-

Posts

138 -

Joined

-

Last visited

-

Days Won

1

Red Kite last won the day on May 27 2020

Red Kite had the most liked content!

Personal Information

-

Location

Wilts / Glos border

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Red Kite's Achievements

Regular Member (4/5)

111

Reputation

-

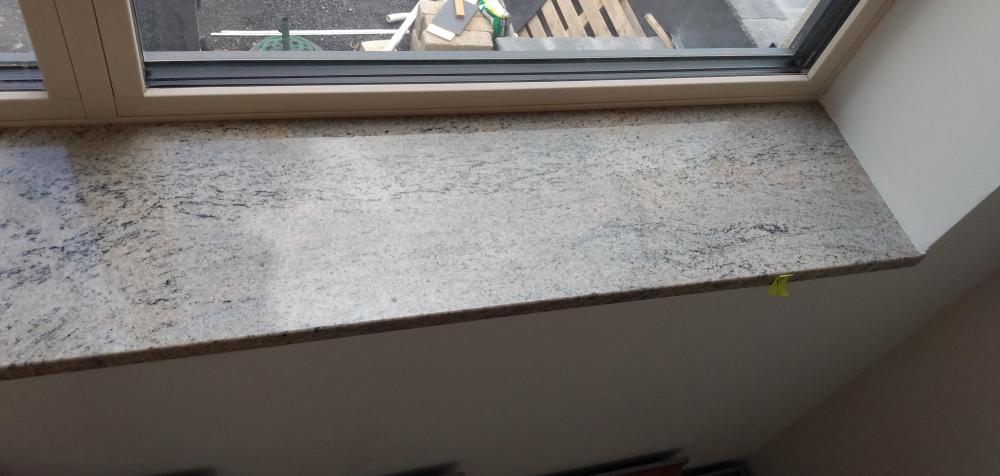

Luckily we fitted the granite cills before the plasterboard so no nibs, just rectangles of granite that were boarded and skimmed to - this way the tolerances can be pretty wide with up to 12.5mm ish on the length (great if your walls are not perfectly square). Isn't foresight a great thing - our plasterers told us they would get a much neater finish this way ? And as an FYI for those who dont know and are fitting the cills themselves - surprisingly granite is quite a fragile material and can easily snap under its own (not inconsiderable) weight if you carry it 'flat', so always carry it (and store it) vertically i.e. 'edge down', and strap it to some timber or ply if it needs really awkward manoeuvring. And if you need very long cills then perhaps specify them in sections and make a silicon joint that lines up with the mullions - for us and our wide window it was much easier to carry three small sections up a ladder!

-

Stairs from Zakuna: anyone else had isses with this supplier?

Red Kite replied to Red Kite's topic in General Joinery

Yes, you are right, and this is the conclusion the fitter came to when he tried to run trunking around the outside - it just wont work as there is just not enough space, so the cables really need to run on the inside of the stair not the outside. However to run the cable inside the stair will likely require each tread is removed and routed so its not a small job. Its fundamentally a design fault and should have been done in the factory so there is some discussion between parties on who will do the work and who will pay - classic! We wait to see how this is resolved, but hopefully in less than another 6 months - the saving grace is we have stairs that work and look great (ish) and our BCO will sign them off now as he doesn't care about the cosmetic side. -

We fitted DIY Kitchens earlier this year (kitchen and utility) and this is the 3rd kitchen we have fitted from them. Generally pretty pleased with them - pre sales and design were helpful and flexible in terms of modifying units to suit. Delivery was great - turned up when they said they would and were helpful and friendly. Some of the doors were damaged (do inspect all the delivery as soon as possible as damage needs to be notified within 3 days I think) but they sorted this and sent replacements. Had a couple of iterations in getting all the doors replaced but they were great in organising this. So would give them a reasonable review - not perfect but worth it for the money. And in our experience really expensive / high quality kitchens are not worth installing. I agree that DIY Kitchens quality has gone down over the last 5 years, probably victims of their own success, but still OK. Not fitted Wickes or Magnet so have no comparison, and not sure if the Germans do the same online design / order / supply only model - I thought they were more supply and fit through local fitters / expensive showrooms??? My only other comment is that a ready assembled kitchen is the way to go - our son fitted an IKEA flatpack and assembly was an alarming amount of work and not as robust!

-

Just wanted to know if anyone else has had issues with Zakuna? We had stairs fitted by them in December last year and though the stairs look great (in general we are delighted) there were some issues with the install. Some of the issues were cosmetic, for example there are LED lights under the treads which are really nice but the wiring to them is visible and REALLY ugly. Also there was some issues with balustrading that meant that our BCO wouldn't sign off on them. For us this has not been too much of an issue, but if we were waiting for sign off for a mortgage this could have been really difficult. So after 6 months of continuous nagging they finally came to fix all the issues and in fairness did fix them all except the cosmetic wiring issue! So we have started chasing them again but are very disappointed, just wanted to see if anyone else has had similar problems with Zakuna or been totally delighted ? As an aside - note to self for next time: when paying for big ticket items (that are complex to fit) make sure to keep a retainer so you have some leverage. We were in a real rush to get them fitted and without too much thought we paid the final invoice in full prior to fitting. Result: no leverage at all to get any issues resolved - if we had kept back 5% we might have been in a better place. Any advice on how to apply pressure to get this kind of problem solved?

-

We have a sliding flat roof light from roofmaker which opens about 3/4 of the size, its electric . Its triple glazed with a rain sensor

-

Boiling Water taps. What and where to buy.

Red Kite replied to ProDave's topic in Kitchen & Household Appliances

We have a quettle , we went for it as you can add a water chiller. we had a built in fridge so no ice or chilled water. Only been in a few months but seems great -

Having had a nightmare with Wiltshire planning we used their building control with some trepidation. No worries- they have been amazing , very pragmatic and helpful. Delighted to see a modern fabric first building - sent the students to look. Helpful during lockdown . Cheaper than private one

-

We had ours from Philip Bines who is near Melksham and they do work in Bristol . we did the whole house so offcuts were not enough . We fitted them prior to plastering . We had kitchen worktop to match - did not plan this in the begining !

-

Ours was really compacted and we were about to hire a rotavator when an electric Mantis Tiller came up on facebook for £40 . best £40 ever ! Although electric it coped well with the clay soil and did much more than we thought. Much lighter than a rotovator and no pressure to do it allbefore rental finished It was also great as we did a main turn over but then when we added compost a couple of weeks later we could run over it again. Its also narrow enough to do the raised beds . We seeded the lawn after loads of preparation and it is now growing - the areas with less sun are noticeably behind but beginning to green up. Its a bit patchy so may need a bit more seed in places, we used a seed spreader and the correct amount . We debated weed killing first but thought as we had dug it over and taken weeds out it might be ok. I am surprised at how many weeds were through before the seed sprouted ! The wildflower meadow seeds we planted in another area have been even slower to germinate - so not sure if they are going to as they went down before the lawn. What to do there I am not sure - maybe be patient for a bit longer

-

Very happy with doors and door frames, we fitted them all ourselves , ours are pale grey with silver infill to match the stairs

-

-

Will take a picture tomorrow of the black cills

-

Also our son got cills from Tev doors so they matched his black skirting and architrave

-

We used granite on the window cills throughout the house . |It came cut to size- easy to fit, never need to paint . We have grey aluclad outside with cream painted wood inside

-

How many objections did you receive?

Red Kite replied to miike's topic in General Self Build & DIY Discussion

We have just about finished our modern houses which we won at appeal after a couple of applications. 105 objections in total but numerous from the same people , who also walked along the road encouraging others to object. The committee was a farce - planning offer wanted approval both times but committee said NO . councillors so ill informed rantiing on about metal roof being seen form far and wide but its a flat EDPM roof !!! Now that they are built so many people stop and say how nice they are its heartwarming. It was so so challenging at the time but now we try to laugh about the ridiculous things the neighbors said - not enough parking ! well we have 3 cars and a camper on the drive and room for 3 more ! 2 will get in the garage very soon ! so even more parking