy. The local building control guy was happy with trench foundations and asked for 800mm deep and 700mm wide ( our walls are brick and block outer and inner with 200mm full fill cavity with Rockwool ) we installed a French drain around these (back-filled the trench outside with 50mm stone) and piped it to a local ditch. The foundation detail was as follows to avoid cold bridges and I am very happy with it, we did not need an SE to design or sign it off..You mentioned “cottage”, ours too is cottage P.s. we also have a DIY installed ASHP ( which I have yet to fire up).1 point

-

It depends. A pressurised cold water system, like we have, doesn't require a Part G3 sign off, and can be done as a DIY job. The same goes for a thermal store hot water system, if the thermal store itself isn't pressurised, and for a Sunamp PV; none need a Part G3 sign off or annual inspection. You only need a Part G3 qualified installer, plus annual inspections, if you fit an pressurised, unvented hot water cylinder.1 point

-

In one way I agree that new PB shouldn't need anything. The plasterboard is unused, but this bathroom is about 10 years in the making and plasterboard is hardly "new" @Onoff is worried about suction. Generally if it is sucking in too much the PVA it, but he works at a similar pace to a man painting the forth road bridge with a 1/2" brush, with his arms tied behind his back, so won't get the plaster on quickly enough. Blue grit is by no means a solve all, but it will reduce suction (and differences in suction if there are different substrates) and is used when compeltely dry rather than tacky like PVA. I think we all agree that the BIL should be doing the job. Why not get him in to consult on what you should do? Invite him for a BBQ on the day you are doing it and he will give you some tips and be able to take over if you make a hash of it!1 point

-

blue grit is great for removing dead skin - just let it set first. Good addition to any bathroom - shame to skim over it. No idea why you would want to put it on PB but its a free world1 point

-

No, Nick said pee in the water and speed it up a bit. People are waiting to see the finished result1 point

-

@JSHarris The idea is to monitor the temp/RH before and after the cooling fins with DHT22s and the fin temperature with a DS18B20. Then, once the data is in, crunch some numbers and see if it is possible to detect the condition that frosting may occur, before it happens.1 point

-

I could relatively fairly easily add an external RH sensor, I think. I already log ASHP flow temperature, floor temperature and outside air temperature just above the intake to the ASHP on the North face of the house. Currently the logger records a set of readings every 6 minutes, and stores the data in 1 month chunks, using a GPS master clock to keep the timing consistent.1 point

-

Old time served plasterer that taught me a lot used to have a bucket set up that he peed in and left for the entire job. He called it dirty water and he used this when he wanted it to go off quicker.1 point

-

Welcome. Re your groundwork/foundation/piling, it may be worth having a word with @joe90. He built on the flattest bit of land in the West Country, and it was very boggy. His local Building Control was happy with trenches. I know little about foundations, and each house seems to have unique issues, though I think half of that is lack of knowledge about alternatives by builders/SEs/BCs. As for SIP's Have you checked the U-Values and associated thicknesses of the panels. You may need secondary internal/external insulation fitted. I have stood next to both @JSHarris's ASHP while it was running, and next to @joe90's with it was not. There was no difference in noise. @JSHarris you may have missed my post about monitoring an ASHP for frosting, I am looking to put some kit on a couple or three.1 point

-

My cousin lives in a Passivhaus in Hamburg, fitted with a log-burning stove. It's usable, but you've got to be careful - you burn one small log (sticks are no good - too much surface area so they burn too fast: they burn short fat logs) at a time, keep the doors open to spread the heat around the house and it's fitted with some hefty soapstone slabs on the top and sides. From memory the room ended up at 27 or 28C after a few hours - actually quite nice in that part of the world in winter, but definitely not a routine occurrence.1 point

-

Worth trying teak cleaner to see if it brings the colour back: http://www.teakcleaner.co.uk/1 point

-

I've told this tale before, but it's worth repeating. We had an open weekend where around 40 people came to look around our house. One of them was a lady who had finished building a Touchwood Homes house a year or so before. She'd insisted on having a wood burning stove in the living room, the smallest room sealed model available, which I think was rated at about 4 kW. They lit it for the first time on a Christmas Day, and within an hour the living room was over 30 deg C and they had to leave the room, even with all the windows open. it took several hours for the room to cool down enough for them to use it, and messed up their Christmas a bit. Since then they've never used the stove again and last time I heard she was looking at getting an LCD monitor installed in it to display a flame effect.1 point

-

Worth looking into how small a stove you can practically run - they really don't like being run smouldering (lots of smoke and creosote), and when run hard most will put out at least 5kW which will be 2-3 times what you might need for the whole house. Again, a lot depends on how well insulated you're looking to go for - at building regulations minimum then you'll be fine with a couple of stoves, if you're anywhere near Passivhaus then you'll have overheating problems.1 point

-

My experience has been that the published COP curves are unrealistic, as the killer is humidity, rather than temperature, and it's hard to get hard data for the combination of the two and the way the defrost systems impact on COP. I spent a lot of time fine tuning the settings on our ASHP, and in the end managed to get it working so it very rarely, if ever, defrosts. This has a massive impact on COP, as the defrost cycle runs the heat pump in reverse for around 10 minutes, pumping heat out of the house, so just one defrost cycle per hour knocks 30% off the true COP. Our ASHP has temperature and RH sensing at the air intake, and uses some form of combination of the two, together with the heat pump operating power, to try and predict when a defrost cycle is needed. I found by experiment that adjusting the weather compensation to remove it, and setting the heating output temp to 40 deg C, resulted in virtually no defrosting for our installation. Our ASHP is significantly over-sized for the heating requirement though; it's a nominal 7 kW rated output unit that rarely needs to deliver more than 1 kW to the floor heating. I worked out that it just wasn't worth paying the big premium for an MCS install, as for us the RHI would only have been around £80 or so per year for 7 years, and the MCS premium was well over £2,000. I knew nothing about installing these things and had it installed in a day, just two pipes and two cables, it really couldn't have been simpler. I did spend a lot of time tuning it to improve the COP though, and it now runs at over 3.5 on average and exceeds 4 from time to time.1 point

-

Not yet - I'm hoping to demolish & rebuild our existing house, just getting the money sorted at the moment (we bought it planning to refurbish but by the time we did everything it's cheaper to start again). One thing I've been looking at quite a lot is heat pumps - my wife is from the US and every year for the week or so when the weather is hot and humid I have to listen to her bitching and moaning incessantly about the fact that "this goddamn country doesn't have air conditioning". This means that - despite the fact that we have mains gas available on site - we're going to be doing a heat pump because it can also provide cooling. I'm also a chartered engineer working in R&D so doing things like setting up a spreadsheet to work out actual COP based in predicted heating/hot water loads and historical air temperatures comes pretty naturally. Instinctively I'd prefer to have a GSHP, but I just can't get the numbers to work out even though I've got a garden big enough for it. Based on 2016 data and published COP curves for a Samsung heat pump I'm predicting something like a COP of 4.4 for heat at 25C and 2.8 for hot water at 55C over the course of a year - and total electrical consumption of 1000-1500 kWh over the course of a year. By the time you get to that point there really isn't very much scope at all to reduce electrical consumption by going from an ASHP to GSHP - and the amount of extra money you need for a GSHP install is enough to make a big reduction in heat demand. You end up with the situation where a GSHP install costs maybe £10k extra including ground works, etc. in return for a modest reduction in sound levels. The logical conclusion to this is that alternative ways to reduce noise from an ASHP should be considered, and that given the cost differential it should be possible to throw a shedload of cash at this problem and still come out ahead. Looking at the noise ratings for split heat pumps is instructive here - the indoors units are very quiet indeed, quieter than an equivalent GSHP in fact, and the noise comes from the outdoor units. This appears to be predominantly flow noise from the air - and silencing air flow noise is something that is done all the time with commercial air conditioning systems. Segregating air flow should also be pretty straightforward, since the blows air out of the fan hole at the front and is sucked in everywhere else. So I'm thinking of maybe putting the outside unit in the loft of an attached garage, with louvres along the lines of http://www.wakefieldacoustics.co.uk/products/acoustic-louvres/ at either end wall, and the ASHP unit outlet directly ducted onto one of the louvres with some draft excluder, using the garage loft as essentially a giant air duct. Not a perfect solution, but looking at the sound curves at maximum power it would be about 35 dBa, mostly in the low frequencies which I can tolerate slightly better. Given that this will be outside the house and the house itself will further attenuate any noise (and ideally it would be at the front of the house so further shielded from the back garden), that should be good enough. So far as brands and reliability goes, any of the big brands should be fine - the main thing to be wary of is that the MCS installers tack a lot onto the price for the privilege of claiming the RHI payments, so it probably isn't worth going down that route. Monobloc units are probably easier to fit (there are a number of people on the forum fitting them as a DIY or quasi-DIY job), while split units need someone with an F-gas license to fit. That isn't too hard though - you'll have any number of small air conditioning companies local to you who could fit it, so it shouldn't cost too much. I'm personally leaning that direction, mostly because I think it should make the plumbing design a lot simpler.1 point

-

Your ASHP with UFH will heat the house easily. With lots of trees around it may at times be difficult to get rid of combustion gasses with the multi fuel heaters. You will probably need to create a fairly big inlet through the wall or floor as well.1 point

-

The answer to that (at least I have found from my tiny plastic tool storage shed) is to leave nothing but crap in it for the first few months. Secure it with something that won't damage the container when it is removed wrongly. Find it open once or twice a week for a month or so. Then another couple of times over the next 6 months, you could then leave the crown jewels in there. (Admittedly it's not big enough to store more than a few basic garden tools and bird feed) But, after the first 6 months, it hasn't been touched for about 6 years or more now.1 point

-

Architects have professional bodies all of whom have complaints procedures. You could loil them up and see if making a formal complaint would have the desired effect. The PB will know what constitutes unprofessional behaviour - which this looks like it might be from the insights we have been given, and will take up your case if it looks like it to them. At the very least they will inform the architect which might have the required galvanic effect.1 point

-

They have a BS number so must be fit for purpose. Personally I'd prefer the rubber ended hand tightened ones as they don't rely so heavily on the nut being quite as tight to create the gas-tight seal. Looks good to me. Would be prudent either way to have a can of leak detector spray to hand specifically for testing after the changeover, due to the cost of the gas. That would mitigate against any concern and guarantee a leak-free transition every time.1 point

-

1 point

-

1 point

-

this is a garden wall in polar white k rend.... I think their whitest white. Whilst its nice its nit as white white as the alumasc silicone stuff on the house. Its not a problem as they are not close together and the light is coming from a different direction but Polar White is not a very white white. You need to go and see some. If you are passing near Stratford on Avon area welcome to look at mine.1 point

-

1 point

-

Just what do you want your attic water tank to do. If it is to provide the header for your how water, that's not just last century, the one before I think. Have you never been in a modern house and marvelled at the hot water coming out of the tap with the same force as the cold water? In warmer climates they put the hot water tanks outside, but that would not work very well here in the winter.1 point

-

1 point

-

1 point

-

Our balcony faces west and it's nice to sit out there watching the sunset, listen to the birds singing and then if we're lucky watch the bats flying around. Good de-stresser after a day working on the house.1 point

-

1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)