Leaderboard

Popular Content

Showing content with the highest reputation on 01/22/19 in all areas

-

We had a leak from underneath our MVHR unit a few days ago. I took apart the u-bend underneath and was horrified to find it 95% clogged with some sort of bio-jelly. The leak was caused by water backing up above this in the cold weather (lots of condensation) and then finding its way out around where the threaded outlet is connected to the unit (loose screw, now tightened). I cleared the u-bend out then decided to check the rest of the internals. For context, until about a year ago I checked the inside of the MVHR unit pretty regularly - virtually every time I changed the filters (so maybe once every three months on average). It was always spotless. I then got a bit slack and probably haven't checked it since last winter. This time, however, it was pretty disgusting. There was a patch on the heat exchanger where some mould was starting to build up. There was also some pretty disgusting biological buildup on the drainage surface under the heat exchanger and around the drain. Worryingly, there was also a pool of standing water underneath the filter for the incoming cold air. There's a pocket there that doesn't drain but could potentially hold quite a lot of water before it would start overflowing into the drain. I cleaned it all out and sprayed it with bleach. I'll be keeping a much closer eye on this in the future, but I thought I'd share this with others as a warning.4 points

-

2 points

-

1 point

-

Standing on the bath surround. Tbh it'd take a few minutes to clear the buckets, tools and tat on the window cill. We're a little way off of the unveiling shots though!1 point

-

@willbish , 15/5°C is the CIBSE defaults for this calculation. I am not entirely sure why they have a positive condensation rate at the interface in layer 2. The vapour pressure is lower than the saturation vapour pressure and the structural temperature higher than the dew-point temperature. Certainly my own CRA software (operating to the same BS5250 standard) does not indicate a problem, even with chipboard added and a 20/-5°C temperature scenario.1 point

-

but, @epsilonGreedy i would suggest there is a difference in the prices of the plot/land1 point

-

Not as unrealistic as you might think,with the prices I see advertised on social media trades groups. You’d need to be quick though,have a decent gang,a well run site,give the forky £100/week drink to look after you & work like a dog.1 point

-

1 point

-

In order to make your money you will really need at least another brickie and a good labourer. If your doing it all your self you will be spending too much time loading up, mixing motar and putting it on the boards and not enough time actually laying bricks and blocks. So you either need to join up with an existing squad or form your own. In terms of experience how many years do you have, it's a big leap from garden walls to full houses. Have you all your cards, csr and insurance, tax man etc.???1 point

-

I think for what you have got that is a very reasonable cost. I have seen lots of features costing far more and being fairly disappointing.1 point

-

Yes, our Vent Axia Sentinel (standard BPC issue) allows you to unscrew the front cover, remove the heat exchanger and wash it out. That said - the exchanger unit is solid - a six sided cell with solid top and bottom - you can get water into it but you can't take it apart itself. I usually clean it in the bath with a shower attachment. I normally do that just after autumn when I replace the filters and give the whole inside a good clean, including the fan blades, summer bypass vanes etc. Just gave the filters a good hoover just now - I should do that every month but usually forget - try and change them every 3/4 months. Not seen any issues with condensate building up though - will double check that. Ours runs straight down to a condensate pump (no u bends) where it mixes with boiler condensate and both are pumped up to the utility room drain from the basement plant room.1 point

-

......I have also had this problem in the past but it was from a bath / shower pipe. The pipe sagged and water must have been sitting in it and the bio jelly had virtually filled the whole pipe from the bath to the main waste pipe about 2.5m ...... what a horrible experience. It takes a lot to gross me out but that was one experience I am not looking forward to repeating. I wonder how wide spread this problem is and what one does to avoid it beyond just using a lot of bleach.1 point

-

Rockwool Flexi? https://insulationcart.com/product/item/100mm-rockwool-flexi-insulation-slabs-1200x600-pack-of-6/252/show#iInfo-tab When I looked a few months ago it worked out the cheapest for my application from those people.1 point

-

1 point

-

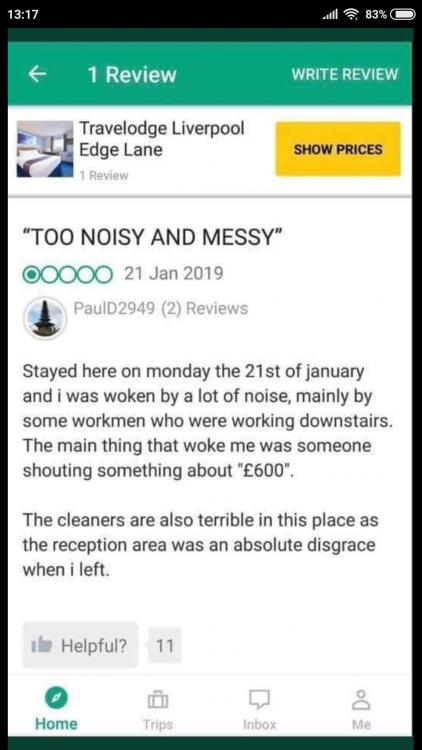

read that on the bus this morning. apparently the work had just finished and it was due to re-open today wasn't it. All for £600. Still at least they must know who it is f it relates to a pay dispute. Plus he clearly knows how to efficiently operate a digger, so if anyone needs to get some foundations underway just make an offer to HMP Liverpool in a couple of weeks cos i'm pretty sure they'll have someone available on day release at the rate of sod all pounds to you....1 point

-

We are cutting Rockwool on site. It isn’t compressible enough to squeeze 600 into 560. Easy to cut though but takes time. The offcuts all find a home though...... And our stud walls are all slightly different size gaps - some 570, some 550 and some much smaller. It’s like a big jigsaw and is taking weeks.......1 point

-

@RandAbuild, (we can chat about this this PM ) We also have a Vent Axia Kinetic Plus, and vacuum out the filters every 3 months and did our first annual service about 3 months ago. It was all pretty clean inside. But I can see Jack's point. Give the bacteria some standing water and warmth and somehow they'll fine a way to make a living out of the air particulates. @jack, thanks for the warning. This all reminds me of a report on a set of MVHR installed in a build of community housing. Over half were incorrectly installed (IIRC, half were installed back-to-front) and only one in the entire community was being regularly maintained and used correctly.1 point

-

I tried when doing my demolition in 2015, both gas and electric said no as it was related to existing services, not new supply. Always worth a punt though. Note that if you route your supply & meter to a kiosk and take the new house supply from there then you avoid paying for a second supply move.1 point

-

Very timely warning Jack. I've just noticed that the uninsulated plastic adapter on the incoming supply pipe from the ductwork to the MVHR unit (a Vent Axia Kinetic Plus) is producing a lot of condensation on its surface, which is running down the side of the unit. I will have to devise a means of insulating this adapter. I measured the temerature of this incoming pipe and it was 13deg (it must pick up some pre-heating through the house). The outgoing pipe was at 16deg, whilst the supply to the house was 21deg and the exhaust from the house was 23.5 deg. So it's pretty efficient. Anyone else had this problem?1 point

-

The wheel chair access requirements (in England and Wales - Scotland and NI may well be different) only requires access from the vehicle set down point, into the entrance level of the dwelling such that the (mandatory) entrance level WC can be accessed. There's normally no requirement for any special access requirements for a garage that isn't used as the normal set down point.1 point

-

We used Wooden Stairs - details are here http://woodenstairs.co.uk/testimonials/richard-northampton/ We wanted a contemporary look without newels. Quite pricey but we are very pleased with the results.1 point

-

You could still ask for the invoice to be zero rated I suspect if you can be bothered ...1 point

-

I have a dry ridge system and used 150mm stainless steel screws straight into the ridge timber.1 point

-

In a nutshell, yes. It'll never get full static pressure as its only dealing with dynamic flow. Will be fine.1 point

-

1 point

-

It will be documented here for prosperity. "In for a penny...….."1 point

-

This weeks episode again shows a lack of understanding of what you are doing. A re fit of a narrowboat. Except they added an enclosed "wheelhouse" on the back where there is normally an open stern. Okay so far but they made the wheelhouse about 2ft taller than the rest of the boat. That will work well until they meet the first low bridge or tunnel. There is a reason why narrowboats are the size and shape they are and all pretty much the same width and height. Okay to build such structures but they must be collapsible.1 point

-

According to their own material it fades, Page 20 of the pdf I ave linked to below. https://www.ribaproductselector.com/Docs/1/26501/external/COL712751.pdf We’re in the early stages of planning a new build and will likely want some form of cladding for the first floor. I have zero interest in something that will need maintenance/treatment to maintain its appearance. We had a Juliet balcony on a previous home which was a contemporary addition to the back of a Victorian house...was made of teak and looked great but needed regular treatment. That was a pain and tiny compared to the area of a whole house. The expense of maintaining/treating wood cladding is a non starter!1 point

-

Well, folks, that's it. The last nail in the last joist. Its been hammered in HARD. Here's why. For reasons only known to the inexperienced self-builder, I put the floor joists up working from both ends of the room to the middle. 400 centers. That makes a gap between joists of about 328ml. The middle three joist are longer than the others - they had to be inserted closer than the others: 310ish. Tight. Well tight if you are my size. Arms and head above the top chord of the joist - beer gut wedged firmly between the POSIs, but swinging the hammer now like a demon (900 nails down and just a few more to go - all because of you @Pete). Easy Peasy Lemon Squeezy. Well yeah, until it came to turning round to reach that sodding wedge to help nudge the top chord a mil or two higher. Christ this is tight. Turned a few degrees. Couldn't reach the wedge. Bugger - - Hand in my pocket - - maybe there's a spare wedge in there? Nope. By this time there is a semi painful wedgie though.? Dropped the hammer. "Foxtrot Uniform Charlie Kilo" Stumped, and firmly wedged, I realise I am going to have to wriggle out of this. Up? No way Jose. Not strong enough to overcome the effects of the beer years. Starting to sweat a bit now. More from annoyance than anything. Down? No choice. Only way . Now, those of us whose work trousers 'need' braces because our trousers have half a ton of tools hanging off them (all lies girls, just lies) will realise that descending through a really tight space has an inevitable effect on your braces. That partially painful wedgie now got worse. A lot worse. You see the back clip of my braces caught fast on the bottom chord of the joist. The front of my work trousers started to pull hard. My eyes started to water I think. By this time, my hands were in the air, and my head altogether too close to the gap between the joists. And suddenly with one bound (as it were) I was free. PING - THUMP The clip of the braces parted company with the waist band - shot up inside my clothing and hit the bottom of my shoulder. No wedgie pain now, just shoulder pain instead. All of this was happening dear reader at the same time as my T shirt, gillet and windproof were slowly making their way past my beer gut on the way to my my head. Couldn't see a thing. But sure as Hell, I could feel my shoulder. A few seconds later, there I was topless on the scaffold boards. Cold? No. Furiously hot. Just a matter now of jumping down to the floor. Yep, I suspect you are ahead of me......... The jump was elegant. Feet and knees together (just like I wuz taught) Thump. I stopped. My trousers didn't. Normally that wouldn't matter. No need to fuss over a small thing like that. Standing in the doorway way my best friends wife with a grin from ear to ear. I wouldn't have minded but her dog went mad.1 point

-

This is Generation Whatever-It-Is-Called, and Internal Consistency does not apply. See for example, all the Starbucks Coffee drunk by people who campaign against Starbucks. Or the "Fair Trade" organisations who destroy local businesses here by working from a deliberately tax avoiding "charity" base (looking at you, OXFAM). Or the "EAT Foundation" people telling us via the entire media last week that we are only allowed 14g a day of sausages and 29g of chicken, or the earth will fail and we are all going to dyeeeee. Turns out that the people behind it are hugely rich with a personal Business Jet in which they spend their time flying around the world running their hotel empire and hedonising. If they are living by their recommendations - fine; if not, they are a waste of space. To be fair they do seem a little spaced out; this was in the Antibes - a few years after 200+ guests were flown to Marrakesh from Norway for the wedding reception. Or any Green Celeb who spend their time flying around in Business Class. It is now an entire generation since video conferencing became a viable alternative, and if you are taking a stance there is no excuse. For me these days, the first test is whether someone demonstrably lives by their declared values. If they do not, I am not interested. Middle-Aged Grump of Nottinghamshire.1 point

-

That's alot of insulation - over 600 bags of the stuff. They cut a load of holes in the MBC vapour layer ply. More holes than we ever imagined. Then they pump the insulation into the holes to fill up the walls (300mm deep) and ceilings (400mm deep). Some of it escapes. Easy to vacuum up though. Then they put the ply discs back in and tape over the holes. They have left us with some patches for areas of the ceiling they can't reach and for any they might have missed. Only found one so far. Sean and his firm - works subcontracted for MBC for alot of the pumped cellulose insulation for them - was fantastic. The house is definitely warmer inside now, and the echo is now deadened. It is so quiet in there. Can't wait to move in........1 point

-

1 point

-

Essentially there are two different requirements in the Building Regulations themselves, but these aren't 100% clear in the guidance in the Approved Documents. The first requirement is that the foul drain has to be vented to atmosphere, such that there can be no build up of pressure inside it - the idea is to allow any gases to escape via a vent. The second requirement is that there has to be a means to prevent a partial vacuum forming in a soil pipe when a toilet is flushed or a basin or bath emptied. Common usage was to combine both of these requirements into a single vent pipe that does both functions, and either run it through the roof or run it up the outside of the house if the soil pipe is external. However, there's no need to do this at all, you can split the two functions and solve each individually. You can fit a vent pipe, to allow the foul drain to be at atmospheric pressure, pretty much anywhere along the pipe run. You can even fit one beyond the entry point of the soil pipe inside a hedge or flower bed, at fairly low level if you wish, or run an external vent pipe outside the house and up above eaves level. To resolve the partial vacuum problem you can fit an AAV inside the house, well above the highest outlet, in a position where it can be accessed for maintenance. This will open if there is a partial vacuum in the soil pipe and allow air to be drawn in, then close to prevent smells from escaping. An AAV cannot stop any build up of pressure in the foul drain, so if you fit one then you need an external vent as well. The advantage of fitting an AAV and an external vent is that there is less heat loss. Internal vent pipes act a bit like chimneys and constantly draw cool air up through them, so unless well-insulated they will draw heat from the house and can act as a focus for condensation. If you have an existing vent to the foul drain, then you should be fine with an AAV for the new upstairs bathroom. It needs to be well above the highest drain and accessible for occasional maintenance/replacement, so you can't build it into a wall without some form of access cover, plus it needs a reasonable air supply.1 point

-

I'm thinking a video of me in the bath and then a FINISHED sign rises slowly out of the bubbles.....0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)