Search the Community

Showing results for tags 'slab'.

-

We have about 130m2 of foundation slab that 1) needs to levelled and 2) needs to be raised by an average of 55mm. The foundation slab already contains the UFH pipes so there would be no intermediate insulation layer - the screed can be poured directly on the slab as far as I am concerned....

- 2 replies

-

- cemfloor

- self levelling

-

(and 1 more)

Tagged with:

-

Hi All So I've posted a few topics on the extension I'm having regarding UFH. So far, I've originally specced a Wunda EPS400 SYSTEM covering 52SQM across both the original part of the house and the new extension. This was on the assumption that beneath the current floor (15mm engineered...

-

Hi, I’ve got a rear extension within 45sqm of floor area which will be new floor (insulated, concrete and liquid screed with ufh). The existing area at rear of house is 25sqm of timber suspended floor. I’ve looked at the void is 750mm deep. Is this too much to make up? So I just leave the existing a...

-

Hi all I'm about to put in a concrete pad for an external water tank that will weigh 3 tons when full. This will be the biggest concrete job I've tackled and I'd appreciate your input please. The top soil has been dug away and the pad will sit on the surface of very heavy clay sub s...

-

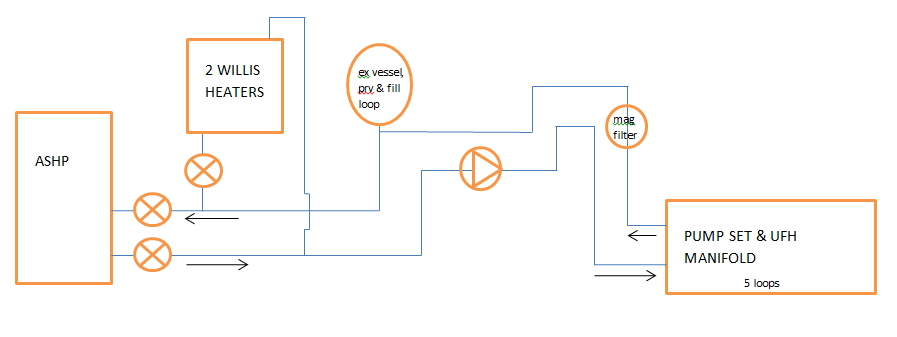

After much heart ache, time and tears I'm looking for some advice from you guys regarding my heating system, which is completely separate from DHW. I plan to directly heat my slab with ASHP using Willis heaters as back up. Hydraulically does this look ok? Input much apprec...

-

Hello, I’m refurbishing a Victorian terrace including removing chimney to create open plan space at the rear. Existing solid floor is being dug up and replaced to include underfloor heating. Existing quote and spec was hardcore, sand binding, DPM, 150mm concrete slab, 120mm PIR insulation,...

-

I'd like to run the slightly vague ideas I have past the forum-mind: How do you bring in mains water through your wall(s) and up through the slab? My hazy idea is that I run the blue alkathene through a suitably lintelled hole in my (solid, 215mm) wall, sleaved in 110mm soil pipe that is in tur...

-

I am annoyed this morning. Once again my washing-up water - the first hot water I have used in the kitchen today - is running warm then cold then hot. And the cold water is running warm then cold. This probably means that the last people, who renovated the house, did...

- 6 comments

-

- 1

-

-

The slab team from MBC arrived on site this morning. It's like having the building version of whirling dervishes who've just dropped a few speedballs. My word, they make progress! The team is headed up by Harry and he has 3 others in his team, but this will fluctuate a little over the...

-

I wasn't going to visit the site today, but we've had heavy rain showers today in Dorset and I thought that would be an ideal opportunity to see how level the slab looks after its late night power floating. My reasoning was that whilst I can't identify any high spots by eye, it would be easy to loo...

- 5 comments

-

- 2

-

-

- power float

- powerfloat

-

(and 4 more)

Tagged with:

-

So I have had a ten ton digger pecking rock out to make way for a basement and extension. Was planning on 200mm EPS under the slab, and 200mm EPS around the exterior of the basement walls. I do have two walls against the existing house to retain the house founds, as well as creating the basement wal...

-

MBC are currently scheduled to pour my slab next Tuesday, no idea what time yet. If anyone would like to come along, let me know. There are details on my BH blog of today's work on the slab with some photos of progress.

-

Spent the weekend setting out our house. Hired a theodolite. Turns out theodolites have gone digital in the 23 years since we last used one ? but a You Tube video helped and we spent a joyous 3 hours setting out all the corners of the house. Amazingly, we have dug pretty much in the right pla...

-

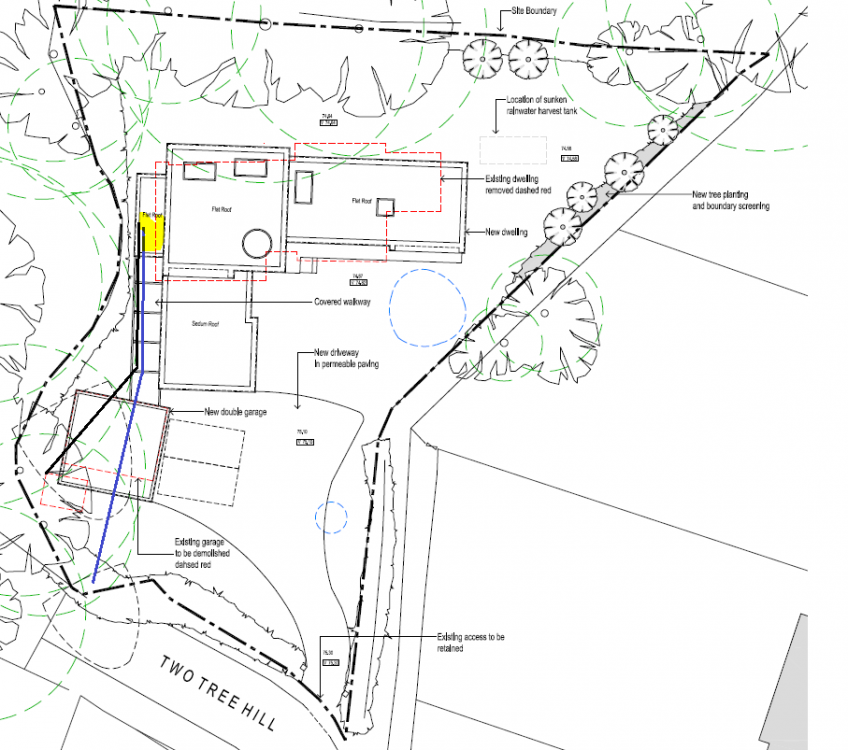

We are looking for some help from anyone with experience of MBC slabs. Its the order of doing things that is confusing us. We believe we need a land drain. We will also have surface water drainage. We have been advised by a drainage contractor to do the drainage (foul and surface inc soa...

- 6 replies

-

- land drain

- drainage

-

(and 3 more)

Tagged with:

-

We're extending rearwards to create a large open plan kitchen / dining / living area. The existing kitchen / diner at the back of the house used to be two rooms (kitchen and back half of the lounge. I built a stud wall to divide the lounge and then took down the wall between the new room and the exi...

-

OK, so I know my slab isn't level, you only need your eyes to see that. As an example; on the large sliding door I've got 20mm difference from one end to another (over 4m). I've got 5 sets of doors with level thresholds. Huge amounts of pre-planning detail was put into ensuring the doors would sit...

-

Pouring slab soon and how have people terminated their soil pipes pre pour? Trying to make power floating easier so do not want loads of pipes sticking up but also may want to make connection for toilets etc at low level. Have people just put on a coupling with temporary socket on the end of the pip...

-

Hi All, I've managed to get a contractor quote me to pour and level our slab. It's a 'renoextension' jobbie (Extensions are up and old slab removed from current house) so all internal walls are up and I won't have any other brick/block walls going up on the new slab. Only major load wil...

- 11 replies

-

- gen1

- concrete mix

-

(and 3 more)

Tagged with:

-

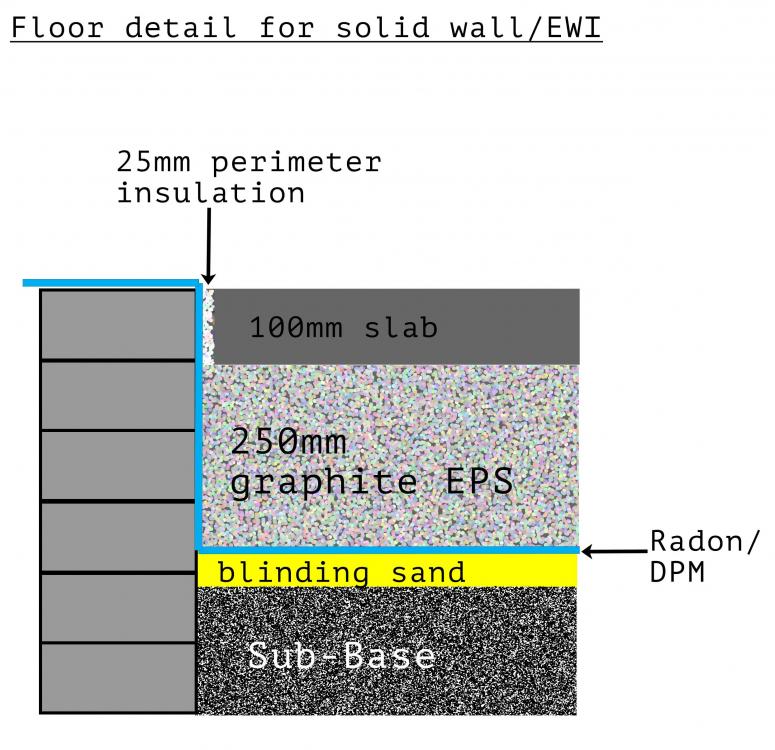

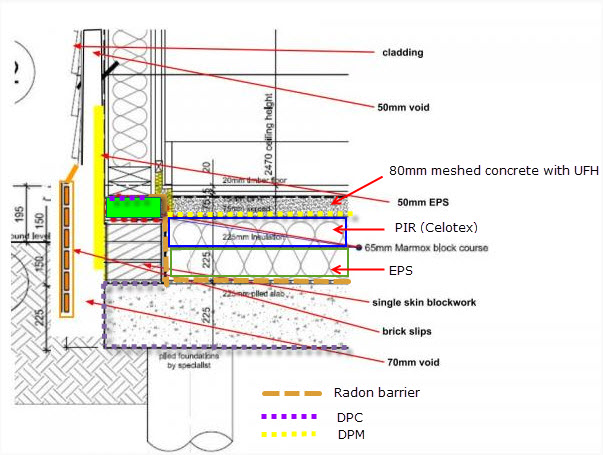

I've just about completed my slab insulation for my extensions (EPS + Celotex) and old bungalow (EPS). I've used 25mm of EPS perimeter insulation and will probably stick on the 8mm roll stuff that I will get from UFH supplier. So I'm just about ready to get my 2.4x4.8m mesh sheets into place (will h...

-

Slab Insulation, UFH and Mesh

MarkH posted a topic in Energy Efficient & Sustainable Design Concepts

Here's our floor construction. I'd appreciate any opinions on it and in particular on a couple of details currently in decision limbo: 1) I'd assumed the DPM would go as pictured in this diagram - under the insulation - as it seems to make sense to have it contained within the waterproof... -

Okay, big iceberg delivery yesterday, so now I need to start laying the insulation for my slab: Bungalow has two extensions which are piled slabs – both extension slabs will have a mix of PIR and EPS. The bungalow floor has been dug up, hardcore is down and I am ready to fil...