Leaderboard

Popular Content

Showing content with the highest reputation on 08/02/22 in all areas

-

Just to say @ProDave kindly gave me a code for Octopus today. The website does look like they're not taking/are discouraging new customers. However if you click the "I know I want to save money, I want to switch anyway" you get through to the option to phone up. I phoned this afternoon, got through pretty quick and spoke to an extremely helpful & friendly agent. Call took about 15 mins all in including holding & a bit of chat. He was able to set me up over the phone - prices on the variable tariff basically the same as Shell (standing charge about 0.2p cheaper) as I'd expected. He also added the referral code to my account, worth £50 each for me and @ProDave so worth having! Less than an hour after dialling the number I've had the email to provide Octopus with closing meter readings so although the official switch isn't till next week I've used my last Shell-supplied units which feels brilliant 🤣2 points

-

We were several hundred pounds in credit with SSE and they still kept increasing the monthly direct debit. I got fed up with trying to sort it out so cancelled the direct debit, got a refund of the credit and set up a quarterly direct debit which just pays off the bill.2 points

-

Buy a cheap touring caravan. Work in comfort, kettle and toilet on hand.2 points

-

In case anyone needs a compactor - this one is discounted to £250. Pretty good for the money but I have one already 🙂 https://www.aldi.co.uk/scheppach-6-5hp-petrol-compactor/p/8074675003416001 point

-

1 point

-

Yep, exactly that. We'd drive up from the left of the picture, past the house, reverse in. Drive straight out. Trying to avoid having any opening on the public footpath, and would then be too easy to drive over the paving for the blind. There's a smaller pillar to the left of my red mark and a bigger pillar to the right, we are taking out a middle section. The gap is actually almost 12 foot wide! - dodgy camera angle. Thanks all. Appreciate your time.1 point

-

1 point

-

I once stayed in a hotel in Bangkok which had a double bed, shower enclosure with toilet inside it in a single room. It also had a mirror on the roof and two walls and a red light and was called the honey House Hotel...penny never dropped till I got into my room.1 point

-

1 point

-

1 point

-

Why do they want it removed? You would be checking / upgrading the existing supply as necessary and installing a 16A commando socket to plug the caravan into. Why on earth would they insist you remove that afterwards? it could have other used for them in the future.1 point

-

1 point

-

I believe any platform or stair less than 600mm above ground does not need a rail. So probably okay on your 3 steps. Surprisingly BC did not pick up any issues with 4 steps up to a patio door here without a handrail, I suspect they knew full well they were temporary for completion and we will be building decking later.1 point

-

1 point

-

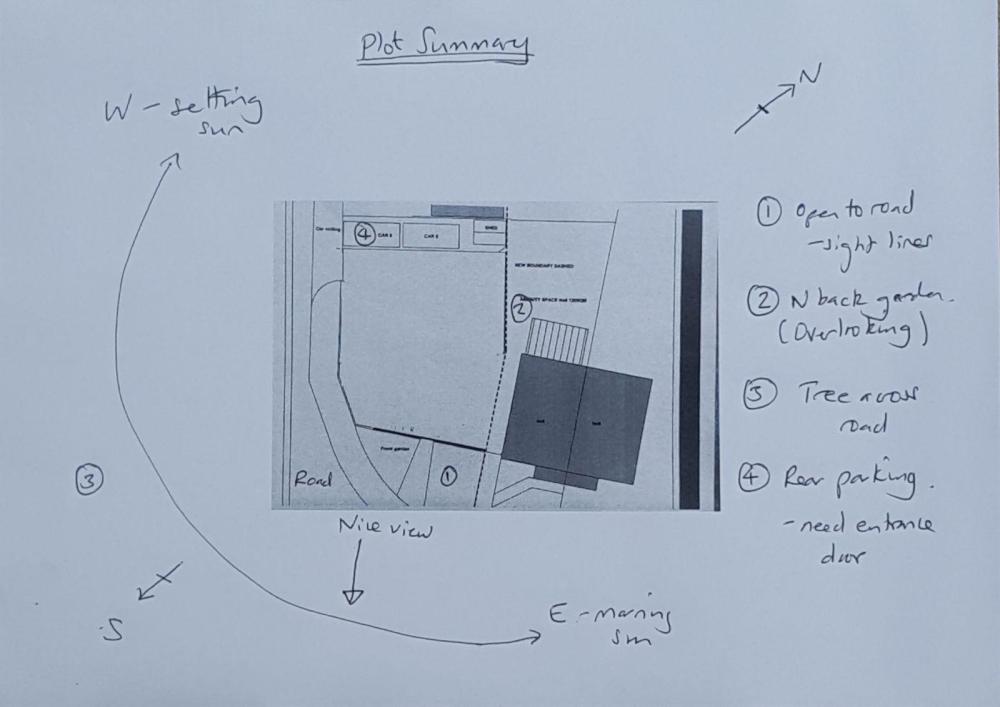

OK, @Duncan62. Some more feedback. It is really good that you are taking the time to let your design steep in your head - that is a real benefit. I think you are part way through the process, but there is still a lot of room to get something even better imo. For example, you say it is a forever-house, yet say there is no prospect of working from home. How do you know? You may be a carer for a parent, child or spouse, or cared for, in 10 or 25 years' time - in which case you may have no option. All it needs is an accident, and it could all change. An architect would start off with the plot, thinking about all the things @Bozza asked you about above (which are the most important questions on the thread imo). Then they would think about your statement of needs (do you have one of those?),. and come up with a house design to meet your needs using that particular plot. That is the defining expertise of the architect, combined with a knowledge and skillset to meet that. The reason for the self-builder to spend time up front is to gain some elements of that skillset. As self-builders we don't have the design training, and too easily dive into the bits of the process we know or touch already, which is usually house layout or engineering detail or house features, rather than the context. I use a simple tool to help me think about reconciling the two, which I call a "plot summary", which sits alongside the 'statement of needs'. It's just a diagram of the stuff Bozza was asking about in one place, and you add whatever is of interest. The statement of needs is what you use to sanity check each version of your design as you proceed. Here's one for a much smaller house on a corner plot where a few of us took a user called @simplepimple through the process. He had purchased a plot with planning permission with a design that had just been taken through planning easily to sell the plot, and wanted help to think it through. When you get into your design, you think about stuff like whether you want morning or evening or all day light in which rooms, if you want a window somewhere to throw the setting sun into your hallway, where your partner wants the herb garden, prevailing wind and sheltering from it, and so on. There are lots of examples of people doing this thinking in the blogs, and other threads. @simplepimple's design thread is here. He actually built it very quickly. HTH and keep on trucking. Ferdinand1 point

-

This just puts me off an "off the shelf" battery storage system. There is too much "we know what it is doing" from the manufacturer and not enough control and information for the user. As a very minimum I would like 2 user inputs "Inhibit charging" and "inhibit discharging" so you could at least have some control over what it does and when.1 point

-

Shell imo are a bargepole job. I know multiple people with very bad experiences. Escape.1 point

-

I am very much coming round to this way of thinking... Of course if at some point the roof was re-done then this would be the time to make it right.1 point

-

Change to Octopus. They are much more flexible and the user ability to set their monthly payment is just one of the nice things. PM me for a referral code which will give you £50 credit when you switch to them.1 point

-

Just raise the slabs on the pedestals and leave alone. Unless you can get the best roofer in the country to pul that outlet apart and redo it, I’d not open that can of worms tbh.1 point

-

Unlikely to be anything serious I suspect. Can you get up above it in the loft and have a look? It might be plasterboard over old lath and plaster where the fixings have failed. Does it move if you push up on it? Might just need some additional screws, a smear of caulk and a coat of paint.1 point

-

I think you’re looking for advice whether to commit to building internal walls, or leaving open plan. I think it depends on how you live. My personal view is if you live immaculately anyway and always put the dishes away after dinner and always keep all your rooms tidy then you can live that open plan dream like the photos in the magazines, impress friends etc etc. I remember seeing a tv show where the family had an open plan kitchen diner livingroom that looked immaculate for guests etc. behind a sliding door they had a second modest kitchen which was untidy/normal. Effectively had a kitchen for show and one for use. if you live a bit less tidy especially the kitchen you can’t shut the door behind you. Big open plan is always impressive but I do wonder about some practicalities for some people. Maybes think about having your central heating, lighting circuits and sockets laid out in a way that if you do need to ever put up internal walls you don’t have the expense or hassle of relocating them. I’m a fan of dividing furniture eg bookcases etc to define zones, especially the seating areas.1 point

-

1 point

-

1 point

-

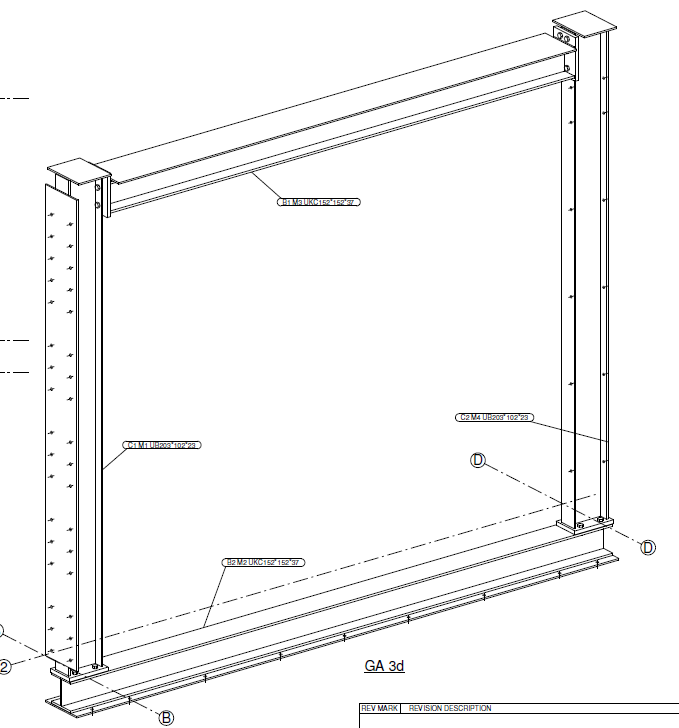

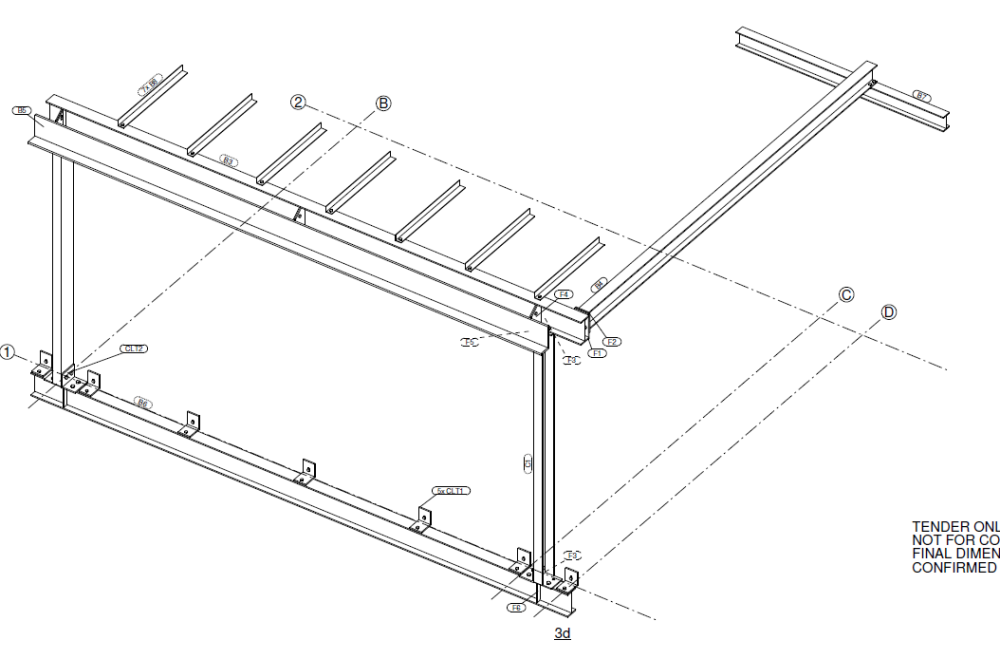

Seems a bit odd at first glance that the outer blockwork support is not designed and detailed. But if the TF company have just designed the TF and the steels directly associated with it they may have put a bit in the fine print that the blockwork lintel over the sliding doors is to be "designed by others". They may have done this to avoid what can be complex to design calculation wise (you need to do part of it by hand rather than being able to use standard SE software, or you can do it all by hand if you have time), time consuming and a challenge wise to detail.. a cost is a attached to this. To explain. After making sure the inner steel (portal in this case) over the doors can carry the loads safely and does not deflect too much to jamb the doors you also need to make sure that the outer leaf intel will also deflect by roughly the same amount give and take. What you don't want to see is a bow in the outer lintel over the doors, no unsightly cracking of the blockwork or of the mastic joints and over stress any wall ties above. Now at 5.0m span things like a sensible cost "L" shape Catnic / Keystone single leaf lintel is ruled out. The next options are.. weld a plate (bottom plate) to the bottom of the inner portal header beam or try to use something like a 200 x 100 x 12 /15 galvanised angle if not too much load above, tight on 5.0m but that is one starting point. There are other ways if the angle does not work out but I'll stick to this solution for now. Go back to the bottom plate idea. What happens here is that the plate acts like a cantilever and introduces a twisting (torsion effect) in the portal header beam. This twisting force needs to be resisted. One way of doing this is to use the floor say above the beam to resist the twisting.. but the floor needs to be right over the beam top flange or very close to it.. then you need to design the top flange connection to the floor diaphragm.. not in the TF manual and it can be hard / sometimes not possible to do.. it's tricky! You'll see in the regs that floors can bear on beams.. simple bearing and be ok but not for beams subject to torsion. You can maybe see that the TF company are thinking the same thing? I'm talking about a pretty stiff connection here.. bespoke. not available off the shelf from say Simpson or Sabrefix. Now if you can't connect header beam to the floor to resist torsion you need to design the header beam to resist the bending / shear and torsion forces. Some SE software packages do torsion design and you can do this by hand if need be using the Blue book with a few extra steps to check torsion. But if you can't rely on the floor the torsion ends up at the beam ends where you have to connect it to the columns. This is where the TF folk probably don't have the time to design a portal frame type connection by hand to also resist torsion as it's a non standard connection and not really covered in the design codes.. which refer often to "Engineering judgement" and "first principles" fine if you have time on you hands but for a TF designer they are working on the clock. What often happens is that you are tight for space to get a 5.0m spanning beam to fit in head room terms at the outset. You want to keep a nice clear square opening for the doors for the fitters and so on.. @Marc can probably fill in on the detail. But when you need to design the portal header beam end connection for torsion you sometimes need to extend the end plate. It can be extended up.. but this can breach the continuity of a TF head binder say, or you can extend the end plate down and put bolts below the bottom line of the underside of the header beam flange.. fitters not happy! In other words you need keep iterating and refining the detail so the structure works and the fitters can do their job. Below is some info showing a couple of way I have done this. The first is from an extension job where I used a single portal frame to support both leaves of the wall with different loadings.. which introduces torsion just as above. This shows a connection that is designed for torsion with the end plate extended upwards. You can equally extend the end plate and bolts down but you then have to check the door detailing and fixing method. This is a box frame that is doing quite a lot of "other things" which is why I have used this for and example.. will expand if there is interest from BH folk. The second detail is where I have used an inner beam with a steel angle on the outside probaly akin to what @Ericneeds. It's not a portal but has other stuff and shows the gusset type connection between the angle and the inner beam. Yes there is a cold bridge but cut me a bit of slack? , the bridge was mitigated in the insulation details. The angle is about 4.4m long and supporting a storey of single skin masonry above. To stop the angle from twisting it's connected back to the inner portal header beam with bolted gussets plates at the ends and in the middle. All these are doing is to stop the angle from twisting and this way you get the best performance out of the angle. There some other what is called "second order" effects happening.. for another day. Again this second detail has a bit more going on.. maybe a bit more interesting? @Eric Hope this helps, post a few more details if you want to follow up.1 point

-

Reading with care and writing well both take time. I am still puzzled by those who - with many thousands of pounds at stake - allow themselves to ; write letters of objection about matters immaterial to the application draft DA statements which are little more than copies of others' applications think that emotion plays a part in writing a Planning Application disrespect the reader by writing illiterate sentences waffle imagine that they also own what they can see from the property they actually own I too read with a delicious shiver the discussions between Central and Local Conservative planning officials. Martin Goodall writes beautifully about it. Shame he retired recently.1 point

-

Yep, that's how it works, though most local authorities are increasingly aware of the implications of operating in the way you describe. As a local authority you only get to lose a certain percentage of appeals against your refusals before the government class you as 'underperforming' and (potentially) remove your decision making powers. That has generally filtered down to local authority chief execs and planning heads, who now take local councillors far more firmly in hand than was once the case. Over the last couple of decades central government has used the threat of the big stick (removal of LPA powers and/or funding) to address both speed and quality of decisions. The implications of this for applicants varies. When I first started, old planners were still in the habit of taking absolutely ages to decide applications. Sometimes this was down to inefficiency, but mostly they were engaged in significant back and forth with applicants and relevant advisors, the mindset being to work together over time to get the best scheme, rather than to make a decision within 8 weeks, as is the aim now. It's good to have a nominal end date when applying for permission, but it does come at the expense of ongoing, fruitful communication with planners. You probably can't have both, at least not often. Regarding the quality of decisions (a good decision being one that complies with planning policies and so should survive at appeal) the major reason for measuring performance is to ensure that local politicians and residents don't get in the way of national strategies. If the nation is short of houses then the regions are set targets for how many new ones they should approve. If the region doesn't meet the target then they have to be less fussy in their assessment of proposals for new houses. If they aren't then they lose at appeal. If that keeps happening then they get cut out of the decision making process altogether. The opening part of my design and access statement addresses that context. I doubt I'd have got permission for my SB ten or fifteen years ago, when national policy didn't lean so heavily on my side. All of this creates an interesting tension between the centre and the regions. I have found that tension most evident between Conservative governments and Conservative local authorities. The former remain focused on national economic performance and deregulation, the latter on reasonable nimbyisim and preservation. They are on the same team, but pulling in polar opposite directions. Finally, don't be afraid of appealing against a refusal, even if only to narrow down the issues ahead of a revised resubmission. Some seem to consider a refusal to be some kind of black mark, but it is often part of the process of knocking an idea into shape, so long as you have the time.1 point

-

I would AAV 2 internally and one external to keep BCO happy. Usually pick the one least visible for external. These are decent ones - better than the Floplast ones https://www.screwfix.com/p/mcalpine-vp100e-push-fit-air-admittance-valve/236HP1 point

-

There will be lots of things that you can do nothing about Delays with materials and trades Deadlines being missed etc All will happen You will have to try not to take it personal and focus on other things1 point

-

I'll touch on the soft skills. Most of us are not daft, yes we have our daft moments from time to time, posting on BH is probably one of mine. A while ago there was a sales theory called the FUD factor. You can read about this on the web (for some on BH.. to take you back..Motorolla / Six Sigma etc..) but it goes; fear, uncertainty and doubt. You puntloos may be at the uncertainty stage? I would start to talk to builders, they will be keen as you now have your permissions. They will take your job as a live job that is worth them putting a bit of effort into getting. Don't forget that this is a people business, builders are people too. Some are great, the best will guide you, deliver what you want, look after you..you can become long term friends! Trust your gut feeling. Open up and start talking to builders, tell them what your are worried about..discuss the technical aspects with them. The builders you want will answer a lot of these questions. You will need to put a bit of work into finding them as they will be very busy. These builders are not cheep but you get what you pay for.with. A good team can work together to get the job done.. you.. the builder and designer! Have a look at this people side of things and it can take a lot of worry out a job.1 point

-

My partner says I have started to catastrophise over this build, so it has changed me, I used to be very confident and have accomplished much in a previous life, but I may have commenced from a difficult emotional starting point, and that was the cause, so it's not a fair comparison. Looking at your list there, it could be you are inclined the same way. I won't lie, worrying about those things you have described has given me bad sleepless nights, but I have learned to distinguish between severe anxiety and just normal, understandable worry. When I read about Toughbuttercup's problems I realised mine were minor in comparison. I think you need a lot of resilience to do this, because the financial uncertainties can be frightening, so make sure your mental health is good and that your coping mechanisms are robust. If you can slum it, you will have less financial pressure to live on site in a static. You know yourself, so play to your strengths and minimise your weaknesses. The people who seem to relish this the most seem to be incurable optimists with a very strong vision plus excellent core competencies to either earn well or do the graft themselves.1 point

-

If the pipe's cut dead square and with a slight chamfer on the inside top edge I can't see why there would be a problem with just fitting a normal swept branch on to it. It's nice to have a socket poking up at exactly the right height out of the slab, but my guess is that this is very rare. We have a swept bend, just like the one illustrated above, under our slab. However, because the insulation is 300mm thick and the slab another 100mm thick, the swept bend is way below finished floor level. We therefore had a tall stub of pipe sticking up out of the concrete, with a plastic cap taped on it to ensure it stayed clean. When I came to fit the swept branch at the base, all I did was very carefully cut the pipe to length, making sure it was dead square, with the required external chamfer to go into the fitting and a very light internal chamfer. The pipe abuts against the stop inside the branch which is, by design, fractionally smaller than the ID of the pipe, specifically to ensure that there's no upward-facing lip to catch anything. On one external 110mm pipe connection (the one from the kitchen waste external trap to the inspection chamber) the only way I could fit it was with a slip coupler. These have no internal lip, so it is essential that you cut the ends of both pipes absolutely dead square. I'm sure there is probably a tool for doing this, but I made up a jig, using a bit of 6" x 6" x 1/4" aluminium alloy angle that I happened to have. I stuck it in the band saw and made a dead square saw cut through 3/4s of it, and I then used this to cut all the pipes dead square. I found that this made life very easy, as I just marked where I wanted to cut on the pipe with a Sharpie, put the jig on so I could just see the black line in the slot, duct taped the jig to the pipe (both sides), then used a wide mitre saw blade in a hacksaw frame to cut the pipe. The wide mitre saw blade is better than any other saw blade, IMHO, as it is wide enough to stay square in the jig and has no kerf on the teeth, so doesn't wear the jig away, plus it makes a cleaner cut through the pipe. To clean the inside of each pipe end to get a very slight chamfer I used a self-aligning metal deburring tool (like this: To chamfer the outside of pipes fitting into push-fit connectors I just clamped my belt sander into a Workmate at the right angle, turned it on then rested the pipe in the gap in the Workmate bed and rotated it against the belt. This gave a nice even outside chamfer every time, and only needed a quick scrape with a Stanley knife blade to get the fluffy bits off.1 point

-

The latest in Saniflow systems Be interesting having a shower whilst your flatmate is doing the paperwork 💩0 points

-

Patience guys ! . I’m driving my EV everywhere so I can flatten it0 points

-

I think it depends on the cultivar. Scotch beans will probably grown to a yard long, taste fine after a weeks boiling.0 points