Leaderboard

Popular Content

Showing content with the highest reputation on 04/07/19 in all areas

-

Exciting weekend for us, the scaffolders dismantled all of the scaffolding on the house and garage, finishing at lunchtime yesterday. Our first view of the house as it is (mostly) supposed to look. Interesting downpipe detail at the moment... The groundworkers were back on site yesterday reviewing the long list of external work still to do, including another retaining wall to keep the drive away from the house.7 points

-

I'm Roger and we have just secured an option to purchase a plot in East Lancs. We foresee some issues with planning as it is outside the urban boundary, so fingers crossed. This is our second self-build: we are leaving the first after 35 years to down size but only moving 150m. Joined the site to get up to speed with latest materials and methods.3 points

-

2 points

-

We have metal boxes throughout - my electrician was damning of plastic backboxes, but I don't know whether he'd tried the Appleby ones mentioned by @ProDave One thing I did that made things a lot easier was to knock up a jig: The front piece is held against the front face of the studs (the nearer stud is omitted for clarity), and the cut-to-length noggin dropped into place and pulled forward against the spacer. This ensures the noggin is installed square. Optionally, you can add a bit of wood to the bottom to rest on the floor or base of the studwork. Saves you holding the jig in place while you install the noggin, and ensures consistent heights without the need for a measuring tape.2 points

-

Quite ! Perhaps though what the lenders perceive as a risk may be in fact be somewhat illusory and just born of them being risk averse ? You'd hope above all else that compliance with the building regs/warrant system would leave any build impervious to weather for as long as is required - all other things being equal. As i'm just about to decide on which way to go it would be nice to get some more clarity on the issue than i have right now though.1 point

-

Hi Lizzie, i got the impression that the reluctance was nationwide. There was no suggestion that mortgage lending wasn't forthcoming but just that a sizeable proportion of lenders excluded full timber without masonry. That said though, as Thedreamer pointed out, the number of lenders is less in Scotland so the effect may be even more noticeable (i'm located in the Cairngorms). So would that suggest there is an impression that timber only is less impervious to water ingress ?1 point

-

The traditional practise in Scotland if building with a timber frame is once the structure is erected a single layer of blockwork goes up and this then has render applied. This is because of the wild weather we have in Scotland. Our build on Skye has a mixture of blockwork and timber cladding. Seems a bit of a outdated approach by the bank as a lot of self builds are 100% timber clad or use alternative methods as the exterior skin. Unfortunately the number of lenders are limited in Scotland and less for the Highlands and Islands.1 point

-

FWIW, I've just checked, and my uPVC garage door and frame is anthracite, and cost £320 inc VAT. It's nice and substantial, and has now been in for nearly 5 years, with no sign of any degradation.1 point

-

@Besidethewye my plant room is approx 2m x 1.5m. I have large hot water tank, ufh manifolds, mains gas boiler, mvhr, a wall of drivers for lighting, a data cab and god only knows what else....they place is a mystery to me! Not one single pipe is lagged in anyway at all. I have an MVHR extract in there too. It was as hot as hades in there and that transferred to the utility room next door, couldnt get it below 26 on a cool day. My MVHr and UFH were not set up properly and this was exacerbating it. The boiler was firing almost continuously (large gas bills). Now I have those things functioning better it has improved but it is still very warm in there.1 point

-

In the past steel doors from AJ Doors have been recommended as being secure and reasonable for both internal and external doors in garages, as have Lathams. A J seem to have folded into Latham. Lathams: https://www.lathamssteeldoors.co.uk/ You want a powder coated one. F1 point

-

Yes it’s amazing how prices go up We keep hearing about ceiling prices But it doesn’t seem to apply for a one off One simalar to ours sold for 720 It was built in the 80 s The chap plans to spend a whopping 200 Nice area fantastic house But it will be a long time before it’s worth a million But will it ? I suppose houses are worth what someone wants to pay A lot of wealthy people out there I was looking online at the company that specialises in second hand high end kitchens The amount that people have paid only to be taken out twelve months later1 point

-

Can’t understand why you all want to squeeze into England, as Billy Connolly once said come to Scotland there’s nobody there?1 point

-

1 point

-

I have a steel staircase construction book that may help you. You have a pm.1 point

-

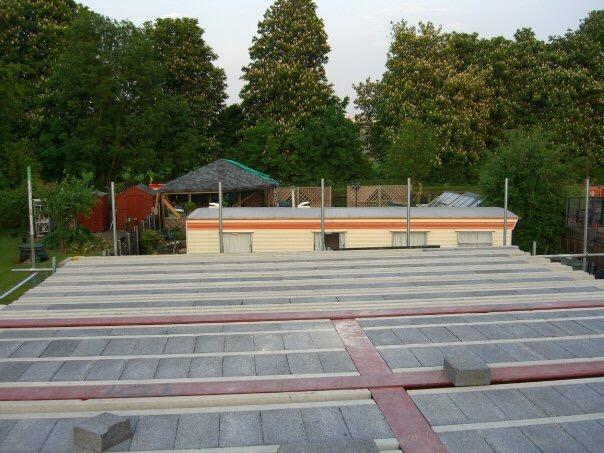

Some of the hollowcore suppliers have span tables on their website which may help. I sent my planning drawings with some additional notes out to 2 if them to get initial ideas on cost. But having read the above posts will check with the SE on deflection. Is it beneficial to use some mesh in the screed over hollowcore to help reduce any deflection?1 point

-

One thing to remember with block and beam is that the dead load is pretty high, due to its inherently high mass. A lighter floor build up may well end up being stiffer, just because the total load (dead and live loads) may well be a fair bit lower, so the overall deflection will be lower for a given area moment of inertia of any support beams/joists.1 point

-

It is definitely not solid. I would suggest going to a house with similar specifications of floor before committing yourself1 point

-

Our last bedroom was over 6m across and we had block and beam floor. The spec came back to triple beam per one row of blocks. The floor still moved more than I felt comfortable with. The kitchen was underneath and it was one of the main reasons not to have an extractor hanging from the ceiling over the peninsular where the hob was - I didn’t want any more weight on the floor. If I’d have realised what the flex was going to be like, I would have asked the SE for more steel which I would presume would fix the problem.1 point

-

i've just put a 6350mm span in with double beams and am shocked by the amont of movement in them. had i known how much deflection they would have, i would have put in a dwarf wall and halved the span.1 point

-

U value 0.15 so not bad, but won't that have a very short decrement delay so likely to get very hot in summer?1 point

-

Sound, and particularly impact noise. It's something I find infuriating. There's definitely a cost implication as you still need a fully boarded floor to support the screed. So you need to add the cost of the screed to the cost of a standard upstairs floor. Just did a quick search that said £17-18/m2 for a liquid screed.1 point

-

@Tony99 I looked around on the internet at various lighting designers and in the end I went for one that was relatively local to me which made it easy to have meetings at their offices. Seeing how some of the ideas they had worked ‘in the flesh’ so to speak was really helpful in visualising how it would look. They had sample installations of all sorts of different lighting. BTW I have timers on my towel rails too I didnt want them on the UFH circuit. I went for thermostatic electric towel rails and used screwfix timers.....cheap and do the job, the fancy ones electrician was suggesting were v expensive and more sophisticated than we needed.1 point

-

Hi Tony, towel rads are electric on timers so not on all the time, Also the heating does not come on at all in the summer months so I went for electric to dry towels whatever time of year it is.1 point

-

I believe it is Thermoroof. https://thermohouse.co.uk/thermoroof/ Unlike Durisol, they managed to smuggle the brand name into the programme. "I can't wait for my Thermoroof". Eventually a list of suppliers should appear on the C4 website.1 point

-

And I'd love too see a new sister show of GD, it would be called Shit Designs and be a fly on the wall doc of a large volume house builder and show just how rubbish most new built stock is.1 point

-

You can wet cut slate if you want - tend to use a slate knife and a square bit of wood underneath but no reason you couldn't use a wet bench1 point

-

Yep, I recall my back boxes protruded about 2-3 mm - guess they were set 15mm, allowing for 12.5mm board.1 point

-

I am not a sparky but on my sparks instructions I put noggins/dwangs (whatever) between verticals for metal back boxes to be screwed too , bit of 3x2 on edge so the box is deep enough to just be flush with plaster finish (15mm proud of studding).1 point

-

If it is not too late, a small pump station would be better - much quieter and more reliable. I would rather burn the house down than live with a Saniflo.1 point

-

I find that build quality is as good as the sub contractors on site. A friend works for a plumbing company who regularly install the plumbing and heating systems on new build site. The company owner stopped employing time served and trained plumbers years ago and now simply employs minimum wage staff to do the installation work. The only qualified tradesmen is the supervisor, he’s supposed to do the commissioning and signs off their work. In most cases the work is never checked and the work quality is just about adequate with plenty of snags. Pd. I’ve just been reminded that the same company has gone onto administration three times in ten years. So customers would be hard pressed to get problems sorted out.0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)