Leaderboard

Popular Content

Showing content with the highest reputation on 03/31/20 in all areas

-

I'm in the middle of 125m² extension, footprint is 75m² so broadly comparable. I was quoted £26k to get foundations in, brickwork built up to DPC, and sub floor slab poured. I did it myself in two months around a full time job and for less than £6k, it is not my trade but if you want something you can make it happen. Enthusiasm has wained somewhat since......2 points

-

I started getting seriously interested in issues around rental law / politics when around then I had a T in my own rented-out house who was in work for unpredictable periods, and I would get clawbacks of random amounts of rent each month from the LA for a few £££, with the instruction to go back to the T and recover from them. Before long there were ludicrous amounts of case law and professionals making their living out of the fine distinctions in the precise circumstances where such clawbacks were lawful or not, or the LL was guilty of fraud in concert with the T if they knew, and who had which burden of proof etc. Far too much buggeration for a system that would ever work sustainably. Our Parliament should be like Texas: "The Texas Legislature meets in regular session on the second Tuesday in January of each odd-numbered year. The Texas Constitution limits the regular session to 140 calendar days." F2 points

-

@Russdl You get about 5 square metres to the tonne from planings so a 3m wide track 60m long will need about 40 tonnes in total. Prices vary from £7-10/tonne. £6-700 should sort your track as a JCB is about £100 a day, Bomag about the same.1 point

-

Try the Paving Expert website. Usually good for this sort of thing.. https://www.pavingexpert.com Index.. https://www.pavingexpert.com/pavindex1 point

-

Planings are ok if you get a big roller. You need a 3 tonne bomag or bigger preferably, a JCB to scalp the top off and then spread the planings and preferably a warm day ..!! If the planings are warm then they bind better and don’t move.1 point

-

Ok so if that is brick and block, concrete tiles and nothing high end then I think you can get there for £100k but it will be tight. First thing you need to do is get an estimator to run the plans and give you the worst case number. Then start to scrub it. From that, start looking for trades. You cannot afford a main contractor as their margin will be 12-15% and that’s lost cost. Start looking for bricklayers, ground workers and joiners now, check for recommendations if possible and steer clear of the TrustaCheckmyRoofer type sites. How close to the site do you live ..? You’ll need to be on site every day, even if it’s only from 6-8pm to tidy up, sweep up and spot the problems. You’ll need to have a good grasp of google to buy at the best price, and make friends with your local builders merchant. As @AliG says, start looking all electric and an ASHP and UFH may be your friend. Upstairs will need Rads, even if it’s just to make sure it’s heated and you don’t have the money for OTT insulation. And above all, you’re going to need a lot of stamina and a sense of humour ..!!!1 point

-

Good luck. I have quite a few money saving ideas below. TBH most people overspend in here for nice finishes, nice specs etc and could build cheaper if they wanted to. However, in saying all that I just don't think you can get close to this budget in Surrey. In saying that kitchens and bathrooms are costly, so you can probably get down to below £1000 a square metre ex these especially doing some work yourself. A lot will depend on the groundwork/foundation costs. It looks like a relatively simple design which is good. The main savings are reducing the spec and doing stuff yourself. Spec - So cheap PVC double glazing, plain doors, white plastic sockets, bog standard skirting, cheap guttering, soffits, concrete tiles etc. You could use an electric boiler. Now these are expensive to run but you won't need a gas supply and this could save £2-3000 including installing the boiler. The other area to save money is hard floors, tiles etc. These are nice but expensive, simple OSB floors and carpets/lino which you can always upgrade in the future. Pendant lights instead of downlights, you could probably lose around £1000 in light fittings that way. The two simplest jobs are probably putting in insulation and painting, painting yourself would probably save £3000ish. A big saving would probably be to go open panel and put the insulation into the walls yourself. As I understand it from the quotes people get on timber frames, they charge quite a lot to add the insulation. However, this is perhaps compromising on the spec. Can the dormer wall not be insulated with rock wool rather than PIR, this is massively cheaper. Or actually, why not insulate with rock wool between the rafters then the doors to the eaves won't need to be insulated. There could be issues with condensation that have to be considered here. Again you could install this insulation yourself. As the house has a lot of roof, insulating this with a lot of roockwool will be cheap yet keep the insulation standard of the whole house up. I reckon that you might save around £15,000 not doing upstairs, but you'd have to pay VAT when you do it later and it would be more expensive and disruptive. I think though if £100k is really the budget, building to the minimum spec you might just get the building plus downstairs fit out for £100k.1 point

-

I am struggling to understand where you can legally erect that. It's 2 storey so that immediately means it can't possibly come under the portable building / caravan building regs exemption (which in any event would mean building it on a base capable of being lifted by a crane) The insulation values mean it will fall a long way short of meeting building regs for a house, and will probably fail BR for a whole host of other reasons. That only leaves a non habitable garden outbuilding which would still need building regs due to it's size but not so stringent as a house. If you have the space have you considered the usual option of a static caravan, giving you temporary accommodation to build the house slowly as you can afford it?1 point

-

My foundations came in at £10K for a similar sized house. BUT I had my own digger at the time. I stripped the site and dug the trenches. The builders just poured the concrete (strip foundations) and built the blockwork up to damp course for that.1 point

-

Both attenuators are commented as being on extract circuit. I wouldn't want the external vents to be any closer than 1.5m, ideally at least 3.0m apart. I would ensure that the 125mm diameter ducting at the vents is not restricted in any way so as to allow full flow of air. Often 125mm 90 degree cowls are fitted which look smart but do restrict air flow.1 point

-

Great idea! 3 years ago I built a 2 bedroom 71sqM bungalow for £96k. Fully completed inc UFH and ceramic tiled floors1 point

-

The obvious thing to do with that is build it as a bungalow first. Build the roof with attic trusses properly specified for the rooms in the roof later and cut the joists ready for the stairwell opening, then close in the stairwell opening for now. Don't fit the upstairs windows except those in the gables. Get it up and functioning as a 1 bedroom bungalow using the living room as the bedroom. You then install the stairs and do the loft later when you can afford it. If you are crafty, you get it signed off as a 1 bedroom bungalow and get the council tax valued on that. The council tax would not normally get re valued when you "extend" it into the loft. That makes it a roughly 70 square metre bungalow and you stand a fighting chance if you are careful of doing that for £100K1 point

-

OK .. so £100k is going to be tight, and that’s without knowing the design either. How practical are you..? And what can you and family/significant others do to help..? First thing is do you really need 4 bedrooms ..?? Can you get away with 2..? Then split when funds allow ..? Do you have planning permission and what for ..? Does it lend itself to a house of two halves.?? Exterior skin is going to cost money, can you go for block and render ... and render when you have the money ..? If you have plans then post them up - let’s see what you are up against.1 point

-

as @ProDave has alluded to above if you want to build for near to £1000/m2 (especially in the south of England) then it takes time. one of either quality or speed of build will have to give and from reading his blog it is definitely not quality that has suffered! remember the time, quality, cost triangle. you can only have 2 of those choices.1 point

-

I'm about £100K short of what I would really like to build and so am planning to do things in two stages: minimum liveable, with an extension later, when hopefully I'll be in a better financial position. Incidentally 'habitable' means you have to have the kitchen and bathroom installed, and a few other things before you can mortgage, if that's one way you could raise more cash. Alternatively jig the layout so that you could have a self contained part for a lodger to raise cash?1 point

-

We built using a closed panel timber frame system. Ignoring the plot-related costs (which were higher than average for us) the house build came in at about £1,380/m² at 2013 to 2018 prices, with me doing almost all the internal fit out (joinery, kitchen, bathrooms etc), the plumbing, heating and ventilation system work. Took a long time, as working on your own can be very slow going at times. The foundation and insulated frame cost, including doors and windows, external cladding and roofing and guttering, came to about £650/m² at 2013/14 prices. From that point onwards I did much of the work, with just an electrician for two weeks, plasterboard and plasterers for two weeks, a floor tiler for two days and a joiner to hang the internal doors and fit the stairs for about a week.1 point

-

I don't know how to break this to you, but 147 square metre house, in surrey, for £100K, not a hope in hell. Our house is a similar size and will be in the region of £150K when finished. The only glimmer of hope I can offer is to try your best and be inventive. We were faced with a similar position with lack of funds and in our case a lack of appetite to borrow. We are 5 years into a slow build now, living in the house but it is not finished. I have had some extra capital from 2 unexpected sources, one was a small inheritance, and the other was upon turning 55 years old taking the 25% tax free lump out of a pension. Otherwise it has been a slow "build as we earn" process. the final completion should come soon (CV delays accepted) by claiming our VAT refund which should give close to enough to finish the build a bit quicker.1 point

-

Be prepared to do lots of the work yourself - check out the Walter Segal method, build your own timber panels or learn to lay blocks. Go for the open-plan industrial look: ditch everything other than structural & bathrooms walls, cut out all unnecessary surface finishings and stick with OSB / fair faced blockwork, keep ducts and pipes exposed... You might also be able to get some tips from the BBC2 programme The House That £100k Built - not on air at the moment, but you may be able to track something down. Don't remember if anyone built anything close to 147m² though.1 point

-

Very few of us get under £1000 per square metre, and that usually involves doing a LOT of the work yourself. That is what we are aiming for, but along the way the work I have done myself would have cost at least £30K if I had been paying someone else to do it. What do you have in your revised budget, and how much can you do? Obvious easy savings are budget simple kitchen and bathroom that you can always replace later on. Likewise with floor coverings.1 point

-

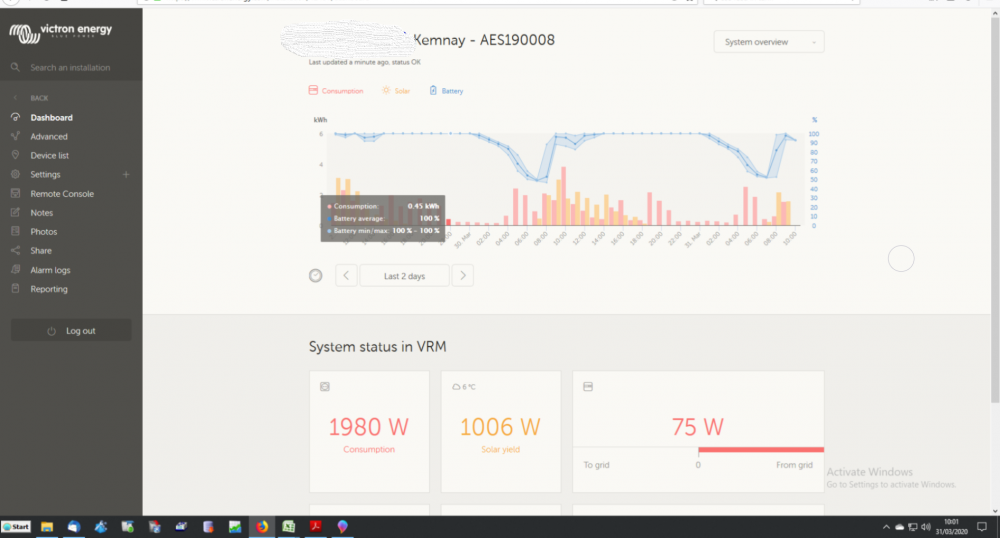

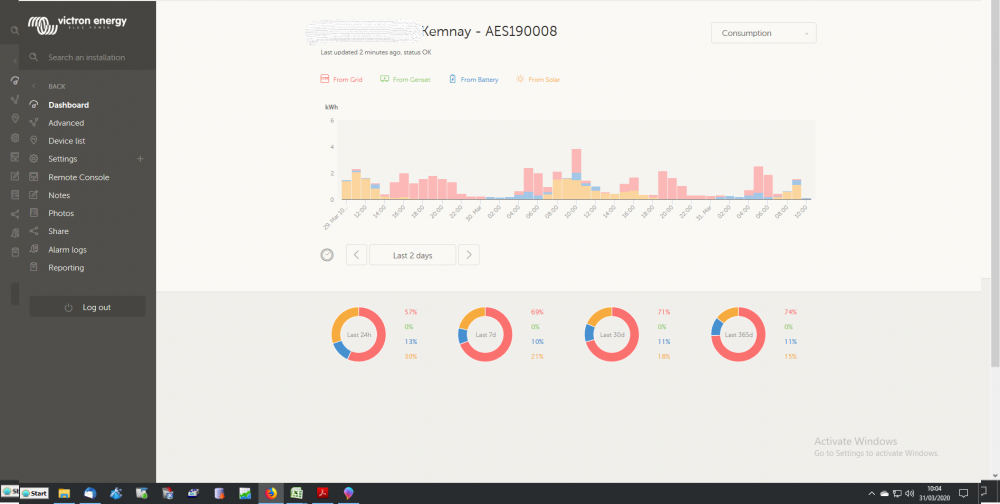

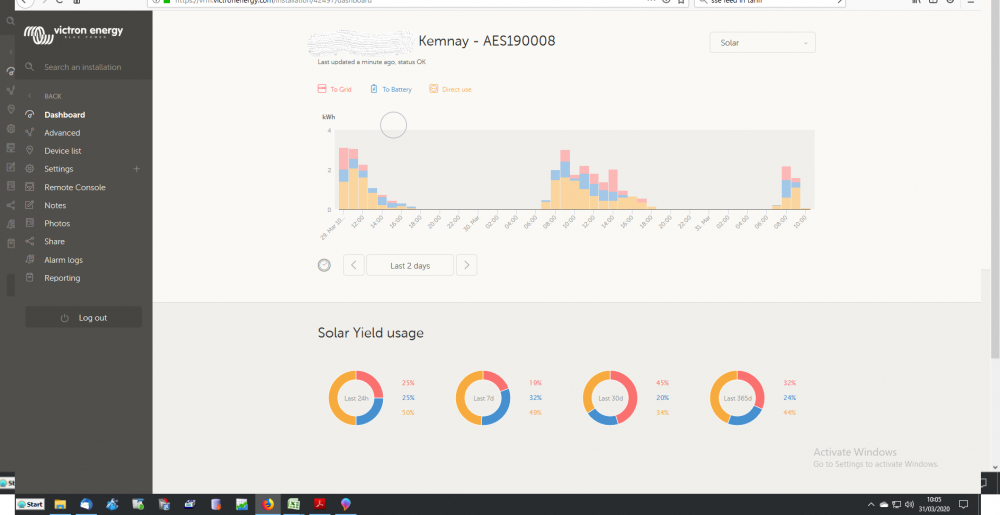

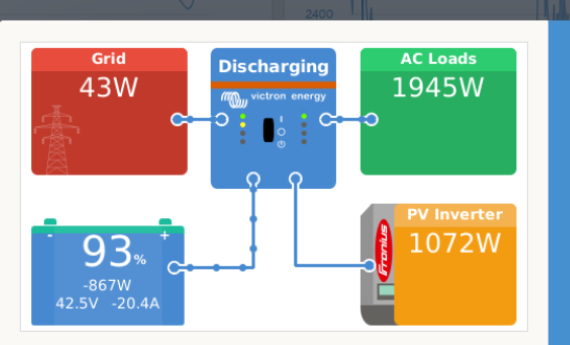

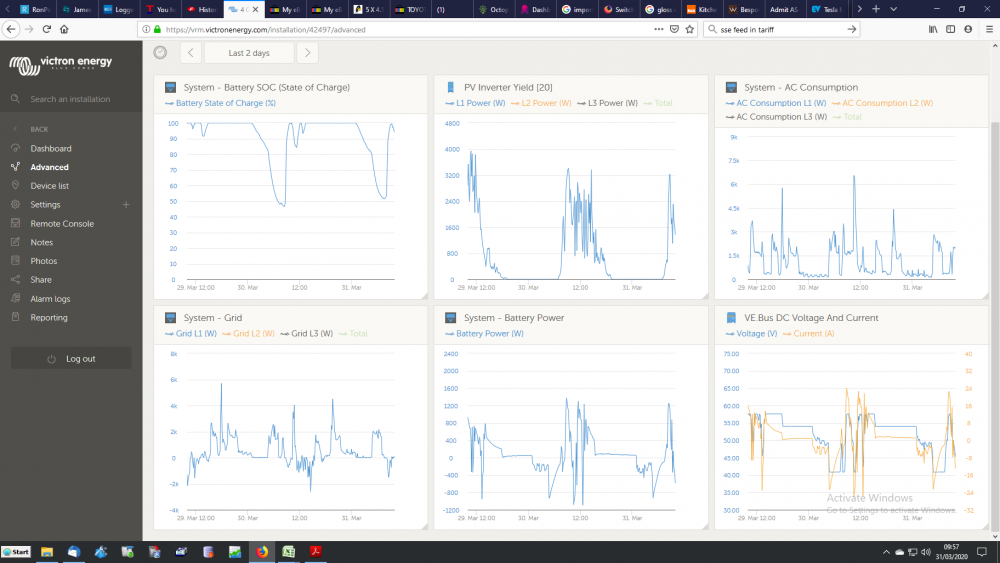

Like herb immunity, eventually most will get it. That last chart collection is useful. Does the Victron software allow you to grab the raw data for each element.1 point

-

Don't forget if you are planning to convert the loft later, to size the MVHR unit and manifolds to allow addition of the upstairs vents later on.1 point

-

1 point

-

I don't think that is a comprehensive comparison as many employee benefits are tax subsidised at corporate level - eg employer pension contributions and all the rest. The last employer I worked for ended up paying a further 40% of salary into the pension scheme - that is a part employer subsidy and a part tax subsidy. The one before that I had a sports ground, gym, ESOP, AVCs and all manner of things in the package. In Transport for London you get free travel for 2 people in the London Region that would cost £4-5k per year for anyone else, Private Health Insurance free or subsidised, final salary pension, Health Cashplan for I think £1 a week, and smaller stuff like bike subsidy. F1 point

-

No problem - if you visualise how the air goes from supply to extract and try to maximise that for each room then you should be ok. In the bathroom, try and locate the extract close to the shower or bath. Given the extracts are fewer in number and usually have a double run of ducting, they will extract at a much higher rate than the supplies deliver air so not as critical to have them in the far corners. Not sure that dining room supply will do a whole lot to be honest.1 point

-

If you bring it up on a rest bend with a y branch horizontally. You can put the farthest one on a 45 bend at bottom of rest bend and keep the drain in a straight line then1 point

-

My Kitchen / diner is 7m by 5m so as it happens 35 m2 Mine is working just fine with one inlet at the kitchen end and one extract at the dining end. Both fed by twin 75mm ducts. I will eventually fit a recirculating cooker hood but I don't have one at the moment. So ithink you can forget the single duct extra inlet in the middle of the room.1 point

-

You'll potentially have a 'dead zone' along the back of the living / dining room. I would move the extract so it's near the cooker hood - I assume this is re-circulating vs extracting to outside? That way the MVHR can remove the extract from the cooker hood and also create a cross draught for the whole run of rooms. For the two end bedrooms, I'd extend the supply ducts into the far corners of each room as otherwise the fresh air will go straight under the door to the nearest extract.1 point

-

Is it just me or does there seem to be a lack of cross ventilation? The vents could be further away from the doors in my opinion to get better cross ventilation in some of the rooms.1 point

-

1 point

-

1 point

-

Where possible I would try and keep inlet vents as far away as possible from headboard end of beds and sofa/chair positions, to avoid feeling "draughts".1 point

-

If you're going to convert the loft, I'd factor this into the MVHR design now: ensure the unit is big enough and plan the duct runs, run them in and cap the ends, then join onto them later on.1 point

-

As per the last post - we live in interesting times and its not getting any easier! The only real upside is that the weather has improved finally. We had the scaffolders in last week and they have built round three sides to roof level and it looks HUGE as it surrounds both houses in one continuous run. It doesn't look it but it is in fact the houses will have the same roof height as the old bungalow (fractionally lower in fact) - we did suggest to the planners that since we have 2 and 3 story houses on either side we could come up to their ridge height with a pitched roof but they were insistent on keeping our roofs at old bungalow level - hence the flat roofs and the deep dig. We cant wait until we have the timber frames up to finally see how they look on the plot. If you look at one of the photos you can see on Plot 1 that the platform steps down which matches the split level heights of the front and back sections. The plan is to get the Beam and Block floor in next week with a crane and then have the scaffolders back to do the front of Plot 1 and the section between the two houses in preparation (hopefully) for MBC Timber Frame the following week. It is still very tight and could easily go off track if one of the steps fails or goes off schedule, or if the guidelines change and non-essential construction is halted. But we have our fingers crossed and are ploughing ahead as fast as is possible and safe.. From the video you can see that the guys (no gals scaffolding on this one - sorry) seem to be maintaining social distancing and its a wide open site with few people and no enclosed spaces so it seems OK from that standpoint. We have managed to take delivery of a few key items for the preparation for MBC - our local builders merchant has been doing a great job but has decided to close as of Friday so little chance of getting anything else. This same picture seems true of the M&E (heating and ventilation) supply but Nick (from Wales) seems to have secured all we need for first fix. The thinking being that even if we get shut down then when we re-start we are all ready to move forward again as that re-start period will be total chaos as everyone tries to source materials at the same time. If you thought panic (or prudent) buying was restricted to toilet rolls .....We hear it from everyone - its a crazy world out there. On a lighter note we decided to pump out the foundation bays which had filled with rain water to about 6 inches (they dont drain as its waterproof concrete!). We dropped the pump in and were just starting to pump when we spotted a load of frog spawn. We stopped and jumped in to collect it in a bucket to take it to a more suitable location when we discovered two (common) frogs - presumably mummy frog and daddy frog. Amazingly they had survived in what was essentially a sterile concrete pond that was impossible for them to get out of. We managed to catch them in a clean bucket and repatriated them, with their spawn to a nearby field pond. Hopefully they are enjoying their new home as ours will be covered over with a beam and block floor and be dry and very inhospitable for frogs! As they say no newts is good newts! We have kind of lost the Week xx thread on the posts - so the latest is called Scaffold plus all the older ones can be found here :- https://www.dropbox.com/sh/th9f6e3cel5dm1q/AAAfsWdAH184J75bCNUUtzVra?dl=0 Our internet is a bit slow at the moment so it may take a few hours (or even days!) to sync up to Dropbox so if you dont see the Scaffold time lapse video pop back in a day or so - its quite fun to see something starting to take shape above ground.1 point

-

I'm self employed... and royally shafted my self in all kinds of ways in terms of an eligibility for self employed help. I have Ltd companies. Left employment in July 2018, had some income from employment (May - July) and just £2k dividends. Saved every penny in my business not to evade tax, just to grow my business and take the leap to employ people in 2020 - I realised that dream in February this year. Only paid myself £700ish a month salary throughout this tax year, again not to evade tax just to grow my business - this year I topped up my income with dividends of £16.5k to £25k personal income. They really are going in on us 'tax evader directors' - Yes I may pay myself with dividends to avoid NI contributions but I do pay corporation tax, employer NI contributions, pensions contributions, VAT etc and we still get taxed on dividends. Another way I shafted myself... rented a business premises in February and my landlord didn't manage to sort the lease and register the transfer of SBRR because he has been quite un-well, I'm not a monster so I didn't put him under any pressure throughout February and March. It's highly likely that I won't get the potential £10k grant on offer for SBRR as if they allow post dated applications there would be a lot of fraud with people renting out empty units to their mates. Still... I'm not too upset. I will manage and one of my businesses is doing really well. I suppose there are a portion of self-employed that do qualify but don't really need the help - they can still claim it as I don't believe you have to prove and hardship do you? I do worry about those directors who live hand to mouth, month to month and there is many of them! It's disgusting that they are disregarding them. They say it's complicated... well here's a solution that works for all. All employees and self employed can have an advance on their self assessment tax return income level or end of year tax return. You can claim it each month IF you need it. It's got to be paid back just like how student loans are paid back and it's written off after so many years. Surely this is a fairer solution and would have been welcomed by all self employed as a god send. Fortunately my friends and family are all well and the nation seems to be behaving and the NHS continues to do a fantastic job.1 point

-

This was an occasional but recurring topic on eBuild, including a topic that Jan and I initiated. Our water supplier (Anglian Water) has a strict policy to the effect that: the pipe into the house must be a min of 75cm deep and their surveyor must review the house installation for compliance before scheduling any connection works on the public highway. (There is a waiver for approved installers but in practice these guys only deal with large installations.) The standard way to get around this is to do this installation in 2 phases: Install a standpipe and request connection to the standpipe. This triggers digging up the road and connection to your property including the installation of a meter, stopcock and double check valve at or near the boundary. This has a 6++ weeks lead time. When the house and plumbing is "finished", then apply for approval to connect up the final supply to the house. This has a 1-2 week lead time in our area. So you can parallel up the external works and 1st / 2nd fit with the roadworks for the costs of a standpipe and the extra site visit, which is often worth doing even if you are never going to use the standpipe in anger. What is crazy is that our water table near the boundary is about 150mm below the street level so IMO there is no way that A.W. will put their meter and stop cock at 750mm because it will be permanently covered in ½m water. I did suggest just making the standpipe available and fitting it at the same time as the digging, but no: there is an absolute rule: the Anglian survey engineer has to review the installed standpipe and standpipe tail for compliance with their guidelines before any groundwords can be scheduled.) See attached photo where I've marked the position of the standpipe; there wil be a second coil of MDPE from the standpipe. The black pipe is for the electricity supply. You can buy made up standpipes such as this one: PL34 Standpipe which costs £235+VAT and is as per attached image, but I will buy the bits and make up my own for about £30. One wrinkle is that A.W. insist that the bibcock must not have a hose connector -- so I can either spend ~£30 for one without a hose connector of use a £7.50 one and angle-grind off the hose connector. Hey-ho!!1 point

-

So I had my Anglian water inspector around. He had absolutely no problems with my standpipe. So my version made from ScrewFix bits at less than £30 has just as good as the pre-assembled one at ~£300. Note my WB don't allow a bibcock tap, but they're a lot cheaper so I've just filed off the thread. The other wrinkle was that he said that we had to have a separate stop cock and double-check valve in our own boundary box within our site boundary, so we bought one at ~£120. My builder then said: waste of money; the crew will refuse to install it. So the groundworks crew came along and installed our water main this Sat and finished the re-tarmac'ing on Monday. The crew boss said: that's a bloody waste of money; there's no point in having a stopcock when there's another a foot away in the pavement. I refuse to install it; take it back and get your money back. You builder will be putting in the house supply as soon as we're gone anyway. When they left and my builder came to site, he said .... Anyone want a nice boundary box / MDPE 25mm stopcock / double check valve?1 point

-

That's excellent. It can tell you so much about when, on average, it is best to run heavy loads. Link it into Gridwatch and you can work out the best time to reduce CO2, which is what it is all about anyway. I think I am going to switch off the auto correct. I had an ex offering a 'lick down' the other day, but I am sure it is not what she meant at all, especially considering what the conversation was about, quite inappropriate.0 points