-

Posts

387 -

Joined

-

Last visited

-

Days Won

1

pdf27 last won the day on April 13 2021

pdf27 had the most liked content!

Personal Information

-

Location

EGWN

Recent Profile Visitors

3084 profile views

pdf27's Achievements

Regular Member (4/5)

160

Reputation

-

How an MBC WarmSlab Has Actually Performed based on 6 Years Data

pdf27 commented on TerryE's blog entry in The House at the Bottom of the Garden

Just looking at this again from the point of view of controlling with a heat pump. Because everything is so slow (~0.5°C/hr temperature increase, and the increase across the 3kW heater smaller than the ΔT between flow and return, would the return flow temperature make a good leading indicator of room temperature? I'm wondering if that's a better way of controlling a very un-responsive slab than a room stat. -

Yeah, they've gone for south-facing instead. Front elevation is the south one though, so 🤷♂️

-

-

It used to use primary energy, nowadays it uses "Primary Energy Renewable" which is complex but not horrific if everything is electrified. If you're burning anything it's really hard to figure out what they're asking for - I think the assume e-fuels, but it isn't at all clear.

-

I know it's possible - I'm doing something fundamentally very similar in Aerospace at the moment - but I'm not close enough to the problem to know if anybody else is doing it yet. Denmark would be the obvious candidate - Norway and Sweden have lots of hydro, and Finland & Sweden have quite a bit of nuclear too. It's pretty easy with a doubly-fed induction generator, for instance, but somewhat harder with a permanent magnet type as that then drives you to adopt a particular rectifier/inverter architecture.

-

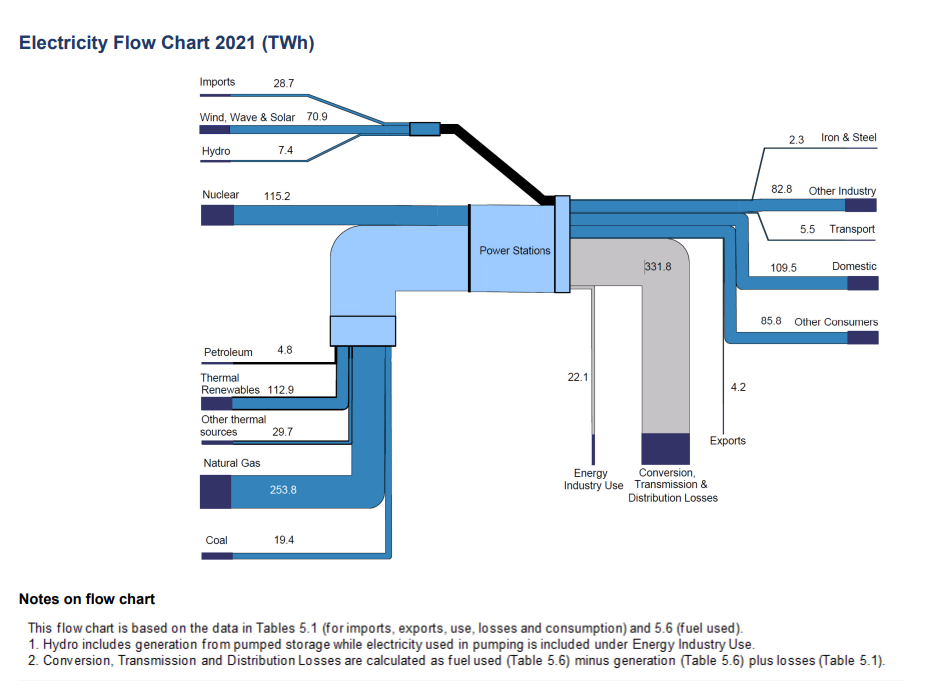

It's mostly a grid stability thing, rather than costs. Wind farms are largely not built where the demand is (the London Array being a notable exception), and as inverter-driven devices they also don't provide inertia to the system. This makes it very difficult for the grid to cope with major faults, etc. without it becoming a cascading failure. With thermal power stations, this "spinning reserve" means that in the event of a sudden load added to the system the turbines will slow down slightly, with the kinetic energy stored in the turbines and generators providing a lot of extra power for a few seconds. At present wind turbine systems can't offer this (although it's possible in theory, the way they're designed at the moment doesn't support this), so to ensure that the system can accept faults and not crash then they need to keep a certain minimum amount of thermal generation on the system. This is rapidly changing, but we aren't there yet. Batteries are already providing longer term (up to ~30 minute) response to peak demand much more cheaply than old-style peaking plant, and we're likely to see them providing synthetic inertia in the future as the technology improves. It's feasible at smaller scales at the moment, but doing it at Gigawatt scale is harder! We're also seeing flywheels being installed onto the grid to provide real inertia. These are just a giant spinning wheel attached to a motor/generator which is synchronous to the grid. If the grid speeds up or slows down, the motor/generator has to drive the flywheel and this provides better frequency stability to the grid. The annual running costs of these are much lower than those of a power station, so if you're only providing frequency stability services they're the way to go.

-

That's overwhelmingly conversion of fuel into electricity. Fuel -> heat is pretty efficient, but heat -> electricity is not. Efficiency for the latter process varies from ~30% for nuclear stations up to ~60% for the very latest gas stations. There are transmission and distribution losses, but they're pretty small in comparison.

-

See https://cen.acs.org/environment/recycling/companies-recycle-wind-turbine-blades/100/i27 - the blades are recyclable at the moment but the economics are problematic (landfill is cheaper in some countries). It's getting better with time though, certainly by the time the current installs are decommissioned it won't be an issue.

-

Calculating for the use of sand for a thermal store.

pdf27 replied to Marvin's topic in Boffin's Corner

Gasification boilers themselves are pretty complex - they typically have exhaust extraction fans and oxygen sensors and a control system to ensure accurate gasification. Plumbing a few extra cylinders is a trivial amount of added complexity in comparison to adding a gasification boiler. As for immersion heaters .vs. ASHP, both are possible - I was suggesting immersions as that's probably cheaper (could be done with second-hand cylinders picked up on eBay) and this looks like the only way it might possibly be feasible is if it's done very cheaply indeed. -

Calculating for the use of sand for a thermal store.

pdf27 replied to Marvin's topic in Boffin's Corner

No subsidies, and all the risk on level of returns (up and down-side) is passed on to shareholders/members/whatever you want to call them. Basically you're buying a share in the profits of a wind farm, which you can only redeem via your electricity bill with a small number of suppliers (possibly for tax reasons). -

Calculating for the use of sand for a thermal store.

pdf27 replied to Marvin's topic in Boffin's Corner

If I've understood their business model correctly, they're unlikely to go bust - all of their capital comes from shareholders, and the business model is essentially to sell the electricity they produce to their customers at close to cost price rather than market price. Unless market prices go below the cost of production (very unlikely for a wind farm!) they're unlikely to go bust. Returns might however be very poor. Plenty of large institutional investors doing exactly the same thing. I get the feeling Ripple was set up because someone wanted to buy shares in a wind turbine and couldn't do it easily, and decided there was a gap in the market to sell these shares. Given the rate of take up, that appears to be true. Energy is very cheap, and most forms of storage have very low energy density. It's a particular problem if you only recharge and use it once a year. Whatever you do a gasification boiler is going to add a lot of complexity. If it's just PV then you can just wire all the immersion heaters up with DPDT relays to replace the SPDT. That way once the first immersion reaches temperature and the relay fires, the current is connected to the next immersion, and so on. Exactly how long would it take for a plumber to get to where you live, 6 weeks? This is supplementing the existing heating system I assume, in which case reliability really isn't that big a deal. Valves, etc. are reliable enough that they're rarely the cause of problems in domestic systems. Problem is to get a decent amount of energy stored you really need a heavy weight a long distance, and there aren't many options for that. Gravitricity seem to be the least hopeless of the lot - using disused mine shafts so the hole is already there - but they don't seem to be able to make it work economically either and are pivoting to hydrogen storage underground. No published data for the big systems, retail price for the smaller ones is in the region of £250/kWh so you'd be looking at £25k or so for a 100kWh system. Capable of storing about £10 worth of heat! 2035 is the current date for fitting no new gas boilers - realistically that means that there will still be gas boilers on the grid in 2050. The transition time is getting up there with the life of a power station, so the capacity really isn't an issue - and I can't find any Labour policies to change this. Electric cars overwhelmingly charge at night when demand is maybe half that during the day anyway. Little or no new capacity needed there. Hard to say when you don't show any calculation! Surface area of the insulation box is ~6m2. To make the maths easier, flatten it out and act as if everything is one-dimensional. To steal from Wiki, In this case, q has units of W/m2 - it's a heat flux not a power. k is 0.035 W/m.K T2-T1 is 500 K L is 0.4m This means q is 43.75 W/m2 and so total losses are 262W (multiply by 6). This means losses are 6.3 kWh/day at full temperature. Sand weighs about 1600 kg/m3 and specific heat capacity is 290 J/kg.K. This means that the heat capacity of 1m3 of sand is 464 kJ/K. 1 kWh is 3600 kJ, so each m3 of sand holds 0.13 kWh/K. This means the temperature in the store would initially drop by 50°C/day - obviously the rate of decay will slow down quickly as the temperature drops, and you really need to solve the integral to plot the behaviour with time (repeating this calculation in excel with time steps is fine). Conclusion: a 1m3 cube of sand is hopelessly small for this application, and 400mm of mineral wool is grossly insufficient as insulation at these temperatures. -

Calculating for the use of sand for a thermal store.

pdf27 replied to Marvin's topic in Boffin's Corner

Realistically I think your best options are to either buy Ripple shares or put in enough PV that the payment for your summer exports covers your winter energy consumption. Ripple is a lot cheaper. -

Calculating for the use of sand for a thermal store.

pdf27 replied to Marvin's topic in Boffin's Corner

Comes back to the question of what you're trying to do. If you're storing solar energy in summer for use in winter, you're likely to be capturing it when the resource is >500W/m2 and be trying to capture a hell of a lot of energy to use in winter - hence most people trying to do this have gone for solar thermal. FWIW I think in this case it's a dead end either way! -

Calculating for the use of sand for a thermal store.

pdf27 replied to Marvin's topic in Boffin's Corner

If you're trying to store heat, no reason to use PV - solar thermal captures about 3x the energy per unit area, and you're going to need a liquid system to get the heat out again. It's been done a few times (search for "Sonnenhaus" or "domestic interseasonal thermal storage"), but it's hard to make a success of it. A lot of the issue is that unless you have an exceptionally well-insulated house you're going to need a lot of heat capacity in whatever you use for storage which adds cost, and it needs to be thermally segregated from the house to avoid overheating as well as keep the store hot. You end up more or less building the house around the thermal store, with the associated costs and compromises. The problem is really that if you are willing to design a house around minimising energy drawn from the grid, you're always going to go for a Passivhaus-esque approach to reduce demand. Once you do that, not only do you not need very much heat but overheating starts to become a significant challenge if you're storing a lot of heat energy inside the house. If you go for the heat pump + PV approach, you can buy an awful lot of PV + battery storage for the cost of building a giant thermal store into your design - and the amount you draw from the grid will be pretty minimal, with the PV helping to cover plug loads too. If I'm understanding you correctly you've got 2 MWh of PV exported to grid over the course of a year (mostly summer?), and are looking to use that for winter heat given an available 4m3 storage volume. Sunamp are about the best you can do here - they're a phase change system (hence very energy dense), in industrial production and extremely well insulated. That could probably store somewhat over 250 kWh in the space you have available, with a standing loss of a few hundred watts - similar to a badly insulated hot water tank and thus probably acceptable. They also sell a large system which is probably suitable - https://sunamp.com/en-gb/products/central-bank-mini/#features . Having said all that, I can't see any way of doing this cost-effectively - you aren't saving a huge amount of energy over the course of a year, and even at current energy prices that really doesn't come anywhere near to justifying the investment needed. You'd make far bigger savings investing elsewhere, either in the house or maybe in something like Ripple shares. -

If it is you have the same problem: if you control everything on roomstats (TRV or conventional roomstat) then because they'll never quite agree the system will spent a lot of it's time heating the house only using one or two radiators (room-to-room heat transfer typically being much stronger than room-to-outside). This is masked with a boiler where you can easily oversize and accept a modest penalty in efficiency and cost, but this is much more of a problem with heat pumps. Correct, in so far as the mean internal temperature is potentially slightly reduced by running some rooms a bit cooler than otherwise. This will reduce the heat loss through the fabric implying slightly reduced total heat demand. However, with a heat pump you also have to cope with the effect that it does this by greatly reducing the surface area of radiators. This means that for the same heating power delivered to the house the water needs to be warmer in the circuit, reducing the COP (boilers also see this effect, but it is much weaker). Unless you have very big temperature differences between rooms with all the TRVs wide open (in which case they are needed for comfort), the COP effect from cooler water will outweigh the total heat demand effect from cooler rooms. Indeed. The problem is that you've got two control loops if you have both a TRV and weather compensation active: the weather compensation curve is based on the assumption that the radiator area is predictable (i.e. for a given outside temperature, the TRV valve position and hence total radiator area is known). In this situation one of three things can happen: The weather compensation is set correctly, so the correct room temperature is only achieved with the heat pump running steadily and all the room stats open (i.e. the water is at the lowest temperature at which it an achieve the desired comfort level). In this case both the thermostat and TRVs are essentially redundant. The weather compensation is set too low, so the thermostat and/or TRVs are continually calling for heat and the house is always too cold. The weather compensation is set too high, so first the TRVs will close off sections of the loop and then the thermostat will stop calling for heat. Because the volume of water in the loop will be quite low as the TRVs start to close, a buffer tank will be required to prevent short cycling. It is also worth noting here that for very well insulated houses (such as those many people on here have built), an additional effect comes into play. Heat dissipation varies as a power law with the temperature difference between the floor and room. This has a stabilising effect - if the flow temperature is 25°C and the emitter is sized to keep the room at 21°C on a design cold day, even with no control system whatsoever then the room must be between 21 and 25°C. Underfloor heating will happily do this (from memory @jack runs his flow temperature at 25°C), radiators will struggle.