Leaderboard

Popular Content

Showing content with the highest reputation on 02/24/18 in all areas

-

3 points

-

3 points

-

Chapter two The reason ive been silent this eve is that ive been studying this beast so I can answer more definitively. 'Tis a mysterious device of many guises.... If you really dig into the MI's ( manufacturers installation instructions ), ALL of them, it gives addendum's for the various configurations and alterations which you should be making according to heat source / space heating etc. So.... For starters we know that the cylinder stats do zilch, thanks to cock guy, so the above statement is right, but for the wrong reasons. The TS has 3 cylinder stats which I thought I understood, but I got a bum steer off their own tech guys so I went it alone instead, finding out why and where and how many there should actually be. So.... The lowest stat should be used to control a heat dump which basically brings on the space heating pump if the TS ever gets to too high a temp, so prob set to around 70oC. The middle stat "can" be used in tandem with the upper stat for 'buffering' heat into the TS. The top would be boiler on, and the bottom would be boiler off. Thats iirc supposed to give longer burn times so maybe better suited to pellet or oil. Not suited to this setup, with electricity and off peak in the picture so we move on... Middle stat should be 'full heat' aka winter mode, and the upper stat should be 'partial heat' aka summer mode / hot water only. These are more commonly seen / understood as 'hot water' or 'heating and hot water' on conventional controllers with say gas boilers with hot water cylinders. The MI's also state that you can locate these stats in different places by moving the stat pockets around according to the end application, so again its a problem as this has clearly been fully loaded to deal with a wood burning stove / solid fuel heat source in the picture, which it was never intended to have. Exactly what its supposed to do, when in hot water / summer mode. Just enough DHW to fill a bath or have 2 showers etc according to the MI's. Space heating cannot be drawn when in summer mode, so the controller that selects that must purposely kill the space heating too. The cylinder stats control the boiler and nothing else. Simple. You select 'summer mode' bringing the system out of 'holiday mode' aka 'standby', and then the upper cylinder stat calls for the boiler to heat the TS upper portion until satisfied. Bingo bingo. Likewise with the middle stat, for 'winter mode', but with the full heat. Bingo bango2. Selecting winter mode will also then lift the kill on the space heating and if there are any rooms stats wanting heat, the relevant pump/s will turn on, as commanded by the wiring centres, and heat will be drawn from the TS as its being injected by the boiler. Eventually the boiler will catch up with / match demand, eg the rooms get up to temp and start sending warmer water back to the TS return, and the TS will eventually satisfy the middle stat and the boiler will go off until the stat next calls for heat. Good news is the boiler will start to modulate as the need for heat is reduced. The next thing is how to get the heat into the TS. The flow into the TS is direct from the boiler PHE, but the return is via a TMV with connections to the mid/upper, ( for super fast heating of the upper section in summer mode as thats where DHW sucks heat from ), and then when the upper section is warmed sufficiently the blending valve then starts drawing cool water from the bottom of the TS so as to blend down the return temperature. Pay attention, this is the important bit. That blending valve is there to keep the return temp to the boiler at around 50-55oC to make the most of a condensing gas boiler. We dont have one here so another over-complicated trinket for the bin IMO. The boiler return should be only connected to the lower return tapping, and the other one that that TMV is connected to should be capped off. Note that the lower return tapping should be above the ST coil to maximise ST input. The ST coil is right at the bottom BTW as its likely to be, on average, the lowest heating input medium so is of best use when injected into the coldest part of the TS. They got that bit right. Or........the posh 'NFW' option..... The return tappings ( upper and lower ) could be via 2-port zone valves. The upper one opened by summer mode, and the lower one opened by winter mode. IMO what they should have offered in the factory for a non gas boiler installation. That ensures that the TS is using the minimum amount of energy in summer mode. For winter mode, even if no space heating is calling for heat so just the boiler and TS cycling, the lower cylinder stat will always try to fully charge the TS from tip to toe, so you will then have stored energy for the 2 hour no-E2000 input times. The PHE needs to go, as it think its cream knackered anyway. As we've had mention of the boiler circuit being full of crud its safe to assume that crud has become lodged in the narrow water-ways of the PHE, thus reducing massively its ability to transfer heat fro the boiler to the TS. I will speak to the boiler manufacturer tomorrow, if they pick up, to see if it can be converted to run on the open pipe gravity feed from the TS F&E tank, as that would mean we could do away with the PHE and additional pump altogether. It would hopefully just involve bridging the low pressure switch so the boiler ignores the low ( prob ~0.8 bar ) that it'll see if the F&E is high upstairs. Im assuming the F&E tank is upstairs as the 1st floor UFH is connected to the same body of water. That would get heat from the boiler screaming into the TS with nothing in the way and should massively decrease the reheat ( aka recovery ) times. After all that bollocks, we should be simpler, faster, way more efficient and have cut a good bit of chaff away from the wheat. You cant do that as the pellet flow goes in too low. In summer mode the flow MUST go in at the top where the DHW PHE feed is drawn from, otherwise your over-heating the TS in summer just to get DHW. On electric its important to make this as efficient as possible. The rest is just down to wiring and commissioning. A LOT to do with that as I find its just usually better to pull all the wiring completely off, put the radio on, and rewire the thing from scratch. Fault finding and working out what cock did would take longer than rewiring it. Enjoy!3 points

-

If the system doesn't leak it shouldn't need any periodic flushing. My system with twice as many panels has been running for getting on for 8 years and has only needed refilling when I've modified it and never been flushed. (25kWhr harvested today!)2 points

-

Just for info this wonderful thread is now at 32% of the length (pages) and at 29% of the number of replies of the 'other thread'. It has been going 4 days approx - that means, at current rate, it will overtake the other thread on the 6th-7th March Unless we fix it FIRST. @Nickfromwales what is the next move, or is that coming in your next missive!2 points

-

You got enough problems without reading my saga! But if you really want to read about how long I'm taking on ONE ROOM then feel free: Started it on 13 Mar 2015 on the old forum!2 points

-

Not sure how old it is, but iirc the new prices for those simulators were 5 figures a couple of times over, so prove it works, auction it, and it may pay for a lot of heating repairs... and perhaps a holiday.2 points

-

2 points

-

The solar controller is below your boiler on the RHS. It looks like it has a resol bs or similar fitted. It should have 3 buttons, a round one in the middle and two triangle ones on either side. You can use the RH button to toggle through the settings and there should be an info graphic showing you which sensors you are looking at (left button to go back) . It will tell you the panel temp, store temp, and pump condition ( on or off). If its sunny, put your hands on the pipes running up through the ceiling to the RHS of the boiler (black lagged) and see if one is warm and the other is cooler. If the system is airlocked as we previously speculated, then the pump will be running but not moving water so you might as well switch the controller off, it will just damage the pump otherwise.2 points

-

2 points

-

Overheard in Lidl: "Brooklyn, which flavour Pot Noodle for tea, blue or green?"1 point

-

1 point

-

It's actually the phase change temperature, rather than the input temperature, in deg C. So PCM34 changes phase from liquid to solid, releasing heat at 34 deg C. Equally it changes phase from solid to liquid when heated to 34 deg C (actually a wee bit over). Same for PCM58, but at 58 deg C. The Sunamp PV uses PCM58, and the water temperature that comes out when it's running is pretty close to 58 deg C when it's got rid of it's residual stored heat. The heat batteries store heat in two ways in the Sunamp PV. One is by absorbing heat energy by changing the phase of the sodium acetate salt, the other is just heat stored conventionally by the heat capacity of the heat batteries. The total storage capacity initially, when the heat battery is still hot, is a bit higher than the phase change temperature. This means that when you draw hot water from one, initially the heat being drawn off is just that stored by the heat capacity of the heat batteries, then when it drops to 58 deg C, the salt starts to self-nucleate and change phase to a solid, releasing the heat from the phase change, plus a small amount of residual heat from the heat capacity of the material. This means there is a variation in heat storage capacity that is time dependent since the last charge for a few hours.1 point

-

1 point

-

I was stunned to see those along with Toffee Crisp on a chippy menu in Edinburgh years ago. Seem to remember they kept them in a freezer and cooked them "fresh".1 point

-

Different composition phase change materials that change state at different temperatures as I understand it. To cope with different heat sources.1 point

-

As I learnt from this site myself, they are two different phase-change material compositions. And it relates to them being tuned to different input temperatures not output temperatures. For example input from an ASHP will be lower than that generated from PV electricity.1 point

-

Quite apart from the above comment you need to stay off the channel cos since I did my calcs things have changed a bit. Now at 35% pages and post number and that brings the fateful day down to the 4th (ish), 'in normal traffic' as Google says. If I were you I would start polishing the crown in readiness for sending it round M25 and up the A1.1 point

-

1 point

-

Oh yessss...!!! Tunnocks tea cakes and Caramel wafers .... Oh, and haggis for breakfast ....1 point

-

Yup. leave that deal with the c-curve of the pump rather than the not great relays on the HM PCB's. Cheaper and easier to replace the ZV head too.1 point

-

Too restrictive. the ZV will open to give full bore. Plus you dont really know which way the convection would 'pull'1 point

-

1 point

-

The hozelock rig is usually supplied with the solar system as you never top up via cold mains through a filling loop. Instead you make up the solution, pour it into that bottle, connect to the fill point ( which has a non-return valve so juice can only go in ), and then you pump away until the pressure is topped back up accordingly.1 point

-

1 point

-

1 point

-

TBH I would just leave the solar as it is currently as it needs a proper flush and then refilling along with the crud draining out of it ... it’s not a 10 minute job ..! What is useful though is you’ve got the filling loops and kit to refill it when the time comes (or the Welshman and his sidekick...)1 point

-

Mine charged 280 plus for the foundation drawings and a further 60 for Steels and lintels Robert Sparks (RSE). Preston1 point

-

1 point

-

If the simulator isn't in the way then don't be too hasty to get rid. Maybe start another thread. There's a massive nerd herd on here who will love to try and advise even to the extent I'm sure of maybe video chats / confrences for some remote diagnostics. Starting with "What mains plug is on it?"1 point

-

1 point

-

Hi Crofter, If you do have a wifi signal (maybe next door's?) then I can recommend the Sonoff TH16 https://www.itead.cc/sonoff-th.html wireless switching from phone, timer, temperature or humidity sensor, it is keenly priced with a nice free app that's easy to program. Two models available TH10 (10 Amps) or TH16 (16 Amps) Scenes can also be set up so setting up a local "IFTTT". If WiFi is lost the controller will still carry on as the program is stored in non-volatile memory. Should you want IFTTT from another operation ie weather control then i would recommend https://ifttt.com/ and set yourself up a free account. Itead https://www.itead.cc/ manufacture lots of other control gear in the Sonoff range - all good value. Kind regards AndyT.1 point

-

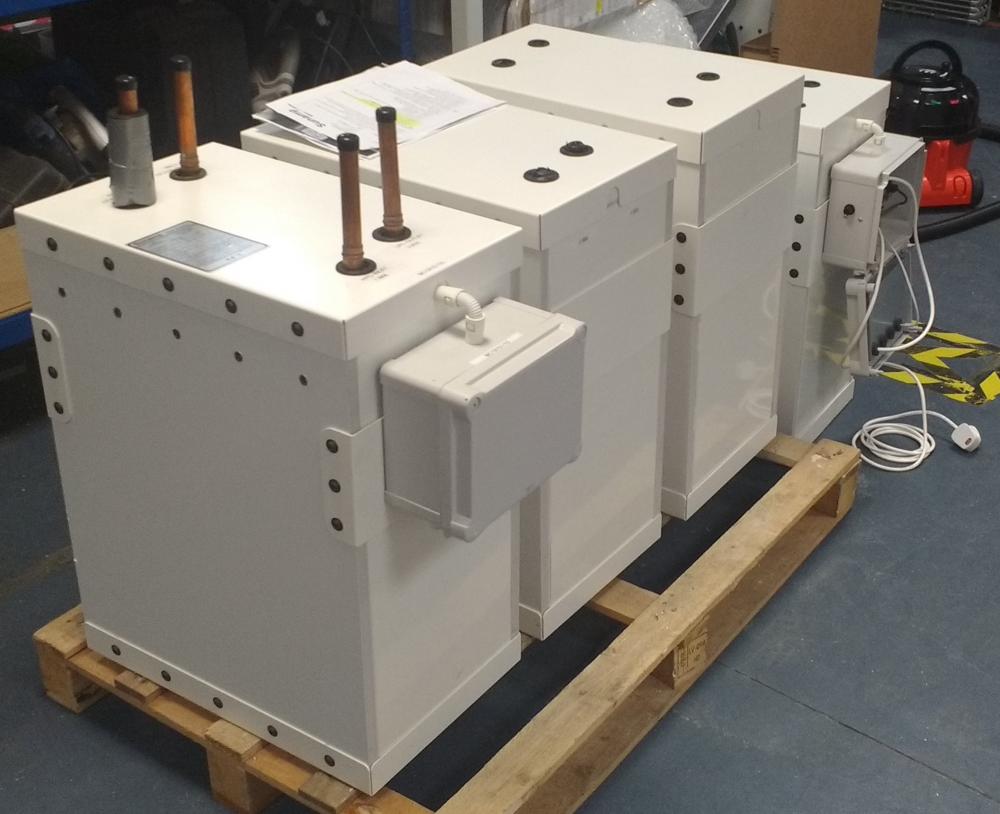

Hi All, Just as a "By the Way" - my Solar PV dashboard http://wattson.energyhive.com/dashboard/AndyT data has been taken off line for the moment while I do some testing two of Sunamp's latest prototypes. Got all the plumbing done yesterday and as a result my conservatory looks like a Steampunk version of the engine room of SS W-s-M with meters gauges and dials everywhere. Very akin to Willy Wonka's chocolate factory. Just got to do the electrics on Monday and then all it needs is the sound effects to go with it. You can still access historic data on the dashboard by clicking the < and > symbols either side of the date. Kind regards. AndyT1 point

-

Isoquick have just quoted for my raft. £550+vat as an extra for structural engineer design I don't know if this is in an in house engineer or who they sub the work out to. Will find out in the coming days as I am also yet to get a SE onboard.1 point

-

I think I'll drop Vent Axia a line to see what they say about the mould growth (and the front cover fixings). I'm not overly concerned by its presence but it would be interesting to hear what they have to say and if there is anything I can do about it. Quite a useful step by step here (I really should have taken pictures myself):1 point

-

Shouldn't do, unless the system has been boiling for a long time and has vented off all the steam. Even then it should flush clean OK. AAVs are normal, as is a PRV to allow steam to blow off if they boil. Shouldn't happen normally, as they reach stagnation temperature and just sit there, assuming the controller is working.1 point

-

I just take a chance on the cheapest ones from the Far East. Some die, others go on forever. The one in my SW facing lounge is reading 26.8, in the unfinished bathroom, NW facing it's 15 and falling! One day is like to get into remote sensors, Raspberry Pi, logging and reading via an app. I fear I'm not bright enough though!1 point

-

1 point

-

I have always thought these grants and renewable initiatives only benefit the installers who can charge such a premium because they are the ones holding a special ticket to allow them to claim the subsidy.1 point

-

That's a wiring centre for the UFH: E07-Generic-H-Box-12V1.2-wiring-centre-09-10-2017.pdf1 point

-

I believe we have at least one member here who is building at Graven Hill, plus another that did a LOT of research into it. Might be worth doing a search here, as there have been some lengthy discussions on the pros and cons of the way Graven Hill has been set up. Here are a few threads to get you started:1 point

-

Yeah, I’ve got loads of free months out of them but I’d rather have the bloody thing arrive when I need it. I’ve set a safe place and they won’t leave it there ‘as it’s not safe’. Been up to the sorting office and had a conversation with them about it but nope!1 point

-

Yeah me also, though i am a constant worrier anyway. Thanks for your kind thoughts, she's had a lot of difficulties since last year, firstly with a multi drug resistant pseudomonas infection, and now with aspergillus! Following a quick google the other day, I discovered that the pseudomonas was actually holding the aspergillus back, now thats gone, its having a party in there! After much consideration of MVHR, and I must have been looking into it now for over 2 years, its not do-able for us at the moment, partly because we just aren't airtight enough yet, and partly because one of our lovely neighbours has a wood burning stove which pollutes the street, the airtighting is fairly easy but time consuming to fix, the smoke issue i've not been able to get round as yet, so for now I've invested in 2 BlueAir Blue Pure 411's which filter down to 0.1micron (anything less and mold spores are likely to get through, aspergillus for example can be 0.2micron), and i've bought a FooBot to keep a visual check on things.1 point

-

1 point

-

The mobilisation cost is always the big one. You are just paying to get the rig there on site. For the type of rig above it was probably a dando terrier which fits nicely in a long wheel 6.5t van. Drove one all over Ireland for a few years. When you go into the holes over 30m then your into much bigger rigs that will need a big compressor as well. So your paying usually for a lorry and a Jeep. As for the soil testing very few companies will do the actual soil tests them selves as the equipment is very expensive. Queens university done most of ours or a company in Dublin if it was contamination. I think @PeterStarck robbed who ever he got in. £3k for 47m is cheap very cheap. Well done!!!1 point

-

Last Night an ex DJ Saved My Life "There's not a problem that he can't fix 'Cause he knows all the tricksAnd if your pan gives you trouble…" 'Cause away goes trouble down the drain Said away goes trouble down the drain Well alright" It was even by Indeep!1 point

-

Just be very cautious when stripping any of this sort of timber and wear a decent mask. Mouldy spores can be nasty when they get in the lungs.1 point

-

This is the Part II roll up of a couple of earlier blog posts and forum topics which provide the groundwork and context. Plumbing Design – Part I Heating the Slab – an overview Modelling the "Chunk" Heating of a Passive Slab Another DHW / DCW / UFH design. in summary, so far into commissioning and early use, everything is at least achieving our expectations and the house might in fact perform better than my predictions. The key design points that I listed in part I seem to be spot on. I want to compare a figure that I gave in the modelling topic with a corresponding plot during commissioning and testing to underline this: The first graph is a theoretical model based on a few simplifications, and the second live data, warts and all, and complete with hiccups as I test and restart the control system. The bottom line is that the slab is reacting exactly as I modelled in overall behaviour, though one of the parameters is different. The UFH pump at its medium setting is under half the modelled flow rate, increasing the delta temp between out and return from 2°C modelled to 5 °C measured. However, I decided to stay with this setting because the pump is almost silent at its medium setting, and the system and its subcomponents are still operating well within specification at a delta of 5 °C. So in my view, if you are building a house with near Passive performance (wall, and roof U values < ~0.15; windows < 1 and not too much area; well sealed warm space and MVHR; decent insulated slab), then you should expect heat losses of less than 40kWhr / day in worst winter months. You therefore need to put roughly the same into the house. You only need to input the net top-up, because your occupancy, normal electrical consumption and solar gains all contribute to this input; this net is going to be 1kW or less on average. Given that a cheap and simple Willis heater can provide 3× this, using something like a gas boiler capable of 16-20 kW is just crazy, in my view; in our case even the economic case for considering an ASHP is marginal at best. Yes, in terms of running costs, the electricity unit cost per kW is more than that for gas, but you also have to factor in other running costs such as boiler maintenance. In our case, the British Gas boiler maintenance contract in our old house is less than our total expected heating cost in the new house so unit price comparisons are irrelevant to us. As I commented in the Boffin's thread, you need to limit the heating going into the slab: one way (the one Jeremy currently uses) is to throttle back the heating rate right back (e.g. using a buffer tank and an accurate thermostatic blender) ; the other way is to use a chunking approach and simply heat the slab in one (or possibly two) chunks per day. In the chunking case you instead limit the total heat injected into the slab per heating round (that is the integral of the power rather than the power itself). Doing this might seem awfully complicated, but in practice you can let the slab physics do this maths for you. You can use any moderate heating source that has a reasonably consistent but limited heat output; this could be an inline heater like a Willis heater or an ASHP with the flow temperature and rate at present set-point giving water at, say, 30°C. The slab itself slab acts as the buffer, so no additional buffer tank is needed. The algorithm is simple: Turn on the heating at a fixed time. This could be the start of E7 or in the window of peak power if you have PV installed. Turn it off when the average return temperature from slab reaches a specific set-point threshold. The actual set-point (which in my house is going be around 27°C in winter) does vary by season because what you are doing is control the total heat put into the slab, and it will need trimming for any specific house and heating scenario, but it is largely self correcting for short term temperature variations in that if the house gets a little colder due to greater heat loses in a cold snap, then the slab will require more heat to reach the set point. At the moment we are using a twice a day heating cycle. This is settling down to ~6 hrs overnight during the E7 window about £1.50 and a couple of hours top up during the day (another £1). This being said, we are still warming the house from a pre-commissioning temperature of around 13°C to a pre move-in target of 20°C as as you can see from the graph, we are currently increasing the house temperature by ~0.5°C / day on top of the sustain heat losses. This in itself takes a lot of energy as we have approximately 17 tonnes of slab, 5 tonnes of plasterboard, 11 tones of wood inside the heated zone of the house and 8½ tonnes of cellulosic filler in the insulation. Plugging these numbers and their Cp's, it takes roughly 25 KWhr to raise this fabric by 1°C, or 4 hrs of Willis Heater to raise it by ½°C. So at the moment roughly half of the heat input is maintaining heat loses and the other half is slowly raising the temperature of the house fabric . This maintenance heating element is less than the JSH spreadsheet estimated for current average outside temperatures. So another way of thinking about this is that if we do without heating for a day, then the house will drop in temperature roughly ½°C to compensate for heat losses. The daily ripple in temperature with a single heating chunk will be less than this. If we only heat the slab during the E7 time window, say from 2 - 7AM, then the house temperature will peak roughly 3-4 hours later late morning and then fall by maybe ½°C during the rest of the day. I feel that a ripple of ½°C will be barely noticeable to the occupants, and given that the heating during the E7 window is effectively half price, it is better to accept a midday peak (and possibly set the target temperature half a degree higher) than to pay double for an afternoon heating top-up to reduce the ripple.1 point

-

Here it is: as accurate as I can get it. No pretense of getting it done cheaper than anyone else. Just the raw numbers and a few words to explain context if necessary (why did I buy a chain-hoist for example). Yes, you'll probably get it cheaper. That's excellent. The point is openness and telling it like it is. March 2014 Home Building and Renovation Show NEC: £100, including fuel and tickets Phone calls about £15:00 extra, and about £70:00 fuel. July 2014 Land: already owned Planner: £1050, plus £70 initial consultation fee, (in cash). LPA Outline Planning Application fee £770 Phone calls: about £15:00 extra, and about £50:00 fuel. August 2014 Ecologist: £1390.15 (works out at about £1 per Great Crested Newt – a further £2000 budgeted for. But see below June 2016) November 2014 Topographical Survey: £540 January 2015 Trips to Timber frame companies and various local suppliers : £50 fuel Subscriptions to various magazines: £70(ish) February 2015 Architect: £4000 (design plus all other matters up to and including submission for Full PP application) QS: £630 – feasibility study Legal: £360; altering title LPA fees: £385 Structural Engineer: £1782; foundations calculations Land registry Fee: £40 Contamination Desk Study and Geophysics : £1260 (plus possible indeterminate decontamination costs) Phone calls: about £20:00 extra, and very little fuel. March 2015 Discharge of Conditions Fee £97.00 Health and Safety Services are being handled for free by a colleague: I’m coding his website in exchange. Notice: no site insurance yet……. :huh: I’m just too mean. Projected cost £568.65 (May 2015) August 2015 Architects fees £2000; from award of Outline PP to Full PP (6th of August) and £40 for bottle of champagne to thank our him: his judgement in relation to what would pass was exactly right. Read paragraph 9 of the Delegated Report (here) Trip to Swindon to visit the NSBRC Fuel £36, overnight stay £85 Strimmer: Polycut head, and set of knives for strimmer £46.60. (No lawn for Salamander Cottage: at last, no mowing…… bliss) September 2015 Legal Fees; alteration to title status £232 October Purchase a four wheel trailer (new) £2500 Purchase a Mutts Nuts (Nick’s term, not mine) Bosch Laser Level £250 First Aid Course (ref. H+S policy) £80 Chainsaw Course £130 December Off mains drainage legal agreement Legal fees and £1000 for access to the land to discharge to stream (wayleave?): £1862 (£300 over budget) Cladding Preparation for processing the wood; Serious Stihl saw (660) and ancillary equipment £2000 (resale value £1000) Trips to open passivhauses £50 + Off – road parking (ground matz) £2800 (resale value £2500) January 2016 SPONS Architects and Builders’ Price Guide 2016. Can’t do without it. And there’s an App that goes with it. £150 Small shipping container (for tools) £300 (resale value £400) Base for container: 4 tons of 20 mm to dust from my mate: £35, yep £35 New wheelbarrow £97 (French made Hammerlin: two flat tyres (in 2 weeks) and a stupidly forward C of G so the damn thing tips forward ON ITS OWN... sodding thing) Local Oak trees (for the shakes and cladding) £1200 (1 square meter of oak shakes retails for £100!) T.K Knipe Allithwaite. £100s of pounds worth of free advice. 1 Sweet Chestnut tree (high tannin content) £140 5 local oak trees £100 (they were going to be cut up for fire wood - I kid you not) Another container (you can't have too many): £1000 (resale value £1000) February 2016 Small hand tools and boys toys £1500 May 2016 2.5 tonne Mini Digger = £14,000 (PV Dobsons, Levens) EPS Licence £1200 (I still haven't paid the bill - because of some really unprofessional behaviour.) Red Diesel £15 120 meters of Temporary Amphibian Fencing (TAF), 80 stakes (37 by 37 by 700) £267.37 Lifting gear: a 2 tonne chain block and tackle 2 shackles, and two beam clamps £181.03 (to run on the RSJs below) 2 RSJs, (6 meters long to span between the two containers) £230 +VAT Filing frame to assist sharpening my chainsaw chains £97 Site signage (ebay) £10 for several (more needed) Plastic Barrier Fencing Safety Mesh Fence Netting Net With Metal Pins £50.95 (for the edge of the car park and pedestrian walkway) Three stillage cages to store material on the site (one cage fitted inside the container) £50 Another two stillage cages today. £25 And £80 worth of 2 inch wire mesh so I can weld it to the stillage cages: slows light fingers down Two (full-on-big-boys) deck brooms £24 A grease gun for my digger and two cartridges of grease £22 Another High Security Digital padlock and hardened, sheathed, hardened chain to secure the buckets (that aren't hooked up) for my digger £55 A 2 Tonne x 1.5 meter Leverhoist £79.95 2 off 2 tonne Beam Clamps £25.98 4 off 2 Ton Alloy Bow Shackles, with Safety Pins £11.96 The above is initially for lifting trees and heavy objects safely off the trailer (on my own) Later the hoist and clamps will do the same job, but in a small purpose-built workshop. 100 meters of 16 amp electricity cable. £71.89 Building Control Fees £600 Red Diesel £18.21 June 2016 Two more stillage cages £25 A Douglas Fir tree and a Larch tree. £40 (Fir tree £10) Will produce stock worth about double that (conservative estimate) 20 8" coach screws £4. 4 sheets of reinforcing mesh £20 (16 by 8 foot for welding to the stillage cages to slow down thieves ) Structural Engineer £1774. And worth every penny (so far) First Aid Kit (10 person HSE Approved) £7.57 (tried getting one locally, couldn't get one for love nor money) Security marker pens £1.99 (a requirement of the Site Insurance: all scaffolding poles must be security marked - not the digger or the saws!) "Curiouser and curiouser" Wood for lining my container £81 HERAS panels, feet, clips, struts, pins for the struts £200 Some steel stock to practise welding £12 (making a small tool table for my SuperJaws clamp: cost on the open market £30) Four Point Lifting Chains ('shorten-able') £139. Fed up of worrying about the webbing strops - they are quite worn already Site H+S sign. £24 ( and I begrudge every penny: it's expensive wallpaper... why do I say that - read on - last but one point) 2 tins of Hammerite for the rust spots on the container. £28 The ecologist had the good grace to halve his bill given the less than prompt approach to fulfilling his contract. £900 July Builder's Merchant bill: £704 - bits and bobs, sand 25mm water pipe and stuff like that August Builder's Merchant bill: < £100 all sorts of tiny things September Builder's Merchants bill £1379.24, Ply wood for the stillage and to make some internal storage in the container, a DeWalt nailer (luxury beyond compare) It starts to get serious now........... Piling will be about £6000, Groundwork price yet to come in, site clearance - I've hired a lumberjack who's coming from Canada - muscles coming out of his ears - off mains drainage and site drainage.... Off to Harrogate next week. (4th of November)1 point

-

I'm sometimes accused of overthinking stuff. And I'm a little weary of it. Here's why. Expert status in many areas is thought to develop after about 50,000 hours of practice. And one of the common characteristics of expert status is the reduced need to think about the hard-learned craft or subject. It (irrespective of subject matter) becomes hard wired. Take my digger. Just bought it a few weeks ago and while using it in the first couple of hours I was like a cat on a hot tin roof. My shoulders ached, my jaw was locked, my concentration fierce. And then I remembered my flying lessons. 'Think it, and it'll happen, lad' growled the instructor. And when the fear had dropped a bit, I allowed myself to relax and reduce the control inputs. Suddenly I wasn't dancing all over the sky like the proverbial in a pot. On the digger, I reduced the control input and slowly the swing was not so large, not so jerky. Then Ed (Construction Channel) said it would take about 4 hours to get a basic understanding. He was right. That was a fortnight or so ago. Now, I couldn't tell you what I do to hook a self-hitch bucket, Now I get annoyed at myself for 'clangy' bucket movements. Slowly I have stopped thinking about it. I just feel it. The next step is over-confidence (pilots call it the Death Zone -about 200 hours into their training). Now, I don't think I'm going to die while using a digger, but I'm going to be extra vigilant in a month or two. After many hours of practice, experts (it's a well-documented phenomenon) simply don't remember that they had to learn stuff. And sometimes are just a little puzzled by someone who asks apparently naive questions. And then -with kindness and reassurance at the root of their response- reply that the questioner is over-thinking it. No, all the questioner is doing is sharing their worry, their lack of expertise, their lack of practice.1 point

.thumb.jpg.84720b9262bdfdd639b2257471fce9e7.jpg)