Leaderboard

Popular Content

Showing content with the highest reputation on 06/16/19 in all areas

-

Quite the opposite, I did my BSc final year project in solar thermal. Since then, the world has moved on and in my opinion, PV is the way forward for domestic use.2 points

-

If I did my heating system again I'd put ufh upstairs as well as down stairs. We've put in rads upstairs - no complaints but they weren't any cheaper and the rooms would be more flexibly without rads on walls.1 point

-

Do you know how poisonous Ethylene Glycol is ..????!!! There are some very very good reasons why you don’t use car antifreeze in solar systems - the big one being that if it leaks in the tank (which is entirely possible) then you contaminate the whole of the water system with something that can put you in hospital. It’s dangerous ok ..?? As in the next person who owns your system could end up in hospital because you saved £50 on antifreeze...!! Solar rated glycol may be expensive but it’s because it’s Propylene Glycol based. It’s not poisonous. It’s doing what it’s designed to do - not some half arsed replacement that’s cheap but has great big poison warnings on it ..!!!1 point

-

1 point

-

Well... Not for the regs no, it is totally ridiculous that British regulatory material isn't free - if they want to write regs and have people adhere to them they ought to be available to all F.O.C. on a government website. I spend £1000's a year on subscriptions to places such as BSOL/BSI for access to British Sandards docs etc. and have paper copies in our office. I don't know the source of the version I pasted above because I had it saved into a text file from a post from DIYnot when someone asked for details on cable routes. It's very handy to have those sections at the ready for the very situation that arose above. Interestingly, British Law is available to all on a government site.1 point

-

followed by 10 lines of text about how complicated it is. It is not just control systems, there are accumulators, pressure valves, safety cutouts, replacing fluids. When a car boils over, you can just fill it with some water, but you really need to fill it with anti-freeze as well, and find out why it has overheated, which could be, in no particular order: broken hose faulty waterpump faulty thermostat internally blocked radiator externally blocked radiator failed head gasket broken fan broken fan motor broken fan belt and a few more things. The above are some of the reasons I think PV is a lot simpler and reliable.1 point

-

But if you do both, you're paying for two complete sets of infrastructure, with increased complexity of control systems, increased maintenance costs, and increased risk of something going wrong. I think you're better just sticking to one technology.1 point

-

1 point

-

The golden rule, never to be broken, is to turn off the power and then always check to make sure that the circuits you intend to work on are really dead. It's not that unusual to find that things are wrongly wired, or mislabelled, so you can think the power is off when in reality it isn't, hence the need to always check (with a meter, rather than one of those supposedly voltage indicating things). When measuring voltages on circuits that are disconnected it's not unusual to find that a meter shows a low voltage on the wires. This is usually just an induced voltage from adjacent cables, and is really just a artefact from using a high impedance voltage measuring device. Ideally, lock off the isolating switch whilst you're working, in case anyone comes along and turns the power back on, not realising you're working on it. I have a small lock that fits over an isolator switch to prevent this.1 point

-

1 point

-

That's a pet hate of mine, that most LED floodlights now come with a flying lead, forcing you to fix a waterproof junction box to the wall, What was wrong with the old idea of a terminal box on the back of the light fitting?1 point

-

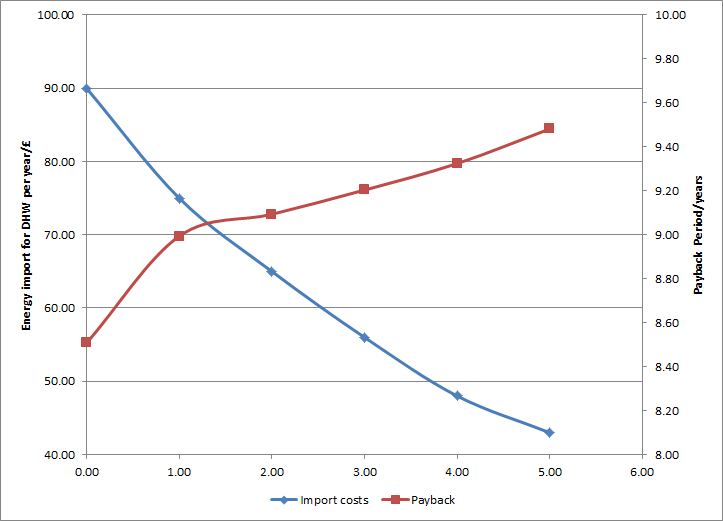

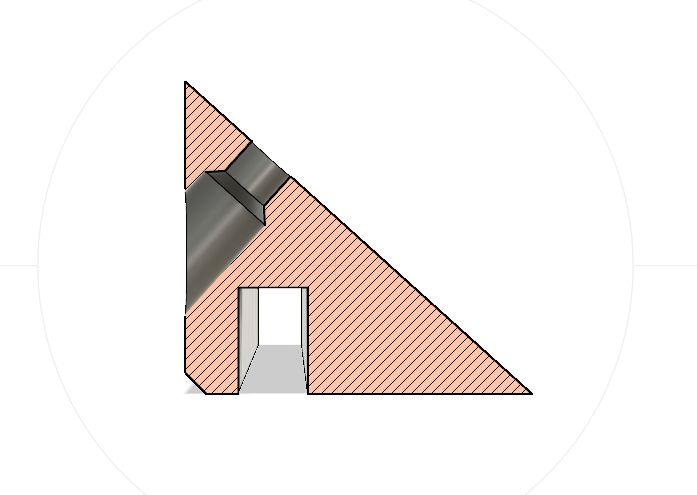

Getting back to the original topic (the diversions have been very interesting and insightful, but I have to appear vaguely sane when I tell my long suffering architect what I've decided to do next week) The latest version of my modelling tool has led me to the following conclusions: * The difference between PV and ETs is actually quite small when just considering DHW. * If there is a limit on roof space (like my current house - and that's why I'm building another) then ETs are probably the better solution for DHW - ETs are more efficient per m^2, until the store is full. * It's not just the cost of panels and ETs (obvious, I know, but let's follow the logic). If PV (or ETs) are going to be there anyway, then increasing the amount of either is a much smaller delta cost. So there's a big saving when one or other technology achieves zero presence. (and a nice saving in complexity) * I can't remove all the PV - it makes no sense at all from any point of view. So it looks like ETs are not going to be part of my build after all. A chart to justify my position. The X axis represents the number of 3.9m^2 ET assemblies on the roof. The remainder of the roof is used for PV. The roof area is held constant, and the calculations account for quantization of panels. (The numbers differ from previous iterations because I included another kW or so of PV on the SE facing roof having looked at tree heights - and my chainsaw - today) So as can be seen, adding ETs reduces the import costs at every level, even when a lot of the energy collected in summer is waste heat that has no practical use until I build the swimming pool. The best payback however comes from the simple PV system primarily because of the reduction in infrastructure and each addition of a block of ETs always extends the payback time, with the extensions getting gradually larger as the waste heat becomes ever more significant.1 point

-

Thats just a lack of understanding on thermal bridging and the architect should know better. If he’s making this error, what others are being made.1 point

-

UFH would be better in zones where it doesn’t cross the boundary but you use conduit sleeves where it has to and that allows slight movement. Casting the whole ground floor as a single slab, where half is a new structure, half is old could be a real challenge unless you reinforce the crap out of it.1 point

-

Apart from the fact that there are some people that will just bodge anything together, I believe that another reason is that it's just so damned hard for a lot of people to find out how to DIY something safely. There's loads of information around on stuff like plumbing, but there's a really strange attitude amongst some when it comes to electrical installation work. Sure the best answer is always to get a competent and suitably qualified electrician to do the work, but if someone can't afford that, then the next best thing is to make sure that all the information needed to be able to do a safe DIY job is readily available. Yes, this means that often an installation won't be 100% tested as it should be, as the test gear needed is beyond the means of many DIY'ers on a budget, but it's really not hard to just do a fairly straightforward job, like running power to a shed, safely, if the information on how to do it is made readily available. I know this probably pisses off some in the trade, but my view has always been that if someone can't afford an electrician then they are probably just going to DIY the job anyway. Better that someone intent on DIY has access to information to do a reasonable job, than have the situation we have now where some people do crap work out of ignorance. It also seems that it's not just DIY'ers that are doing some really dodgy electrical installation work. YouTube is littered with videos by competent electricians highlighting really dodgy stuff that has been done by incompetent members of one or other of the Part P cartels. What really gets my goat is that after getting a degree I had to sit CEI Part 2 in order to join the IEE (as it was back in 1975). Now someone that's done a 5 week Part P course can be a "competent" person and IET member, yet they may well not know their arse from their elbow. How any short course can produce someone of equal competence to someone that's served their time I just don't know.1 point

-

I cant agree with you there. I think it is a case of lack of understanding and the architect just doing what they have always one. Understanding and importance of thermal bridging has moved on and perhaps the continued proffessional development hasnt kept up.If you go to the effort of drawing a section you don't do it wrong because you are busy, it is because you don't know the right way to do it. It shouldnt be your job as a lay person to check an architects details, that is the whole point of employing one. I have been told by a number of architects that my house looks German because the windows are set back deep from the face of the cladding. It isn't German it is just detailed properly for a well insulated house with no thermal bridging.1 point

-

I've long felt that the wiring regs should be freely available, in the same way as the building regs are. We have the incredibly daft situation (in England and Wales) where Part P is freely available (here: https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/441872/BR_PDF_AD_P_2013.pdf ) and yet BS7671 is not, it costs an arm and a leg to buy. This is plainly ludicrous, as Part P is pretty meaningless in places unless the reader has a copy of BS7671 to hand.1 point

-

Yes, it's copyright, but there is a fair dealing provision, and that provision allows for sections to be copied where such copying may inform and educate, amongst other reasons. I see no problem with this, it should be actively encouraged, as the very last thing we need is more secrecy and control around safe practice. We have enough of that from the dubious Part P cartels trying to profit from giving an illusion of safety. If anyone wants chapter and verse on what is allowable under fair dealing, then this is from the government website: https://www.gov.uk/guidance/exceptions-to-copyright And, just to be 100% clear, as an IET member I have paid for copies of 7671, the OSG etc, so whenever I've quoted excerpts from those documents I've done so from documents I have purchased, not "ripped off from dodgy PDF" stuff.1 point

-

I must say it is quite odd that the regulations text is copyrighted. Vaguely remember this was discussed before.1 point

-

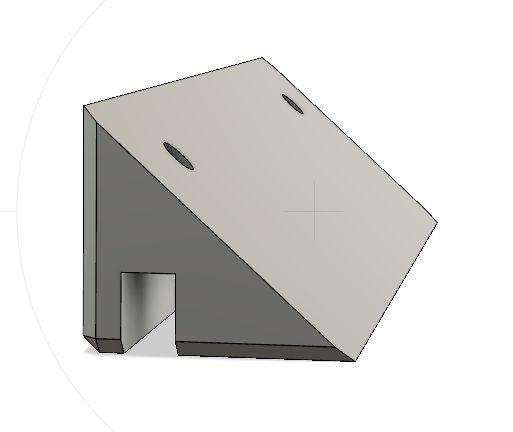

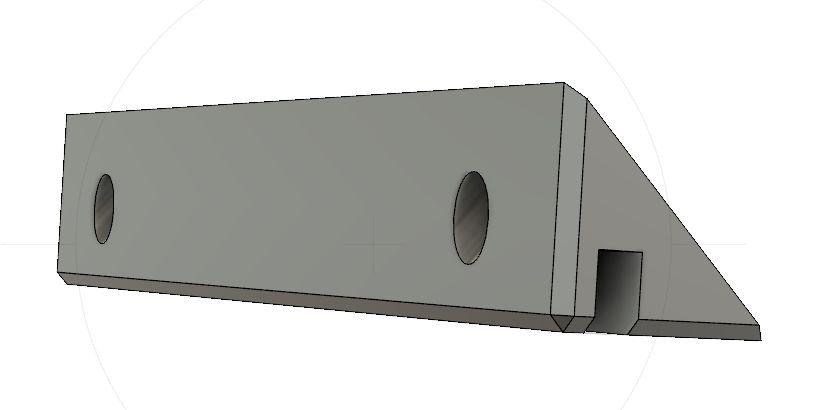

Just had a quick 15min play around with Fusion 360 over a cup of tea. At 150mm long and 25% infill Cura says it needs about 12m of filament which isn't much but more than a 10m sample. Holes might be better going up from underneath. Anyway have a think. I'm painting the church hall next door most of tomorrow.1 point

-

1 point

-

To neaten things up, if you're really anal, you can get carriers to save the Wagos floating about. Meant to clip to a DIN rail but I've screwed them to other things: https://www.connexbox.com/din-rail-mounted-connector-carrier-5pcs.html You also get their bigger connection boxes: https://www.connexbox.com/wagobox-xl-junction-box-in-grey-for-use-with-wago-2273-and-221-terminals.html Even a Wago wiring centre.1 point

-

If dimensions are tight then just be aware that celotex varies - I've used 140mm in our frame BUT in some areas the celotex sticks out from the frame - I've measured them and they are more than 140mm. Next time I will order it a wee bit thinner to save on grief. It may not affect you but worth noting just in case.1 point

-

Celotex have a calculator on their website. If you use 150mm of XR4000 and PL4025 (37.5mm thick) you get a U-Value of 0.15 for the roof. This is the minimum level in the Scottish building regs for a new build house or an extension (unless the extension is to a house with wall U-value >0.7 and roof >0.25 then it has to be 0.11 or better, but your original spec wouldn't have achieved this so I guess this does not apply) If you use 150mm of XR4000 and PL404 you get a U-value of 0.13. I suspect either would be acceptable, it depends how low a U-value you want, there is maybe a minimum target listed on the spec. It won't make an enormous difference to your heating bills.1 point

-

Celotex withdrew the whole 5000 range of products following Grenfell. A shame as they were better than standard foil backed PIR. You can probably use any PIR in place as the u values are not that different. You could use a thicker board on the inside of the joists to compensate if required.1 point

-

You get about a 1/3 m out of the pump lines when they clean them through @Adam2, a good idea is to have someplace to put it, shutter up a box for the chicken coup to sit on or make a base for the wheelie bins, I have 3 posts that hold up our carport that sit on concrete pads, so pre dug some very rough holes ready for the overspill. You need to nominate a washdown area for the pump guy, plastic on the floor with a sheet of ply on top so it’s easy to shovel up the mess. Its all relatively straight forward with a bit of planning.1 point

-

Bang on schedule the raft components arrived on Monday morning. We knew it would be quite a big volume of material on a small site and getting it unloaded and put somewhere it would not get damaged or need moving was s little tricky. JUB insisted on sending the raft on pallets. Our builder was not that impressed with this as unloading the lory requires a folk lift which is something we don't have on site. So we had to hire a set of folks for the digger. With the raft safely stored at the back of the plot the work to prepare the site progressed. The drainage had been marked in the site setting out exercise along with electrical and water ducting. Trying to keep raft punctures to a minimum but also allow for future needs was a concern. In the end we kept it to a minimum with electrical conduit for the rain and foul water pumps and two for water. Along with the raft we received a letter from our neighbours complaining that I had put our water meter box on their garden wall. In retrospect a valid complaint, it was one of those decisions made in expediency without enough thought. Our water supplier Portsmouth Water will now only make new connection when an above ground water meter box is installed. I duly bought the one box they permit (so much for choice), water pipe and water conduit. Not having a house on which to mount the box, I made the required connections and left the box mobile so it could be put in place in due course. At which point I called in the Portsmouth Water, regrettably they said they could not make the connection until the box was in situ. Having explained our situation and the need to get water on the site it was suggested I could mount the box on the wall by our property. At this stage I should have thought about it rather than simply get on with it, my mistake entirely. The wall it outside my boundary, by millimetres true , but still NOT ours. Our neighbours were not impressed so Monday was spent moving the box and apologising to my neighbours. I shuttered and cast concrete into the wall footings and backfilled with type 1 MOT to repair the wall. Having done this I then putting in two concrete posts 200mm inside our boundary and mounting the water meter box on them. This is what I should have done in the first place. Slightly different subject, the Groundbreaker Water box, this is the only box that Portsmouth Water will connect to. At around the £150 mark it's a pretty hideous piece of kit both aesthetically and in product design terms for installation. Given their current monopoly and the fact that all new connections will require one it made me consider looking into producing an alternative. A swift kicking from the boss and I was reminded to get on with the house...maybe later once the house is done. . With the drainage in place the MOT type 1 sub base was spread over the raft area, levelled and compacted. Our builders ICF-homes did this with considerable care and we ended up with a good surface to spread the sand layer which was again compacted before putting down the membrane. Our structural engineers had specified a Radon barrier, we ended up using a standard plastic DPM as Radon is not a problem in our area. The DPM gets glued to the side of the raft sealing it and providing some additional protection for the polystyrene. . With the membrane down the work of setting out the raft. The perimeter is all keyed together It took a while to get the corners located precisely but once this was done the raft slotted together very well with a really solid interlock. The raft was then completed by adding the rebar, four layers around the perimeter. All in all a lot of steel, Pat and I spent most of Saturday morning helping get the rebar in place and wire tying it to make is solid before the concrete pour. Our raft is now complete and this week the surface water drainage will go in. Along with the problem with the water meter box our neighbours also bought up the "Party Wall act". Doing a self build is nothing if not educational. The act came into law following problems with basement excavations in London. It dictates that excavations in close proximity to your neighbours 0-6M have to be notified and agreed. In our case we were within notifiable distance, but fortunately were not excavating to a notifiable depth. Our builders were not familiar with the act and no mention had been made by building controls. The act did effect our other neighbours and I contacted them letting them know what work has been done. Fortunately all the excavations were made and backfilled without incident. Hoping for a less eventful week to allow us to regroup before our first block delivery next Monday. As this is the first build for JUB in the UK the factory are sending someone on site to assist with the build and wall bracing. It's very positive to see the house taking shape, we have our EPC which suggests we should require in the region of 68wats/K to heat the house which is great, but we still only come out as a "B" energy rating! the rating system is bonkers.1 point

-

Absolutely spend time getting what you believe through research is the right mix - choose a mix company that will let you speak to the lab (rather than just the sames person) and get a sense of whether they are reputable. But when a jeager full of concrete turns up - unless it's like water or treacle, I don't think there is a huge amount of merit in doing detail slump tests - let's say it's a bit thick - they'll put up to 50litres water in it (answer to first point). If it's too high a slump you'll need to make a call - it's going to go in no problem and will compact round every nook and cranny - and as long as it's not going down more than say 3m will be fine. You're going to give yourself some serious stress trying to turn round a truck full of concrete and any others that are following at 30mins intervals and already en-route from the batching plant. If you want 80 slump and you measure it at 110 - it's not the end of the world. Some companies will be fine with a slump test but it's going to take up time and as I say - if you don't like the results... For ICF, yes you need to be more particular, but Polarwall is pretty robust stuff. And I think Durisol has a far higher slump recommendation anyway. I know @recoveringacademicand @Vijay you're probably grimacing and I don't mean to be flippant - I'm not - I'm a pragmatist at heart but also having done two pours I've realised I fretted too much about the mix when it turned up - it's not the Empire State building and the structural loads are in the grand scheme of it, miniscule. Vijay - Alan always seems to relaxed about concrete but that's because he's done it so often - get the mix specified right and a reputable company to mix and try not to worry too much about whether they mix it right. The problem I had with the garage floor mix was that the contractor hadn't paid enough attention to the mix specification and it got lost in translation - they delivered what they were supposed to as opposed to making an arse of the mix. . As important, if not more, it planning exactly how you will place it - where you will start, how high, where a jeager should take you two, how many you need, where the excess will go, how they will move about the scaffolding, your burst control strategy, tracking the other trucks, where they will stop to off load, how you can stop any excess ending up on the roadside ( @Vijay) - if the trucks cannot get right on site, I would recommend in your case getting cheap ply/osb sheets and placing them where you want the tail of the truck to be, and mark out in spray where they should park - the last thing you want is any overspill or a lazy driver washing down onto the street!), how ) @recoveringacademic) you will get the concrete it - will you use the nozzle or make up something that avoids spillage down the walls?, how will you finish the wallhead - do you need to leave it rough of smooth, how will you place your wallplates if using? Btw - if you turn away the concrete there's a chance you'll not get that batch remade up depending on what time of day. When I under ordered for the walls they told me at first they couldn't get it batched that day as all the trucks were now out, but thankfully they sorted it somehow and got a final 3m3 up to us to finish off. I suppose all I'm saying is get the right mix specified but be pragmatic when it turns up.1 point

-

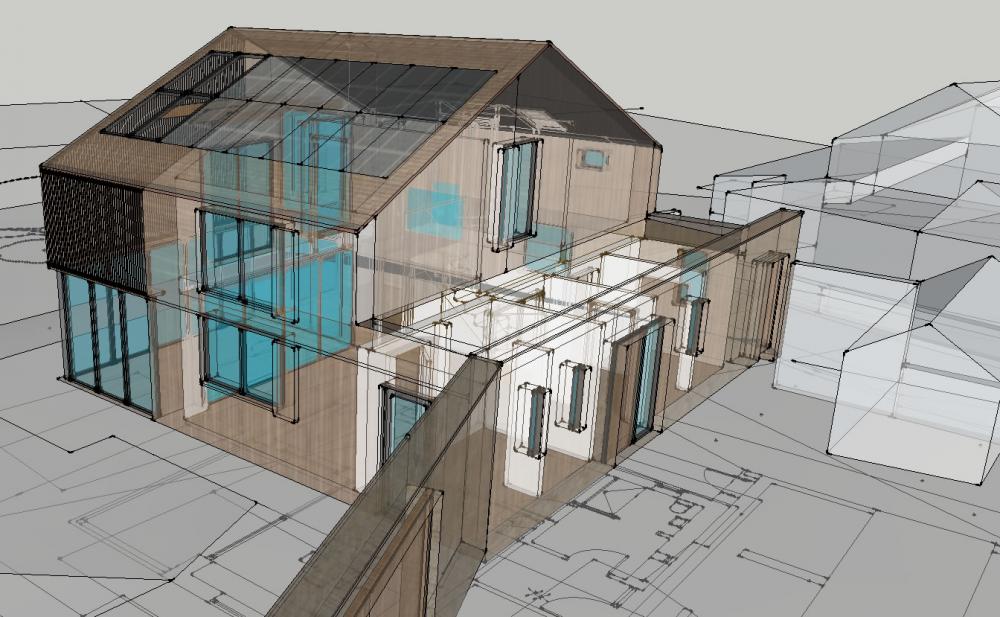

This week has been hard work, but for all that, there's a lot to show for it. This post is an update - much more detail to follow when things have settled down in a week or so. First of all, what's the end in mind? Have a look at this. Its roughly 10 by 10 with an internal garden (on the left hand side - the dark area is open boarding to allow air to circulate freely) The Piggery (of which more later) is the small (wire-frame image) building on the right of the image. We are using an ICF called Durisol. This shot shows a corner detail with our (as yet roofless) Piggery in the background. The blue marks show where the blocks were cut to size: and where the gap is a little bigger than finger width. A little foam was injected into those gaps. Here's a more general shot taken at about mid morning. As yet all hand laid, dry, no concrete. You can see the main contractor (Dan) framed by the the front door framework. The house fairly shot up... Here's where we'd got to by Wednesday And here's where we are today. A couple more window gaps to make, the final pour of concrete and that'll be it for the main build. Everyone walking past says something like 'Where did that come from then?' I always take the time to talk to anyone who expresses an interest. It's important to explain to locals what's happening. There's a very big anti-build atmosphere centered on the Local Plan - it has identified the A6 corridor (100 meters away) as the main area on which to achieve Wyre Borough's housing target. Why the A6? It's a little higher than the local flood plain - ie. the area west of the M6, but East of Blackpool. Lot's of development has already taken place on known flood plain area round here; and justifiably, the LPA is taking stick for it. I'm knackered. Lot's of challenges, lots of hard work, lots of satisfaction. It didn't all go smoothly. Next post, much more detail and an analysis of what issues we faced and how we solved them. The good bit? Needing to buy an SDS+ drill. (The term 'need' is correctly applied in this instance @Ferdinand )1 point

-

All of our services came up through our slab. No pipes or ducts embedded in the ICF block at all. We do now have the flow and return pipes to the ASHP, and two electric cables (cable to heat pump, cable for outside light) going through the wall but these were cored through long after the pour. We didn't for example actually decide which heat pump and therefore know pipe centres etc until a couple of months after the pour. The biggest challenge with ICF is getting the concrete to flow properly without it being too wet. The use of a vibrating poker greatly assists in this process but if the space which the concrete has to flow is restricted or partially blocked, you may well find you end up with pockets of air in your wall.1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)