Leaderboard

Popular Content

Showing content with the highest reputation on 02/09/18 in all areas

-

3 points

-

2 points

-

2 points

-

Just had an idea. If I nail a roofing batten on the inside edge at the top, over the DPM, and set it a bit higher than the planks, then I can get a pitch with no real effort. I could also make the larch planks that I'm going to use as capping a bit wider, so they overhang inside and hide the metalwork. Might even make the planks last longer, a bit like the principle of a lot of the old chalk cob walls around here. They traditionally were topped with pitched thatch, to keep rain out of the chalk cob at the top and deflect it well away from the walls. It's a pity, but many of them now have cement tile pitched "roofs" instead of thatch. Spoils the look.2 points

-

I'd go with another layer of 12mm on the new side. Can't see that you could loose 12mm without a physical step.2 points

-

2 points

-

2 points

-

I don't believe you will need planning permission but I would write to the planning office. Tell them the replacement will be the same size, shape and use similar materials to the house. You don't normally need permission to block up an opening or add doors and windows so I doubt planning permission is required to make it an "indoor facility". I believe you _will_ need Building Control Approval but providing you follow the building regs that shouldn't be a problem. You will need to achieve specific insulation levels and it would be easier if the electrics are installed by a qualified electrician and the windows by a FENSA approved installer.2 points

-

Hi all, I self build 20 years ago in Milton Keynes in the glorious days when the Commission for New Towns were knocking out building plots left, right and centre. The house has been a great family home but having read about Passivhaus and visited one, I know have itchy feet to build a Passivhaus all over again in a more rural setting. Following up on a couple of leads at the moment but realise this is going to be a long game. The forum is a great source of information and inspiration particularly as the building technology has moved on so much since I last self built.1 point

-

With the recent interest in air quality hitting the news, plus the TV programme earlier this week on an experiment to reduce the particulates and NOx for one day in the Kings Heath area of Birmingham. (it's still here on iPlayer: https://www.bbc.co.uk/iplayer/episode/b09m2djj/fighting-for-air ) I've decided to see if there's a way to make an affordable air quality monitor/data logger that I can fit outside and see what the air quality is like around here, and what impact things like diesel cars driving past, wood burning stoves, weather conditions etc have on it, from day to day. What's interesting is that there are now some pretty affordable particulate monitoring sensors available, certainly good enough for hobby use. Looking around I've found two or three for around £15 to £25 each, that output serial data in the form of a count of each size of particle, over a time bin. From what I've read so far, it looks pretty easy to just sample the air periodically and plot the concentration of particulates within the size bins over time. As an example of the sensors available, here's a link to one that currently sells on Ebay for less than £17 delivered: http://www.aqmd.gov/docs/default-source/aq-spec/resources-page/plantower-pms5003-manual_v2-3.pdf?sfvrsn=2 Not sure when I'll get the time to build and test a unit, but it would be interesting, both to see how the air quality changes in a fixed location, and, perhaps, to fit one to the car so that I can correlate air quality with GPS position and time as I drive around. I''m off now to see if I can find some equally affordable NOx sensors.1 point

-

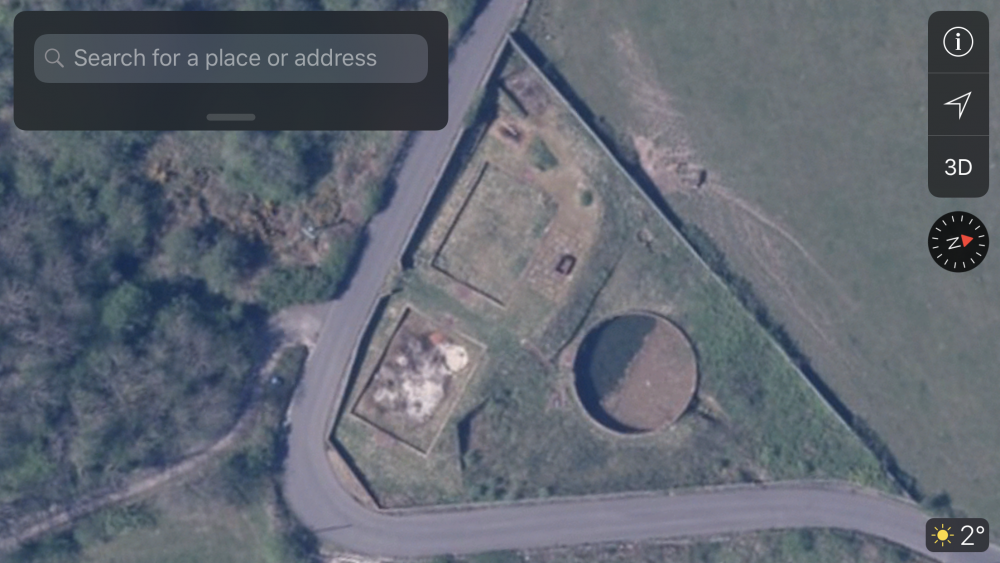

Quick hi from me. David from just North of Glasgow and looking into building our first home. Plot is is an old Scottish Water spot, with a couple of large filtration tanks and a water tank on it....lots of old pipes, inc a live pipe running right through it. 3 levels and it varies in height quite drastically, as it’s on quite a steep hil. Good fun!1 point

-

Ask them to put "one in the bank". You square them up when your next flush with dollars and they've helped you out.1 point

-

Yeah 15 moisture and sound boards All in now one Of will sleep tonight Think I’m making T1 point

-

One of my favorite trees is Willow, my eldest bought me a sapling last year... I love Pussy Willow too... Allergy to the sap / flower ? How awful :-(1 point

-

We ended up with little choice but to use Buildstore and they were frankly awful! Paperwork lost, hung on to until it was out of date before they'd do anything with it, (so you'd have to get new payslips etc), not even having processed the very first part until I chased them up after 3 weeks - only for them to let slip that they'd done nothing. Their way of processing applications seems to be in a haphazard manner - that was certainly the impression we got when being asked for documents we'd already sent, or to send new updated ones and so on. The building society themselves are lovely as a couple of times I contacted them to explain what was happening and ask what they really wanted - they basically contradicted what BS (such an apt set of initials) were telling us. If you must apply via BS, insist they tell you what documents they need in one go - with us they asked for them one at a time (after weeks of this I challenged them and they claimed the Building Society was doing it that way - which seemed so unlikely that I rang the building society who confirmed that they had sent a list of everything they need in one go to Buildstore as you would expect - and I know who I believe! ) dragging it out for weeks and weeks more unnecessarily, when we could have simply sent in one pack of documents. Once past that point though it has been OK, with stage payments released if not quite as quickly as promised, only a few days late. Trouble is BS have pretty much a monopoly for some types of self build and know it so there's no pressure to get their act together. If I had to use them again, I'd contact the building society itself much sooner and call BS bluff about the document drip feed "method". So they will get you there, but you may have to keep pushing them to get on with it.1 point

-

Yuk No wood where it needs to be on show, get it overboarded. By the time you've typed this you'd be on your second or third board and closer to the pub ?1 point

-

I’d forgotten about pipes in non vented voids. I Think you might want some @Nickfromwales input on putting a gas pipe in your battened out service void. obviously you aren’t doing it now but In future it might not be ideal like this.1 point

-

1 point

-

1 point

-

1 point

-

I found that this can happen with the Harvey (and all the many re-badged Harvey units, Twin-Tec etc) if the outlet pressure momentarily exceeds the inlet pressure during a regen cycle. In my case it was because I had a 100 litre pressure vessel after the softener and accidentally allowed the inlet pressure to drop too low (I was working on the borehole system at the time). This did result in salty water! The fix was easy, I just re-positioned the 100 litre pressure vessel to the inlet side and added a non-return valve to the outlet. That removes any possible chance of a reverse pressure event occurring. Since then all has been well. The main thing I like about the Harvey system is that it doesn't need an electrical connection. There are a couple of others that don't either, but Harvey claim to have the best water meter on their unit (not sure if that's true or not now).1 point

-

1 point

-

1 point

-

1 point

-

@Hecateh fortunately for me i have a network of friends and businesses that know i just love to up cycling as a first option rather than just going out and buying new, every time a couple of the local builders merchants do stock takes they put damaged stuff aside for me, its all approved by the management and i am always very greatful. I have done so many quirky projects that i could not have justified without free materials, i get everything from windows to paving slabs. Love the challenge of using randome materials and it saves it going in land fill.1 point

-

Hi sounds very interesting, got any pics, who on here built in a water tank, i know someone did.1 point

-

Definitely "cap" the top edge of the top board. Angle, strip, plastic trunking / trunking lid, inverted mini guttering, tile offcuts as you say. Some even bevel / double bevel the top. As an aside I've before capped wood fence posts with the aluminium from heavy duty foil take-away containers! Back to "long" edges, on my curved top wooden gate I temporarily put plastic trunking over the cut ends. (The gate will eventually have a rolled, galvanised steel, spiked feature). For now it's disguised in black duct tape. (That's my versions of "temporarily", "eventually" and "for now").1 point

-

1 point

-

Hello David, Just up the road from me and very near the hut at Carbeth ? @jamiehamy should be along soon1 point

-

Welcome, sounds like a really interesting project..... cant quite get my head around it but hope to see a picture if possible, and hello from the west coast.1 point

-

It’s barmy sometimes you see them going round all the skirtings with the blue foam Then it’s air tested Followibg day the carpet fitter pulls it all out to get his carpets down Resulting in a draft house that’s scraped through an air test1 point

-

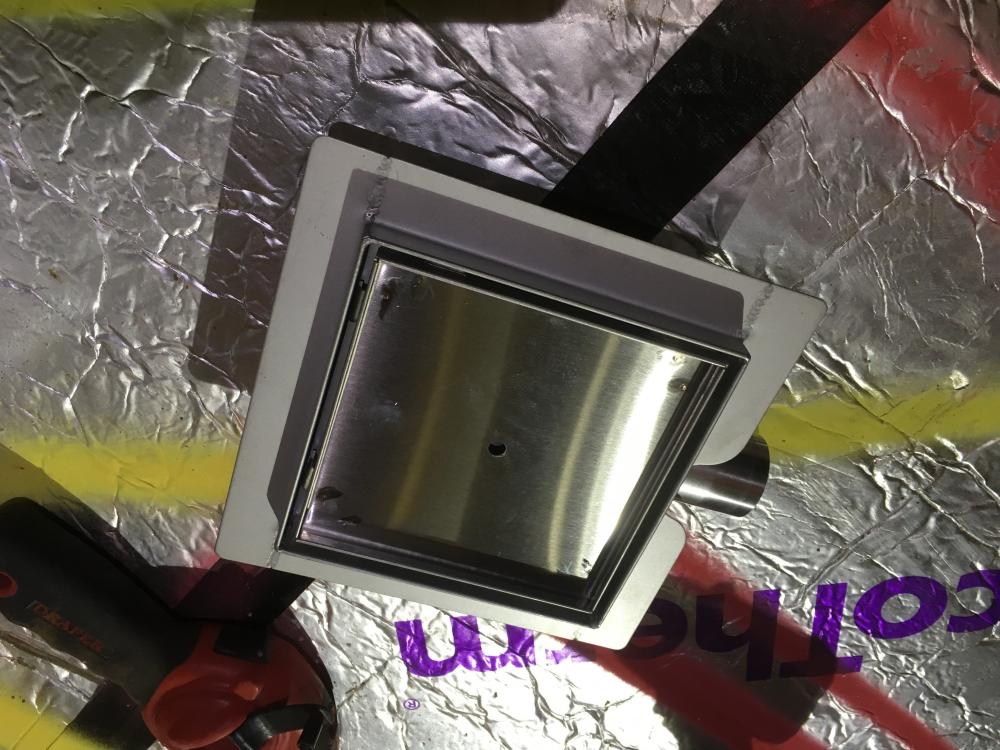

Now for the tools ? obviously as I have no idea to stand half a chance I NEED all the gear. First job is coring out for the boss adaptor. I already own some hole saws and arbours but not the right size so I have treated myself to a nice new 14 piece quick change Bosch hole saw set (£88) now it would be far too easy if the kit had the only size I actually need so I had to buy a 60mm one separately but I didn’t find that out until the kit turned up ? next job job is to cut some 2” pipe. I already own a hacksaw and grinder but who uses that rubbish anymore. All 3 sizes of plastic pipe slices (£50) and they work a treat. now you you might think surely that is enough to get on with the job but you would be wrong. Even with the fantastic pipe slices I was ever so worried about nasty burrs on my pipe so I bought a nice debarred for (£8) so now I have all the gear and a forum. What could possibly go wrong ?1 point

-

Evening everyone we’re back to messing about with the bathroom. Before we get into all my new toys we had better get the technical stuff out of the way. The shower is a straight run now so plain sailing I hope. I will box off where the yellow hashing is when I pour the slab then screed it to a fall later on. I have angled back the access point so I can have a smaller boxing but I am happy with this bit unless someone tells me I shouldn’t be. Next bit is the bath and basin. Plan is to be in the concrete along the back wall behind the bath. I will angle the first T up and out of the concrete to take the bath waste. Then it will continue along into the corner where it will come up again to the T which will go above the concrete to the basin with the AAV above it (still behind the bath) after the T I was just planing for a bend going up to the basin or would it be better to put a rodding access here? Does anyone one have any issues with this so far? Otherwise I’m going to get the glue out ?. Im here all night so please ask as many questions as necessary1 point

-

Probably do it bit by bit, documented at the each stage, and call it repairs. Building Regs will apply, of course, as you are repairing thermal elements. And check the spec of your back door and where the internal/external threshold ends up.1 point

-

Always worth talking to them - buildstore only act as brokers and their charges are higher. Also - I started my self build in December and have been hit with a few extras I wasn't expecting - with hindsight there are some that I could/should have checked out before. The biggest one is because I am on a slope - I expected foundations to be a bit more but they came in at 12k more Second one - there isn't a sewer near by that I can tee into (on a neighbour's property and under a shed and the neighbours are not pleased that I am building)/ another 3k extra to put in a pump to a sewer on my property. Water board may have been able to sort something out but that may have come in expensive too Latest one - electricity. Nearest wiring is up to capacity - have to come about 70m from nearest junction £8.6k instead of the 1.5 to 3 I was expecting. None of these increase the final value of the house so would not have been able to add more to a mortgage because of them. You probably won't have the same issues but you will almost definitely have some. They aren't kidding when they say you should have at least a 20% contingency. That is more than 20% of my build (only a small bungalow and I already owned the land. Do you already own the land - the value of that can be used as part of your 'deposit'1 point

-

I can't answer the whole question but the legal costs of the mortgage itself can be included in the mortgage - In my case I have a ridging loan rather than a self build mortgage as I don't have an income. The interest in this case is also rolled into the loan until I pay it off. One thing I think other members will tell you soon don't go with Build Store but try and go direct. In my case the same mortgage came in at about £1,500 cheaper by using a broker but I suspect I could have gone direct and saved even more. You are lucky to have found this forum earlier on in your quest to self build than I did. There is so much help, knowledge and support on here.1 point

-

I finally bit the bullet and got an Outlander PHEV. Where would I find your schematics, pretty-please Mr. @JSHarris, sir?1 point

-

0 points