Leaderboard

Popular Content

Showing content with the highest reputation on 08/28/24 in all areas

-

I don’t think that would be clearly justifiable or necessary. The principle when granting planning permission is that the new dwelling that is approved is assessed for approval in the context of retaining its PD rights. The removal or those rights via a condition should be justifiable in the context of the application and site. For example, a contentious site that only just passed in green belt would typically have PD rights removed so as to afford the LPA the ability to control future development of the site. It should be site specific and necessary and justifiable. Our LPA no longer adds this condition by default (it used to) following a number of successful applications to remove the condition post approval by a fairly industrious local planning consultant… each time he asserted the test of necessity and justifiable to the site and the LPA didn’t even question it. I think an earlier post regarding appeal inspectors dim view to removal of these rights is valid.2 points

-

Theres a lot of mention that your doing this to the outside but your OP states battens to the inside with PIR between. I considered adding insulated plasterboard instead of regular board to the inside of my self build walls which were the same construction as yours plus a 50mm cavity air gap and these are 0.17W/m2K. The whole property heat loss for 200m2 was only going to improve by 0.3W/m2K when I tried it on my heat loss survey which didn't seem enough for a 2 grand+ outlay on the boards. I was also unsure whether it was worth adding 37.5mm insulated plasterboards because it affects the thermal mass of the building. Some say more insulation trumps thermal mass, but others say having thermal mass is good with weather compensated controls in an unstable weather area so I'm likely to leave the insulation & not to risk it. You need to think how you will heat your home, will it be on all the time weather comp, or will you have on off controls and the house be fluctuate from really cold to full temperature and how fast you want it to respond. Masonry build will take a lot longer to warm from the heating being off than timber frame or if you always keep a minimum set back temperature of no less than 3 degrees of your desired temperature.1 point

-

Hello, we have also installed a Blachotrapez roof (terrano 525, with double shallow stiffeners) as it was priced very competatively, was simple to install and looks lovely. I installed the panels onto the special condensation drain membrane which also claims to reduce noise (similar to DuPont Tyvek) and I was careful to not tighten any screws, to ensure the slotted holes can allow movement for temperature change. However there is still significant 'ticking' as the surface temperature changes rapidly, for example when the sun goes behind a cloud. The noise is similar to a car engine cooling down. Worse, one of our roofs is aligned with the prevailing wind and the panels can be heard to 'wobble' which I think is due to lift and turbulance as the air passes the gable end. Hardly noticable from outide, but inside the noise is quite dramatic! I wonder if anyone else has similar issues or is this just typical for all standing seam? maybe the 0.5mm blanchotrapez is just too thin to be suitable on a windy site and the use of slotted holes rather than separate clips is a compromise too far? would welcome any thoughts!1 point

-

Hi, we are looking to to start our new build in the north of Scotland. This will be our first build.1 point

-

Hello, Thank you for letting me join the forum. We broke ground on our ICF self build near Newmarket in March 22. Currently at first fix, cant believe its taken over 2 years! Hoping to learn lots about ASHP, MVHR etc in the coming months.1 point

-

Whoever drilled the borehole could have a record of where it is - if you don't know who did it try ringing around a few of the local companies (probably not very many) and one should have a record of it.1 point

-

Plumbing them top bottom opposite ends gets you an extra 5% over the usual BBOE.1 point

-

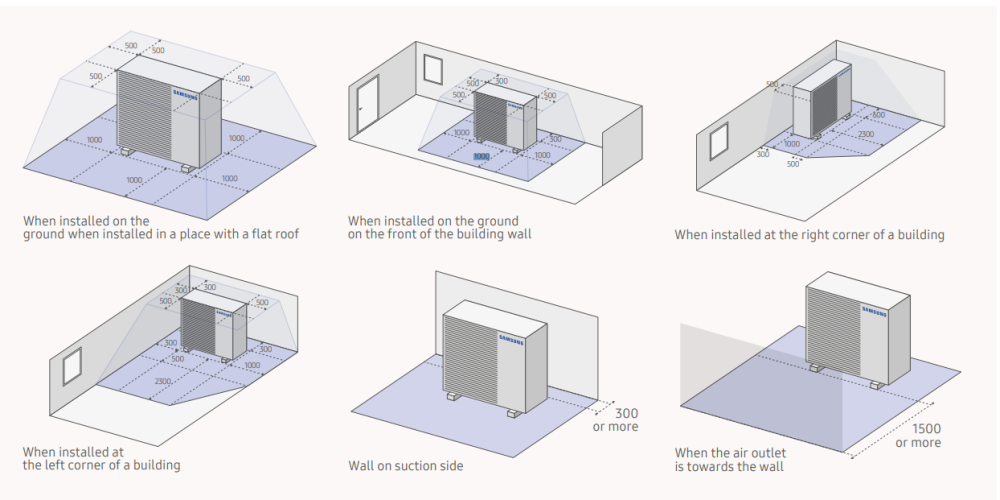

The protected zone as specify by vaillant (as I read their diagram) does not extend above the unit. That's logical too, propane is heavier than air. I'm not sure about @JohnMos second sentence, in my version of the manual this comment is only attached to the instructions for wall mounting not floor mounting - is it an instruction for safety reasons or just a recommendation eg for noise or structural integrity (since wall mounted is more likely to be close to a bedroom in the house they draw/the structural integrity of a wall reduces close to a window). Surely if it's outside the defined protective zone then it's outside it, end of? You could always call tech support if your chosen manufacturer will speak to mortals (some will, some wont, if its Vaillant they will). That should convince your installer (or not depending on what they say) Here is a samsung diagram, again the zone extends below but not above the unit, the dotted lines show that if there is any doubt. Of course what the installer will do (not what the manual says) trumps everything else!1 point

-

My understanding is that VRF system have branch boxes that contain some valving - which is fine but extra expense My "proposal" was for the pipework to be dead simple. Effectively the same layout as a 2 pipe wet central heating system. The major difference would be the indoor units would have a valve roughly analogous to a TRV but electrically controlled that woukd either allow gas to flow through the finned coil (and turn fan on) or not. If you want to add a second indoor unit to a room all you need too is tap into the existing flow return and wire up the electrics. More or less the same as adding a radiator to a room or even extending the system on to a new room. Rather than having to run a new flow/return set from the outdoor unit (assuming you have enough spare ports) Was really just an idle thought on how we could make installing A2A systems easier and quicker (thus cheaper).1 point

-

would not disagree with you -- depending on price to hire and transport it and how tight the site is . a 3ton can be by a large van and trailer or small truck and trailer --5ton no way also depends what else he has to do after removing catery . If buying you can get a bigger one relative cheaper than a small one --1 point

-

From hiring many machines over the last four years, bigger is always better. 5t would be my choice. The bigger bucket will make cleaning up faster.1 point

-

If its 100mm thick then probaly no rebar so a 3tonner will murder it ,probaly with out a pecker start lifting it and see it break ,then do same to next bit ,prop one end of that bit onlast one and break into smaller lumps. how much of it is there .cos it you need hardcore then maybe rent a conrete crusher and make your own sub base or road stone --savess on skip and you something usable1 point

-

Just to add that we have a 14kw residential scale VRF system (Mitsubishi Electric). It's a City Multi ducted A2A system so probably designed for small retail or office units primarily but works fine - we have 2 indoor units running off a single outdoor unit with the intention to add a 3rd in the future which this gives us the flexibility to do easily. There is an indoor junction box which controls refrigerant flow between the indoor units and the outdoor. It was about £500 more expensive than the equivalent non-VRF multi-split but has a lower operating noise (not sure why).1 point

-

>>> No expansion tank on the cold side, just on the hot for the unvented cylinder. Good point, but I think as they're linked through the HW cylinder, they should get roughly the same pressure variations. Mine hasn't mattered for a year or so , but I'm thinking I should get round to it.1 point

-

1 point

-

Utility (& telecoms) companies have powers (enshrined in Acts of Parliament) to seek retention of their equipment via the courts even if a wayleave has expired. As others have said, you need to get hold of a copy of the agreement. If it's a Wayleave (temporary) as opposed to an easement (permanent), has the utility company paid their rent? Has the Wayleave expired? If you want to terminate you may have to provide grounds for terminating (eg. redevelopment or non payment of rent). If you want to relocate the asset it likely this is provided for in the agreement although my guess is you would be required to pay the cost if its mid-term and/or you require the equipment to supply your house.1 point

-

Think of all the other jobs you can do get a machine for the week and get all the hedges out and tree stumps and other shite.1 point

-

Sounds like a tiny amount of water hammer. Agree with above. Problem may go away as the valve gets furred up. I have this problem too (I must fix it someday ) - caused I think by high mains pressure - it's 4 bar here. There's also an off-the-shelf version of B above - look for water hammer arrestor or similar. Just possible it's also related to the expansion tank - either the diaphragm going or set at the wrong pressure - so it's not absorbing any fluctuations.1 point

-

A - Restrict the feed with an isolation valve? B - Add a small length of capped pipe vertically before the cistern connection - creates a pressure absorber with no mechanical parts to worry about Upstairs in my house the toilets are all gravity feed so no issues with shut offs causing pipe work noises - downstairs I have one on mains pressure I tried A but it was still filling very quickly and causing pipework noise so I did B and that made the pipework silent1 point

-

Wayleaves aren't necessarily tied to the owner. Conor has the right approach. Check your legal pack as it should be mentioned. Get a copy of the title for your plot and check for anything in there as it may be registered against the land or may be a specific easement. If there's nothing in your legal pack or title for the plot, ask SSE to provide the wayleave and then, assuming one exists, you'll be able to see the terms and decide how to proceed.1 point

-

Couple of points 'So in essence no electricity bill except the standing charge' is unlikely to be true. With batteries you can shift generated capacity by a day or so to match load, but you cant shift it from summer to winter. So you will almost certainly have an electricity bill in winter, particularly if you also have an ASHP. My advice is to do the sums on the battery (and as suggested above consider a cheaper brand). Unlike solar panels there is no material ecological advantage, so you need to be making money on them to justify. Unfortunately many solar installers are just not interested unless they also fit a battery, because that's where the margins currently are! A solar diverter and your DHW tank make a very cheap 'battery', and a 200l tank of hot water heated from 10C to 50C is about 10kWh of storage capacity very cheaply. If you are planning to get an EV and its at home during the day in summer then you will soak up quite a bit with that (weakening the case for a battery). On the other hand if you can use a battery in conjunction with a ToU tariff there is potentially quite a bit to be gained. Basically its worth doing the sums for the mode in which you intend to operate, and of course check that the inverter (and any other relevant controls) are capable of operating in that mode. My consumption is similar to yours. I have 4kWp solar (from 2011) and couldn't make the case for a battery (unless cheapo + self installed) work even before I got an EV. Now I have an EV the case is only getting weaker.1 point

-

Thank you all, I have just spoken to Lawn Smith and they have been very helpful on the phone so i might go with them!1 point

-

If the site entrance is where the Heras fence is at the right of the last picture, then surely you would want a lot of it to remain as a site road? If not start breaking it furthest from the entrance and you have the "concrete road" there to push the first batch of rubble to the entrance with the diggers dozer blade. Then keep working your way to the entrance. Not the larger diggers might not have a dozer blade, something to check. I moved about 100 tons of soil around my site just pushing it with the dozer blade then digging it into a nice pile at the destination.1 point

-

If you need to move the material any distance then you really need a dumper with the machine or a “JCB” (backhoe) to break it up then use the bucket to move it. difference between 3 and 5 tonner would be negligible, while you are paying the extra transport an 8t machine would be the better option. Unless the slab is thick or reinforced then you probably don’t need a pecker, especially with a JCB type machine as it will pull up the slab in chunks1 point

-

Thanks Russel Griffiths - I've taken a look at that website and am now working on a version of one of those wall make ups. Maybe I can post on here later for people to cast an eye over?1 point

-

we ran all our towel rads (electric so they can be used independant of ASHP) of a single smart breaker in fusebox. Each has a TRV for user preference. Then Home Assistant controlls the whole lot, enables dumping of power into them based on the half hourly rate from octopus etc1 point

-

I believe the wayleave is also keyed to the landowner, not the land - so it becomes void with a new owner. Check out old posts here on this subject.1 point

-

My passive standard house doesn’t have a UFH because it’s an upside down house, so a battery, EV , PV and ASHP with low flow rate radiators does work for me across my financial and environmental goals. given that energy prices and how tariffs work will change significantly over the next few years as more dynamic pricing is introduced as opposed to broad TOU tariffs currently in play, I think batteries will become an important element of home energy management along with V2H and V2G. just my opinion.1 point

-

1 point

-

1 point

-

Yes, a S73 is a minor amendment - in our case we just moved and re-sized a few windows to match the significant internal re-design, and changed a velux window to a dormer. The internal changes were not of any interest to the planning dept, and as the outside looked very similar to the original consented design they were happy to wave it through. It is simply a case of replacing the original design drawings with the new drawings on the consent. All of the other original conditions remained unchanged.1 point

-

Joints should be fine, you need a 24 hrs leak test at 6 bar done prior to accepting. Read here fir direct reference to leak test pressure https://www.johnguest.com/gb/en/resources/blog/common-underfloor-heating-mistakes-during-installation#:~:text=Installers shouldn't automatically expect,the pipes reach maximum expansion.1 point

-

For better or worse, the combi is the yardstick. I don't think people really need actually infinite hot water. They just want to not have to think about it. They also want the space a big cylinder takes up for other things. Right now the relatively big cylinder specified by manufacturers and installers is a bit of a barrier. Both in cost and size. The HG system is a good attempt at making the installation a bit lower friction. As long as the hot water delivery is good enough - ie the times where the customer has a tepid shower or has to wait 20mins for the cylinder to recharge are very few, then it's a great idea. A 9kw instantaneous water heater (variable power controlled to just top up the temp if too low) afterwards would extend the hot water delivery time and not fall foul of g3 regs.1 point

-

My point is you have to compromise on _something_; there is not likely in the foreseeable future to be a perfect solution of the sort @Beelbeebubis asking for, because the physics/material science doesn't match our (imho unreasonable, but definitely unrealistic) expectations. A better compromise for the planet, than a vast uvc, would be an aerator, 6-8 l/min, and not expecting to have several showers in quick succession. yes indeed... with a bit more capacity squeezed out by doing real time reheat. That's probably why they couldn't patent it, too much prior art. Indeed so1 point

-

But it's DHW cycle is limited. For true combi performance we need to produce hot water for an infinite time. If you don't defrost you HP the capacity and efficency drop (which is why we do defrost them). That will eventually mean the amount of hot water you can instantaneously heat will fall and your bath or shower will become tepid.. You already get this if you have to many hot water draws on a combi. If someone is showering and someone else fills the bath, the flow rate and temp fall. What people really want for a "just like a combi" heat pump is an installation that takes up similar internal room to a gas boiler. As HG identified the issue is more the storage of hot water. Current approach is a large UV cylinder. This is OK if replacing a large UV cylinder but when you are swapping a vented cylinder you get the g3 issues and when you are swapping a combi you get the G3 and space issues. A combi or at most,. Kitchen unit or kitchen cupboard hot water storage and delivery system that could operate efficiently on a HP (ie no high temp bricks or phase change) woiod be very useful.1 point

-

Full spec and pricelist now published https://newarkcylinders.co.uk/heatgeekministore/1 point

-

Hello all, my build is in IP31 mid-way between Bury St Ed’s and Stowmarket. We broke ground back into 2021. My wife and I have tried to do as much of the work ourselves. We are halfway through the internals. On site most days pushing the project forward. Found BuildHub very early on in the thinking process, so was able to incorporate a lot of the ideas discussed here. We have an insulated slab foundation, and used ICF for the fabric and EPS boards for the roof. ASHP, MVHR, UFH in the slab, Solar panels in roof. Target PH airtightness. Metal framing, Fermacell boards. Sun cool solar control glass. Very happy to have visitors, if you want to get a better feel for some of this stuff, please PM. We are complete beginners, with no previous building experience. The people and resources on this forum are amazing.1 point

-

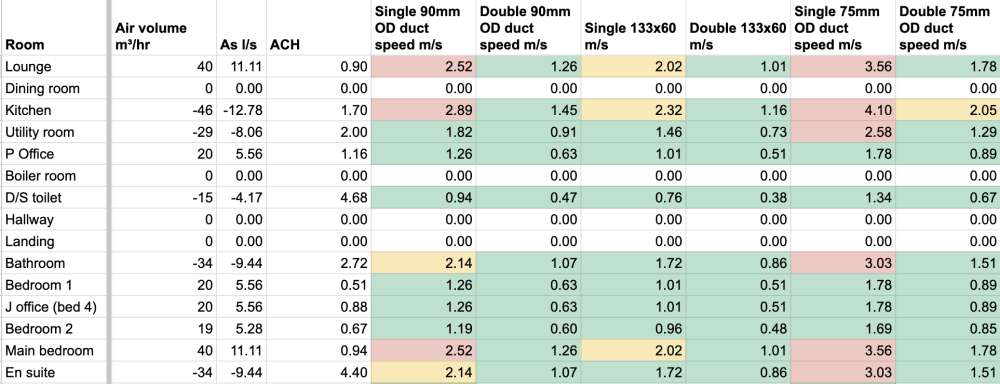

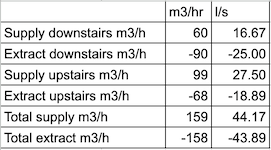

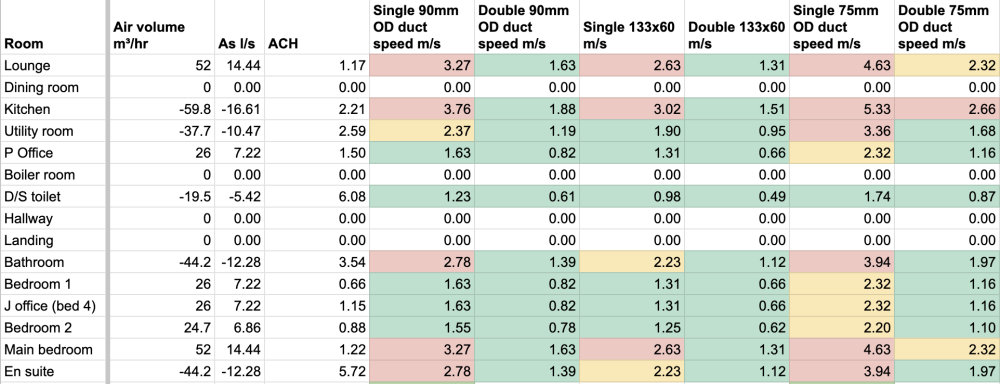

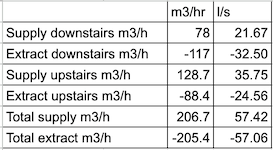

Latest update: I've redone the floor area reducing it for the skeilings, excluding areas under 1m in height and taking 50% of the floor area for areas 1m-2m high. 50% seems to be the done thing, but makes that part have an effective ceiling height of 3m instead of the 2.5m elsewhere 🤷🏻♂️ That gives a floor area of 142m² (previously 162m²) ADF for a 4 bed (Table 1.3) = 133.2m³/h ADF on floor area (1.24a): 154m³/h ADF boost extract rates (Table 1.2): 156m³/h And 0.33ACH of the volume is 120.6m³/h So designing for a minimum ventilation rate of 154m³/h: This gives distribution of (downstairs = lounge/P office, upstairs = bedrooms) For 2 of us in the house I expect to need to turn this down (based on forum members' experiences), but I think we should still have 40m³/h into our bedroom which will need it rebalancing. We will see. Nevertheless, I thought I'd best calculate a boost mode. I arbitrarily chose 1.3x (the Passivhaus figure is 1.42x). This results in: with distribution as Should I keep boost mode under 2.5m/s? If I should, Boost mode means doubling more duct runs. This leads to unit size. Blauberg talk about a 40/70 rule, where "The trickle rate is no more than 40% of the MVHR units full speed. The boost rate is no more that 70% of the MVHR units full speed.". Is this a common rule of thumb? 159m³/h is 40% of 397.5m³/h. 207m³/h is 70% of 295m³/h. I'd been thinking to use a Zehnder Q350 (rated by PHI for 270m³/h) or Brink Flair 325 (rated by PHI for 251m³/h). Given my floor area's only 142m² getting a result that says "increase unit size" sends me looking for a mistake. Looking at the initial quotes I got based on 155m2 floor area, BPC specced an "Up to 425m³/h" unit (will be less once F7/G4 filters are added), GBS a Zehnder Q350, HS&L a Zehnder Q350, and CVC a Brink Flair 400 (rated by PHI for 313m³/h). So a bit of a spread.1 point

-

Is that recommendation from personal experience? I've not heard that approach before. I found 75mm semi-rigid radial ducting perfect for the job and a joy (well, almost!) to use once I'd got the hang of it. No joins (barring the two end points of course!), easy to route around obstacles, swept bends, loose coupling with the house structure to avoid vibrations etc. I didn't find the pricing particularly offensive, especially given how quick it was to install, and it wouldn't surprise me if it was far cheaper the drainpipe given all the fittings you'd need. My case was a retrofit and so solid piping would never have been any option but I think my positive experience would be equally applicable to a new build with much easier access. P.S. Being more specific, I used Airflow Airflex (the red stuff) and whilst Blauberg do a similar (compatible) product in green I had a piece and found it far less flexible and not quite as self-supporting in making a tight bend should that be required.1 point

-

@bgmill, good luck, please keep us posted on the outcome, as it's always useful to have examples of the cost of this stuff. Prices seem to vary a lot (I sometimes suspect the DNOs make the numbers up!), and it helps others if we have some sort of baseline as to what the true costs might be.1 point

-

0 points