Leaderboard

Popular Content

Showing content with the highest reputation on 01/12/20 in all areas

-

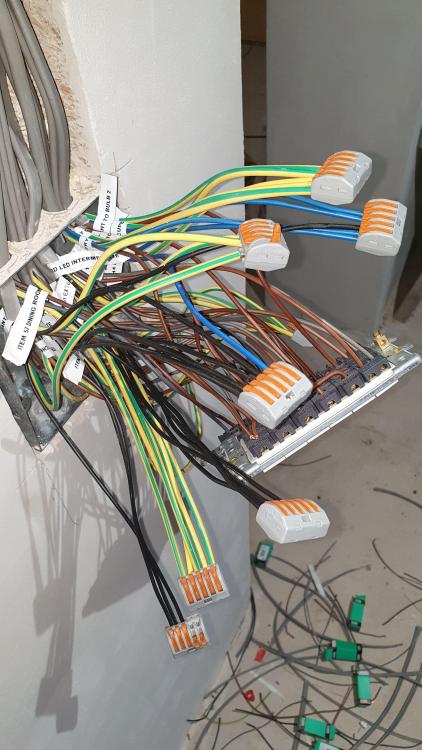

My brilliant stepson called me over today to show me how he was getting on. Here ya go : it's just a little thing .... but massive to me A humble GU10 working on mains electricity for the very first time in Salamander Cottage. Another milestone. There was this nest of spaghetti which makes it possible to switch the lights from three places and this set of intermediate switches ... Quite how sparkies 'see' it all, I have no idea. I could not be more pleased. So thanks @ProDave for telling me about Scolmore Click Mode and for all the support. Had it been up to me there would have been the mandatory 3 gang switch at the door. And that's about all. A small beer tonight methinks. Just to mark the passing of another milestone.2 points

-

In any walk of life, people will have different opinions to what is best, which is great, as I’m now in a much better position than last night: a) I now know that using blocks is fine for external walls and I can avoid engineering and face bricks entirely b) I’ve been introduced to aggregated blocks - so will investigate these compared to aerated blocks All the work will need to be signed off by building control anyway, but forums really help with the (often obvious) questions that a compete novice struggles to find answers to2 points

-

search for lead came which is the proper term https://tempsfordstainedglass.co.uk/38-stillemans-h-section-half-round-lead-came-11 point

-

Cost ... and it’s not got a BBA cert for standard blocks from memory. It also courses really badly with bricks so you end up using driven wall ties rather than standard ties.1 point

-

1 point

-

1 point

-

the vapour permeability of the outside sheeting material will depend upon the insulation used in the kit wall. with cellulose it will need something which has plenty of permeability, don't want soggy paper in the kit.1 point

-

Same with my house, builders made a plywood former and filled with lime, so there's a nice squarish profile covering the foam.1 point

-

I would cut the foam back a little and fill with lime. It is what I have done on my house with wooden windows and stone walls and it has been fine. Looks like pretty large gaps in places so you would use a lot of mastic if you go that route.1 point

-

Foam is Probably not UV stable either. You cut scribe and cut a capping strip to match the windows and hide it.1 point

-

im with @ProDave, I have a similar set up (ASHP outside, tank and pumps inside), if (when) the ASHP fails I can change it out simply, even fir a different size, spec, efficiency as techknowledgy changes. Like Dave my ASHP does UFH and DHW.1 point

-

Thanks @joth yes we already have a 3 phase meter, but the other two phases are capped off after the meter so presume we’ll just tap into those. Avoids the risk of trips on Christmas Day when we have too much demand! And yes I had no idea about the net metering so impressed he knew. He’s an “ex” Electrician so comes at this from a different angle to the usual double glazing salesmen turned solar salesmen! Glad to heat that sounds competitive. Just need to crunch some numbers and see if it’s worth the larger 9kw array.1 point

-

Horrible things unless you’ve got an overheated leaky house ... they need to get heat from “somewhere” and that’s the room they are in - they can’t get enough without a decent high volume air flow so take ages to reheat. I’d never fit one.1 point

-

1 point

-

Nothing wrong with aeriated internal or external Millions are used each year in the U.K. Great to render to1 point

-

Hi Angela, though my project is different to yours, I’m currently self-building just near Westhill. If I can offer any local advice please do ask.1 point

-

There are two considerations, really, as U value is only part of it, decrement delay is at least, if not more, important than U value, as that's largely what determines how comfortable the house will be, in terms of not suffering from rapid temperature fluctuations. Decrement delay is described here pretty well: http://www.greenspec.co.uk/building-design/decrement-delay/ and, although related to insulation performance, it's equally closely related to the heat capacity of the fabric. One problem with making very thin walls, apart from decreasing the U value to a sensible level, is in increasing the decrement delay to a sensible level, too. In general, lightweight foam materials tend to have a pretty short decrement delay, as they have a very low heat capacity, whereas some other insulation materials, like some fibre materials, wood fibre or blown cellulose tend to have a reasonably long decrement delay. It's quite possible to combine material layers so as to achieve both a low U value and high decrement delay, as another option. Alternatively, you can accept having a short decrement delay and just fit a heating and cooling system with a very rapid response time, so it can cool the house as fast as it heats up, and vice versa. Location and orientation also play a big part in this decision. If the fabric of the house isn't exposed to bright sunshine for long periods during the day, then decrement delay becomes less of a concern. It's primarily an over-heating issue, as in bright sunshine it's pretty easy for an external surface to get to well over 40°C (I've seen outside surface temperatures of around 50°C at times here). That creates a pretty high temperature differential across any wall or roof, and will tend to drive heat more rapidly through the fabric of the house unless the heat capacity of that fabric can absorb some of that heat and so slow down the rate of heat transfer. If it can slow it down enough for the heat not to reach the inside face, before the sun has moved away, then generally that's good enough, as as soon as the outer temperature drops heat will start to flow back out.1 point

-

I've always bought 221s from CEF, fair bit cheaper than Screwfix and usually in stock. Not as user friendly as 222s IMHO, it's easy to break fingernails opening the 221s. Nice and compact, though, not really much bigger than the push fit Wagos.1 point

-

https://www.screwfix.com/search?search=wago+221 https://www.toolstation.com/search?q=wago 221 https://cpc.farnell.com/search?st=wago 221 http://www.discount-electrical.co.uk/search.php?xSearch=wago+221&x=0&y=0 https://www.tlc-direct.co.uk/tcl/search?query=wago+221&Submit=Search I think everyone does them1 point

-

You could but WAGOs are a constant force connector and deemed maintenance free pretty much. Fit and forget even if inaccessible later on. With a terminal strip you have screws that WILL loosen over time and need periodic checking.1 point

-

Best of luck getting all those wires tucked away in the back box !!!! Re step, I use a pair of "combination ladders" that can be a short extension ladder, a pair of regular steps, or a pair of offset steps for use on a staircase. I have had them for probably 30 years, they are sturdy and secure and I have never once doubted their integrity. Plenty of people have told me they are "illegal" and dangerous, but nobody, not anybody is going to stop me using them. I do admit I have seen similar looking things to mine that are rubbish and dangerous so choose carefully and use your own judgement.1 point

-

There is a physical limit. How crazy do you want to get? I think Aerogel has the lowest thermal conductivity known to man so wall made only of that stuff would be the thinnest possible. However its horribly expensive not readily available and wouldn't carry much load. Its also translucent. The next best material is PIR (polyisocyanurate) insulation which is a lot cheaper and more widely available then Aerogel. Some form of timber frame infilled and covered with PIR is probably going to give the best U value for minimum thickness. The outside could be rendered, clad with brick slips or battens and some form of rain screen/siding. One issue is the difficult of cutting and fitting PIR tightly between a timber frame. Poor workmanship can ruin a good theory. Some form of compressible rockwool batt between the frame might work better because its easier to get right even though the U-value is theoretically worse than PIR. A combination of Rockwool between and PIR outside would be reasonable. A layer of plywood or OSB would probably be needed to prevent racking. You might also look at a SIP panel construction.1 point

-

@Adam2 I have two sets of LED strips up there - 1 light switch does one set (dipped headlights) and the other brings on the second (full beam). One set of lights is more than enough to read by - they are very effective. If we're watching tv, we just have table lamps on and I have an overhead LED reading lamp if I was to read whilst OH watches the box.1 point

-

hi @Patrick, going by this site, https://www.metsawood.com/global/Tools/DoP/DOPOpenDocuments/DoP_MetsäWood_Birch_Plywood_PF_2019-12-2_en.pdfit states a vapour barrier can be used in the substrate. it does give a vapour permeability, however, i've no idea as to its effectiveness. they are useless for the outside as they definately won't be vapour open. you will need something akin to panelvent dwd, medite vent or egger dhf if you can get it. i went with medite in and out cheers1 point

-

If so this may be of use... https://www.gov.uk/hmrc-internal-manuals/vat-construction/vconst24550 Thanks Google :-)1 point

-

Get a good quality Spanish slate (CUPA), the H3 is just as good as Scottish slate and you can get them in random sizes1 point

-

We had same conditions Welsh would have been our first choice But a good compromise was grade 1 Spanish Ive a friend who sells large quantities of slate She earned me off Chinese & Brazilian1 point

-

Sometimes you just have to suck it up. And now is as good a time as any to accept that we aren't going to get a roofer to come and help before Christmas. I have asked til I'm blue in the face: no dice. Debbie's being brave about it, conclusion: I'd better Just Bloody Do It. So, I'll be paying for my own mistakes rather than pay for those of others. Differently put: the Full-On-DIY -experience. I thought I'd teach myself how and in the process, document it. And then read your critiques. And wince I expect. This post builds on the earlier thread about the Piggery, and the roof beam saga : that proved remarkably painless, and quite safe, for two people because we'd thought it through. It only weighed 160 kg : just over 7 meters long. £500 crane fees saved. The very nice man from Haldane Fisher's HIAB played a key role: it's reach was about 2 meters short of what was needed. Some ya win. Where are we now? Here : a set of rafters which are currently subject to close inspection by our swallows, What's the roof build up? Rafters Counter battens Felt Battens Slate There's provision for a few kWh of PV, and a Velux in there somewhere too. I list the better resources I have found below. Most of them contain commercial material, none of which I or BH endorse(s). As usual when faced by this type of problem, I resort to YooChube, hence: How to slate a roof: layout ready for slating, Slating a roof, reference points The accompanying website There are many other sites: This one is Irish, very well edited, deals with the basics - some interesting comments too Setting out: perhaps a bit direct, but detailed images Setting out the lats: brief but to the point Wincing, I add this video because with the sound off and ignoring H+S its illustrates a 'normal' truss roof DIY Doctor often focuses on repair, but this is about tiling and battening as well as felting Construction Channel carries a series of time-lapse based videos about roofing at least four of them are here There's nowt like reading the comments under many of the videos: my God they can be bitchy: I thought it was only lecturers who were bitchy about colleagues' practice. I'll add to the list above time goes by. If you find a good support / teaching / learning resource about roofing and slating, please share it below. Ian1 point

-

1 point

-

Looking some guidance for the verges on my roof. I am hoping to use the Kytun dry verge trims which a number here have used already @dogman @Barney12 @JSHarris. I am trying to work out how these should be installed in relation to tile battens. We don't have any fascia and soffit with the hope being that we would render gable ends up to the underside of the kytun trim. Any installation guidance I have seen shows the trims installed on top of the tile battens, which is fine if then fitting a fascia board. In my case this would leave the gable walls with visible battens and then the tile trim. How should this be detailed to allow for rendering gables? Thanks in advance.1 point

-

Brett deepflow from Drainage Central is the cheapest I've found and do a discount over £300. Delivery is free and very quick too.1 point

-

1 point

-

0 points

-

0 points

This leaderboard is set to London/GMT+01:00

.thumb.jpg.3b6b15d3106e827438eb5379ca45d9f1.jpg)

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)