Leaderboard

Popular Content

Showing content with the highest reputation on 07/07/22 in all areas

-

Does he work for the council? Put up your own fence on your side?4 points

-

Taking a slightly different tact here. Might I suggest that your neighbour potentially isn't a bad character at all. Perhaps he was slow to have the works completed due to covid worries and felt a duty to accept a pushy contractors "take it of leave it" offer and he went ahead out of a duty to you to reinstate the fence. Almost all disagreements are due to physiological effects, ( pain, tiredness, fear, hunger) combined with narrow communication channels, (e.g forums!) when the meaning gets lost. Pop round with a cuppa coffee and a few buns, chat face to face and importantly listen to the neighbours thoughts before you go any further. This will ensure you have all sides of the story to make a reasonable plan to rectify the situation. Remember the saying " a good neighbour is better than a far friend". With a consideration you might be able to use this situation to improve life both sides of the fence.3 points

-

Please ask a properly qualified SE to do the design for you. We used Tanners: very experienced in this sector, and very keenly priced. (£1008.60 )3 points

-

When you put your boards back on Don’t forget to stager either side ie Start with a full board on one side Then start with a half board on the other side A layer of gyproc plank laid on horizontally will dramatically reduce noise2 points

-

Price seems a little high. I would recommend splitting the job in to two parts. Groundworks in preparation for the raft. And the raft itself. Personally, I would say neither part is suited to a general builder. Use a groundworks specialist for the preparation. I used a team I found locally that were digging up the streets to lay new cables. I just stopped in the road and asked them if they were interested in some side work. For the raft itself, get a local concrete specialist to do it. He will have spent most of his time doing commercial jobs (such as the floors of warehouses) but will have no problem adapting to your needs. You'll get a much keener price. I agree with the others: make sure an SE designs and specifies your raft. From the SE, you should give the dimensions drawings, detail cross-sectional drawings showing steels, and a steel schedule to your concrete guys. He will pass the latter on to his local steel supplier.2 points

-

Don't be in a hurry to fill it in straight away. It sounds like a handy place to lose all hardcore, rocks and anything else solid and inert that you need to get rid of when you start building.2 points

-

1 point

-

What's the return temp to the heat pump when in DHW heating mode? Is the return path heating the buffer as it flows back to the ASHP?1 point

-

1 point

-

1 point

-

dumper converted and working well consists of a kwickstage upright 10ft with a length of thick walled steam pipe tack welded to the scaffolding pole brackets ,so I can reclaim the pole when done and bolted with brackets to the dumper at one corner -so i can still use it if needed in the mean time dumper can still tip fully ,pole end is close to ground when tipped It lifts every stone i have tried so far with no bending or even flexing average granite stone size I have been moving about is 700mm x 350m x 350mm. the capping stones for my big long wall. taking down wall to repair and rebuilding with morter ,not just dry so far 12t of sand 70bags of cement and only about half way will post pictures at some point1 point

-

Interesting insight into the challenges of fixed price contracts, they are only ever any good in times of low inflation or predictable inflation times.1 point

-

It could make a useful soakaway if you are not on clay and you want to drain surface water.1 point

-

But inert crap, rubble and stuff! Not stuff that will contaminate the soil.1 point

-

Everybody above is correct. £250/ day not per hour , easy error to correct. Concrete at £200 / m3 is high. Stone by the lorry, and find what options available...type 1 spec'd as standard but ask for crushed concrete and other options. BUT first. Not knowing the circumstances of course, but my gut reaction on that slope is for beam and block, not raft. As well as saving materials it makes it all easy for traditional trades. Also removes retaining walls or banks that are not in your budget. Spend some of the saving on a good local SE. Question all suggestions politely and stress value. If you pay an SE for 10 hours work then they cannot test alternatives. The extra £1,000 can be repaid many times over IF you choose the right SE.1 point

-

1 point

-

Your building a house, not a patio, why are you talking in 800kg bags, you get 3 15 tonne truck loads at £450 a truck. Stop thinking Like a diy bloke and think like a construction guy.1 point

-

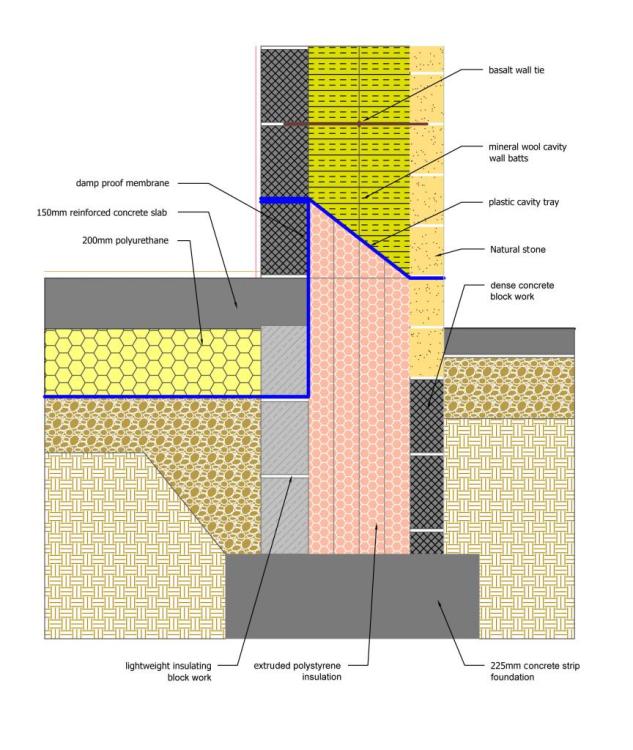

Your prices seem well over the top. Our foundation, consists of the following for 194m2. Level site Reinforced strip foundation (2m wide at front of house) 70m perimeter. Hardcore and blinding sand, DPM. Stub walls, 100mm PIR insulation in cavity 160mm deep reinforced slab over whole area 200mm PIR insulation 100mm concrete finished floor. I install the insulation, contractor did the rest £36k. U value 0.09. If your buying sand and hardcore, buy direct from quarry, about half the price the builder merchant charges. You need an engineered design, based on your site.1 point

-

1 point

-

1 point

-

I think that one problem of being 'off grid' is that people expect to get the same controllable levels of comfort that we have all come to expect. It really does not matter of your house swings 4°C in temperature day to day, or you have to take a short shower, instead of 3 baths. When I was a student in the early 1980s, we had flat that had a 2 kW bar heater in it, that was it, apart from the cooker. We survived, through studying, fresh vegetables (one flat mate was a farmer) and alcohol (2 other flat mates died from it, eventually). Just a change of lifestyle, and thermal underwear.1 point

-

An update for anyone specifying and purchasing similar. I got two further quotes from the suppliers linked above. Order placed with one of them for £760 including delivery. The local company I got the first quote from was not interested in competing with the other quotes. On the specification, the consensus of all three suppliers was that 13.5mm toughened and laminated glass would be required where no handrail is fitted. Also the holes need to be a minimum of 1.5 x hole diameter from the edge.1 point

-

My site has bed rock at shallow levels (300- 450mm). For my house ( insulated raft) I did as previous suggestions and dig out the house plot. I made my excavation 3 meters wider and longer to allow for scaffold and room around the build and stripped off all the soil until I hit rock. There is a slope on this, but it's all rock ( Caithness flagstone). The intention is to raise the lower corner with free draining hardcore, compacted with vibrating roller to end up with a level plot for the EPS. SE and BC have no issues, no requirement for load testing etc. The rock is going no where and neither is the compacted rock.1 point

-

Biofib trio every where for me. Chasing lower U values alone misses much of the bigger picture about house durability, heat protection and real world vs theoretical performance. Fire hazard, summer heat protection, construction waste, off gassing, thermal looping and high cost are all negatives with phenolic and to a lesser/greater extent with aerogel.1 point

-

Pair of Shelly 1’s would do fine- one switches on via the flow switch, sends a signal directly to the other and it starts.1 point

-

We did this. Took the cavity 600mm below floor level and pumped full of beads. Didn't use any cavity tray either. Separate DPC in both leafs.1 point

-

This is what I do with every slab penetrations design, as it's just sooo much easier to not have smaller bore waste pipes traversing the walls / cutting units etc.1 point

-

1 point

-

1 point

-

0 points

-

0 points