Leaderboard

Popular Content

Showing content with the highest reputation on 12/05/23 in all areas

-

Well that's well over 30m2 floor area. It'll need a building reg application so design and calcs for the foundations. Given that the house is yet to be given planning approval you may want the flexibility of not having garage foundations set in concrete so to speak... The crossover may be worth at least getting a quote on to compare with what will be substantial foundation works.2 points

-

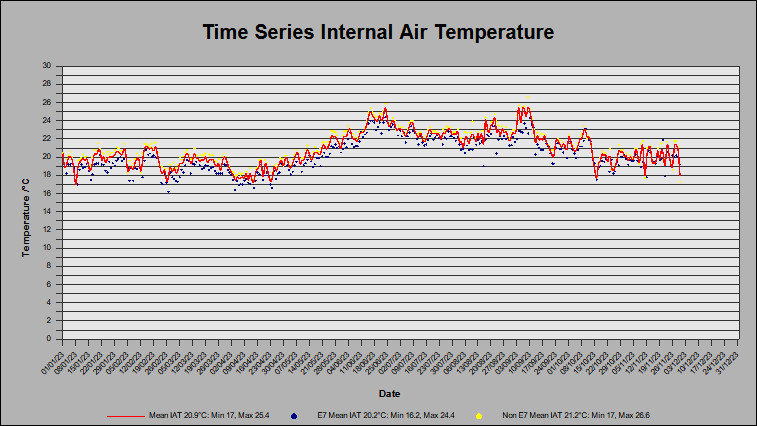

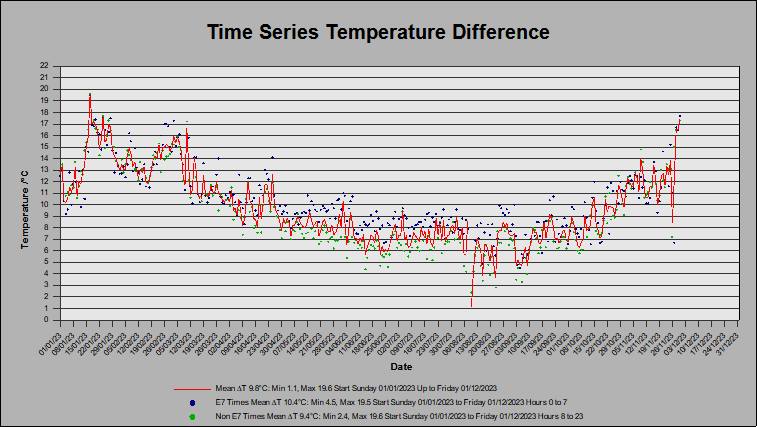

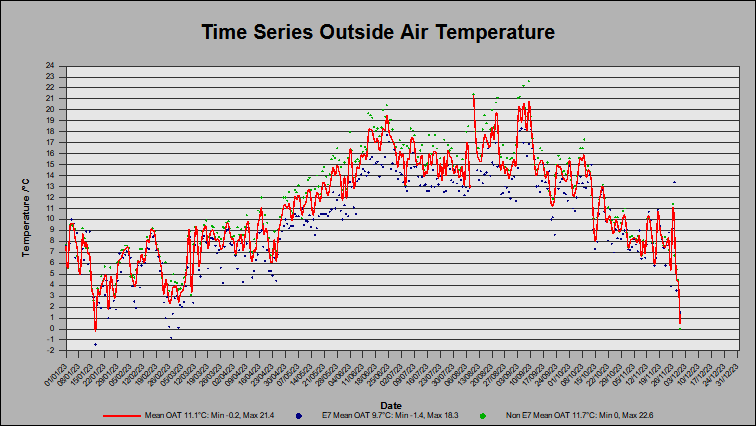

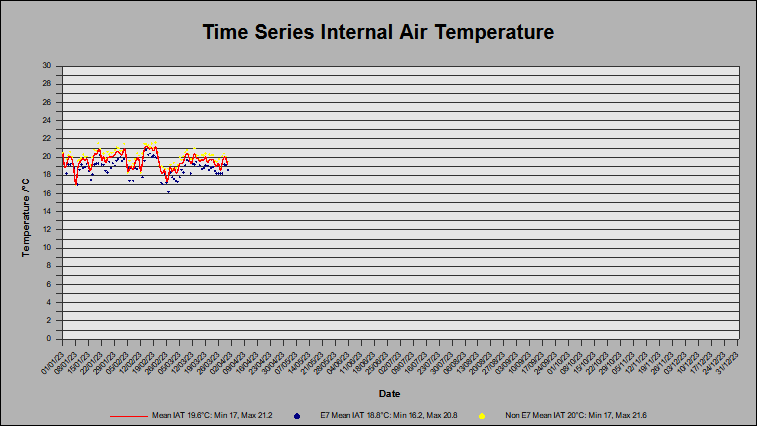

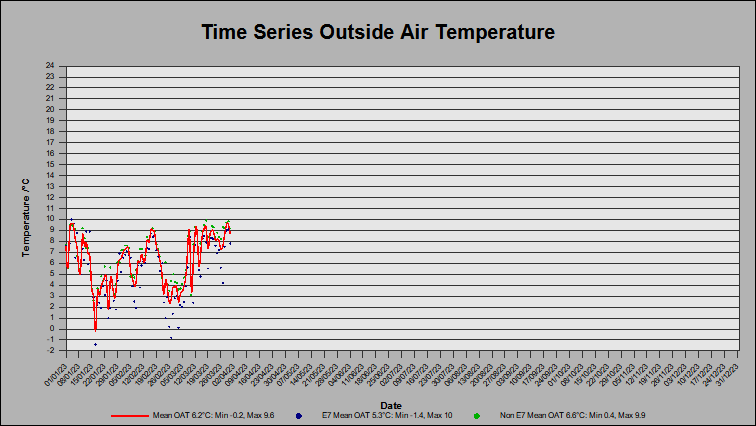

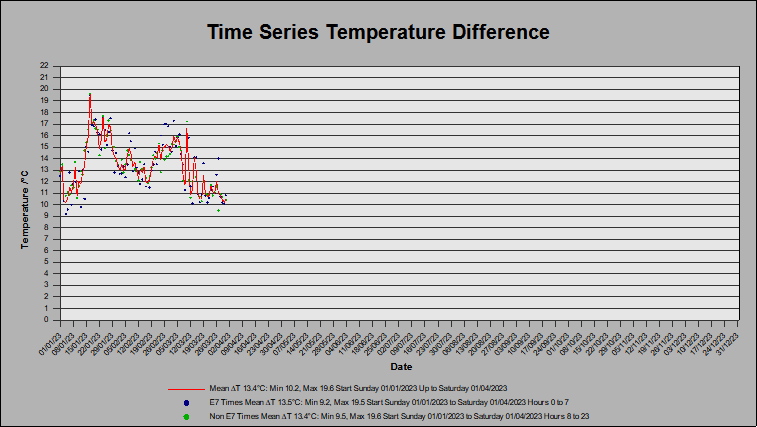

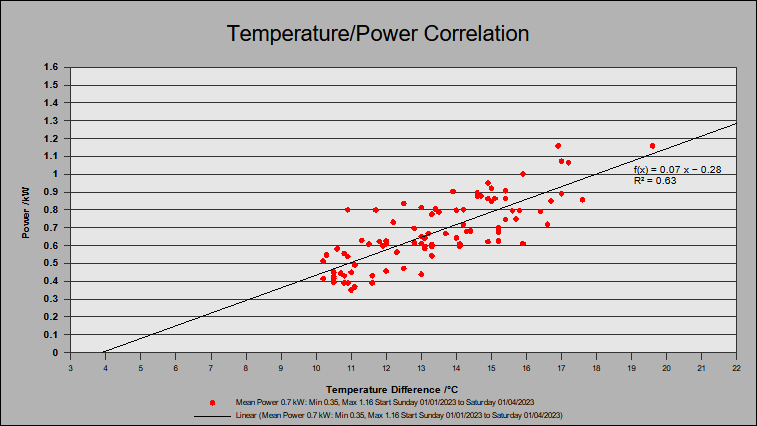

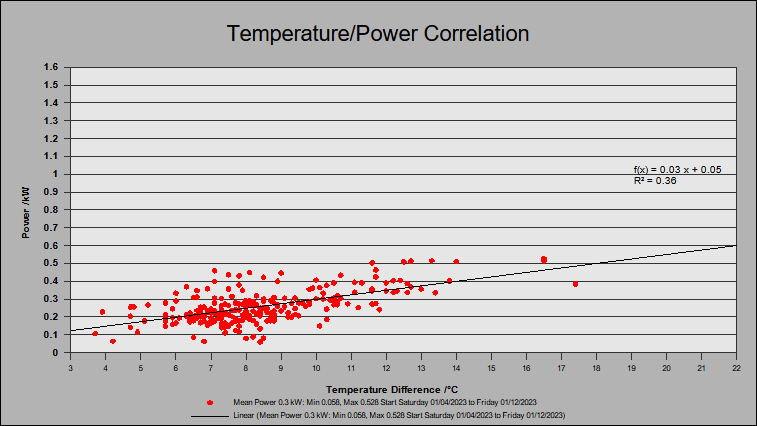

As it is winter, the same questions are coming up, again, again. I decided to have a look at my temperatures to see what is happening at different times of the day, even though I don't have an ASHP, I thought it would be an interesting exercise anyway. I sample, and log, temperature data via my energy monitor (approximately every ten seconds) and via a RPI and a DS18B20 outside (every 600 seconds). For analysis purposes I take the mean temperature over each hour and use that. The standard error of the mean is smaller than the resolution of the DS18B20, so I am not worried too much about accuracy being way off. For this analysis I am using daily means taken from the hourly means, while not perfect, they are easily good enough to get a decent understanding of what is really happening. Over the last 11 months, the daily mean internal temperature has been 20.9°C (the secondary glazing fitted last year has raised my temperature about 1°C compared to previous years), the minimum has been 17°C (Jan 8 when I was away) and the maximum 25.4°C (was that heat wave, on June 24, I grew up in the tropics so don't find it excessive). This is shown, by the red line, in the chart below. The chart below shows the outside air temperature. Another way to look at this is temperature differences between the internal temperature and the external temperature, again it is the red line. You may have noticed that there are two other series on these charts. These show the temperatures between midnight (0 hour) up to 8 AM and 8 AM to midnight. Over the year the mean temperature difference has been 9.8°C, with a minimum difference of 1.1°C and a maximum difference of 19.6°C. The 0 hour up to 8 AM (near enough my E7 window) mean difference is 10.4°C, minimum of 4.5°C and maximum of 19.5°C. The non E7 times the mean temperature difference is 9.4°C, minimum of 2.4°C and maximum of 19.6°C. Now I do not know how much of a difference the coefficient of performance is affected by, at worse, a 2.1°C difference when the mean temperature is 9.4°C (E7 window), compared to 10.4°C (non E7 window). Now this year, I turned my heating off on the 1st April. Thought that would be a laugh. So below are the same charts adjusted to just my heating times. Taking just the numbers from the temperature differences, which are the important ones as they show how hard a heating system needs to work. The mean temperature difference is 13.4°C, minimum 10.2°C and maximum difference 19.6°C. During the E7 window, the mean difference is 13.5°C, minimum 9.2°C and maximum difference 19.5°C. Outside the E7 window, the mean difference is 13.4°C, minimum 9.5°C and maximum difference 19.6°C. With those differences I don't believe there is anything to worry about regarding the CoP of an ASHP. This analysis is, obviously, only for my location and my house heat loads, and I am not sure how well it would describe other locations and houses/households. One way to try and make a universal model is to look at the energy usage over the heating period (1,463 kWh) and adjust that to floor area and see how it compares. For my house (~50m2), for 90 days heating (and DHW/Cooking/Laundry/Lighting/etc) it works out at 0.325 kWh/m2, which is 13.5 W/m2. I am not sure of that is good or bad to be honest. It seems quit low to me for resistance heating. If the above is plotted, then the correlation between temperature difference and energy usage shows that for every 1°C increase (in difference), and extra 70W of power is needed. That is an extra 1.4 W/m2 or over the 90 days, 3 kWh/°C. Looking at the rest of the year, to 01/12/2023 (non heating), shows that for every extra 30 W, the temperature difference increases by 1°C. This is nonsense as it is the non heating season and the house is ventilated a lot more (windows open). What is actually happening is that the house is at a relatively stable temperature and the OAT is varying. What needs to be done here it the 36 W/°C (from the trend line function calculation) needs to be subtracted from the 70 W/°C trend line in the above chart. This leaves 34 W/°C needed to heat the house. As a power per square meter number that is 0.7 W/°C, which is very little. The important point there is that my house is thermally stable, even though it is a timber frame. It can 'store' enough thermal energy for short term OAT variations (just as well as Cornwall has extremely variable weather). I am not sure if any of the above is going to be of use to anyone else, but the main point is that for a few quid, basic temperature and energy monitoring can show a lot of useful information when deciding to change a heating system. There is enough information on here to build your own monitors and it amazes me the amount of people that don't monitor and spend a couple of hours analysing the data.1 point

-

1 point

-

1 point

-

What type of blinds? Internal/external? What have you seen so far? The cheapest/easiest is 230v IMO which requires a 4-core radial run. Unless you want "pull to open" which needs a permanent live, or plan to use SMI protocol? If you don't know then run 4-core radial + CAT6 and keep your options open.1 point

-

1 point

-

I have used This company in the past and found them good. https://theukelectricgatecompany.co.uk/?gclid=Cj0KCQiAsburBhCIARIsAExmsu6_sEpNNtsAc3BrDTTXkHGdNYgx4PYl85HdFKC4mDJAt57hrOPwYX4aAu3kEALw_wcB1 point

-

It's normal to shorten, cut, strip, and re terminate the drop cables. What is the issue? just use the original connector. You will have to use lever wago's if you choose that as they are almost all stranded cables.1 point

-

Sorry had a new phone after dropping mine in a bucket of oil and didn't get alerts as I wasn't signed in. No developments.... focusing on getting the garage sorted and watertight and driveway planning and quotes..... I think we are back to getting the path in porcelain but perhaps a different colour. Until spring we have sort of abandoned it.1 point

-

This is what I had - after comments, advice and suggestions hare and a chat with my architect, I have allowed it to pass - and keeping a close eye on it for (no) cracks etc. Thanks @all1 point

-

Yes, that end wall (opposite doors) will be shorter in height at the point than where it joins the side to the right to maintain an equal slope over the whole roof (shame I can’t do CAD 🤷♂️)1 point

-

I'm not sure, as it was installed by the previous owners. I guess it's not that thick as the temperature on it changes under 10 minutes. I was brought up in a house with UFH, so I understand the principles of it working differently to radiators, and that it will heat up slower BUT I also understand enough to know something is amiss with the way something in the manifold is behaving. Annoyingly, keep getting similar responses from plumbers, assuming I don't know how it works and they don't even want to look at it. I wondered if this forum might be able to give me some suggestions that I can pass on1 point

-

As upthread you might get 10kW pk installed power for your £15k budget. Facing SW you would need something like 75 sq m plan area of roof for that allowing something for margins, chimneys etc.1 point

-

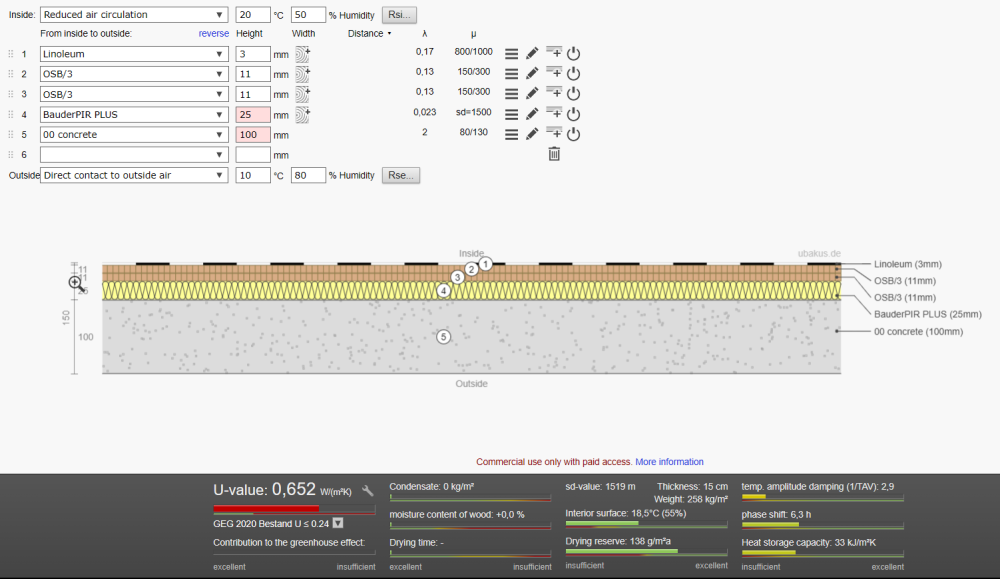

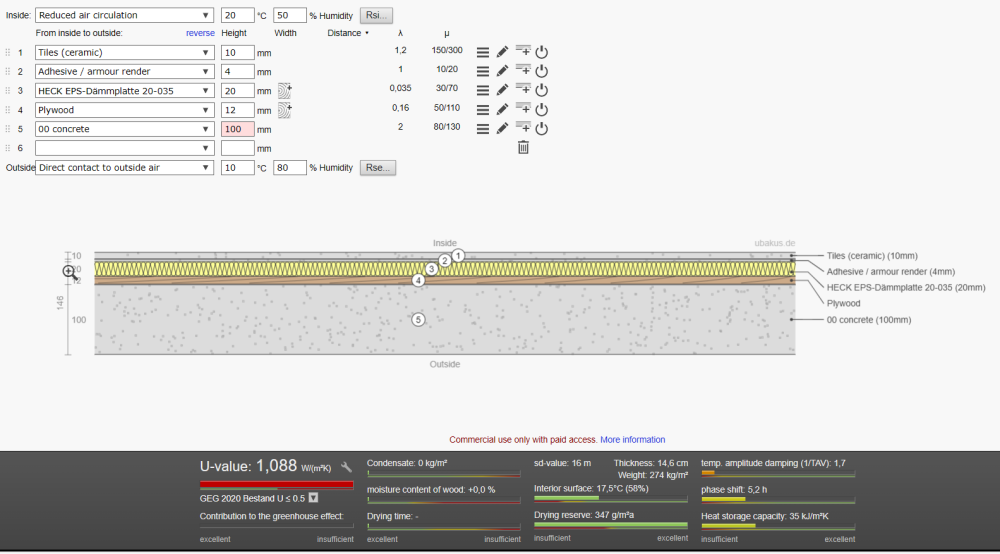

Here's a look at the Wunda system with 12mm ply. 46mm thick, That U value isn't the whole story because where the pipe tracks are there's almost zero insulation under them and they're the greatest point of heat loss. Here's my proposal. Sand cement slurry to fill any large gaps in block and beam. Self levelling compound to level out any big dips. 25mm PIR, all joints tightly fitted, foamed and taped with aluminium tape. Foamed with IL330 or taped to walls for airtightness. Float 2 x 11mm OSB layers , joints crossed, screwed and glued. Then finish with lino or LVT. Total 50mm thick. Much cheaper than the Wunda system and 40% less heat loss. No specialist materials and more solid to boot. Alternatively replace one layer of OSB with T&G engineered flooring glued down. You may need to lay the OSB on a diagonal to avoid any joints lining up. For the heating I would opt for radiators throughout. Easier to balance for this application and with suitable floor coverings you won't suffer from cold feet. Make them as large as you can to future proof for an ASHP.1 point

-

I would not bother with the UFH, not had a good experience with the UFH trays similar to those suggested. Seem to need very flow temps to get any heat output.1 point

-

Sound not too bad. If you were to finish the suspended floor and really work on the airtighess it'd help. Being a similar climate to Ireland I imagine keeping a handle on the dampness is vital. Maybe a PIV or some dMEV fans might make it "feel" warmer.1 point

-

Agreed, as the bulk of the air needs processed is external air then maybe having the unit outside and ducting hot air inside is the answer. Effectively a "monoblock" A2A. Anymore so than another heat pump? A Genvex unit from memory.1 point

-

That was my first thought too! I suspect its not so much the plugs' prongs scraping the metal but rather the wiring terminals inside the sockets that could be the issue?1 point

-

With UFH it is really down to how much insulation you can get under it. I suspect that radiators are going to be your best option. But still add floor insulation if you can. If you can put up with a bit of noise, and the new room/s are not constantly used, then plinth/fan assisted radiators may be an option. They take up less space.1 point

-

My mitsubishi A2A system can be managed remotely. The models I went with have built in WiFi. I find the app clunky - setting timers relies on the app having Internet connection when timers are triggered. Handy for turning on when I'm commuting home or checking / changing temps but not for scheduling in my limited experience. Remote controls for each unit - didn't have any need for hardwired control panels . The unit itself does have thermostat and with high wall mounted, it's always reading a few degrees higher than floor level.1 point

-

the swan neck will come out, it's got a grey rubber seal around it so one way or another will break free1 point

-

Do A2A heat pumps allow external controls like room thermostats? Perhaps a proper Air to Water heat pump might be better? It will do your DHW and heating but you will need radiators or UFH. But at least the HP will have provision for external controls. In this situation I would say the best would be UFH with an individual room thermostat in every room. Then those room thermostats can be replaced with remote programmable ones. I installed a system like that at the local community hall, a lot of the time the hall sits empty so they can turn the heating down, and when there is a booking, they can remotely turn the heating up for that. I forget which remote system it is but I can find out. It was not one of the popular ones like hive or Nest.1 point

-

Well what do you know! Every day a school day. 43C flow is quite high for UFH. Assuming you are running weather compensation turn the slope down by 0.1 per day until it gets too cold then back a bit. If not then switch it on. Well during the daytime a Willis heater will use peak rate electricity with a CoP of 1.0 which is less than ideal. If your tank has an immersion heater then it would be more economical to heat the DHW with it at night-time rate, freeing up some HP capacity if you need it. If not, can you fit one, might be cheaper and less disruptive than a Willis heater. So that is 42W per m^2 which is not very generous according to this cheat sheet and might not be enough in a cold snap, air changes per hour are crucial so stop up the draughts you mention in the OP!1 point

-

CO2 fits all of those criteria. Sadly it needs ludicrously high pressures (like 150bar instead of the usual 15bar maximums), so I’m not convinced it will go mainstream. If you could fit a propane system together without brazing, it would be safe enough for diy I think. We’ve been looking for magic new refrigerants for 100 years, and we’re back to one of the earliest ones - propane - again, so I wouldn’t hold your breath waiting for a significantly better one.1 point

-

Build an appropriately sized rectangle the use maths to mark out your two triangles. The smaller the gap between your hypotenuse lines, the lower the volume of waste. Adjust your rectangle to get the lines closer together. A combination of circular saw, recip and hand saw. An appropriate offcut put into the blocks can stop it collapsing whilst being cut.1 point

-

The only really power cut proof heating systems are ones that use no electricity at all (eg wood stove) and if you have one fitted already it's not a bad idea to keep it as a back up. Ironically my wood stove with back boiler was the backup for my gas boiler when we were without gas for 2 weeks a few winters ago due to a fault in the main! The vast majority of power cuts, for the vast majority of people are fairly brief events lasting less than a few hours. Whilst "what happens during a power cut" is a factor, it's not the huge differential between HP and gas that some make it. In the majority of cases the answer is "the same thing as if you had a gas boiler"1 point

-

The government is so terribly good at solving things with targets. Ask them how their smart-meter rollout targets are doing.. As you say - simply address the price ratio between gas and electricity and the market will solve it itself. Like all these tinkerings, I expect massive unintended consequences.1 point

-

Btw this wiring does limit your choice of motor. Some require permanent power and 3 core of "dry contact" relay switching, so they would need T+E and a 3 (or more) core control cable. I now specify 3+E and cat6 to each motor where the model isn't yet selected. OTT but it's the most flexible option1 point

-

I think it's mostly down to whoever is signing off your install for part P and what they're happy with. I've worked with 3 sparkles on installs now, none of them wanted local isolators for switched mains feeds to blinds/curtains/windows but they do want isolators for any permanently powered fused spur. One was happy for the isolation switches all to be grouped together in one cupboard per floor, another wanted then in the closest "obvious" place. Interestingly they all want local isolator for electric underfloor heating even if it's remotely switched and even though the odds of needing to do running maintenance on a heating element glued under tiles seems way lower than a motor and blind with strings and stuff that may get tangled up day to day. But there you go, I've given up trying to guess and just ask them what they want1 point

-

They wanted to do mine a week earlier than planned because they’d gone to a job that wasn’t ready. Customer had forgotten to tell them! So they turned up at mine unannounced to see if I could take it. We tried really hard to accommodate them as it was all going to be dumped otherwise apparently but we just couldn’t get it ready for them.1 point

-

I can imagine 🤯, same with our tarmac, was pre-warned so lots of little jobs lined up for free 👍1 point

-

The suppliers want orders to the nearest half m3. Being short can be a big problem, so it is always rounded up. That is a small proportion of waste in an industrial floor slab, or a bridge abutment, but significant in a domestic pour. The typical waste is therefore about 1/4 m3 per 'pour'. Dumped somewhere on site x how many projects every day?1 point

-

Volumetric is great for supplying the exact quantity. I didn't know that any would do a pump mix.1 point

-

1 point

-

Yes they dropped off the twoable pump the day before. All very slick. Team of three guys, lorry driver and another guy came to check it and sign off. In and out before my other half managed to drive from the rental to watch the pour. 😂1 point

-

1 point

-

1 point

-

1 point

-

Great description. So they set the arachnids, dipped the levels and ordered the exact amount of screed? Clever. No waste? There is always some, or they're scraping out the mixer for some more.1 point

-

1 point

-

Yes the guys that did mine had those wee spider level things and marked on a sheet the screed depth at each one.1 point

-

1 point

-

Presuming it was a flow screed pour? If so the screed supplier would have records as to how much was poured.1 point

-

who did the install? Our guy was very open about his calculations, pointing out every high or low spot on the PIR. The subfloor was poured as three slabs and the middle one ended up with a bit of a dish, so our hallway has closer to 65mm.1 point

-

The MI may show the power of the crankcase heater, but if you don't know the conditions it is activated, it is of little use knowing. Also, if you have a small usage i.e. 3 kWh of DHW a day, delivered, burning 1 kWh a day to warm the crankcase is going to half your CoP. A proper meter like this is only a few quid and easy to wire in, even as a retrofit.1 point

-

My air pipe comes up through the floor connected to a socket on the stove. All air for the stove goes through this pipe. Not true for all stoves, some take primary air via the outside air connection and secondary air via the room. So check before you buy. Our stove has a primary and secondary air controlled via a rotary dial, this can be turned off fully. You can also get a butterfly valve that goes in to the air supply pipe, but was not really required for our stove - some do need it. I considered heat loss, but concluded if I was stopping continuous airflow though the stove in the grand scheme of things the heat loss was insignificant. The air pipe is required if you want a stove. So stove need air pipe, don't want air pipe - no stove. But to be frank - well insulated house - do you really need a stove? - NO. As mentioned a day or so without heat make a small difference, so put your jumper on. My wife wanted one - different story, different argument.1 point

-

Stuffy room.. You light the stove.. big flames.. warm the room up.. then you turn it down to ticking over. After a while you'll notice that the air in the room does not "smell fresh".. very difficult to desrcibe but you just know that the air in the room has changed since you lit the stove. Your nose is very sensitive so trust it. Another way is to think of this. If you are a parent with a young child and you go into their bedroom.. instinctively you know if the air is bad.. "just not right". You open a window for example. That is the test.. it's in our genes as parents. Yes MHVR is great but I have Clients that send their kids to "outdoor schools" see my point? And no amount of technology is going to over ride a mother's instinct in terms of air quality. That is a diffucult question. For me having grown up in the country and abroad (Africa) I'm not that keen on relying on the gas / electric company / modern interconnected electronics to save the day in the short term when the shops are shut for a few days. At least with a stove you could keep one room warm for your kids, boil a kettle and cook a meal on the top in the short term. I'm not a "survivalist" say like in the US but have lived in the borders of Scotland where the power used to go off for days. I admire what you are trying to achieve and hope this helps you to reach a conclusion that works for you.1 point

-

Ok on paper if you have a floor vent directy under the stove that is not connected to the stove air inlet and you do an air test.. it will contribute to a bad result. Yes.. I acknowledge that folk want to have an air tight house and agonize about having a stove that is "room sealed" like a gas balcanced flue boiler. But if this is your forever home you need to be aware that unless you want to change the door seals on your stove yearly you'll end up with a "stuffy room". Your strive for air tighness could come back and bite you! For those that are concerned about PM 2.5 levels this is the last thing you want and for those that want an easily maintained house it is also the last thing you need. If you don't create a negative pressure near your stove then these PM 2.5s are well into the house! Buy the time they get filtered out by any other system you'll have breathed a lot of them in. You may have some semi automation or internet connected central heating thermostats that need some wireless control. The idea of a stove is often to give you a "Flintstone" backup when all your electronics/ phone apps break down. This is not the time for "posing" it's a time for praticalities and thinking.. what if the gas / electricity goes off and god forbid.. my phone stops working! Keep it simple and stupid. Think about it.. are you really going to do this (change the stove door seals every year) with all the other things in life you need to do. What I have is a duct from under the floor that rises directly under the stove.. there is a ~75mm gap. When the stove is working cold air gets sucked directly into the stove bottom air intake. When not it provides trickle venitlation.. in the summer. If the door leaks a bit during use there is some positive suction that stops the PM 2.5 from getting into the room as they are sucked mostly back into the intake flow by the Venturie effect. I would encourage all to think about this in the round.. how you are going to live and use your home rather than blindly following the air tight current doctrine. In summary it's your house so make it suit your and your way of living.1 point

-

As @PeterW said the floor needs to be spotless first. If you want to go 'belt and braces' then you can add cheap foam underlay, I've seen it done on premium jobs. Something like: https://www.onlinecarpets.co.uk/graphite-carpet-underlay.html?gclid=EAIaIQobChMIgJL1v6Wc1QIVx6ntCh31fw_LEAQYCSABEgLcc_D_BwE Also spend a bit of time ensuring it's fitted well without unprotected areas or large gaps. They become dirt traps. Now for a strange comment: Protection sometimes increases the chance of damage!! You might think thats that's a crazy comment but site protection often causes less reputable tradespeople to stop caring. "cut that on top of there mate it will be fine" or simply throwing things around. Protection is not a cure all for damage. I would hope this isn't an issue for a selfbuild site where you have better control of trades.1 point

-

Two good choices are: Corex I.e. Something like: https://ewistore.co.uk/shop/corex-sheeting/?gclid=EAIaIQobChMIxbOJl6Gc1QIV4bftCh0LSgCYEAQYBCABEgJfCvD_BwE or simple hardboard. Tape the joints with gaffa tape. If it's down for a long time remember that any area that is visibile may get bleached by light quicker than the areas covered. You'll only notice it when you take it up and youll be very upset.1 point