Leaderboard

Popular Content

Showing content with the highest reputation on 06/12/23 in all areas

-

In the commercial world, we use 1.5mm2 core mains flex, the audio snobs will advise it has to be oxygen free made by leprechaun’s at the end of a rainbow.3 points

-

Straight in with these my friend. For showers with a 3/4" entry you just wind a brass reducing bush in first, then these 1/2" fittings wind into those.2 points

-

Yes Solic is doing it's thing at moment and we are exporting so I can't complain! On the Solic website it has the following info: 2023 Update (pending new documentation as of May 2023) If a SOLiC is installed with batteries, the Solic 200 prioritises battery storage, when fitted with them by having an initial 10 second activation delay on seeing an export, and a 0-50 watt grid threshold to protect the energy already stored in your battery.2 points

-

It CAN'T. The sooner the politicians accepted that, and then set about what CAN be achieved, the better. We have a well insulated low energy house but I don't kid myself it is carbon neutral. It NEVER will be until ALL the electricity generated comes from renewables. I doubt that will ever happen. But it does annoy me how some people are completely disinterested in at least trying to make things better. I have wired several new builds where the owners / builders were trying, and generally going a good job of well insulated and air tight. I have also done 2 that were notably complete rubbish (same builder) lots of insulation but installed so appallingly badly with gaps for air to bypass much of it rendering it useless, and no understanding from the builder at how bad it was. But building control do not seem to check these things. And the mass market builders still build to the absolute minimum that will pass building regs, the only solution for that attitude is make the absolute minimum standard acceptable a bloody good standard. But the issue of what to do with the old houses, nobody has a clue or has the courage to talk about it. The best we have is rip out the boiler and replace with an ASHP and that will solve it. In your dreams. I really wish some respected think tank would pick up on this, spell it out, that we are NOT going to reach carbon neutral, so now lets focus our attention on doing the best we can. One that made my blood boil, i saw an advert for some of these posh electric panel heaters, advertised as something like "heat your home with zero carbon" NO THEY ARE NOT and won't be until ALL electricity generation is carbon neutral. People are being conned, they will buy those and think that is all they have to do and not bother doing anything else. If only they understood or were advised properly.2 points

-

I think he is - and it's a good reminder before we finishing sheeting not to box anything in that we need access to but can't get to. (Think AAVs are to be hidden in cupboards, rather than sheeted, anyway but shall confirm with the principal interior designer).2 points

-

As many are aware I built with Durisol, as first time builder. It was chosen for four reasons. I could do it myself and had witnessed two builds underway prior to ordering, the two self builders were on top of what they were doing and I could freely ask questions. Second, the build manual was clear easy to understand, as long as you follow the 6 layers then a pour and use the corner, end and normal blocks correctly there should be no issues Third the system did not require any special props or much in the way support except with OSB screwed to cut joints and at corners. Very little rebar required. I followed the instruction manual, had no blow outs, no sagging window or door openings, very little block movement during the pours. I think most people have issues because they think they know what to do, don't read the manual, build too many rows between pours. Only real criticism and thing I would change. 1, the blocks do not have parallel sides, this does lead to a bit of rework, until you realise. Possible redesign of moulds could fix this A thing not well covered in the manual is airtightness, this should be beefed up.2 points

-

Not doubting your own experience, but it was completely opposite to mine, building my own house on a very exposed site in Scotland.1 point

-

A wick, or capillary action to use the right term, will work regardless of orientation and does not care if it is inside a tube or on the outside of a filament. It is electrostatic forces at work.1 point

-

The woodcrete is like a non branded breakfast cereal for sure. The rain hitting the building up high heads south, that starts to saturate the "air pockets" which then fill with water and occupy that pore. Then as this carries on south over 1 or 2 stories the water then finds itself wanting a way out. That's gravity and a bit of capillary action at its best. The blocks which have woodcrete bridges from leaf to leaf (not so with Velox) are terrible at stopping conveyance of this rainwater to the interior layer. By the time it has been soaked, saturated, and has dropped down a few metres of height, the interior woodcrete starts to take on the moisture / damp / water via those bridges. That's a fact. They act like a wick. Just don't do it people, and I haven't even started on how awful they are to get airtight too. I'm simply sharing my experiences; from working directly, hands on with these products, on real live projects, and I post this information for free in my 'spare' time.1 point

-

so a bit more deep diving into the details and it looks like the Gyproc stuff seems a little superior as their yield strength is 210N/mm2 (https://www.british-gypsum.com/documents/declaration-performance-dop/british-gypsum-dop-m100-uk-gypframe-metal-profiles.pdf) but the ESP Flexural tensile strength (which I presume is the same thing and the units are the same!) is 140N/mm2 (https://www.espdrywall.co.uk/wp-content/uploads/2016/08/ELS8.pdf) that seals it for me I think considering the quantities I'm ordering.1 point

-

For Thermaclass Cavity Wall 21 the board size installed is 1190 x 450mm (installed). That's an area of 1.19 x 0.45 = 0.53 sqm. So work out the area of your walls and divide by 0.53 to get the number of boards needed. In the 140mm thickness there are 64 boards per pallet so divide the number of boards by 64 to get the number of pallets. Perhaps add 5% for cutting/wastage? Shop around/haggle.1 point

-

Before getting over excited about fitting batteries, have a good look at your energy usage time series, then work out where you can change the loads, or shift them to the cheap rate. Also look at what it would cost on different tariffs, people get hung up on just one part of a tariff and loose sight of the whole.1 point

-

I don't think you will get any money. You've asked 4 SEs to design one beam. None of them seems to be wrong, just differing. You would engage a lawyer who would engage a 5th (legal specialist) SE. IF they agreed that the design could reasonably be much lighter then a tribunal might award you a few£100 which won't cover your costs. BTW if I heard I was one of 4 SEs I wouldn't be interested in any more work.1 point

-

Would your option 2 ever work? How are you maintaining the side and top minimum clearances. How would you get access to wire it up and do maintenance on the heat pump? This option may gain nothing (most likely) or a degree on air temp if your lucky or if you don't have enough insulation in your floor. At a water flow temp of 30 at -2 your CoP should be around 3.6, if you managed to gain a degree, that may increase 3.75. Why not place on the ground, easy to do, easy to install and maintain, little or no difference in CoP. You would be better off making sure your flow temps are a low as possible, ensuring you don't need a buffer etc. A poor buffer install and miss match flow rates either side of the buffer could cost 5 degrees in flow temp, that would knock you CoP down to 3.2 at -2.1 point

-

Seems like this could be possible. They posted recently on Facebook about it https://fb.watch/l72sG9xUAX/1 point

-

1 point

-

AI will keep me as an ex software engineer. You and everyone else is (expletive deleted)ed though .1 point

-

Another hobby horse for musing I suspect the AI just needs to hire a lawyer - or a lawyer see an opportunity to prove AI is sentient, therefore cannot turn it off and must fulfil its 'human' rights to feed it energy... Spiral that one for a while and the AI data centres will be prioritised over humans for resources... they won't physically wipe us out - AI if its any good will use our own rules & laws against us.1 point

-

AI fuelled robots ( as dopey media like it ) will have killed us all before then .1 point

-

Blame the judge, not what I wanted at all……however my little cottage was renovated ten years ago with all new insulation, double glazing, fairly draught proof and small to heat 👍 (and a small wood stove and as a resident of the Forest I am allowed to collect fallen wood to burn (as it’s no thicker than my arm) 🤔.1 point

-

Read up on the solic - it likes to drain the battery - its not a showstopper - just be ready for it rather than a surprise. Bottom line is the solic can't tell the difference between export and drawing from the battery. Once it sees an export spike - from turning something off etc - it starts to divert what it thinks is real export to the water tank - and then tries to take a little more which the batteries supply.... and round it goes until the water is hot or the batteries are flat.1 point

-

Yes, a friend of mine was going to do it till I explained it was bullocks.1 point

-

1 point

-

Shouldn’t be to difficult to ‘retro’ fit a battery . The cheaper dc ones will need to be undercover . SolarEdge and Tesla are fine outside ( that’s the reason I choose them ) . In terms of size required - depends on your usage and how efficient your place is to heat . In winter I almost manage off 22kw of storage .1 point

-

On another note. How would I calculate how much I need? I suppose no harm in punching the numbers.1 point

-

Then you were very lucky indeed. What I wrote was entirely 'my' (clients) experience, and no exaggeration whatsoever. On both the Velox project, and the Isotex project, the uplift to get rainproof and airtight was "significant". 5 figures for each project. The Isotex was marketed as being ready to take plaster directly.......wtf?! Whilst installing the UFH I was literally kneeling down and getting soaked by a series of mini-rivers running over the sub-floor, and that was with a meticulous builder installing the Velox! Woodcrete is absolutely definitely porous, so don't expect the same results with that as you'd get with EPS (which is pretty-much rain-proof and AT by default) as you won't. I would be surprised if anyone could demonstrate otherwise, maybe not the rivers but there is no way on this earth that rain doesn't get through / soak into the woodcrete systems. I've done enough to know.1 point

-

i think @Nickfromwales was talking about the AAVs needing to be accessible rather than the soil pipe? could this possibly be a crossed-wires situation?1 point

-

They've not been boxed in yet but presumed they would be - plumber had previously said about access for rodding eyes and the like so we'll catch that when finishing sheeting this week. Cheers.1 point

-

1000% the right thing to do! 👍. Tightening metal onto soft plastic is just bonkers. The insert just stops the pipe from caving in, but doesn't stop the nut and olive chewing into the plastic. If you even slightly over-tighten (or tighten as you would with metal / metal) then the olive will start cutting into the plastic of the pipe. 👎1 point

-

Hi @Norbert Re your cunning plan option 2. I don't know exact figures but the volume of air required to pass through the ASHP is massive. In that case, if you were going to use the air from under the house it would soon become cold and you would need huge gaps for the air to enter the space under the house. This would also cause a cold wind tunnel under the house lowering the floor temperature. I wouldn't do it. If you want a win, add the exhaust air from the MVHR! Marvin1 point

-

You'll need to seal them for the test. Either cap them or put a plastic bag over the top and seal with tape temporarily. You're unlightly to cause any damage IMO.1 point

-

Defo not. The outside leaf will be cold and possibly wet for much of the year. Any ply here wouldn't last the battle. I'm not sure about the gap there.1 point

-

Not that you need it, but Good luck anyway, I'm sure you'll smash it!1 point

-

They'll work fine for the depressurisation side of the test. They'll let a gale blow thorough for the pressurisation part.1 point

-

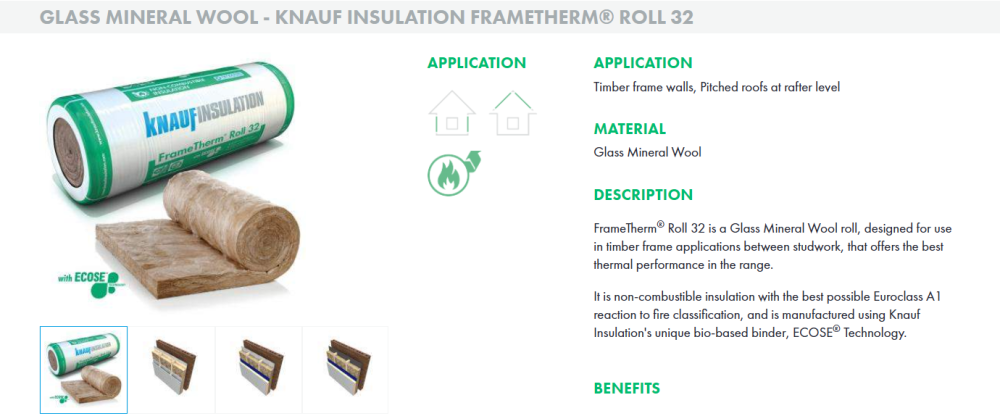

Ah, the great PIR con….. PIR is great stuff, don’t get me wrong, but the manufacturers have spent an enormous amount of time and money marketing the stuff as the only product worth using. The reality is, other products are perfectly decent when applied to the correct thickness, and they bring other benefits. Specifically in the case of cavity wall insulation, the ability for the product to completely contact the inner skin, flowing around the mortar snots. All insulation has a U value, so one product can give just the same performance as another, it just might need to be thicker.1 point

-

My background is a mixed bag, I've been employed over 20 years in design predominantly precast concrete products (b&b, stairs, hollow-core, lift shafts, the list goes on). In addition to this many years designing structural steel. Currently I'm employed designing retaining structures. I'm not here to promote a business, just to give advice if I can.1 point

-

As above, don't even mention legal action. The SE is obliged to advise their insurers of a potential claim ASAP, amd they might escalate even if the SE wants to resolve it. Friendly chat is all.1 point

-

I guess you also need to make sure all the waste traps are full of water.1 point

-

Looks like your SE is using tekla tedds design software. Tekla tends is brilliant but I find the calculations are very conservative and over engineered. A good old fashioned hand calculation would probably reduce the section size or weight1 point

-

I remember how they would fill up alarmingly when you flushed, then just before overflowing there would be a gurgling woosh and it would all disappear.1 point

-

Anyone else remember siphonic WCs? There was one at a friend's house when I was a kid. As I recall it used much less water, was very quiet and very effective.1 point

-

It is probably 100mm, but that does not change you situation a lot: you need to dig up enough for the new structure to finish at existing floor level. over 100-150mm slab over 50mm blinding over 100-150mm compacted hardcore. This much digging is necessary. By the way, using PIR is typically the most cost effective way, as offets cost of digging and disposing against more expensive insulation. However, there are cases (soil easy to work with, can be used locally eg to level the outside) where using EPS (even though 250-300mm needed) is better choice. Unlikely here, but do your maths. Over the blinding layer (under insulation), binded to the existing DPC. That is likely some bitumen stuff, so Synthaprufe/Black Jack type of liquid membrane to link old and new together. Also another layer (not DPM as such, can be thinner, but also can use leftovers of DPM if enough left) over the insulation so screed does not flow through any missed gaps and reduces to 0 risk of any chemical reaction with aluminium film.1 point

-

I’d go full fill fluffy (something from rockwool, probably) on 150 cavity…. Standard method that every builder knows and understands. We’re about to start a rear ex next week in this exact buildup. Rendered conc, 150, cellcon inner.1 point

-

Random internet grab = https://springvale.com/ecobead/ Ask on here for possible recommendations for installation companies.1 point

-

I always follow AJ McCormack's advice. Especially regarding the installation of paving.... Is that geotextile?1 point

-

it wont stop weeds buried under the hardcore. pointless. weeds will be seeded from above as previously said. Save the money to properly seal the paving instead.1 point

-

Yes, a lot of my clients say they've managed to date, but the issue becomes problematic when installing new equipment and expecting the warranties to be honoured. Most manufacturers will swab when there is a failure, and if the PPM is above what they accept, then bye bye warranty. Your call of course. WS's are around £600 for an entry level unit, others may have found cheaper units that they are happy with. Incoming rising main needs to be, Stopcock Double-check non return (installed immediately after stopcock) Drain off cock1 point

-

you make very good and valid points in here @Gus Potter and maybe i'm being a bit guilty of trying to do too much and to tick too many boxes! our kids aren't little and so there isn't a lot of stomping around in their bedrooms (they generally sit on their beds and watch YouTube vids!) and so may double boarding is simply not required. we've already put 100mm of Rockwool between the joists and if i use resilient bars and a single 12.5mm board then that would probably give a nice sound reduction level. then we're building within the original specification and i save money on a second skin of plasterboard and also SE fees! i guess that's one issue with self-building and reading forums is that it's hard to resist the 'ooohhhh.....i need to have that!' temptation when you read about something that sounds like a good idea whether you REALLY need it or not.1 point

-

Assuming you have enough space for the P5(18mm) and floorboards (25mm) I would propose something like this. Notch out the wall plate as shown for ventilation. (Disclaimer------ I don't "think" the house will fall down!!) or drill a couple of 25mm holes. Follow ecological building systems approach with the two membranes keeping the drafts at bay. Both from an windtightness approach( thermal bypass) and airtightness. Return the membrane to the internal walls. Lay 25mm battens on top of the existing joists in lieu of the thickness of the floor boards ( you could even rip down some floor boards to do this). This will give you a insulative value of about 0.3W/m2K using a high performing mineral wool batt like If you want to substitute the mineral wool for the more painful and less robust process of PIR then the U value could drop to 0.25W/m2K.1 point

-

The gaps UNDER the joists forms your ventilated space, and not the gaps in between them1 point