SBMS

Members-

Posts

873 -

Joined

-

Last visited

Recent Profile Visitors

SBMS's Achievements

Regular Member (4/5)

177

Reputation

-

Did you do ducted AC upstairs or wall units? Think we are going this direction..

-

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

It doesn’t you’re right I was reading someone else’s article on a blog and I don’t think the regs say that. I initially thought it was the greater of 43l/s for 5 bedrooms or 0.3 * square meters floor space. Think i went down a rabbit hole reading someone else’s blog. I think it’s as simple as 370*0.3=111 as I put originally for BR?? -

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Sorry typo before. I read the above and worked out that the BR ventilation rate is 124l/s. 43l/s as per your table plus the adjustment as the floor area is greater than 100sqm. (370 - 100) = 270 m² × 0.3 l/s/m² = 81 l/s 81+43 from the table is 124l/s. Which I think requires a unit size of circa 450 cubic meters per hour. Seems close to the ideal 60% most recommend running a unit at although I wonder if the BR calculation is on the high side. Paul heat recovery calcs just seem a bit on the low side but I don’t know. -

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

To be fair the AI calculated the BR value which I checked and it was correct (111l/s). The occupancy figure was around 120-130l/s. So fairly similar. -

Not for new builds. They require developer contribution capped at 2k. Although sliding scale - the more you build, the cheaper it is.

- 9 replies

-

- vat

- zero-rated vat

-

(and 2 more)

Tagged with:

-

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

It’s coming out at around 650-720m3 according to the ChatGPT estimate… who knows which is right?! -

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I asked ChatGPT to do me an estimate and it was surprisingly useful. It asked me bedrooms, volume, sqm etc and concluded with the following: 🧮 Here’s what that means in practice: Normal continuous mode: You can expect around 400–460 m³/h (≈ 110–130 L/s), depending on your ducting layout (). Boost or peak mode: Up to 600 m³/h (≈ 166 L/s), assuming your duct system doesn’t exceed 200 Pa pressure drop . Free-air (no duct resistance): Might get up to 700–750 m³/h, but this isn’t realistic once ductwork is in place (). ✅ So: Is the Q600 enough for your needs? Continuous operation (~430–470 m³/h needed): ✅ Yes, Q600 handles this well, especially with low-pressure ducting. Boost mode (~650–720 m³/h ideal): ⚠️ It’s a bit below ideal, maxing at ~600 m³/h. You might see slower clearing during showers/cooking, but this is a common and workable compromise. -

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Would You agree with Paul heat recovery’s assessment of the size of unit required or do you think the unit would run undersized? -

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

If ventilation is nothing to do with volume why do all the calculations and sizing reference volume and why do the units have sizing related to volume (genuine question as this repeatedly confuses me. If ventilation is to do with number of occupants generating co2 then shouldn’t mvhr units be based on number of people in the dwelling?) -

Ours was not - openreach wouldn’t entertain it apparently in the last 12m they had sought advice from hmrc who stated it could not be zero rated.

- 9 replies

-

- vat

- zero-rated vat

-

(and 2 more)

Tagged with:

-

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

The thing for me is the fact they’ve excluded the volume of the hall and landings as that is quite a bit of volume. -

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Same dilemma. And Paul heat recovery have over estimated mine as the top floor bedrooms are rooms in roof so not 2.4m high for the whole room… -

Are these MVHR numbers correct?

SBMS replied to SBMS's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Who have you had quotes from? Have you tried Paul heat recovery (what did they say if so?) -

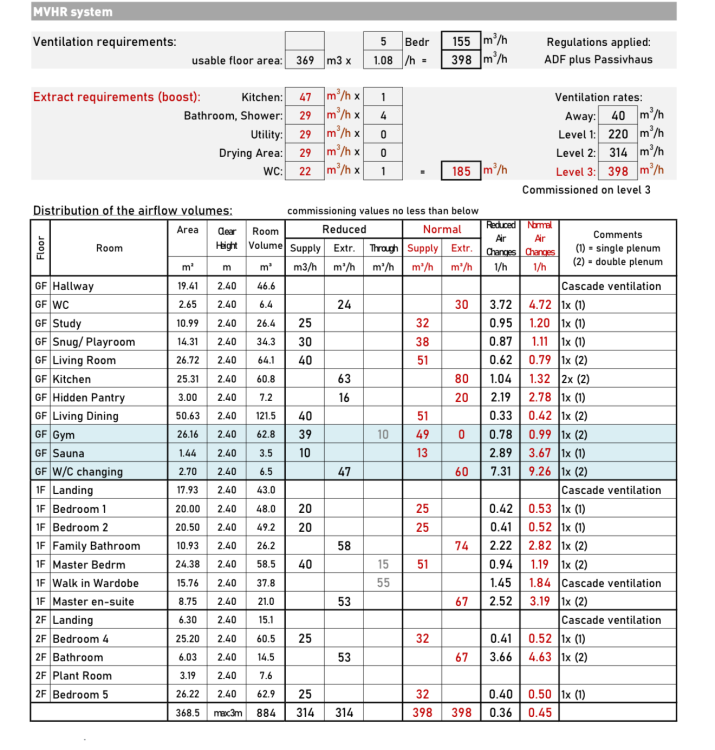

So we’ve got a fairly large sqm required for MVHR - circa 400sqm. A couple of other MVHR suppliers (including BCP) have suggested large units such as airflow and komfovent to shift up to 900m3. However Paul heat recovery has come back with the zehnder comfoair q600 with a much lower estimate required for airflow. Does the below look right? In particular it looks like they exclude the hallway and landing areas from their estimates (cascade ventilation)?

-

A2A + A2W ASHP or a more powerful A2W ASHP?

SBMS replied to puntloos's topic in Air Source Heat Pumps (ASHP)

@joth currently got the same dilemma and I am erring towards option a as well. Did you put any heat emitters upstairs or do UFH upstairs? My rudimentary calculations indicate my downstairs UFH surface area is enough to heat the whole house and therefore upstairs emitters not necessary. Nice side effect of A2A upstairs is if it is chilly I can put the units in heat mode to top up. Downside is I am struggling with our preferred installer who considers that for the MCS install and BUS grant for the heat pump they need an emitter in each heated space including upstairs…

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)