Leaderboard

Popular Content

Showing content with the highest reputation on 12/06/23 in all areas

-

5 points

-

Reported in this link from Heat Pumps Today newsletter. Full report downloadable here. Well worth a read, IMHO contains many sound and practical recommendations for levelling the playing field (gas vs electricity and HPs vs boilers), simlifying PP and DNO approval, increasing/training the workforce, and international comparisons. @JamesPa and @Beelbeebub will be particularly interested I think as all readers of this forum.4 points

-

I suspect we're a bit more exposed than you are Gary, so we swopped our horrible, but oh-so useful container for these lumps of limestone. The difference is that we are expecting to have to defend the front of our house because of the open-front design: there's no wall between us and the single-track road. Have a guess who hit one of these first while parking .... well, we had been to the pub. And it was just a 'touch' I'm never ever gonna live it down. 😑 She was in the car with me.2 points

-

Think the following happens - found this the other day with my ASHP. Both ASHP and GSHP manage dT first based on return temp, as return temp increases the flow temp increases towards set point. Our flow from the UFH completely overwhelms all other flows which are very small. So as the floor heats up the flow temperature increases. So just running the radiators has a different feedback to the heat pump compared to UFH on its own or as a mixed system. A mixing valve on the UFH resolve?1 point

-

1 point

-

I have only read the first little bit, as I basically couldn’t be bothered. However being an ex bricky I hope I can help a bit. You will not have any cut bricks, none, don’t do it. Work it out in brick sizes exactly on the exterior face. if you need movement joints then put them exactly in the middle of a brick so the wall basically stops and starts as if it was two independent walls. All of the above is based on you using basic stretcher bond. Block work will have to fit accordingly, block work is secondary it’s the brickwork that needs to look right.1 point

-

Back to the question and my first response https://www.ofgem.gov.uk/environmental-and-social-schemes/boiler-upgrade-scheme-bus/property-owners "We do not check EPC reports for eligible self-builds." So no need for an EPC if you qualify as a self build. Fig 2 on page 28 of the attached clearly say no EPC needed at any stage, in the guidance notes by ofgem. So fill your boots and get it installed ASAP. BUS PO guidance V2.3.pdf1 point

-

We did have mains gas as an option, and I'm only 70% sure ASHP was indeed the best short term solution (I don't think we will get the gov grant for our installation) . Long term I'm very confident it will be, as electric & gas prices are disconnected/swung as more renewables come online, but having watched it during a week of sub zero temps I accept there's more compromise then I was expecting. Hence always warning people to really REALLY be sure ASHP is the right thing to switch to, and to never rip out a working gas system 'because ashp is in the news and everyone is discussing it'.1 point

-

I fitted the utility room this morning from diy kitchens. Now I’ve had a good chance to look at it and the ironmongery I’d say you get what you pay for. It’s a perfectly good kitchen. It is let down a little by some of the fittings. The towel rail drawer is a little flimsy and I had to add extra screws as it was only held on by two screws. Not entirely convinced it will last the test of time. It was also a bit shoddily put together in places. The sink and tap are pretty decent and the solid oak worktop was good value for money. All in all happy with it but I’m not sure I’d have been so happy with it as our main kitchen.1 point

-

I drilled holes, filled them full of sealant and then screwed the battens into them. Haven't done an airtest but it seems to have done the trick.1 point

-

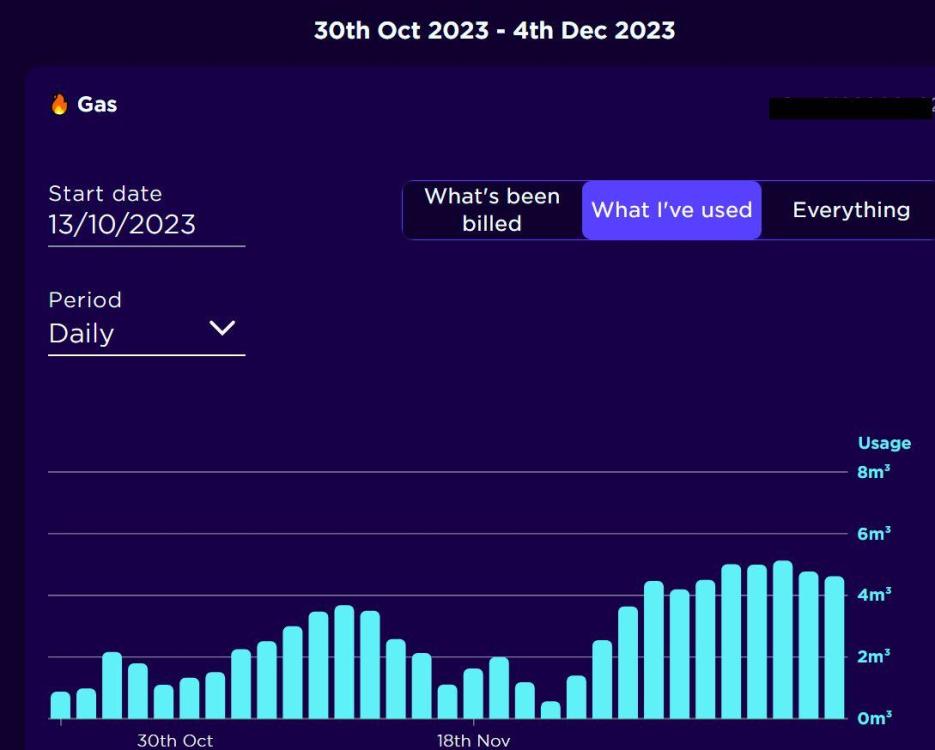

For a comparison, these are how my usage has worked out recently. Factors are: - It is Gas for heating, nearly all hot water (one electric shower), and cooking. - The A2A heat pump as described. CoP about 2->2.5, so puts out 2.5->3kw for 1>1.5kW of input. - I have a new air-fryer cooker which I have been using quite extensively -> transfer from some wok cookery on the gas, but also from the Electric Oven. - I have a solar array put in in 2016 which reduced my annual electricity consumption by something like 30-35% like for like (finger in the air estimate). If I go for more electrical heating that will work the other way. - Living on my own in a largish 4 bed house (200 sqm approx). Usage numbers. - During the summer I was using about 4-5kWh of imported electricity per day. Figure from smart meter. - When I got the air fryer in, and started dabbling with the ASHP in heating mode during Oct, that went up to around 7-8kWh per day. - During the current cols snap that has jumped to around 10kWh per day. I hope to keep it at that level as a max. - Gas use during the summer was cooking / water, so very little. - Since early Nov I have been running a bathroom radiator a couple of hours AM and PM. Put usage up to about 1-1.5 cubic m per day (which I make ~15 kWh). - My downstairs heating controller was replaced in mid-Nov, and I have that on driving the UFH over the downstairs to provide some baseload heating. That has put usage to about 4 cubic m per day, which I make around 44 kwh. - For an early morning boost I have occasionally been using the wok ring for 15 minutes whilst cooking breakfast, which is not quite optimal efficiency or C02 wise, but a good instant boost. - Bills for 4 Nov -> 3 Dec were £60 gas and £70 elec. I think I need to get to grips with the the new GFCH controller to use gas more efficiently by setting up daily timings rather than default, judging by the weekly gas usage where 45% of the last 4 weeks was in the last week, or it could run away with me like last year. - TBF, my current regime is a little hair-shirty, back to the old "warm certain rooms" method (baths + kitchen-diner), and the rest running .. er .. 'cool' ! House is OK-good, rather than near-passive. Graphs Reflections - Last year I was caught out a little by the amount of gas I used for heating, which having done a retrospective audit of bills recently was more than I thought it was. But I was incapacitated by illness. - This year my stretch goal is to keep bills below £100 per month except for Nov / Dec / Jan / Feb (say £800-£1000 total for 12 months), and to break even when solar exports and FIT are added in. That is a bit of a stretch goal TBH, especially on the heating side. - Further improvement will depend on the supply side and a switch to electric heating, so likely more solar / solar export and a house battery. Not much scope for improving fabric performance since it was all done just before we bought it around 2008 - except perhaps draughts and drylining as I need to redecorate certain areas. A detailed heat model analysis may help.1 point

-

Natural stone is likely to crack from the thermal expansion and contraction fracturing any discontinuity in the stone. If you don't want joins then cast refractory concrete died black should work. The sides could be black stone so long as they're not in direct contact with the fire. I don't think there's much point insulating an open fire. Only really makes sense for pizza oven type set ups1 point

-

Agree with Dave, Not much you can do in applying it to save the paint/finish. It’s mainly about removing it. We not long in removing a huge amount of painted wood chip wallpaper in a 1960’s house (160sqm floor area, every wall had 2 layers of it). We took it off with a chemical spray & a hole cutting tool, walls underneath had minor damage so was a simple fill & sand job after.1 point

-

The secret to removing wallpaper is to wet it, either with a wet sponge or a steamer. The things that will make that difficult are painted wallpaper, or waterproof vinyl. Anyone who lived through the 80's will remember the horror of painted woodchip.1 point

-

1 point

-

You need a slide hammer nail puller. e.g. https://www.kawstore.co.uk/products/kawtool/hand-tools/builders-tools/nail-pullers/priory-150-nail-puller-integral-slide-hammer You use the inbuilt slide hammer to drive the jaws down into the floorboard either side of the nail then push it sideways that tightens the jaws on the nail and pulls it out with a lot less damage than just pulling the board up with the nails still in place. Mine was my dads and is probably as old as me, but looks identical to that one linked above.1 point

-

I vaguely remember setting mine at 2 lpm on each circuit bar the bypass (bathroom) and the boiler pump is set to 80% max flow. Been running for around 6 years so far with some big vertical bar radiators and a couple of standard single rads, no complaints from me. temperature won’t affect the manifold itself, only thing I can see ever wearing out is the flow rate meters which can always be replaced, and you’ll find they get a lot dirtier quickly with rads, mine are black inside and can’t read the rate anymore, really need to clean them at some point 😂 no other components in there you wouldn’t find in the rest of the heating system. ran for most of the 6 years at 55C, just moved to 45C this autumn1 point

-

you would have both extract and supply go on boost as @JohnMo said, it's a balanced system and whenever the speed of one fan increases the other one should follow so you don't get differential pressure. You could have it the just the extract boosts but there might be a disadvantages to it, not sure.1 point

-

Is the joint between boards 1 and 2 at all open? Could you run a circ saw down to cut the tongue? Even if not, if you punch the nails down into the joist with a parallel-sided punch you should be able to wrangle it enough with the existing (lack of) 'weasel room'. Even if you cannot get the nails right through the bottom of the board, 75% of the way should loosen everything off enough. I once did a floor of approx 32m2 like this. We allowed for 20% wastage, and ended up only replacing about 4 linear metres of board.1 point

-

Ply or OSB behind the plasterboard in kitchen and anywhere else you expect to hang heavy stuff?1 point

-

1 point

-

it's a good question. We did 25mm service void with traditional battening and gypsum pasterboard, and I've made a dogs dinner of installing various things on it. Especially in the plant room, which I've now found is much better done with Ply or MDF, and perhaps no service void but surface mount pipe/trunking for electrics etc (general feeling in my build team was drilling through the airtight layer is OK for fixings if necessary, so long as squirt the hole full of some glue or sealant prior to putting the screw in. We achieved 0.5ACH on a retrofit so seems legit) For the service void approach, some people recommend Habito or Fermacell for much more robust internal walls, various threads on them here e.g.1 point

-

I've got one of these cheap R290 units in the gym shed, and the wifi app is quite usable for monitoring temperature and adjusting settings remotes. Despite going through Chinese servers (actually central europen data center, but Tuya is the chinese company in control of it) it's far easier to use and more responsive than the Mitsubishi MELcloud app on our A2W hp in the house https://www.appliancesdirect.co.uk/p/eiq-12wminv/electriq-eiq12wminv-wall-split-air-conditioner Not specifically pushing that model, just saying if fairly entry level units have reasonable app support then I'm sure more luxury brands would (although honestly think their proprietary apps could be worse, given the Mitsu experience). Doing a multisplit unit might complicate built in wifi controls a bit, I don't know As a bonus I linked mine to Home Assistant so have made automations to act as frost protection, auto power off after a period of inactivity in the shed, etc. but it's fine to use without that. (The Tuya Smart Life app has some basic routines support built in, and you can link to Google/alexa routines too if wanted)1 point

-

1 point

-

Good link. I love this bit at the end: Alternatively, you could make this a DIY project. Often the best installations are completed by homeowners who have taken time to install materials correctly. The most important skill needed is care and attention to the intricate details. You must also follow the appropriate health and safety measures at all times. We would be pleased to support you with further installation information if DIY is an option for you. If ever there was a vieled reference to crap workmanship by builders, this is it. Still at least they know what actually goes on in the real world.1 point

-

Are the joists located into the brickwork, or on joist hangers? Im assuming cavity wall? If the former, then you do definetely run the risk of moisture forming at the interface with the cold brickwork which will struggle to evaprate, wool or otherwise If on joist hangers, you may still have the problem. Obviously you could pay someone to do a proper analysis, but my take is that it is a high risk solution. Its examples like this that just demonstrate the practical difficulties with insulating older housing stock. That you are asking puts you way ahead of the other 99% doing this stuff.1 point

-

Oak framing does not have to be expensive if well designed. After all, you are substituting another building material for oak frame. I'd say the majority of the extra costs can be associated with additional time required with finisihing details around the oak frame. For example, if you have lots of oak studs, joists and braces, then this creates panels with loads of details to finish to; battening, plastering, running cables around etc. In addition, you have to consider where services interact with an exposed timber frame. Such as plumbing, MVHR pipes etc. Good luck with it though. Happy to share my opinions on here, though it is a forum, so take them with a pinch of salt!1 point

-

Oh yes @Alan Ambrose, and McGruer yachts (Helensborough) , German Beaver-Tail slating, and irreverent gargoyls. Oak frames lend themselves to small bits of architectural wood carving. Loads of inspiration in older North German houses. One famous one is called the Dukatenscheisser. Literally translated, the DucatShitter. The saying goes that the house cost so much that they had to get the ducatshitter to pay for the build. History repeats itself doesn't it.1 point

-

>>> Omega Seamaster watches, pre-war Leica cameras, Umbrian villas You forgot Riva launches... @sunflower - congrats, there are not many oak frame-style people on here, but there are a few. Me, for one. A couple of drawings / images of the plot for us to be jealous over?1 point

-

I would not put one in a bedroom, and want it to work whilst I was asleep. But you can arrange it so that the unit is outside eg on a balcony. The thread I linked has a copy of the manual linked, which tells you a lot more. I am not sure that it would be able to drive the flow up the height of a chimney. My view is that I would probably not make one a permanent installation but would go for a minisplit, or one of those where there is a single unit inside the room and a 70mm hole carry the connections. If eg I had a summer office it would be useful as tactical heating. / cooling. For me, it is also a spare powerful dehumidifier which I might ultimately use as another lend-to-tenants or dry-the-washing device.1 point

-

Ideally you would need a duct for inlet and exhaust for those portable units to work well.1 point

-

You could get a cheap PlantPower particulate sensor, stick it into the MVHR input pipe, then with a bit of code, set a limit for it to turn the MVHR off.1 point

-

We came home Saturday event to find the postman had almost demolished Snapping one post and badly twisting the other our oak porch I’ll I’ve ordered two new oak posts and barge board Il have to strip the roof and under boarding They have agreed to pay me 4K to sort it out I really don’t have two days spare at the moment But the house is sold and we can’t leave it like that Just to add Apart from knocking it down in the first place The Royal mail have been excellent0 points

-

I scraped the corner of my car on my front wall. I have left the scratches there in the hope of deterring anyone tempted to steal it by making them do a bit more work before passing it on.0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)