Leaderboard

Popular Content

Showing content with the highest reputation on 02/15/18 in all areas

-

4 points

-

It's starting to feel like the finish line is in sight now. Since my last entry, I've largely finished the interior including all the flooring, the doors, most of the kitchen, the windowsills, and the huge and daunting task of the bathroom (big thanks to @Nickfromwales for answering my hundreds of questions on that one!). I got a plumber in to install my UVC (sorry Nick, forgot to get a photo of that). I've also done a bit more of the cladding, but the exterior work has been on the back burner. I've also gone back to work full time since my last blog post, which is why everything has slowed down so much. Still managing to get a bit done in the evenings and at weekends. You'll notice some furniture has appeared, some of this was given to me by a neighour and was very handy for storing all my tools etc; the bed and sofa were in storage with family and eventually I exhausted their goodwill and had to take delivery of them! The shower has had a couple of test runs, and SWMBO reports that it is very nice indeed. The plan is to be open for business in April, which should be tight but doable. I expect that at that stage I'll still have some outside jobs left to finish but the inside is only a few days away from completion now. Sorry for the crappy image quality- will have to do a bit better when the time comes to do the proper marketing shots3 points

-

A court will require that you have attempted resolution anyway, and will base its judgement partly on who acted reasonably. Perhaps talk to your architect as a first step, who should know something about these things, and have met similar before? After all, he is your architect, employed by you to work for you.2 points

-

Could you just withhold 2k from the final invoice, explain why, and leave them to incur the legal costs? You may end up counter claiming in the Small Claims Court when they sue you.2 points

-

Our as built SAP shows 6500kWh for space heating. In Dec and Jan I would estimate we used 1600kWh per month, or 400kWh on input of ASHP based on scop of 4 (actual). £50 per month, some of which will have been offset by PV. The trick to keeping scop high is to run the flow as cool as possible. Keep ufh spacing tight, avoid driving the pump for hard and short cycles but rather on all the time and heating gently.2 points

-

I couldn't see any merit in solar thermal, it's expensive to buy and install, produces very little output in winter, needs regular maintenance and doesn't perform as well as might be expected from the apparent efficiency difference between that and PV. There are some interesting comparisons of costs etc here (although a bit out of date now): https://edavies.me.uk/2011/12/pv-heating/ https://edavies.me.uk/2012/01/pv-et-flat/ https://edavies.me.uk/2012/01/solar-per-area/ https://edavies.me.uk/2012/11/pv-dhw/ Yes you can have both, but you have to bear in mind that solar thermal can only ever deliver heat energy when the collector on the roof is hotter than the tank or other thermal storage system. PV can deliver heat into a tank or other thermal storage system no matter what the temperature.2 points

-

2 points

-

1 point

-

1 point

-

They look like they would do the job, especially as it looks as if they are designed for things like spray booths, so will presumably have a pretty high capacity for VOCs. I wonder what sort of flow resistance they have? MVHR probably needs a more free-flowing filter than something like a spray booth, with it's higher flow rate/greater available dynamic pressure. Might need some experiments to see what sort of pressure drop you get across one. I've been thinking that a long, thin, carbon granule panel filter might be a good option. If you made up a long box, with a rectangular carbon granule filter fitted as a divider down the centre, then fed air in at one end, on one side, and took air out at the other end on the other side, I have a feeing that the air would have a longer exposure time to the carbon, yet not be overly restrictive.1 point

-

Very stubby drill on this Silverline thing, it pushed up and only just pierced the vcl. Yep, BHP451...I wish I'd bought a couple more tbh. The body dryer comes with some weird "material" straps. Not fitted yet so I added a few more screws. NO I didn't measure them! That was a horrible moment cutting the vcl, OMG the draught! In she goes temporarily: The timber box will be lined with Asbestolux or similar. The rest of the vcl under the dryer will go: A few more screws. A couple of 20mm holes for the control cable and the DRAIN! To fit, the cover. 4 screws but the positions aren't on the card template. I'll figure it tomorrow!1 point

-

3 questions, - where is the hole in the VCL from the pilot hole? -is that a 3 speed makita drill? if so, you lucky bastard, someone stole mine and they are virtually impossible to replace. - how can you sleep at night with so few screws in your ceiling?1 point

-

If the architect has written a response that states that they couldn't be bothered to fully read your weekly emails as they were "too long" a judge would tear a slice off them. Hold back £2k and tell them it's going to court if they want it. Then when they walk away, £2k the lesser but £2k penalty the wiser, use that to go on holiday. ??1 point

-

I have just been on the catnic training course for the standing seam roofing sheets, I liked the product very much and it is nice and easy to work with. Just depends on the look you are after.1 point

-

To be perfectly honest it is not structural ! I had been trying to get info about the glass fixing on the internet and all it came up with was structural glass so I sort of carried on the theme with my post but it is a piece of 8mm toughened that will be placed in the funny shaped opening. The wall it is going in is just an exterior wall which has no insulation as it is outside the thermal envelope.1 point

-

1 point

-

Yeah I might hold off on the sauce 'till a bit later!1 point

-

1 point

-

Can you explain why that is structural? I need to be educated :-). I understood structural glazing to be loadbearing.1 point

-

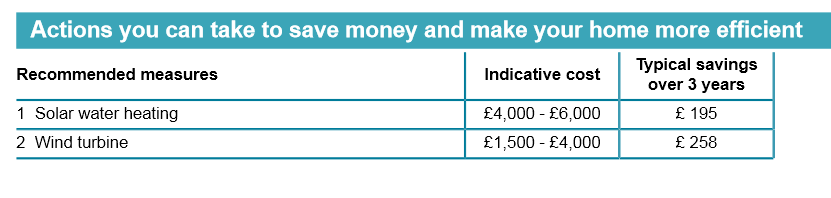

The EPC recommendations are hilarious, especially the pay back periods. Here's a screenshot from ours: It doesn't mention any band change presumably because we're already well above Band A. If solar thermal cost £5k, then at £195 over three years it would take over 76 years just to recover the investment, not accounting for repairs, maintenance and replacement of out-of-life parts.....................1 point

-

I am tempted to Rename it....... "The Bog Supa-Blog"1 point

-

The doors and liners came from an online place, something like "door deals direct"? I can check later. The staircase was made by Pear Stairs: https://www.pearstairs.co.uk/ who I can highly recommend. Everything was a perfect fit, and the whole staircase, including the landing balustrade and 10mm glass, came to just over £2k, IIRC.1 point

-

1 point

-

That makes good sense. @DundeeDancer, you are not in a therapeutic relationship with this builder: you aren't responsible for pointing out poor practice. And he (or she) isn't going to bother about 2K.1 point

-

Good advice. I got myself into a contract for rendering and did not understand the consequences. In the end the costs were nearly 50% more than they had estimated. Vendor took me to small claims and the judge, while sympathetic, said he had no option but to find in vendors favour. So had to pay the balance plus court fees. And of course the mental stress on top - surprisingly it was a lot of pressure, I always thought I was good at handling that, lesson learnt.1 point

-

Just been chatting to @hmpmarketing about SIP's so I thought I would just update. I didn't have to do anything naughty to the trees, I got the OK from the council to remove everything apart from the three big ones (two beech one scotts pine) between the lamposts. The only condition is I replant four, which I really have no problem with. From previous posts I have discussed the problem with living 300mls away and getting people to do the work. I have met 6 tree surgeons, some of which have actually given me quotes but all have just dissapeared. I now have it sorted by "The Backyard Barbers" who are taking everything out next week (which is fantastic 'cause the bird nesting season starts 1st March and I would have been snookered until September again). I will visit and take some photos to post here next week for those who are interested1 point

-

Move on. That was then, now is now. Look forward.1 point

-

1 point

-

My experience has been that SAP massively over-estimated our energy demand, particularly the space heating requirement. SAP also puts a really daft COP figure on the ASHP, in reality were getting a COP of between 3.5 and 4, over 4 sometimes, whereas SAP seems to assume that the COP will only be 2.5. This makes a pretty big difference to the primary energy figure, especially since SAP seems wholly unable to account for either the ASHP preheating the water or that most of the hot water comes from diverted PV energy. The net result is that the SAP primary energy consumption figure is massively in error, so much so as to be meaningless, really. Equally meaningless is the way SAP just subtracts the PV generation from the total - it's crude and wholly non-representative, IMHO. In fairness, I suppose SAP was never intended to be useful for a passive house, so perhaps being critical of these gross inaccuracies shouldn't really be blamed on the SAP methodology.1 point

-

I once designed a large new-build curry factory located right next to a lot of housing. All extracts from the food production areas were filtered through an externally located shipping container that was fitted with racks of carbon.1 point

-

It seems that a fair few of these odour-reducing filter manufacturers have sprung up from the need to ventilate indoor cannabis farms without letting the distinctive, and rather strong, odour escape.............. Making a home brew carbon filter with fish-tank granules should be really easy. The cross sectional area needs to be large, as the granules will restrict flow, so I would suggest trying to find a carbon granule based recirculating cooker hood cartridge, as large as you can find, and then make a case to house it inline with the fresh air feed to the rooms (not on the intake side of the MVHR, on the fresh air outlet side, so it has the benefit of being warmed up and pre-filtered). If you include an ozone generator before the carbon filter you may well be able to extend the life of the granules before they need changing/regenerating. All told not a hard thing to DIY, and it would have the added advantage of acting as a silencer on the fresh air feed side, too. Fish tank granules are cheap when bought in bulk, I still have around 5 or 6 kg of them from the 10kg I bought years ago to replenish our cooker hood filter.1 point

-

Sounds great, and a similar concept to my own place but a bit bigger. As IanR says your u values look to be better than the BRegs minimum. I thought that an air test figure of under 5 meant you needed MVHR? Or have I mis-remembered that?1 point

-

Floor, Roof, Windows and air tightness all appear to exceed Regs, or are the Welsh Regs more stringent than the English ones I'm familiar with.1 point

-

@JamesP my only additional comment to this thread is that when I did all the leg work on this at the start of my build I found NuHeat (who you mention in your first posts) massively over-specified the requirements, over estimated the likely RHI payments and was obscenely expensive for their solution. Personally I'd keep shopping. One supplier not mentioned here that seems to have a reasonable reputation is Earth Save Products. When I spoke to them they certainly had a much better grasp of the requirements of a well insulated new build.1 point

-

You can use any thickness of the marmox, dependant on how much insulation/VCL effect you want from the product, obviously the thicker it is the better, but all thicknesses are suitable for tile finish. You don't need any tanking with Marmox, its ready to use once fixed, and is far less vapour open than the other products mentioned, which do let water vapour through despite being waterproof.1 point

-

1 point

-

@JamesP - here's a link to a thread specifically on sunamp, but there's plenty more elsewhere on the forum. sunamp heat battery thread The big picture principle is relatively simple, the task of applying those principles to a domestic heat storage system is anything but simple and way beyond my pay grade! It is, however, a clever and new solution to storing heat energy without the use of a water tank that is certainly gaining popularity amongst members on the BH forum, including me.1 point

-

Message to the Mods really. Does this need re-naming to be the Encyclopedia of bathroom renovation with chapters etc!!1 point

-

1 point

-

One of ours (the extra I bought when I decided to add the walk-in wardrobe) is a Geneva from Wickes. It's almost indistinguishable from the Mexicano doors we bought for the rest of the house, but is nowhere near the quality. Luckily I didn't need to trim it, as I built the frame and lining to fit it, but I would have had problems if I had, especially at the top and bottom where the trimming allowance was pretty modest. It also had a much softer chipboard core, and it was easy to over-tighten the handle screws. I ended up using a syringe to inject glue into several of the handle screw holes. The Mexicano doors had what seemed to be a laminated oak strip core around the edges where the handles and hinges fit, so were a lot more robust. I'm not convinced you can tell by just the weight, as the soft chipboard cored door from Wickes seemed as heavy as the others, although it's had to be sure as it's a bit smaller.1 point

-

ABsolutely. I bought a 32kg version partly for the weight, while the Wickes ones are I think 27kg. I also wanted it to feel heavy when opened. As far as I could tell the weight difference was in the fibreboard core but I am no expert. My joiner was impressed with the doors I gave him to work on, and apparently creating the holes for the latches etc was a bit of a sod ..1 point

-

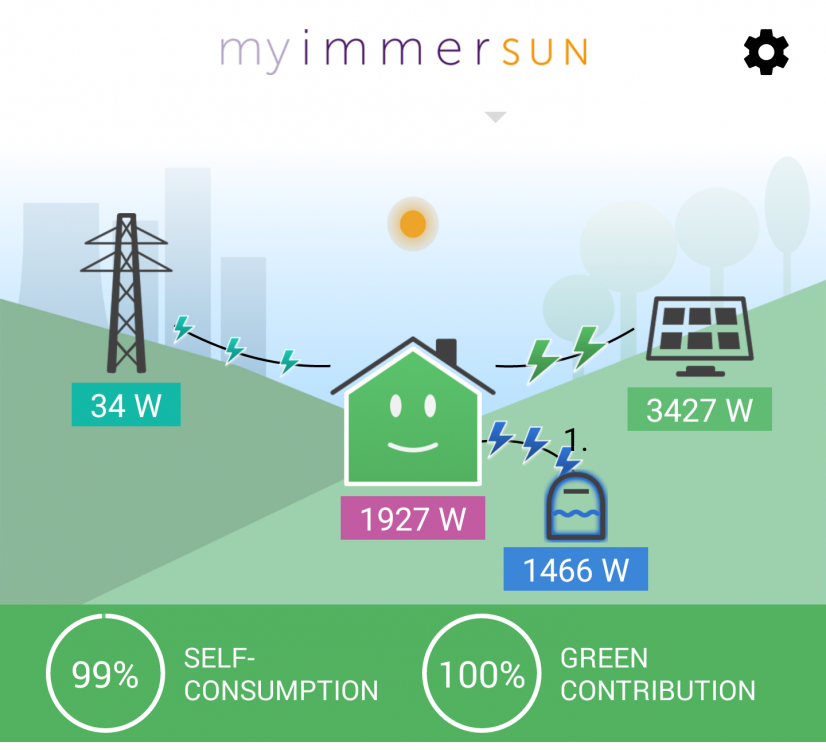

If you have a low energy house, close to passiv, then gshp may not be worth it, it is going to cost a lot more to purchase and install and I doubt you would recover the extra outlay. As you already have PV then just get a diverter. In our case we have 330m2 to passiv standards, inc pressure tested, and manage with a 7kW ASHP with 4kWp PV and an Immersun. We manage to use 97% of generated power with a total savings and income of £650 to £750 per year.1 point

-

I don’t think you should tile it i could look at those neat screw lines all day long.1 point

-

1 point

-

If you’ve a two storey building to do you’re going to need so many that it’d be worth hiring a bench saw with the diamond blade & water feed. Your Labourer/bucket carrier/fool will get a lot more done & possibly was born with extra digits so can cope with potential loss of a couple.1 point

-

Does depend what you mean by an immersion. Assuming that you mean a traditional hot water cylinder, then you can think of it as just a large kettle. You put cold water in, heat it up with a 3 kW element at the bottom (or midpoint/top depending on design), once the water is hot enough, you use it. Then it gets refilled with cold water (does this without you knowing as it is just replacing the hot water that you need) and either automatically turns the heating element on, or waits until the timer says it is time to switch on and heats the water if it needs it (think Economy 7 after midnight). There are generally two ways to 'manage' domestic hot water (DHW) in a cylinder. One it to use the water that is actually in the cylinder, the other is to have a heat exchanger that separates the cold mains water that you want to heat up from a volume of static stored water in the cylinder. The heat exchanger does not have to be very fancy, often just a coil of pipe within the cylinder. The Sunamp is basically a box of 'heat' that cold water is passed though to get warmed up via a heat exchanger. The difference between a normal cylinder is that the substance holding the heat (heat is the old word for energy) is not water but a phase change material (PCM). PCMs are sometimes a little hard to understand, but the easy one is water changing from solid ice to liquid water at 0°C. So imaging that you have some ice at exactly 0°C, as it changes into liquid water, the temperature stays at exactly 0°C. As it changes state (called phase in grown up science) it releases energy. We call this melting (or latent heat of fusion for lab coat wearing grown ups). The energy released can be transferred, via a heat exchanger, to 'something else', usually the air around the ice. The really odd thing is that a disproportionate amount of energy is released as materials change state. So imaging that solid ice can store 2.1 kJ/kg.K (J, joule, is the unit of energy) and liquid water can store 4.2 kJ/kg.K of energy you may think that as it fuses it would be somewhere between the 2, well it isn't. It is 334 kJ/kg, or about 100 times the difference (note that there is no K (kelvin) as the temperature stays the same at 0) The Sunamp does a similar trick but at a higher temperature, about the temperature you want your hot water at (that was lucky or it would be useless). So, when you want some hot water, though some sciency magic and trickery, the material in the Sunamp changes state and releases energy though the heat exchanger, warming up the water. If you want to know exact details, ask Sunamp or a Physicist, or at a push a Chemist (not Boots or Lloyds). This allows the Sunamp to store a relatively high amount of energy is a small box. There are some other odd things that happen with PCMs, one is the ability to store a lot of energy at a low temperature i.e. room temperature, but still release the energy at a higher temperature when needed. This reduces the need to have lots of insulation around the store. To give you an idea of how high thermal losses can be with a traditional hot water cylinder, I was loosing more energy from mine than I actually needed to bathe every day (reduced it with extra insulation, so not insurmountable). Some things just need lots of insulation, a DHW cylinder is one of them. A Sunamp is not much good in an airing cupboard as it looses little thermal energy to the air around it. So pros and cons. A normal water cylinder is well understood by most people, is simple (if electrically heated) and relatively cheap to install. The downside is that they are large, can be noisy (if you have a bad installation), heavy when full of water and can have very high thermal losses. A Sunamp is much smaller and lighter and has much lower losses. It is more complicated as there is a pump and control systems, and can seem, in isolation, more expensive, but that is down to installation and location to a certain extent. I do not have any connection with Sunamp, but have seen @JSHarris installation and was quite impressed with the unit (apart from the old bleed valve position which I think is now improved). There is probably a lot more to discus about the two different technologies, and I may not have got everything correct, or may have got muddles. But basically they are both ways to make cold water into hot water, which is very basic technology and engineering, so don't fret too much when comparing systems/installations.1 point

-

1 point

-

The chant "Yer wanna get a digger mate!" started in 2014, and I finally got one two years later. The chanters were right. But what I didn't hear was what they were chanting (sniggering) under their breath. "You're gonna get covered in grease". Let's start at the beginning. How much does a digger cost to hire? £70 per day. How much does it cost to transport it to and from your house / plot? £25. All plus VAT. Bang goes £300 / £350 per week. And it rains, or there's a delay, and it sits there leering at you like some hideous demented mechanical giraffe whispering softly in your ear Use Me Use Me If You dare. But you can't because it's hissing down. And suddenly it's Friday, a couple of hundred pounds has flown out of the window, and two of the jobs you had planned haven't been done. And soon you're driving around noting every single digger sitting there idle in a field or on the roadside and NOBODY'S USING IT. It shouldn't be allowed. Diggers are expensive; they should not be left idle. Or rather those ones that are idle should be loaned to you the second the owner decides to have a day off. It's OK, you'll come and fetch it and bring it back when the owner needs it. Anything but let a digger be idle when you haven't got one. And then you do a bit of maths: how many jobs around the site do we need a digger for? And the list gets longer by the week. The children start muttering about dad being on about a digger for Christmas and birthday present all wrapped into one. And then you start noticing things like zero-swing diggers, and that's a 22 tonner, and is that a 2.6 tonne or 2.5 tonne digger? Soon, you know how to tell. The next thing is: JCB or Kubota? Or maybe Volvo? Hmmm. Well Kubota have reliable engines (other companies fit Kubota engines) JCB - well, a bit sloppy round the edges. Looking on Tinternet for prices and maybe the odd trip out -just to look, no more you understand. A budget number bubbles up in your spreadsheet against the Heading Plant and Equipment. Suddenly there's 10K more than planned. But, you can re-sell it at the end of the build. So nett off the cost against the hire cost (minus VAT) and you're in profit (Ha!). The digger duly arrives. And suddenly a whole world opens up. Move that Cherry tree, no problem (that wasn't on the list), shove those steels through your son's windows (after he takes them out) no problem; move two tonnes of stone quickly from one place to then other - well not quite no problem, but you aren't sweating. See a problem, turn the key. Dig your SuDS drainage in less time than you thought. Move that newt hibernacular three meters to the right: done. The dozer blade is awesome (I hate that word: but here it's the right word). And then there's the maintenance schedule. A Kubota has more nipples than a prize sow. And God can they suck grease. And I'm not the best at changing grease cartridges - when I'd finished I knew what the phrase Grease Monkey meant. I will not want to sell it. How on earth am I going to get that past Debbie?1 point