Leaderboard

Popular Content

Showing content with the highest reputation on 03/19/23 in all areas

-

3 points

-

I’m really surprised by the title to this thread. I think MVHR is amazing. Probably one of the best “green” aspects of my renovation. I went out for dinner with some friends the other day who were complaining about how much it costs to heat their house, and how they have lots of draughts but still have condensation problems. I couldn’t help feeling smug that my bills haven’t been too bad this winter and the house never feels cold, smelly, damp or draughty (especially now we got the window fixed).3 points

-

Floor joists must sit on structural walls, so yes, some internal walls will be structural, with footings. There is nothing magic about 6m, but it is the standard maximum for timbers at a merchant. Longer is special. But at 6m clear span joists get very deep, so you are getting into intermediate steel beam territory, or fabricated (and deep) joists.2 points

-

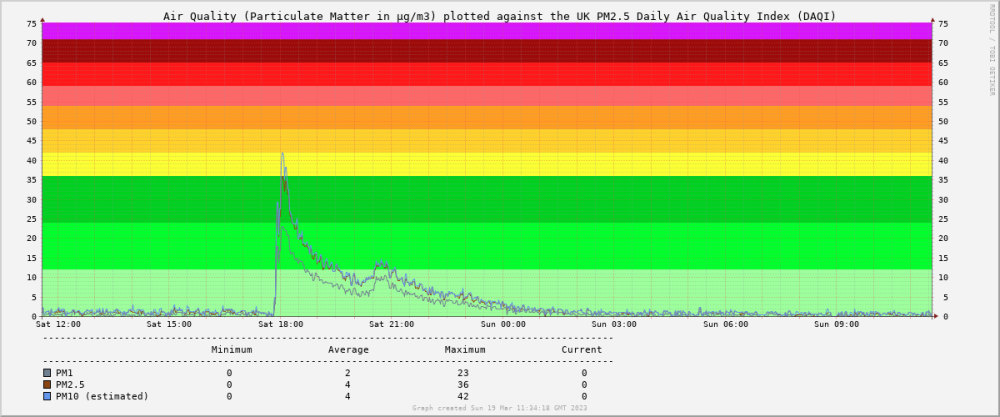

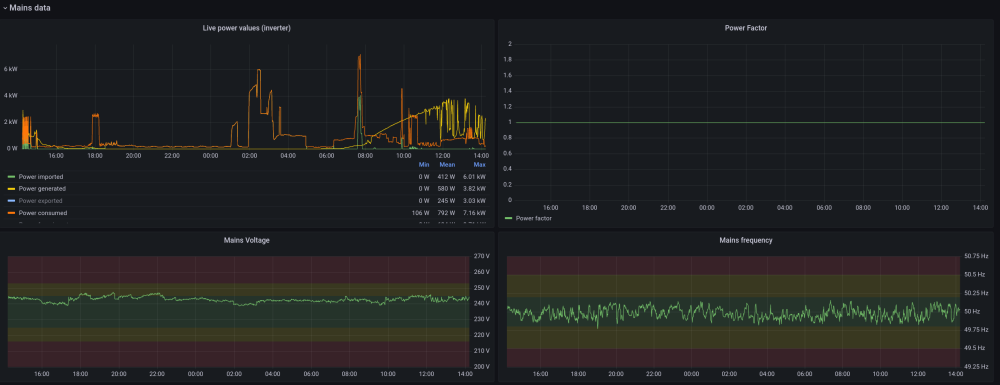

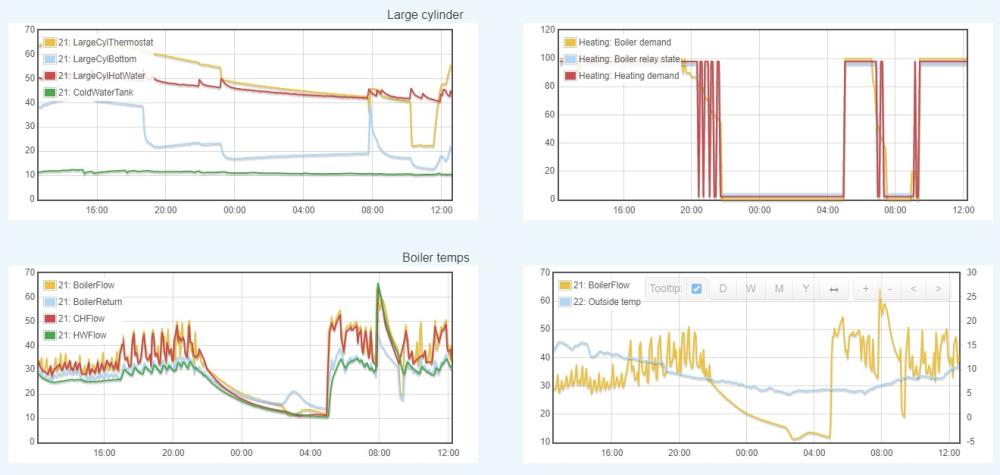

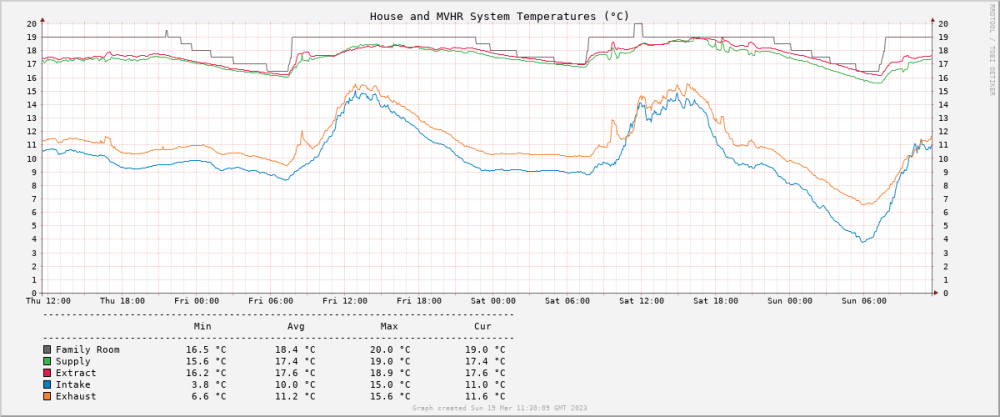

As evidenced above there's almost an infinite ways to achieve this sort of thing with pros and cons for each. I think familiarity plays a significant part in people's recommendations so there's a certain amount of bias in what people might say is the 'best' way to do it. Notwithstanding this I'll throw in my suggestion: RRDtool. It has been around a long time (since late 90s) and was based originally on MRTG - Multi Router Traffic Grapher - designed to monitor routers which is what I first used it for (measuring interface throughput and the like) however it can be used for pretty much any time-based logging (and graphing) and I've found it great for visually monitoring temperature, humidity, air quality, boiler state/flow/return etc around the house. The name RRD refers to Round Robin Database and it is this that sits at the heart of the approach. It is a database in the form of a text file that simply records specified values at specified intervals. This is an massive oversimplication though as it is enormously powerful. As such there's a bit of a learning curve but when you make a start you soon pick it up. To illustrate with an example of monitoring my MVHR unit I created an RRD database with the following command: rrdtool create temperaturedatabase.rrd \ --start N --step 5m --no-overwrite \ DS:supplytemp:GAUGE:10m:-20:50 \ DS:extracttemp:GAUGE:10m:-20:50 \ DS:intaketemp:GAUGE:10m:-20:50 \ DS:exhausttemp:GAUGE:10m:-20:50 \ DS:lofttemp:GAUGE:10m:-20:50 \ DS:efficiency:GAUGE:10m:0:200 \ DS:altefficiency:GAUGE:10m:0:200 \ DS:humidity:GAUGE:10m:0:100 \ DS:power:GAUGE:10m:0:1000 \ DS:supplyintakedelta:GAUGE:10m:-10:30 \ DS:familyroomtemp:GAUGE:10m:-20:50 \ RRA:AVERAGE:0.5:5m:3M \ RRA:AVERAGE:0.5:30m:6M \ RRA:AVERAGE:0.5:1h:5y \ RRA:MIN:0.5:1h:5y \ RRA:MAX:0.5:1h:5y Quickly running through this, it creates a database in the form of a structured text file that is ready to record and manage the following at 5 minute intervals: Supply, extract, intake, exhaust and loft temperatures (obtained from locally-connected DS18B20 1-wire temperature sensors) System efficiency (calculated two ways from the above readings) Humidity (obtained from a locally-connected AMS2302 humidity sensor) Power (obtained via an HTTP API over the network from a smart relay) Supply-intake delta (again just the result of a calculation of other values) Family room temperature (obtained via an HTTP API over the Internet to Honeywell's cloud service) The database automatically retains the readings at 5 minute intervals for 3 months, averages of the readings at 30m intervals for 6 months, averages at 1hr intervals for 5 years then finally min/max readings at hourly intervals for 5 years. The round robin aspect refers to the fact that new values eventually replace old ones thus the database will always stay the exact same size as it was built - 15MB in this instance. So that's the database built, but empty, and so now needs filling with data. I have various scripts capturing readings and they are fed into the database with the following command every 5 minutes: rrdtool update temperaturedatabase.rrd --template \ supplytemp:extracttemp:intaketemp:exhausttemp:lofttemp:efficiency:altefficiency:humidity:power:supplyintakedelta:familyroomtemp \ N:$supplytempcelcius:$extracttempcelcius:$intaketempcelcius:$exhausttempcelcius:$lofttempcelcius:$efficiency:$altefficiency:$humidity:$power:$supplyintakedelta:$familyroomtemp As the database fills up with data you can then interrogate it, and in particular build graphs from it. For example, a 'system temperatures' graph covering the last 3 days can be created with: rrdtool graph $graphlocation/systemtempsgraph.png \ --start -3d --end now \ --full-size-mode --width 1200 --height 500 \ --title "House and MVHR System Temperatures (°C)" \ --watermark "Graph created `date`" \ --lower-limit 0 \ --y-grid 1:1 \ --right-axis 1:0 \ --right-axis-format "%2.0lf" \ --slope-mode \ COMMENT:" ---------------------------------------------------------------------------------\n" \ COMMENT:" Min Avg Max Cur\n" \ COMMENT:" ---------------------------------------------------------------------------------\n" \ DEF:familyroomtemp=$rrdfile:familyroomtemp:AVERAGE \ COMMENT:" " \ LINE1:familyroomtemp#666666:"Family Room" \ GPRINT:familyroomtemp:MIN:" %4.1lf °C" \ GPRINT:familyroomtemp:AVERAGE:" %4.1lf °C" \ GPRINT:familyroomtemp:MAX:" %4.1lf °C" \ GPRINT:familyroomtemp:LAST:" %4.1lf °C\n" \ DEF:supply=$rrdfile:supplytemp:AVERAGE \ COMMENT:" " \ LINE1:supply#3cb44b:"Supply" \ GPRINT:supply:MIN:" %4.1lf °C" \ GPRINT:supply:AVERAGE:" %4.1lf °C" \ GPRINT:supply:MAX:" %4.1lf °C" \ GPRINT:supply:LAST:" %4.1lf °C\n" \ DEF:extract=$rrdfile:extracttemp:AVERAGE \ COMMENT:" " \ LINE1:extract#e6194b:"Extract" \ GPRINT:extract:MIN:" %4.1lf °C" \ GPRINT:extract:AVERAGE:" %4.1lf °C" \ GPRINT:extract:MAX:" %4.1lf °C" \ GPRINT:extract:LAST:" %4.1lf °C\n" \ DEF:intake=$rrdfile:intaketemp:AVERAGE \ COMMENT:" " \ LINE1:intake#0082c8:"Intake" \ GPRINT:intake:MIN:" %4.1lf °C" \ GPRINT:intake:AVERAGE:" %4.1lf °C" \ GPRINT:intake:MAX:" %4.1lf °C" \ GPRINT:intake:LAST:" %4.1lf °C\n" \ DEF:exhaust=$rrdfile:exhausttemp:AVERAGE \ COMMENT:" " \ LINE1:exhaust#f58231:"Exhaust" \ GPRINT:exhaust:MIN:" %4.1lf °C" \ GPRINT:exhaust:AVERAGE:" %4.1lf °C" \ GPRINT:exhaust:MAX:" %4.1lf °C" \ GPRINT:exhaust:LAST:" %4.1lf °C\n" And this gives a result like this: With a small tweak to the --start and --end options you can create a graph showing a different time interval from, say, a single week from last summer: The graph appearance (colours, legends, scale, background, titles etc) are fairly customisable too: I have this sitting on a Pi Zero and it (re)builds a bunch of graphs every 5 minutes which I can view via a web browser.2 points

-

At the volumes of data implied by a single house, any given approach is likely to work; including dumping it to firebase and doing your own querying from there. What matters most is how comfortable with managing it you are, what the hardware you can get supports, and what software you're most familiar with. At larger scales - or if you want an excuse to play 😉 - you'd want the data to end up in a "proper" time series database. The new shiny for that is victoriametrics; one could push via MQTT, using something like mqtt2prometheus, or use something like https://github.com/hawkw/tinymetrics to go direct from ESP32->vicky. Then you can use grafana to create shiny dashboards from the time series data. Another option would be to push the data from your ESP32 via MQTT, and have something like home assistant take care of storing it and displaying it attractively for you.2 points

-

Just a quick post to say hello as we're starting out on our self build (hopefully) this year. I say starting out, because the last year and a bit has been doing the prep work. We've been gifted some land on the family croft and now have full planning permission in place after what seemed like a never-ending process and some very strange requests from the planning body. We went with a design from Heb Homes as its a modern take on the sort of crofting properties which were common back in the day. We've made a couple of modifications so that's all finalised. Next step is funding, so found this form when searching for info on structural warranties - next steps are to work on the final build costs with our quantity surveyor and then apply for funding I guess. We have a house we could sell to cover the costs but its going to be so much easier if we can stay where we are until its finished, then sell up. Biggest surprise so far (as I expected planning to be long and torturous) has been the difference in cost between estimates for full turnkey services and then the actual, proper build costs from them. We have access to some machinery so hope to be able to do some bits ourselves to save money and I'm looking forward to that to be honest. I'll have a look on the forum and start a thread with the build "diary" once we get going as I"m guessing that might be useful for others. Mike.1 point

-

Fantastic.. it's great fun, sometimes frustrating but sounds like you are putting a lot of thought into it and reading up, reading around and expanding your knowledge. You'll reap the rewards of your efforts. The best thing you can do is to post what you have in mind in terms of conceptual design. Don't be embarressed if you think they are rough looking (you want to see some of mine!) and you're not under examination. If you do this you'll get loads of help, ideas and suggestions.. then you can pick out the best bits, discard the ones that don't suit. For all... here are two key points: Many two storey modern houses have big open plan spaces on the ground floor and big glazed openings. While this is ok and can be designed for SE wise if you don't want to break the bank then there are a couple of things (not least but start here) that you want to aim do. Try and avoid a layout that results in the roof loading landing over / near the middle of the big glazed openings unless it is spread out. With big open plan spaces you often have a floor (maybe another?) above that may need to have long spanning joists thus you may need to split up the joist span with a transfer beam.. try and avoid transfer beam end loads landing over glazed openings. You can do it.. it just cost more as you need to control deflection. Also big openings reduce the amount of solid walls you have to stop the building moving sideways as per next point. This other key point is what we call lateral (global / overall) building stability.. we need to design the house so it does not move sideways in the wind. This is different from "buttressing" covered in the regs for small buildings. Yes.. if you add up all the small buildings guidance bit you could well end up with every wall being structural.. and then find that non of it works anyway in terms of point loading from transfer beams and global lateral stability. The above said you are on your way (well done you taking the time to study) by recognising that the individual wall panels need to be braced to stop them from buckling sideways, out of the vertical plane. The buckling effect is commonly caused by two things.. the fact that the vertical load from above does not sit directly over the centre of the wall and by addition of wind suction / pressure loads. And you have movement joints.. it's quite complex to arrive at a reasonably economic solution and all this changes depending on the type of construction.. masonry, timber frame, SIPS, ICF. Roughly concrete blocks shrink after laying and clay bricks swell over a long period of time. But both move about depending on the temperature. Generally I get nervous when a block wall gets over 5.0m long.. and if I was designing using a traditional English clay brick I would not stretch it to 9.0 m without a movement joint on a self build unless I new exactly what brick you were using and had control over the mortar. Basically it's self build and the brickie may be hand mixing so there lies the risk. Good point.. at the right time you can detail this.. you let the lintel slip at one end and put a small movement joint above. Now that has made me think.. You are right.. but both the English and Scottish regs are kind of giving rules of thumb, small building guidance... maybe also called deemed to comply.. if you do this and provided there is nothing "odd round about" it will be ok.. maybe.. In terms of the regs in this context a lot of them were written a long time ago.. call it tacit knowledge but also a lot of thought has been put into it.. by some clever folk.. and each reg has to be read in conjunction with all the others. They also get updated so let's take them as current. My thoughts on the 6.0m thing is that beyond that you may get a lot of defection in say a joist / steel beam. That causes the end to rotate more.. the guidance assumes a simple support at the joist / beam ends. The rotation introduces (springs to mind) two deterimental effects. The first is that it shifts the centroid of the bearing closer in span.. thus you get an eccentricity of loading on the wall.. introduces a bending moment which masonry is not ameniable to... it can significantly reduce the load bearing capacity of the wall. The other one is that if you are using timber joists (if you could get them to span that far as you say) then you'll get concentrated load and crushing of the timber. Or if using steel you need to check for crushing at the inside face of the block.. well you don't as you design the steel beam to deflect no less than say span / 360 (12mm is a also good number... but not over glazing) so you reduce the beam end rotation and the problem goes away. Yes keep posting and loads of folk will chip in.. then you will be in the best place to make informed decisions as to how to spend your money.1 point

-

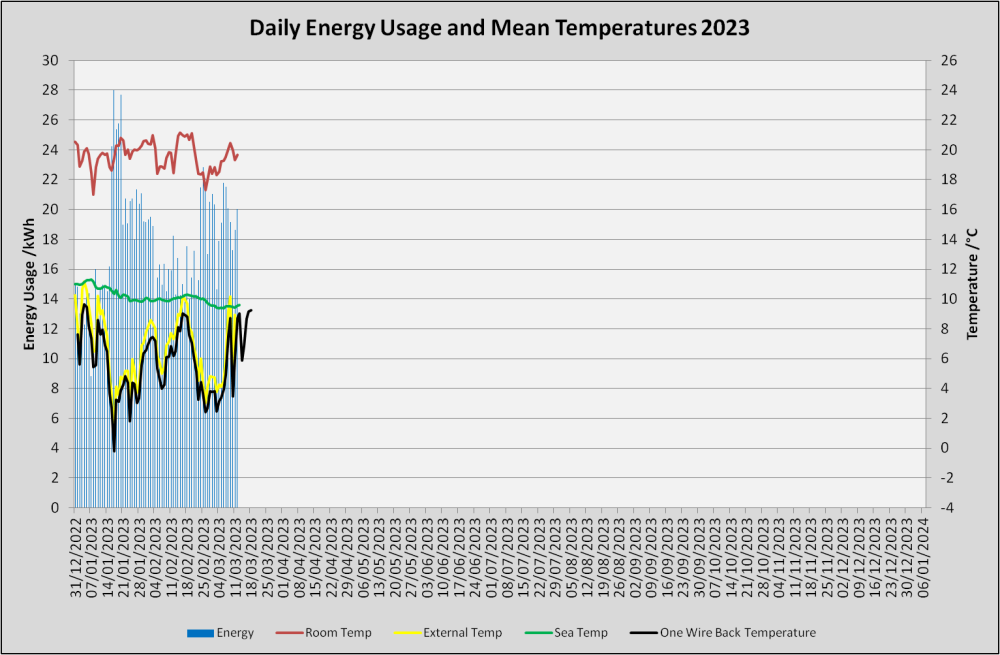

Forecasting and control systems are indeed the reasons to be gathering house data. I started logging internal climate and smart meter data a long time ago. When I came to make an investment decision on PV and A2A ASHP, the data was already available to calculate the real life ROI bespoke to my house and installed system. It also provides the required data for evaluating the performance of a time of use tariff. Now I've bundled that historic climate data into a heating demand forecast model which coupled with live smart meter and climate data drives the ASHP control system. That will never be a fad, it will continue, year on year, to increase the yield of the investment by 75%. Priorities for me are ease of use, minimal boilerplate and active maintenance. I haven't seen better than a Raspberry Pi running InfluxDB with Grafana. InfluxDB's Python bindings mean you can easily connect pretty much any data sources up to it with a few lines of Python then configure what you want to see with a few clicks in Grafana. There are caveats to any of the proposed solutions including mine, but Python is there to pick up the slack if you need something not supported, e.g. average time of day binned data. Finally, storage for this sort of data is cheap. Log it all, often.1 point

-

From Natural England: Thank you for completing Natural England's complaint form received by the Complaint Resolution Team on 17 March 2023 regarding you [sic] Great Crested Newt and District Level Licencing. We take all customer complaints seriously and are committed to fully investigating any issues you have raised. We will aim to provide you with a full Tier 1 response by 11th April. If our i nvestigation [sic] is taking longer than expected, we will notify you and provide you with an update. Details of our complaint's [sic] procedure can be found at: https://www.gov.uk/government/organisations/natural-england/about/complaints-procedure. I'm going to lodge my planning application, and if the DLL licence needs to be implemented I'll continue arguing the case for the methodology to be changed. I'll update the thread when appropriate.1 point

-

Dig a test hole against the existing founds down to desired depth, if the existing go full depth then you will (should) be able to leave the existing in place and put starter bars in to tie new and existing together. Good chance the existing founds and quite shallow so measure the depth and give this and a pic or two onto the SE for suggestions, hopefully you don’t need to go under as this is a pain to do.1 point

-

Agreed. This is the second house I have built fitted with MVHR (Zehnder Q350), and yes we struggled to meet the 8 ACH required by our BCO on our airtghtness tests (APT), vented cavities being the main culprit. However, after 6 months I have the balanced MVHR turned down to 1/3, all rooms in the house are dry, warm where required and fresh. We dry clothes regularly and fast inside, bathroom steam and smells clear within minutes, and my wife is looking forward to improved hay fever symptoms come the season. I have a recirculating extractor in the kitchen which stops cooking smells from escaping to the rest of the house and doesnt impact the MVHR airflow. The next test will be a warm summer, do I switch off the MVHR when windows are open?1 point

-

After spending half the weekend painting our balcony steels with two coats of bitimous paint, I'd stick my hand in my pocket every time and get them galvanised. The stuff is horrible. I've even left stains on the bath FFS.1 point

-

I think it is now permitted development to have a caravan throughout the works. Ours came from GNR Sutherland too. If you have good access (we didn't), the ex holiday park 'caravans' can be good value, esp if you don't mind the first job being to do it up, as they have been very well used. But watch the £1,000 transport each way. And perhaps more difficult to resell.1 point

-

It is pretty impossible to provide a realistic cost. Our joiner got a qs to cost his work, and I thought it was high. I analysed it and found 10% added to all quantities. Then extras which the joiner agreed he didn't need, and some doubling up. So the agreed price was 30% less and I think the joiner did OK. But that 30% could have been needed in different circumstances. Also as I have explained elsewhere, there are multiple oncosts when using a main contractor and project managers. It depends an awful lot on your own ability to manage and question, as well as DIY.1 point

-

1 point

-

Breakout behind? Not in front ( which is what I am saying to avoid. Surface is cosmetic, but the plasterboard behind is the functional bit. I think that’s the bit the Gripit people offer / say to use? That’s due to the size / splay of the Gripit wings, me thinks.1 point

-

I just took these. 3pm and cloudy. The widows you see face south east, the sun is currently southwest. All three side of the kitchen have windows except where the kitchen is In order these are 1. No lights 2. Lights between the island and worktop and in the wings to the kitchen. 10x 5w GU10 3. All ceiling lights, adding in lights in the sitting area. 16x 5W GU10 4. Ceiling lights plus under cabinet and above island lights. We use number 2 nearly all the time. If it is sunny outside, you can sit at the table without the lights on, but it is never quite light enough on the kitchen area to work. If it is very sunny and in the middle of the day, I notice that there is no difference at the table between lights on and lights off, but by that point someone has nearly always turned them on. We basically never use the under cabinet lights or above island lights, we do almost all prep work on the island. I split the lights into two circuits, kitchen/entrance/table area and sitting area. I never turn on the sitting area lights, my family always turn on all of the lights. By my calculation, the kitchen lights use more electricity than all the other lights in the house put together. This reflects spending a lot of time in the kitchen plus GU10s being a less efficient way to light an area so the kitchen have more bulbs to get a similar spread of light than other rooms. I added a picture of the whole room with no lights on. I think it quite clearly shows that light doesn't penetrate much more than 2-3m into the room from the windows. If I was redoing things I would also have put a couple of GU10s directly above the island, although it is well enough lit by the ones around the island. I would say it is much brighter above the island with just one set of lights on which I don't think the picture captures well.1 point

-

If a door has a U-Value of 1W/m2.K, the mean temperature difference over the heating season, of 5 months is 14 K, then: 1 [W.m-2.K-1] x 14 [ΔT] x 5 [months] x 31 [days in month] x 24 [hours in day] = 52,080 Wh.m-2 or 52 kWh.m-2. That is about the same as 5 litres of diesel, which if you by it at the highly taxed gas station will cost about £8. Double it for a 2 m2 door. The U-Value of a door is not the problem.1 point

-

Hello. Yes we are building a HH in Perthshire near Blairgowrie. Kit arrives in 4 weeks. I would be happy to share our experience with you as it’s not been the best experience with them. In fact it’s been rather poor and I’ll be glad to see the back of them frankly. The difference in cost from estimate to actual is also typical after speaking with other HH clients. We are only doing supply and erect with them though.1 point

-

East of Inverness us. Currently tiling. Heating went on last week. Looking forward to hearing your progress and helping if poss. Btw, the caravan will be redundant shortly.1 point

-

It's great to live on site, wish we'd spent a little more on the caravan quality, but it's giving me a push to get building.1 point

-

Hi and welcome. Another Highlander here just north of Inverness. You are in good company. Dare I say if for getting a reputation, but how about selling the house and moving into a static caravan on the croft? WAY better if you can avoid borrowing and the hoops that makes you jump through.1 point

-

One thing rrdtool did well early was downsampling, making it easy to store time series data for long periods. Storage is so much cheaper than when it was created, though; I'm just not sure it's worth the effort to do it to collected points any more. I just store every data point at the highest resolution it can be produced at. For instance, all the data about my house, stored in victoriametrics, takes up ~50MiB for the last 6 months. Applying aggregations and rollups at query time is fast and flexible. Mostly, drool at it 😅. You can generally do without it, but then you don't get to show off puppies like this:1 point

-

@mrmike, welcome, there are a few Highlands self builders on here, some already built, some building. Where abouts are you? I'm near the North Coast just South of Wick.1 point

-

Well done on getting planning and welcome. Pics and plans always welcome! I think @Kelvin is a fellow heb homes builder and there may be a few more about too.1 point

-

I use EmonCMS https://docs.openenergymonitor.org/emoncms/index.html .When I started this monitoring business years ago the likes of SQL and RRD were the common options but well beyond my capabilities to use. EmonCMS has a learning curve but it's trivial compared to other databases. The easiest option is to write the SD card image to a micro SD card and put it into a RaspberryPI (if you can find one) then you configure it with a web browser. The database is looked after by the program; all you have to do is decide which version to use and how often you want the data recorded for some db choices. You can log the raw data but there is also the possibility of processing the data and logging the processed data. It was originally developed with power monitoring in mind so logging power, energy and daily energy are basic uses, but it will store and process any numerical data. I use http or mqtt to get the data into the db. Once there you have multiple graphing options.1 point

-

A door is ~ 2m2 in area and you only have a few of them, so a U-value of 0.65 vs 1.0 or whatever is small beer in terms of the contribution to total heat loss. What is more important IMO is how airtight it is. If it doesn't seal properly then you will lose far more heat through draft cold air exchange, especially if you are using MVHR.1 point

-

1 point

-

I remember cladding our sun room, a major part of the planning was setting the spacing between boards to work, meaning a different spacing on different walls, a bit like gauging a roof so a whole number of tiles fits the gap. And I wanted to get a common detail around each window so an outer board comes up to the corner. I painted all mine because I don't like the weathered "old wet shed" look. One coat before fitting and one coat after fitting. In this case the windows outer edge was only slightly back from the inner surface of the timber so just a small filler was used around each window and the outer boards overlapping over this filler. Above the windows the bottom edge of the board was cut at an angle to make a natural drip bead at the outer edge.1 point

-

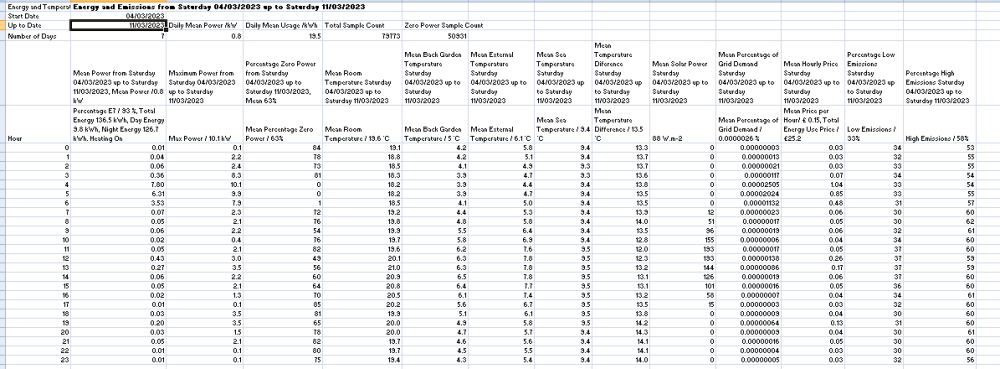

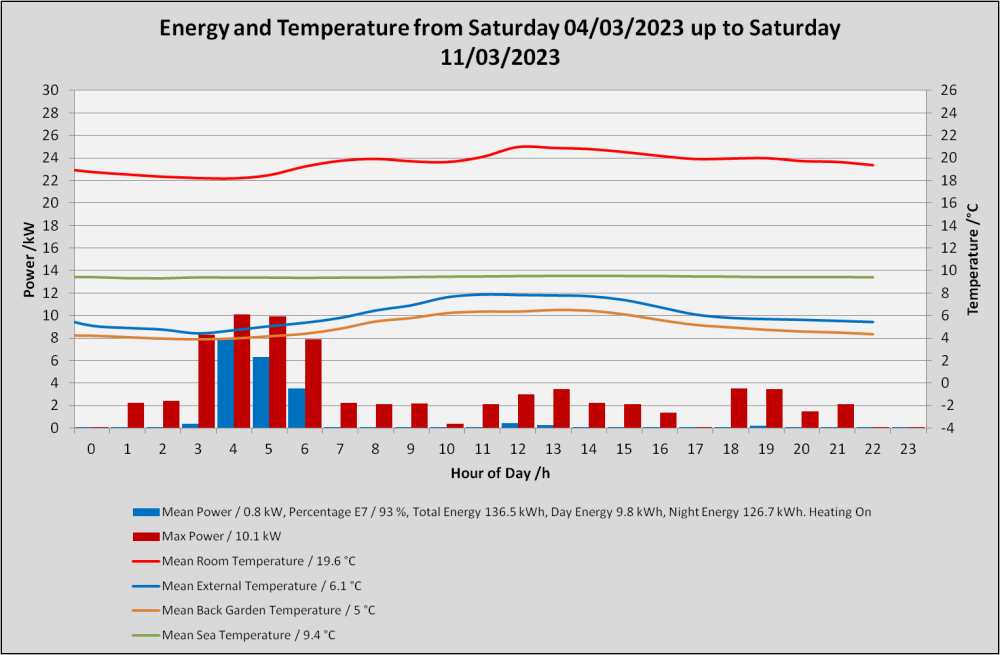

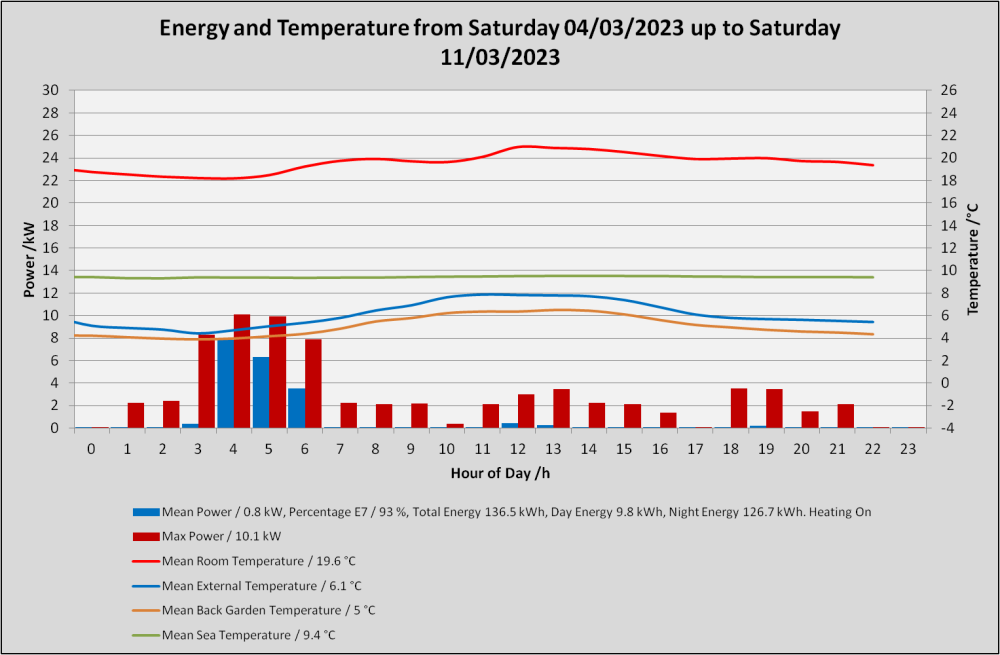

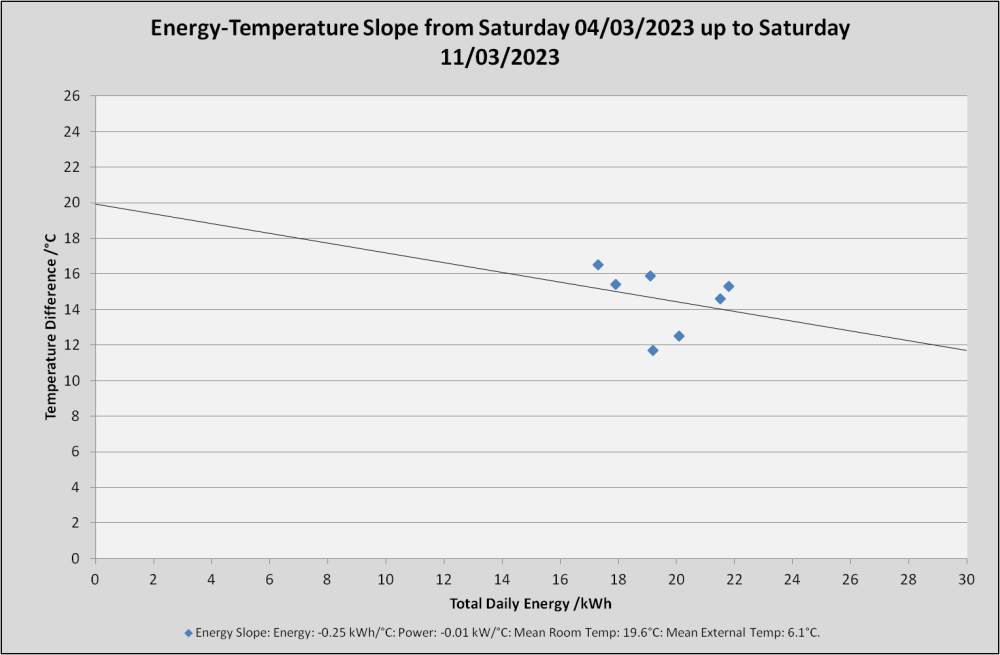

Always is the hard part. Why there is so much low quality data analysis about. Spend the rest of the day thinking about it. But, as an example, I take my power data that is collected every 6 seconds, then average it out to the hour mark. This makes life easy as if a group of data is collected between 00:00:00 (hh:mm:ss), anything with the hour 00 in it is greater and equal to 00 h, and less than 01 h. (the date and time format I actually use is DD/MM/YYYY hh:mm:ss, and I keep it on UTC, which is actually GMT). Then when I come to analysis the data , I can group it by date, the DD/MM/YYYY but look at the hourly results, so between 00 (midnight) and 23 (11PM). That gives me a table of what is useful to chart from. From that, I just chart what I want as I can vary the dates to look closely at any year, month, week, day. I do, from the hourly data, plot a time series chart, but i don't find it that useful. The trouble with a time series is that you have to visually calculate, and correlate temperature differences and energy inputs/outputs. Just makes for a messy chart really. Correlations are useful as they can show an overview of that is happening, and what to expect. Major deviations can easily show if something is amiss i.e. leaving a fan heater on in the garage. They are limited though, and have to be used with caution as 'correlation is not causation". Edit: I think I have my axis titles around the wrong way, seems to be showing that the greater the temperature difference, the less energy I use, which is nonsense, shall look at this later. I use Excel as it can usually handle quite large data sets, I put each data set on a separate sheet i.e. electrical power, internal temp, external temp, grid data etc. Then from those sheets create the hourly data, and from that sheet, start the analysis. All my data is saved as basic comma separated text files. These are small (relatively compared to say the same data in Excel), easy to merge together (dos command copy) and can be highly compressed and saved somewhere after the data is put into the main spreadsheet. All of my power, and house temperature is 110 MB for the whole of 2022, once compressed it is 8.89 MB. So tiny, really. You can also easily encrypt the data as most programs have an encryption utility built in.1 point

-

This hand book is good, however doesn't answer your question. I'm also thinking of how this detailing will work, one option I was thinking was to reduce the boards widths slightly between reveals of windows / door close to each other to get the base board at the edge of each reveal the same? still not sure if this is the best way forward though. TTF-Cladding-Handbook.pdf1 point

-

Put the drill on very high speed. Drill a small hole, then a larger and then the final, without pushing on the drill whatsoever. If the plasterboard blows out behind, then these fixings won't hold very well.1 point

-

Any HSS drill bit will do it, as long as it's a real one, not cheap Chinese ones. The import bit is applying the correct pressure, this doesn't come from a hand drill, unless you are drill small holes. You need coolant also.1 point

-

Me two, I plan to fully charge my batteries in the Flux period, then hold the charge until peak period, running off solar or the grid in between, then fully discharge batteries as much as possible in the peak period, then run off what's left and the grid. Any excess generation will be exported. I will have about 28kWh of storage and have an inverter capable of charging/discharging 8kW. So daily electricity costs should be in the negative in the good months and very low in the winter months, net result is it should pay a nice chunk towards my gas bill, hopefully.1 point

-

I use these on all the extract ducts https://www.epicair.co.uk/products/extract-air-valve-filter-for-8960-125mm-valve-10-pieces1 point

-

1 point

-

The height of the wall will make a difference. If it doesn't go full height then the wall at first floor will need to be subdivided some other way to comply with Part A, else it'll need an engineered solution. These sorts of things (Inc the movement joint) are detailed design things which an engineer can help you with once the layout is sorted.1 point

-

Isn't this the key point. Hydrogen isn't a viable alternative yet and may never be. Relying on something which doesn't exist to fix a problem which we have allowed to become urgent is a fools game, with the consequences selfishly foisted on our children. Leaky Victorian homes are difficult and expensive to heat irrespective of the heating technology. So insulate them! It's disruptive, but the consequences of global warming are orders of magnitude more disruptive. Then fit a heat pump. Unfortunately there are two many vested interests in prolonging the status quo for another decade or two, by which time the problem will have become even more urgent.1 point

-

BRegs give stated max lengths for ‘small bore’ waste runs, iirc max length 3m before upsizing to next pipe diameter etc. For showers I never run anything less than 50mm, as the air break in that size pipe allows free flow from the bubbles / foam creating an air lock, which happens in 40mm. The difference is quite significant tbh, where the water etc travels in the lower half of the pipe and air is free to travel over the top keeping things flowing very well. Its an odd phenomenon but it makes a big difference in my experience. Smaller pipes do slowly clog up from the soap etc coating the inside of the pipe, layer by layer, over many years of use. 32mm waste pipes from basins and 40mm waste pipes from kitchen sinks are the ones that suffer most, with pipes eventually blocking completely. What is found in the cut out sections of pipe are evidence of this. Quite unbelievable how bad they get. If you are burying / boxing any of this then upside by 1 in every instance. 40mm replaces 32mm - 50mm replaces 40mm etc. For wash basins I run 40mm up vertically and fit a 40mm bend with a 40x32mm reducer in it to come horizontally into 32mm pipe and then to the trap of the basin. Makes a huge difference in discharging water away from the basin.1 point

-

0 points

-

I've got to wonder how Uncle Google is listening in. I've just gone to YouTube and for the first time in months I've had something like: YouTube -- Fixing Big Holes from Drywall Anchors! recommended to me. 🤣0 points

-

0 points

.thumb.png.01d67d0cfce6aa583b15ba27963852e7.png)