Leaderboard

Popular Content

Showing content with the highest reputation on 06/11/21 in all areas

-

This was all a long time ago, but we are now one of the 3 "small projects" shortlisted for the Passivhaus 2021 awards, with the shootout being on June 30th. See https://passivhaustrust.org.uk/passivhaus_awards/uk-passivhaus-awards-2021/ We are also finally getting visited by the RIBA jury as they have moved their 2020 awards to 2021.3 points

-

You need to buy an expandable foam gun and gun grade expandable foam. make sure that all the insulation is flush with the face of the wood, check with a long straight edge over a few at a time as it will make a BIG difference to how well the 25mm stuff goes on.. are you having a service void ? Either way I would be filling ALL gaps with foam, cut it back and silver foil tape over all joints before starting the over boarding. if you use 100mm tape it should bridge right the timber - it will stick to timber but better to foil faced boards. there are numerous threads on how to do this… you should read them before starting the detailing.2 points

-

I struggled to find much info previously before our build, now it's completed, I'd like to share our experiences for those who are in a similar dilemma as myself. Our build has a south east facing pitch at 40 degree, designed to be optimised for solar pv, with 16 in roof panels installed, total of 5.3kwh output, in Stockport, Northwest, by no means the sunniest part of the country. We wanted a storage battery from the start, which plays a catalyst in energy dependency since we only have electricity, which also powers air source heat pump, in the end we decided on Tesla Powerwall, more capacity, better warranty, cheaper tariff (Tesla Power Plant or Tesla Energy Plan if you also drive a Tesla), better app control and more advanced battery tech etc. Some, including ourselves were skeptical about how well our theory would work, whether there would be enough sunshine to even fully charge the battery, never mind export back to the grid to offset cloudy days. The results are staggering. We have 82% energy offset since the system was commissioned (two months approx) including charging EV, and recently we are running 98% self sufficiency, with battery getting full charge by 10am! Selling the rest back to the grid for the same cost as we draw from it, thanks to Tesla's tariff. Of course, on rainy days we draw from the grid, but it's definitely looking like a worthy investment, especially when we experienced our first power cut, battery took over seamlessly, and the only house on the street with lights on! We now only wish to installed more solar pv on the rest of the roof! So far, solar pv + storage battery is working very well, far exceeded our expectations, and it's worth bearing in mind, it is not about the absolute saving on your electricity bills, but more self sufficiency and energy independence. Of course, the longer you have the system running, the more you will save, it is only a matter of time to recoup initial investment.1 point

-

Well the job is done. What a morning of bodgery / adaptation. I bought the second one in my first post. As expected, I had to cut off the two "pips" on the bottom and it located using the two side notches for location. (bodge #1) As expected the body of this one is 2mm shorter than my original, and the locating ring would not clamp it down. I had to make a spacer washer. I found a large 2mm thick rubber washer and cut my spacer from that. (bodge #2) Next issue was completely unexpected and not mentioned as a "selection parameter" anywhere that I saw. In these, the shaft rotates (to select hot or cold) and tilts (to select flow rate) My original, the shaft tilts from lets say 10 degrees one side of vertical to 10 degrees the other side of vertical. The new one tilts from vertical to say 20 degrees off vertical. So clearly the tap handle mechanism is now offset and does not fit on. That one was a real challenge. I ended up filing 2 sides of the shaft to give it the angle I needed, which of course meant the shaft was now too thin across one dimension so I had to make a flat spacer to pack out the now correct angled shaft, to make it square again. (bodge #3) Then, due to a slight change in geometry, the microswitch in the tap handle mechanism did not work, I had to reposition the microswitch slightly, which involved a sharp knife and araldite. (bodge #4) Having re fitted it, the original leak has gone (gross leak from tap body) but only to reveal a slower leak from where the hoses join on at the bottom. That one I doubt I can fix so it will be a new tap eventually, but for now a cup can collect the drips.1 point

-

1 point

-

What does the Building Regs drawing show? Can you post it? # If it's a cold ventilated roof you'd normally have another sheet of PIR below the rafters. That can be taped or another (!) layer of PE can be the vcl.1 point

-

The one above is ideal, the other thing you need to consider is stability - does it turn a corner at the ends? will it be subject to high wind loads? likelihood of crowds or groups of people leaning on it? 20m and 2m high is a big surface to catch wind and will need something to stop it falling over as one big slab1 point

-

1 point

-

Potentially but I was thinking more about compaction due to plant movement and material storage around the footprint of the structure. There's too many variables to give much advice - but some of the ideas in this thread will be good so you can challenge any consultants you use to make sure they're suitably experienced.1 point

-

You could drop I beams vertically in to concrete and build panels in between...but would look crap. Either double or Pillars.. Remember- you have criminal not just civil liability for defective construction if it falls and injures someone.1 point

-

You won’t get away with it with a single skin The ones in the photo are double skin1 point

-

When I design/build things I always work on the principle of the hat with the big brim - get water away from the house, shed, garage, external power distribution cabinet with as big an overhang as I can. Remove the sill and you remove a layer of protection.1 point

-

1 point

-

Don't block any vents, don't stuff insulation right in to the eaves. No further than the edge of the wall. Keep all insulation in the floor. Keep the loft sealed from the rest of the house - e.g. minimise gaps around the ceiling light fittings, fit a sealed loft hatch.1 point

-

It was about three years ago when timber was cheap, even from B&Q. Just screws at an angle. From memory I only need a couple lengths as the area was only about 2x4m. I kept the 100mm insulation between the joists and put 200mm across.1 point

-

1 point

-

looks good! A cheap float to make a nice finish, if you have a multitool tape it to a length of 2x2 or 4x2 to use as a handle then screw another piece on the end the width of your pad. The vibration will make the conc come up lovely. Wait a bit till its sets a little and the water comes to top.1 point

-

They will be "Main Stream" from 2025 - read up about the Future Homes Standard Not true, just like a gas boiler the heating system needs to be correctly sized for its use Where is your reference that says a 7 year life is typical. They're not £10K now and will only go down once the RHI/MCS scheme is removed. I think you are burying your head in the sand.1 point

-

Not all clay is equal- ours has high volume change potential which lead us to pile (we also have mature oak trees within 4m of the foundations). The next step would be a Soil Investigation which will entail drilling bore holes and taking samples at various depths for lab analysis. Our SI cost £2300. Although I’m not sure if simply drilling trial holes with a digger would suffice - our Structural Engineer wanted the full soil investigation. Choosing the structural engineer is key - eg if you want something like an insulated raft foundation for passive house choose an SE with experience of this.1 point

-

Just standard carcassing. I costed it up and there wasn't much difference in using 100% loft legs or timber / 50% loft legs. I did it mostly for the stability of the boards. Didn't trust the plastic legs on their own! Plus I formed a step around the loft hatch and a handrail.1 point

-

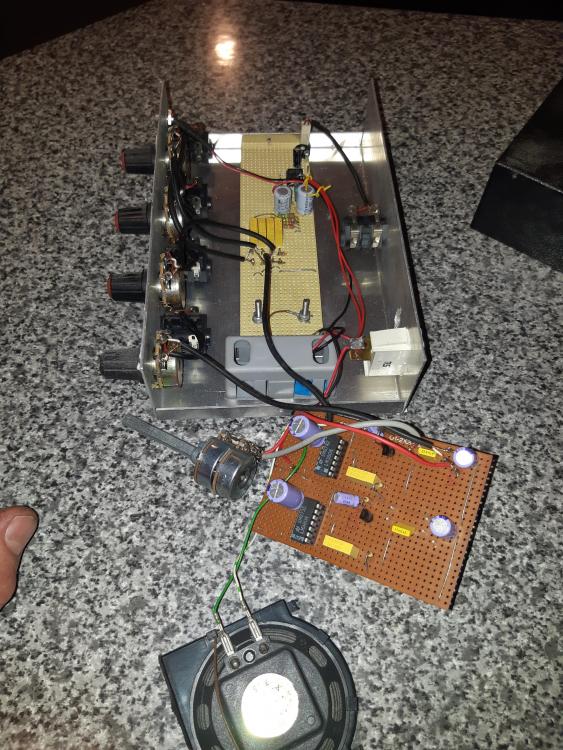

I'm using DS18B20 temperature probes with WIFI relay switches (https://shellystore.co.uk/product/shelly-1) to control extractor fans and central heating. What's nice about this is that it's plug and play - no soldering required. Each wifi switch can run up to 3 probes, but you have to combine with with an addon to link the probes to the switch. (https://shellystore.co.uk/product/shelly-temp-addon). The wifi switches broadcast their temperature data using MQTT - you could easily set up an MQTT server on your old laptop and capture the temperature data. The cost of a switch and an addon works at £20ish per 3 probes (plus the cost of the probes). A cheaper option is to use a teeny tiny ESP8266 wifi chip. Connect it to power via micro usb, wire in the sensors and you're good to go. Check out https://esphome.io/components/sensor/dallas.html. I haven't tried this approach though.1 point

-

I placed additional 200x50mm timbers across the joists around the area to be floored to create a "box". I also tied these in to the existing angle rafters that connected to the purlins. This helped spread the loads around a bit. If you are placing anything very heavy up there, try to have it at the edge or corner of the room, or above a supporting wall, rather in the middle of the timber spans. This is why cold water tanks are nearly always placed in the corner eves or on top of a supporting wall.1 point

-

It’s really about putting stress on ceiling joists which are not meant to be used as floor joists , if you use legs, the point loads may be a bit high for the ceilings joists whereas additional timbers will spread the load a bit. Also depends what you put up there (load).1 point

-

1 point

-

our architect has mentioned that maybe we could think about entering in to awards once the build is finished. I assume from that that he's very happy with the design he came up with (as are we). fingers crossed the planning department like it and we can get it built. then we can think about awards but it's something we hadn't even considered until the architect mentioned it.1 point

-

We've been entered by our architects for the RIBA 2020 awards, but all the regional shortlist announcements have been postponed. RIBA are now putting a big emphasis on sustainability for the awards, which is good for us. So finger crossing will be for longer than expected....1 point

-

Well no _____ the cost of the project was over one million I was the main contractor. When your using helicopters to bring all your materials in one million + is a tight budget.1 point

-

Not quite but i won a UNESCO - Award of Distinction - built heritage projects over 1million dollars - but it was for a stone walking track I built ! Did take me six years...... but gave me the money to buy my site !1 point

-

0 points

-

I have a yellow stripe for swimming a width of the swimming pool. Think I got a red one for doing a length0 points

-

Zer iz nussing rong viz being a Hun. Vot ver you sinking about making zat comment Gary??0 points

-

0 points

-

Kick them out as soon as you can, you will do them no favours keeping them at home.0 points

-

Maybe it gives the occupant time to lose enough weight to squeeze through the narrower gap.0 points