Leaderboard

Popular Content

Showing content with the highest reputation on 07/12/19 in all areas

-

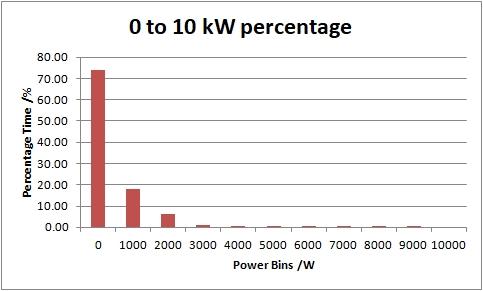

Nexgen heating– Desktop performance comparison with electric wet underfloor heating Nexgen ( @Clive Osborne ) claim in their advertising that their electric resistance heating system uses, quote: “around 55% less energy than a Water based system”. This desk top analysis seeks to examine that claim, using known data. Example used for comparison For simplicity, and because I have hard performance and heat loss data to hand, the house used for this comparison will be my own. This has a wet underfloor heating system, that covers about 85% of the floor area. It is an electrically powered system, so is a fair comparison with the electrically powered Nexgen heating system. In terms of energy efficiency, in the context of primary energy usage versus delivered heat energy output, our electrically heated wet underfloor heating system is comparable to using a gas boiler as the heat source, and slightly more efficient than if it used an oil fired boiler or LPG fired boiler. Primary energy efficiency factors can be found in the BRE definitions that are used in SAP (https://www.bre.co.uk/filelibrary/SAP/2012/Emission-and-primary-factors-2013-2027.pdf) and are: Mains gas = 1.28 Electricity = 3.28 For example, for a house heating system that consumes 1 kWh of energy at the point of entry of the energy source, then for mains gas that would be equivalent to 1.28 kWh of primary energy required, and for electricity it would be equivalent to 3.28 kWh of primary energy required. These ratios are roughly equivalent to cost, so mains gas is currently about 1/3rd the cost of electricity for any given amount of energy. I have a fairly accurate thermal model for the house used in this example. The key data are: Worst case heat loss (-10°C OAT, +21°C room temperature) = 1,672 W Underfloor heating floor surface temperature (for above conditions) = 23.2°C Heat loss to the underlying ground (ground temperature constant 8°C) = 136 W Basic efficiency of wet underfloor heating (ignoring energy source) = 91.87% Heating power required = 1.0885 * 1,672 = 1,820 W Heat source primary efficiency comparison The source of heat for this wet underfloor heating system is a Carrier air source heat pump, and with an outside temperature of -10°C and a flow temperature of 40°C this has a coefficient of performance of 2.7. This directly equates to an efficiency (in terms of electrical power in to heat power out) of 270%. If the heat source was a condensing gas boiler, then typically the efficiency would be about 88% for these operating conditions, perhaps slightly higher due to the low return temperature and high probability of full condensation heat recovery taking place. If the heat source was a direct electric resistance heating element, such as an electric boiler, then the efficiency would be extremely close to 100%. Applying the primary energy efficiency factors to these three fuel sources/heating types gives the following primary power equivalents for the specified conditions: Electricity, via ASHP = 1,820 W * (1/2.7) * 3.28 = 2,211 W Mains gas = 1,820 W * 1.136 * 1.28 = 2,646 W Electricity, direct resistance water heating = 1,820 * 3.28 = 5,970 W Heating system efficiency comparison In the Nexgen advertising material there is a specific efficiency claim, namely that the Nexgen electric resistance heating system uses “around 55% less energy than a Water based system”. If we take the Nexgen advertising claim at face value, and use this with the data from the known performance for the wet underfloor heating system in this example, then “around 55% less energy” implies that the Nexgen heating system only requires around 45% of the energy input for any given heat output. We know, from the data provided by Nexgen, that their heating elements are resistance heaters, and we also know that (ignoring any loss in the mains voltage to low voltage conversion system) that all resistance heaters have an efficiency of very close to 100% [1] . In the comparison below this upper efficiency limit of 100%[1] is used. If we compare the advertised performance of the Nexgen system, with the known performance of the wet underfloor heating system, then we get the following primary power figures for the example house heating requirement: Electricity, via Nexgen heaters = 1,672 W * 3.28 = 5,484 W Converting the primary power from all systems considered here gives the following relative efficiency comparison, in terms of primary power, with electricity via an ASHP being assumed to be 100% : Electricity, via ASHP and wet underfloor heating = 100% Mains gas, via condensing boiler and wet underfloor heating = 83.6% Nexgen heaters = 40.3% Electricity, via direct resistance heating and wet underfloor heating = 37% Conclusions Is the claim made by Nexgen that their heating system uses “around 55% less energy” supported by this evidence? The short answer is that their claim seems to be unrealistic, and very unlikely to be true. In this worked example, for a house that has wet underfloor heating and known heat loss characteristics, then, at best, the Nexgen heating system might be around 3.3% more efficient than direct electrically heated wet underfloor heating. It should be noted that very few wet underfloor heating systems use a direct electric boiler. A more realistic comparison would be with a mains gas heated underfloor heating system, as this is probably the most common arrangement for this type of heating. The Nexgen heating system is 37.2% less efficient than such a heating system. [1] The Nexgen efficiency claim seems to defy the laws of physics. We know that the Nexgen heating elements are of a fairly conventional resistance type, albeit using a non-metallic film as the element. All resistance heating elements, no matter what they are made from, behave in exactly the same way in terms of their efficiency in converting electrical input to heat output. The Nexgen claim amounts to that for an over-unity device, and such a device cannot exist, as it would contradict the First Law of Thermodynamics: https://en.wikipedia.org/wiki/First_law_of_thermodynamics Additionally, the Nexgen system operates at 24 V, so must include some form of voltage conversion unit. Any such unit will be less than 100% efficient, so there will be losses associated with that which reduce the overall system efficiency (unless the voltage conversion unit heat losses contribute to the room heating).4 points

-

I appreciate what you're saying, but there is a very clear, fundamental, principle here. To heat a given space, that has a known, fixed, heating requirement, to a defined temperature, requires a defined heat input. This cannot be changed, it is a fixed function, determined by the heat loss rate from the space. Ventilation rate is just one element of the total heat loss, so is included in the basic heating requirement; it has as much significance as the other forms of heat loss from the heated space. The form of heat input is irrelevant The time taken to heat the space is irrelevant, as we are dealing with a steady-state condition, not a dynamic one. It matters not whether the heat be entirely radiant, convective or conducted. The area of the heated surface is also irrelevant as far as efficiency is concerned. All that matters is the amount of electrical power required in order to provide the required heating power into the space, to balance the heat loss rate. As we live in a self-build passive house, that I designed and thermally modelled, I understand the challenges of managing heat loss, heat recovery ventilation, ensuring that the decrement delay for the external structure is adequately long to ensure good thermal stability, and the heating and cooling challenges of such a build. I look forward to seeing your energy efficiency data in due course.2 points

-

Took me ages to find out the difference between an oral and anal thermometer. It is the taste! Jeremy is going to post up something really serious and sciency about efficiencies soon, hope I have not put people off.2 points

-

I'm part way through doing a desk top study, comparing the efficiency claims made by Nexgen in their advertising, using a specific, known, whole house heating requirement, using hard data for primary energy efficiency and local system conversion efficiency. It'll probably take me an hour or so, as I want to be 100% certain that the data I'm using is valid.2 points

-

1 point

-

A hinged bucket on wheels then. Now, I lived in France and was joined by my Belgium cousin for a few days. He was always amazed how well I got on with the local girls and wanted to know my secret. I said it was simple, I just put a potato down my Speedos. The next day, he came up to me and said that he had been trying the potato trick but he was just laughed at. I said 'You need to put the potato in the front of your Speedos'.1 point

-

According to herindoors probability of any sort of intimacy and warm body radiation theory you stand no chance with a pasty in your pants and you must not neglect the latency corollary that clearly defines the quarantine period, according to the inverse inverse cube law of time since any sort of pasty in the pants. There is considerable research, sadly now rather old, start HERE, that examines the nature of containment for pasty products - including what will happen to your collar, the screw extruder required, the need for a flat bottom and the probable effects on the container design. Along with the challenges to ones relationships the laws of physics also apply the the pasty phase, but, one guesses, that is a whole nother conversation. (Sorry Peter)1 point

-

Yes - it’s called Newton’s Law of Thermodynamics .... Just to advise, until there is some solid technical and accredited research shown by @Clive Osborne regarding Nexgen then please can we leave this thread as is.1 point

-

@Clive Osborne, can you please just answer the question asked about efficiency. The laws of physics are pretty well proven. If you take a house with a known heat loss, under defined conditions, then it will require a defined amount of heating power in order to maintain a given temperature differential. If your heating system requires less electrical input power in order to provide that heating power, then please give the EXACT mechanism by which that can happen, with supporting evidence. You seem to be exceptionally adept at obfuscation, referring to irrelevant control and maintenance cost aspects in order to avoid answering the fundamental question about efficiency. Some may view that as being suspicious, but I'd like to give you the benefit of the doubt. Your advertising is clear, it states unequivocally that your heating system uses, quote, “around 55% less energy than a Water based system”. I have shown very clearly that this doesn't seem to be the case. The onus is on you to prove that my analysis is flawed. Why not just post the energy efficiency rating for your system? A simple photo of the energy efficiency label would be a start. By way of background, before I retired I was a senior principal scientist, my first degree was in physical chemistry, my second was physics with electrical engineering, my post-grad training was in aerodynamics and aircraft instrumentation. I am, therefore, reasonably well-qualified to try to understand the way in which an electrical heating system may perform.1 point

-

I haven't used it for donkeys years, but it did what it was supposed to last time I tried it.1 point

-

So just how are these Nexgene panels trying to work. If you are just trying to heat a room to a set temperature, then it does not matter two hoots what form of electric heater it is, it will take the same number of KWh of heat to heat the room to the set temperature so no form of electric heater will be cheaper than the next one. Or are you trying to keep the room and it's contents at a lower temperature, and just heat the people in the room by radiant heat, so they feel warm, even though the room isn't, as in the old cold church example previously mentioned? If that is what you are trying to achieve, then why don't you clearly state that, and then people would believe lower running cost claims?1 point

-

You can just about braze with ordinary butane/propane mix, as used in cheap plumbing-type blow torches, but it's right up at the upper end of what one of those will do, especially on anything other than small parts. Silver solder is a great deal easier, as long as the parts are clean, and doesn't need as much heat as brazing. The downside of silver solder is the cost of the stuff, but for small jobs it's not too bad. A MAPP gas torch will braze pretty easily, but you're then swapping the high cost of silver solder for the high cost of gas.1 point

-

1 point

-

Windows are almost certain custom goods, and so are excluded from this right.1 point

-

A further one is that if you ordered online, you have 30 days to return the goods as of legal right. No idea how that works out with a bust company, though, and for goods that are not here yet. Ferdinand1 point

-

Yup, a tea20, known as a grey furgy, I have another one for sale if anyone is interested? I picked up the tractor and topper for £1500. You can still get every spare part fir these old tractors so very maintainable.1 point

-

1 point

-

I do not see how Development can start whilst you only have Outline Planning Permission, by definition. I do not think that you can start development in law without Detailed PP. Outline is about the principle of development. But this is the sort of area where it may all turn out to be muddy water, and I can well see someone trying to argue that you had started because you did and therefore xyz, even if it is not allowed to happen. I would definitely be wanting a Council Confirmation in writing to cover my back.1 point

-

1 point

-

Hi Mark. I believe the local authority has a legal duty to fund certain adaptations of your house if it costs less than £1000. ’Building Regs’ sounds like a bit of a red herring, though that could be the convenient standard your HA has adopted as policy. This rather comprehensive info sheet from Age UK covers it I think. You will need one or several pots of tea to read it ... 28 pages. Then talk to them, and you may get a visit from an Occupational Therapist. I might anticipate attempted buck-passing between the LA and the HA. Though it is Age UK, disability is covered too, which should ... by the sound of it ... apply in some way to you. The key is to pay attention to what categories of need they have to meet, and place yourself in those categories. They like to do things like keep you out of services requiring more extensive and expensive support. I suggest checking in whether it is means tested. Though we did not qualify due to savings etc, they were still happy to come out and advise us before I installed an Accessible Bathroom for an elderly relative. .Ramps are specifically mentioned in I think 3.2 . https://www.ageuk.org.uk/globalassets/age-uk/documents/factsheets/fs42_disability_equipment_and_home_adaptations_fcs.pdf You can also talk to the Disabled Living Foundation, and other orgs. Age UK may also have a directory of local tradesmen and installers who MAY be pre-approved in some way. Ask. HTH Ferdinand1 point

-

We're getting an electric opening skylight and flat roof-lights, primarily because they are otherwise too hard to reach. One of the supplier also suggested, unprompted, adding a "Hautau Primat 190 electric opener" to the kitchen window too, again because being high over the sink it'll be tricky to reach. Adds about £1000 to the cost. But this does open the possibility of automated overnight stack venting in the summer. So I asked a very similar question over here and @jack made the very good point that key thing overnight is cooling the bedrooms anyway, so thinking about fitted fly screens is more useful than automated opening, in his experience, for those rooms1 point

-

I have used : “fine mesh metals “ twice in the past. Decent stuff. When I priced up buying my own sheets of weld mesh it worked out more expensive than buying made Gabon’s from these guys. They do come flat packed and don’t bother with the 1m coil closers as they look naff.1 point

-

For another possible example, I tend to pay about £30-40 per barrel for anti snap anti bump keyed-alike locks ordered together from a local hardware shop. These are for rentals. Ferdinand1 point

-

1 point

-

1 point

-

Had a petrol Flymo for several years, was as tough as old boots, which is what you need if you don't want to cut your big toe off.1 point

-

Had a couple of petrol flymos over the years. They're heavier to handle than an electric one and don't give the shortest neatest ever cut. But they will tackle anything you can get them to plough into.1 point

-

As there appears to be some issues with clarity of information on this thread could you just confirm that you put the pasty in your pants? Do you have any efficiency calcs?1 point

-

Same thing happened to us when we built our garage many years ago, the steels were incorrectly measured, I realised the moment I saw them (and I can count to 4 when only 3 turned up....). Someone I know who did a self built recommended getting the steels cut on site because measuring with accuracy is so difficult, which saved him an awful lot of money and headache and I think I would do this in future. There are a lot of unforeseen circumstances with building, right right from the first pencil chewing and one bit of legislation seems to fight another, so there are no straight answers in how the solutions are managed. BC are used to working with builders and architects to solve problems, so you will find a way through.1 point

-

1 point

-

@temp I envy you if your painting smooth render. I'm painting our roughcast and it's almost like applying an additional render layer in it self. We gone with a paint that's a bit more expensive and made on Skye. We have tried where possible during the build to help local businesses. http://www.isleofskyepaintcompany.co.uk/1 point

-

OSB over the joists, battens on top following the joists, UFH in between filled with biscuit mix1 point

-

1 point

-

Our 110m2 basement was £1000/m2 before fit out (plastering, flooring, electrics, doors etc) and that included demolition of existing and water, power, telco, drainage to the plot. They key is to avoid any contractor with basement in their title. it's just a RC box in the ground and any competent groundworker can build one (they usually sub out the concrete works to a specialised crew). These crews are building underground car parks, etc all day long for developers so you're nothing special. SE will spec the necessary waterproofing requirements, if ground water is below the basement then a land drain to the perimeter and warrantied waterproof concrete (e.g. Sika) will suffice - no need for membranes or sumps & pumps. Site access and space will also impact cost as will the muckaway depending on whats in the ground ) clay, gravel, chalk etc. It's a great use of space on site and the best rooms you will have in your house - cool in summer and warm in winter. No heating required if you build off an EPS slab and clad external walls in EPS. Ours have 2m wide high level windows in GRP lightwells and are as bright and sunny as any room in the house.1 point

-

I've been tempted to make a new perspex cover, TBH, as being able to see the whole of the inside of the controller would allow all the LEDs on the circuit board to be seen. It seems a bit daft to have half a dozen status LEDs inside the box where they can't be viewed.1 point

-

My Father chopped some toes off with his petrol Flymo. Just for clarity, if you chop your big toe off, you only temporarily loose your balance.0 points

-

0 points

-

At least I now know my SE isn't the only crap one out there lol I've been dealing with his mistakes for the last 5 months and always does my head in when he sends revised plans which still have such obvious mistakes. I would honestly say it's been the worst part of my self build0 points

-

yes i am feeling that way too i have spent a lot of time measuring up how ever there is in my opinion now an issue with what steel is going to or even possible to fit above doors because all beams are connected would mean they all are about 2100 above finished floor level i think that's to low its only at this stage i noticed incorrect details for position of plate and a size stated at 8mm when its 12mm these professionals have let us down you put a lot of faith in people and set yourself up for a lot of disappointment thanks for your time pocster i am worried that i will have to start again with new so called professionals because i don't think it will get past BC to fit another steel under RHS beam No 4 cheers0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)