Leaderboard

Popular Content

Showing content with the highest reputation on 04/04/23 in all areas

-

To much emphasis is placed on the acoustic values and it’s generally the glass that is rated and not the unit. That being said, most ignore the most important aspect. That is how sound travels. Sound is like water, it’ll find a way. That’s why a very important factor is how the window is installed and the materials used. If they just used PU foam for example, that will have lots of pockets of air. Having the outside aspects around the window filled with a Compriband seriously reduces the noise levels. Noise doesn’t just travel through the window but around the window. Noise will also travel through the ground and up through the floor and through walls etc. Very good idea to get a good dB level of glass but installation of that unit is paramount to it’s success.2 points

-

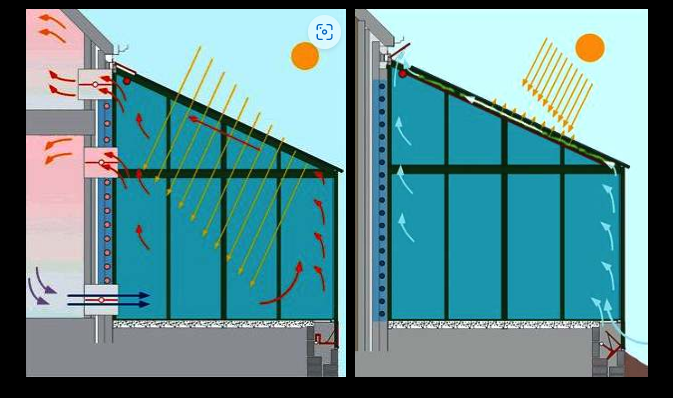

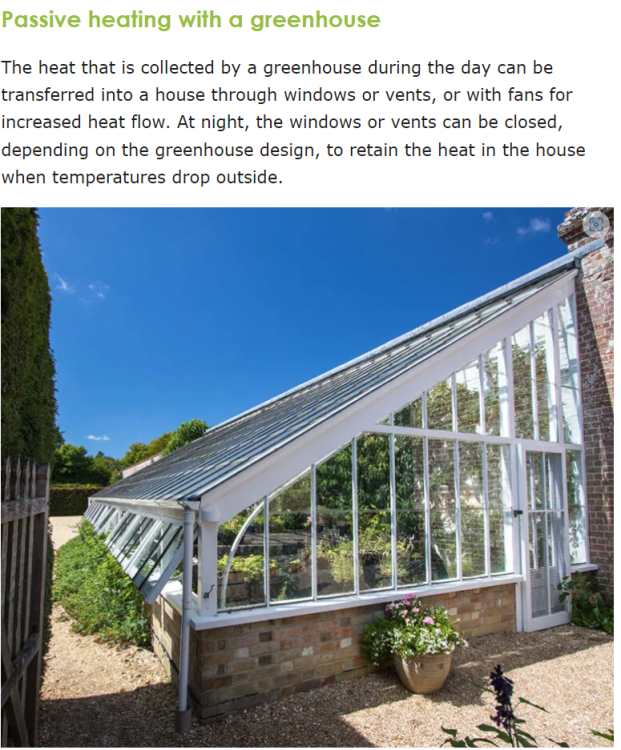

@joe90 SOLAR CONSERVATORY PASSIVE HOUSE GLENGARIFFE IRELAND VIKING (cherrymortgages.com) this one? Yes, the issue becomes cold weather I think. There will be days that you have little sunshine and low temperatures so an over glazed heated envelope will need lots of heat input. A hypothetical house with no window's in the main body, just super insulated shutters opening onto a south facing conservatory could perform very well. Try selling that idea to a human however and they'll tell you where to shove it!1 point

-

That is what I will be doing, there is a local government and social care ombudsman that has the power to make building control compensate people if they make a mistake. But it's quite a grey area. The officer came up with a really weak excuse for why they approved the drawings wrongly. So I've sent out an email to the head of building control and if that fails then on to the ombudsman, I have also asked the architect if I can claim off of his PI insurance for the error. I would absolutely not put in a temporary door just to pass. it's very annoying because it would of been so much easier to deal with at the start of the project I could of added a pocket door but now the layout does not allow it.1 point

-

Although you may discuss it with BC they will still insist that the house complies. Think of it this way - if there was a fire in the kitchen and smoke filled the staircase you have effectively ruled out escaping from bedrooms through the staircase. Yes - there are EEWs but if you have small children there is no way that you are going out the EEW without collecting your children from their bedrooms. Ultimately the Regulations and the Approved Documents/Technical Booklets are there to protect you and your home. To ignore them can be dangerous and foolhardy. I do not agree with those posters who advise you to put a door in temporarily and remove it once the Completion Certificate is issued. It’s dangerous. Having said that you might wish to seek legal advice in relation to the liability for the cost to make the works comply. Good luck.1 point

-

your end goal needs to be an airtight, highly insulated box containing all your rooms ventilated by an mvhr system. Aim to meet new build U values for insulation as the refurb ones are crap.1 point

-

Yes as above BPC do the calcs. We had it commissioned by someone recommended by them to their calcs and they provided a certificate for Building Control.1 point

-

BPC do provide airflow calculations. Building Control will require a commissioning report. Have a look at the thread enclosed.1 point

-

Def no step, as above it makes access to appliances a real pain. If laying a floating floor (laminate, solid or engineered) either lay the entire floor or lay it after the kitchen fit. If only the front support legs land on the floating floor it often causes the underlay to compress and ‘domes’ in the centre. Run a floating floor right up to the support legs (not forgetting expansion gap) and under any appliances1 point

-

I now always continue flooring under units. Getting an appliance in or out is very tricky with a step, and there is increased risk of the worktop being low. Also, a dishwasher' feet might not slide on a plain concrete surface. The material could be changed to save cost. Another option might be to surface only where an appliance will go. What if I replace or reform the kitchen and expose some floor? Only you can answer the chances of that.1 point

-

1 point

-

With MBC, they generally eat the tolerance but not always. Sometimes we will with MBC. Most others it will need to be us that eat the tolerance.1 point

-

Anything with 300mm of a door should be. However, Pas 24 will generally be all ground floor windows and any that are easily accessible from ground.1 point

-

1 point

-

Mirrors my experience. On a cold sunny day once the sun room temperature is above the lounge, the doors get opened and the lounge will generally climb up. Even on a cold day (5 degrees outside last week), the sun room hit 24 and that brought the lounge & kitchen up by 3 degrees. If only I could pipe that heat to the baltic north facing room. To avoid energy waste, we simply don't open up the sun room when it would leach heat from the house. It still benifits the rooms its build off as it's generally at worst 4 degrees warmer than outside temps.1 point

-

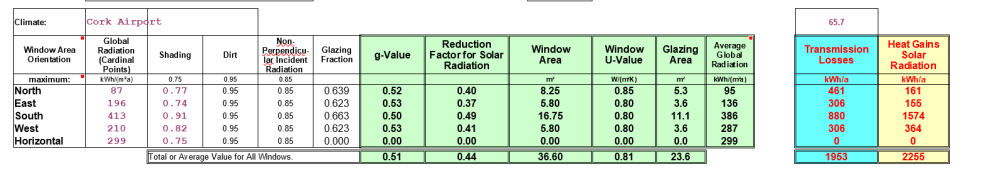

From our own PHPP Losses are indeed offset by gains but we have pretty good windows. However without the South facing glazing it would be a loss. Sadly with this it's lightly that it'll loose the simple beautiful glass boxiness of the design as there'll be too many add ons. You may end up at a place where aesthetically you'd be better off with less glazing. @Radian is your garden room above inside the heated envelope? I think there's a place for a highly glazed room outside the main body of the house to be used as a solar air heater amongst other things like below.1 point

-

@Furnacewent with Senior Architectural Systems Pure. I think acoustic performance is a bit like u value in that you need to consider both the glass and the frame but someone more knowledgeable that me will hopefully confirm if I'm talking nonsense or not. Overall we were given a figure of 39 dB and u Value . 95. The other thing that comes to mind purely based on my experience is I specified no trickle vents. Didn't want any more ventilation than we already have. Was reminded it would be a sell on issue without alternative ventilation installed but in my limited experience, trickle vents were assumed unless you specified otherwise.1 point

-

"Does it mean I should put some extra insulation?" No. Not if the insulation is, as I assume, on the ceiling of the room(s) below, and the vents are on the slope at the top of a cold void. There should be a howling gale up there anyway for water vapour control. As long as it does not infiltrate to the 'warm side' of the insulation, no problem. If you want to put more insulation in top up to 400 - 500mm, but make sure not to block eaves ventilation. You could staple some membrane at the 'point of the triangle' in the eaves to deflect ventilation air above the insulation.1 point

-

Triple. I assumed the same but looking retrospectively there are DGs that give the similar values to my TG and alternative TG that have better acoustic performance. They are a vast improvement on our previous but I think I expected better and should put more weight on that requirement as we're near a busy road and have loads of seriously noisy birds nesting in the hedge!1 point

-

1 point

-

I'd add any acoustic requirements to the list and get the acoustic performance included in any quotes. I didn't pay enough attention to that and it's the one thing that irks me post install.1 point

-

Safety glazing should be inner and outer, no current regs re triple glazing. Yes, regarding middle pane and thermal stress.1 point

-

An excel sheet with the sizes quantities and types is usually good enough, window schedules are usually best and take away any ambiguity. If you can also specify what windows are below 800mm from FFL that will help, with any specific security requirements (i.e. SBD/Pas24, Emergency escape windows). The one thing to look out for with your quote is glazing (especially triple). Look out for the middle pane of glass being float glass and those that toughen the middle pane (more so on South East to South West windows). We did this with one of our suppliers for a while to match everyone else's price as it's very competitive and to be honest, you all like to do cost comparisons on m2 prices and it can be the difference between winning or losing a job. However, it's important to note that this is the number one way to save costs but it can cost you in the long term if it breaks (whether that be from slamming shut, thermal stress, or thermal fractures) the bill for this is left with you. We always did this with our Austrian supplier but not with our other suppliers - a lesson has been learnt.1 point

-

I have done a few now, plumbing and wiring for my own, wiring only for a few others in conjunction with a plumber. I really don't know what installers are frightened of? From a blumbers point of view it is usually just like a system boiler and HW tank. It can be a little more complicated for the electrician as every one is different, which just means you have to read the manual and do what it says. 2 days each trade should do it normally. I suspect the issue is your standard plumber and electrician won't know how to size one. Easy on a new build house where you have had a full SAP design done giving you the heating requirement. I do agree it is time the over priced MCS cartel is shown for what it is and their near monopoly broken. The worst part is the government BUS grant is not benefitting the customer, but lining the pockets of the over priced installers. If you have a plumber and electrician willing to install it then just do it.1 point

-

This was a while back (2016) but we used MBC for the passive frame and Gaulhofer (via EcoWin @craig) for the passive windows. Very impressed with both firms, can't recall who ate the tolerance in the end, think it was Gaulhofer The golden rule here is to double, and then triple check all window schedules before committing. Errors can creep in, even with the best supplier as the s/w they have to use to order from the manufacturer can be painful and can reset previously selected options etc. Even then, errors may be made at the factory but as long as your schedule is clean then you'll be able to get them to resolve it at their expense. I fkd up our door order from RK Doors - fit fine but the ratio of door to glass was off and I didn't spot the mistake so had to live with it.1 point

-

We had the debate between frame and window supplier of 'who owns the tolerances?' i.e if the aperture and window are exactly the same size then they won't be installable - one party or the other needs to allow 5mm all round and compriband & tape will take care of making everything airtight post install. Also, if it's a supply and install package (which I'd insist on), make sure that any plant required by the window supplier is either specced or is part of their quote. We had some confusion over who was paying for the telehandler at the 11th hour.1 point

-

You need to get them to stick to YOUR numbering Window suppers have a habit of adding there own numbering or get to say window 5 and put x 2 Looks crystal clear to me1 point

-

What you have looks good, you need to give them enough so that they can get it right first time rather than change things when they find out that your openings are not what they assumed in terms of build up. So other things to think about including are: Making sure the quote contains the Uw values for every window - you need to meet PH standard there. Specifying if the installer is responsible for attaching air tight membrane tape and / or connecting to the airtight layer adjacent to the window. Which windows are designated escape windows, if any. Which door(s) is(are) your accessible door(s) for BC purposes. If you have section drawings of your openings that will help them, and stop them coming back and upping the quote when they find a difficult opening. Including / not including such things as compriband on the external connection to the opening. Which foam to use when sealing around the windows - You can say a brand and /or say it should have similar properties to a brand. The finished colour(s) inside and out (Some colours are standard others cost), also if coastal location you will need a marine grade finish. Do you want secured by design as standard on all doors / windows on GF - this affects the glass build up and the locking. If you are expecting the windows to be installed with access to both sides. IE will they work from the inside or both sides. (On ours the windows are bigger in their boxes than the surrounding tile hanging so they need to go in from the inside although you can work on the outside.) Section drawings will show this to them. What is access like to the the site - can they get a lorry close and / or a window robot around all sides. Is there / will there be scaffolding - window robot then no good. Hope that helps.1 point

-

They may not be that bad and some adjustment might stop the drafts for now. I would be wary of buying any windows unless you really have the final design sorted visualised. They're two expensive to buy twice.1 point

-

1 point

-

Octopus have a tiny share of the ASHP market. While this will increase it will remain a tiny share. Most ASHP installs are by smaller independent companies and that isn’t going to change. They don’t insist on connecting the ASHP directly to the meter cupboard. It just sounds like a conspiracy theory to me. I really can’t see Octopus switching off power to your ASHP willy nilly when it suits them. Octopus seem to be one of the better companies.1 point

-

Centre it. Our architect taught us to prioritise the feel and look room by room, rather than the building as a whole from the outside.yoy spend a lot, lot more time living in a space, than looking at it from the outside. We positioned skylights to be central within rooms, rather than uniform across the roof from the outside. Best approach as hardly noticeable from the outside.1 point

-

If it helps I've compiled a list of ways you can connect blinds/curtains to Loxone.... Option 1: Hardwired Power with Loxone Wireless Control Example motors: Geiger Solidline Air - this is the motor Loxone promote Loxone Parts Needed: Loxone Air Receiver Pros: Loxone wireless protocol built into motor makes integration easy and no additional hardware needed at the window location (such as a wireless transmitter) Hardwired power means no batteries need re-charging No need for wiring back to a relay or main panel or plant room Only need 240v power at each window which could be taken off a socket or lighting circuit Cons: This is a 45mm motor which means it will only go in a 65mm+ tube meaning the minimum rollup size is going to be around 70mm which is quite large High torque motors (great for RLs but overkill for standard blinds) Wireless control limits distance from transmitter to receiver Wireless control is not 100% reliable although it is good and always getting better As more devices become wireless there is more radio traffic and more risk of interference 'Dumb' motors with no 2-way communication or feedback to the system Option 2: Hardwired Control Switched through Power Example motors: Somfy WT, Nice Action, Vestamatic MM or ME Loxone Parts Needed: Loxone 240v relay appropriate to the number of blinds you have. Pros: Total reliability of control Hardwired power means no batteries need re-charging Easy to trouble shoot Wide range of motors Cons: Home-run wiring needed from the relay to every window Intermediate stops need to be done via a timer rather than using logic in the motors 'Dumb' motors with no 2-way communication or feedback to the system Option 3: Hardwired Power with Wireless Control Example motors: Somfy WT, Nice Action, Vestamatic MM or ME Loxone Parts Needed: Shading Actuator Air Pros: Hardwired power means no batteries need re-charging No need for wiring back to a relay or main panel or plant room Only need 240v power at each window which could be taken off a socket or lighting circuit Wide range of motors Cons: Wireless control limits distance from transmitter to receiver Wireless control is not 100% reliable although it is good and always getting better As more devices become wireless there is more radio traffic and more risk of interference Intermediate stops need to be done via a timer rather than using logic in the motors 'Dumb' motors with no 2-way communication or feedback to the system (Loxone say it is a pain to setup) Option 4: Hardwired Power with Dry Contact Control, 0v Control, DCT Example Motors: Nice Edge AC or DC, Gaposa Sileo XS50 AC or DC, Somfy Sonesse 30 DCT, Glydea DCT, Movelite DCT Loxone Parts Needed: Loxone 0v Relay with number of channels appropriate to the number of blinds Pros: Total reliability of control Hardwired power means no batteries need re-charging Easy to trouble shoot Cons: Good range of motors but mostly in a higher price bracket than the switching through power option Home-run wiring needed from the relay to every window Intermediate stops need to be done via a timer rather than using logic in the motors 'Dumb' motors with no 2-way communication or feedback to the system Option 5: Hardwired Power with Digital Control Example Motors: Sonesse 30 RS485, Sonesse 50 RS485, Vestamatic SMI, Nice Smart, Glydea RS485 Loxone Parts Needed: Loxone RS485 extension Pros: Total reliability of control Hardwired power means no batteries need re-charging, power can be local to the blind Easy to trouble shoot Easy to set multiple intermediate limits and get hembar alignment at the stop positions Data can be daisy chained making communications wiring easier 'Smart' motors with 2-way communication, system can see blind status (open, closed, etc.) Cons: Slightly limited motor range although some good options available Potentially more complex commissioning needed, especially when intermediate stops required Power and communication wiring should usually be separate, therefore two cables to run (although power could come off a socket or lighting circuit) Option 6: Wireless power with Wireless Digital Control Example Motors: Sonesse 30 WF RTS Loxone parts needed: Loxone RS485 extension Other parts needed: Somfy RS485 RTS transmitter; Pros: Easy installation as no cabling required Long battery life (8-12 months depending on frequency of use) Cons: Maintenance required, battery charging once a year Wireless control limits distance from transmitter to receiver Wireless control is not 100% reliable although it is good and always getting better Slightly complex commissioning for AV integrator and blind installer Option 7: Wireless power with Wireless Dry Contact Control Example Motors: Sonesse 30 WF RTS, Nice Edge Battery motor Loxone parts needed: Loxone Dry Contact Relay Other parts needed: Somfy DCT RTS transmitter or Nice 0v radio transmitter Pros: Easy installation as no cabling required Long battery life (8-12 months depending on frequency of use) Cons: Maintenance required, battery charging once a year Wireless control limits distance from transmitter to receiver Wireless control is not 100% reliable although it is good and always getting better1 point

-

I found Zurich (via selfbuild.uk.com) the chepest by good margin just a couple of months ago. (vs. selfbuildzone and protek)1 point

-

I realise this is an old thread, but for anyone else wondering about G99 and G100 forms... G99 seems to be needed for proposed grid connected power generation systems up to 50kW and G100 for over 50kW. So almost all of us will be looking at G99 forms.0 points