Search the Community

Showing results for tags 'concrete'.

-

I'm building an extension (basically corridor) between my house and a detached garage I plan on converting. The trenches at 600mm wide leave just a small strip in the middle. Aside from the cost of concrete, is there any reason for this to be 2 trenches or could I just excavate the lot to the levels specified by BCO and fill the whole thing with concrete? Blue lines mark the inside of the trench

- 4 replies

-

- concrete

- foundation

-

(and 1 more)

Tagged with:

-

A word about concrete slabs, especially in hot weather. Concrete is a highly sophisticated product, and with proper handling it produces effectively rock to the shape you want. Many things can go wrong, but they can all be controlled. The principle is that we are gluing together bits of rock, back into the form we want, using cement. There should always be a proven formula for the mix. For a bridge or multi-storey it is very much more precise and controlled than for a garden path, but it is always worth attention. The main thing that most public don't realise is the difference between cement and concrete. Cement is ONLY the dust that goes in the mix to make mortar or concrete. The biggest important thing that many in construction do not know is that concrete is strong through curing, not drying. Do not assume that your groundworker knows all, or much, of this. For a strong concrete mix there are large stones, with all the gaps between filled with small stones, and the further gaps filled with sand. Every surface is coated with the slurry of cement and water that has been carefully mixed in. There are no pockets of cement, it is all aggregate to aggregate contact. A chemical reaction then happens that makes the cement stick everything together, and water is used in this reaction, and taken out of the mix as a permanent part of the matrix chemistry.. Any additional water will simply sit in the mix, until it evaporates, leaving lighter concrete and miniscule gaps. It is essential that there is the right amount of water. a) enough to allow the chemistry to occur. b) not too much that it spoils the mix and eventually leaves voids in it. The chemistry takes many days, and concrete gets harder for at least a month, if properly looked after. For this to happen, the laid concrete must not be allowed to dry out, so it must be covered with plastic or wet hessian. Once the surface is hard, water can be sprayed over it. Don't use too much water, and don't allow the concrete to dry out through sun or wind. If it is very hot or windy, postpone it. (Frost is another matter). Why do supposedly expert groundworkers have problems with cracking? Mostly because they add extra water, by hand or by asking the delivery driver*. This makes it much easier for them to handle. Secondly because they don't know the difference between drying and curing, and want it to go hard so they can go home. Thirdly incorrect use of steel mesh (which is for cracking control not strength), dpm, and joint preparation. (* A readymix company will allow water to be added, but will record this on the delivery chit, and thus it is not their problem. They may also takes samples and make cubes for testing, and store them in a tank of water for ultimate strength, for 7 and 28 days.) All concrete cracks. How and how much it cracks is the skill. Enough for now, do ask for clarification or more information.

-

Feeling both silly and satisfied at the same time right now. I read the (bleep) manual before starting, setup the two levers on the drill and set to drilling 26 - 30 holes in concrete. 14 holes in, over two days, and a lot of aching joints and muscles last week, I started up again this morning before the rain comes. 2 more hours done and I think that lever is showing a drill, not a hammer. Flick. OMFG. 10 minutes later, 2 holes done. Hallelujah, hallelujah, hallelujah. The rain is now arrived, so waiting until tomorrow so as not to mix water and electricity. But now looking forward to the job 🙂🙂

-

Hi, I need some advice on what wet UFH system to get for our renovation of a 1970s 3 bed bungalow. The house had subsidence so in the process of fixing that the floors were dug up and replaced with the following construction: hardcore base, membrane, 150mm insulation, concrete finish. Unfortunately we had no say in this setup so we're stuck with it now. We're left with a 40-50mm gap between the concrete and the base of the front door, which obviously limits what we can do with UFH. There are of course low-profile retrofit UFH options and we'd have liked to have gone with the Nu-Heat LoPro Max with self levelling compound but that is way too expensive for our budget (double what we want to pay). What are our other options, especially considering our 40-50mm gap, and the 150mm insulation beneath the concrete? I've seen the pre-cut boards that pipes are laid in which have no compound/screed on top, would these work well enough with our floor construction? Or should we go down the normal route with pipes in screed but only have 40mm thickness? Insulation below a concrete slab means the concrete becomes a part of the thermal mass, so because it has a slow response time would it make sense for the UFH to be run continuously? We'll be installing an air-source heat pump together with insulation above the ceiling and on the outside of the house with a render and/or cladding, so would this help with the response time and/or be sufficient to run continuously or intermittently? Any help would be really appreciated!

- 4 replies

-

- underfloor heating

- insulation

-

(and 2 more)

Tagged with:

-

I have an old (1810) listed building which has some damp issues. In the kitchen where there is damp at the base of the internal walls there is a (added in the last 30 years) concrete slab. Buildings of this age have no DPC and as the concrete itself looks to be damp, my feeling is that the concrete slab meeting the solid brick walls are probably contributing to the problem. Reading on buildingconservation website: https://www.buildingconservation.com/articles/solid-ground-floors/solid-ground-floors.htm One of the suggestions is to use a limecrete perimeter around the slab. This provides the capillary break required, allowing the substrate to breathe and preventing the footings from drawing trapped moisture into the walls. "A hybrid floor design with a modern slab isolated from the walls by a vapour permeable limecrete perimeter strip" To me this sounds like a sensible and relatively un-invasive option. Just wondering people's thoughts on this? Has anyone ever heard of this being used with success/failure? Modern DPC injection is out of the question so this sounds like a decent thing to try.

-

I have acquired a number of (plastic) concrete slab moulds (riven face) with the intention of casting my own slabs. I plan to trial different aggregate types (coarse gravel / quarry dust), and adding colourant to see what comes out best, using a basic 1:2:3 mix. I'm aware I will need to use a release agent of some sort in the moulds. I know vegetable oil has been suggested here before (rather than the significantly more expensive release agents you can buy). Anything else anyone would advise using?

-

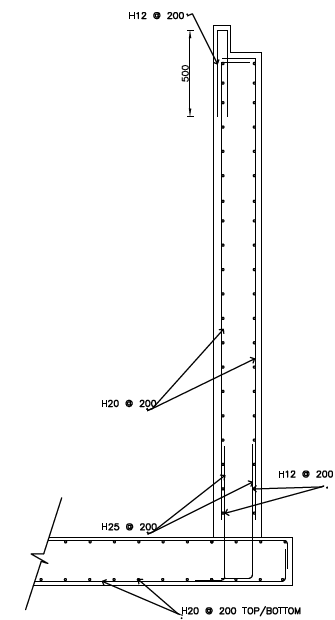

Hey, I am building a new home with basement. My structural engineer has specified a 400mm thick sl ab, and the slab reinforcement is 100% H20 rebar. This is to support a 5 bed property over ground, 1st, 2nd floor, meaning the basement walls are structural. I assumed that the slab would have been mainly made up of steel mesh, and H20 starter bars for the walls. Instead, over a 240m2 base there will be 8259 linear meters of H20 top and bottom. The wall starter bars are specified H25. Does this H20 and H25 sound overkill? £16k + vat worth of steel in the slab alone. If you know groundworks well, I would be interested in your thoughts Thanks

- 37 replies

-

- basement

- concrete slab

-

(and 3 more)

Tagged with:

-

Hi all I'm about to put in a concrete pad for an external water tank that will weigh 3 tons when full. This will be the biggest concrete job I've tackled and I'd appreciate your input please. The top soil has been dug away and the pad will sit on the surface of very heavy clay sub soil (currently also supporting the foundations of our self-build house). Dimensions of the pad are 2700mm square and 125mm thick. A C40 mix seems to be best for septic tanks so I'm assuming the same for this. I'll be mixing it myself, and I plan to add grid rebar. My questions are: 1. should I put down membrane and gravel layer first? If so, can I use a random mix of rocks and stones (we have plenty on site)? 2. there's currently a layer of soupy churned up clay on the surface, is it best to remove this first? 3. I've found variations online for a C40 mix, can anyone tell me the correct mix? 4. If necessary could I pour the slab in two sittings? TIA, any other suggestions welcome.

-

Hi, I am planning a project to make a concrete shed into a live-able room. The walls are made of concrete and the roof is made of wood, I plan on insulating the roof but I'm not sure weather I need to insulate the concrete walls or just the concrete will be enough to keep it warm all year round. I've never done a project like this so if anyone has any pointers or ideas that would be great! Thanks!

-

It's not a roof update . . .

canalsiderenovation posted a blog entry in Canalside Bungalow Renovation

To those who commented on our GRP, this is not an update. The next installment to that will hopefully be at the end of next week when the crap roof will be off and a proper company coming in to sort after we insisted on an insurance backed guarantee. I shall update then, watch this space! Flat roof aside..... All our new extension had insulation laid and our existing flooring excavated for insulation too. We had the UFH pipes laid and there was A LOT. And then screed laid which is suprisingly even and flat using TG Cemfloor – a liquid self-levelling screed. Needless to say they did a better job of this than the roof. And part of the in roof solar frames have also gone up. Our builders found these up the loft when taking down the old ceilings. Unfortunately empty! Someone had a good party ? -

Hi all, Very much a novice with a small project here but this looks like the place to come to get some great advice and experience. We are landscaping our garden and have just finished decking outside the kitchen door area. There is a very ugly block concrete wall directly opposite the door, running down our lovely new decking which is an eyesore but cannot be changed. It is north facing and gets 0 sun exposure all year round so I cannot hide with planting. We looked at timber cladding it but the opposite side of the house will be timber, as is the decking so I thought that might be too much wood. We have decided to go with Corten to cover it as I really like the look once it has 'weathered'. I think it will work well alongside the timber as well. My question is, how to I fix it to the concrete block wall? Ideally I do not want to have to put timber framing up as it will eat into the decking space. Can I just screw/ nail it to the wall? Do I need special screws/ nails for this? I would like them to bend in with the Corten once it has weathered. I have trawled through Google but have only found one vaguely useful video on how to put it up (attached directly onto the concrete (not block) wall with "Hammer-set" Heavy duty nail drive anchors.). These stand out against the rust colour though and i would like to avoid that. Has anyone else done anything similar? Any advice very welcome. Thank you

-

Hello, I would like some info/advice regarding a cold concrete flat roof. Sorry for the length of explanation.... But first a little background info...... The house we purchased was gutted, renovated and then sold on to us by a local building company... All certs for all upgrades and works were checked and passed.... Our problem.... 1 We moved in Sept 2107 all is fine until the first frost off this winter late 2018..when we started to notice a water stain in the rear utility ceiling (formerly downstairs rear loo and storeroom). These rooms were incorporated in to the house via the kitchen to form a utlity/cloakroom and extra kitchen space..... The roof itself is around 8 inches of concrete topped off with felt.. This was refelted just before we moved in... And the rooms below batterned, insulated, boarded, skimmed and redecorated. Oh and rads fitted. Since this watermark has appeared and got worse over the last month or two.. I cut a peice of board out, to be greated with a soaking wet inner roof, droplets everywhere.... Our problem 2.... The house is a semi formerly a council house, we have great neighbours who are council tennents... They have the same sort of rooms as us but still the original loo and store (no heat sourse).. And attached to ours So taking advise online of fitting a VCL then a thick insulation then watertight layer is not really an option without affecting the council properties roof.. So I am left with trying to sort the problem from inside.. Although there is much advice regarding how this is now not advisable.and insulating from outside is they way to go... Is there anyway I can fix this from within... I am happy to take down the internal ceiling and start again. But what would be the recommended materials etc etc.. To ensure no water ingress... You can see by the images that there is no VCL inside and the insulation is very thin and not sealed in anyway. Just placed in the roof void not a good job at all.. ... Please please any advice would be gratefully received.... Mark

-

Hello, I’m refurbishing a Victorian terrace including removing chimney to create open plan space at the rear. Existing solid floor is being dug up and replaced to include underfloor heating. Existing quote and spec was hardcore, sand binding, DPM, 150mm concrete slab, 120mm PIR insulation, 75mm sand cement screed. Builders are now suggesting hardcore, sand binding, DPM, 120mm insulation, then 150mm flow screed i.e. no concrete slab. Aside from issues this might create with the heating (less responsive due to thicker top layer), is anyone able to comment on the structure of this build-up? I've seen specs for similar build-ups (i.e. insulation directly onto hardcore instead of slab), but that's when the top slab is 150mm concrete, not flow screed. I'm not convinced in not having a concrete slab somewhere in the flooring structure, but would be good to get some thoughts... Many thanks, David

-

Hi, I have just bought an old stables conversion that needs some serious TLC! One of the things that needs addressing is the driveway. It appears to have been some nice looking cobbles that have been concreted over. See picture. Is it possible to uncover the cobbles and return the drive to its former glory? If yes, is there a specific way of going about it? thank you.

-

Up to now, I have needed to fix large bits of wood into concrete. And I'm (well, was) happy with that until I found myself reaching for a 10mm SDS bit and Thunderbolts to attach something quite small to the wall. . I'll soon be hanging a range of things into the concrete walls, from electrical back boxes, to shelving to the MHVR box. I'm trying to use just one product - in the same way that Thunderbolts have served me very well for the last year or so. Which single range of fixings would you use to fix stuff into concrete?

-

Building on the comments from this thread, the good weather forecast, and the current low level of the water table , we're planning to 'sink' our poo tank this coming weekend. Using dry mix concrete. (Thanks J for the advice, we'll do exactly what you did) In recent weeks I've been reading a lot about concrete - and more specifically dry mix concrete. @Bitpipe talks about using up spare cement and and sand: this search provided some very interesting reading. It seems a very versatile mixture, which until recently, i would not have given it any thought. The search above points to all sorts of uses. But without water - how does it go off? Does it just take the water out of the atmosphere? And so that means you can't guarantee when and how fast it sets? Is there a rule of thumb about when to use dry mix instead of wet mix?

-

Hi, We're about to start our project - 250m² 1.5 story house with basement on a sloping site in Holywood, Co. Down. Drawings all done, just waiting for planning to come through. My background is an engineer/project manager in the water industry, so I'm planning on using a lot of innovative, rapid, and non-traditional construction methods - focus on safe, rapid construction and simplicity and reduced dependence on trades. We're also aiming for passive levels of insulation and airtightness - south facing site with lots of glass. So, expect lots of posts about insulated foundations, ICF systems, tanking, shuttering concrete walls, floor deck systems, MVHR, the lot! Thanks.

-

Well those of you who read my introduction may well know that I am planning on building a new garage and converting a sun room into a proper room for a new kitchen. Anyway, I have started the garage, although I still have no planning permission I have started the ground works, even if there are changes in the proposed garage much of what I have done so far still needs to be done - even if we were outright denied planning I would still pave this area for parking - hence works not a waste. I have not fully exposed the site to keep the garden secure for now but I have cut in most of the shear key for the concrete and then dug the trench for the rear found - it needs squared off etc. but that was the first dig to get it all into rough shape. I will have a 1.5ton excavator soon so I can scrape the rest of the site, I am also building up the lawn/dropping the patio as part of these works so the current lawn will be dug up, then a deeper hole or trench dug that the gravel from the garage site can be dropped into a good few feet down (if it was cleaner I would have used it for the first layer before hardcore for the concrete - I guess I still could), then working carefully I will then scrape the good topsoil off and that can go into the lawn. Then I will lift a big patio, scrape the sand and whatever else is down there off, if good sand I will work that into the soil for the lawn, then basically pull the whole patio area down into the current lawn, I will then basically accept whatever level that leaves me with, but it will be the same level throughout with a very slight incline to the garage. I will keep this posted as stuff happens. This will be a true build thread and it will be slow as I am doing it after work and weekends as well as other projects and interests.

-

Howdy. I want to fit a log gasification boiler in a garage. The garage is akin to a basement, offset to the right and one floor down from the entry level of the dwelling. If the appliance goes to the left rear corner I can rise vertically and bolt onto the side of the gable, rising accordingly to clear the ridge draught. Problem is, the garage roof is the right hand 'garden' of the house ! I haven't had a look as to whether its already leaky, but needless to say I need to meet or exceed its current state if I make a penetration through it. Im assuming B&B with ( water proof ? ) concrete over-pour as this is an existing turn of the century cottage. The garage, I think, is an afterthought as it looks to be built off the side of the house ( which is elevated 9' higher than street level ) but if original what would it have been ? Was reinforced concrete formwork around back in the day? So. Concrete core drill or series of holes and punch through to make the hole, then what? Sleeve and 'grout' with a waterproof slurry? back-fill with a resinous HR material ?Then take the flue through the sleeve with an intumescent seal and rain deflector ring? First time I've ever had to punch through a living roof, so any pointers would be appreciated. Take me now lord! Cheers.

- 4 replies

-

- concrete

- living roof

- (and 4 more)

-

I wasn't going to visit the site today, but we've had heavy rain showers today in Dorset and I thought that would be an ideal opportunity to see how level the slab looks after its late night power floating. My reasoning was that whilst I can't identify any high spots by eye, it would be easy to look for the low ones by where the puddles were lying. Here's a photo taken from a slightly elevated viewpoint (the top of a pile of wood chippings!), looking from the south east corner where the snug will be, over towards the north west corner, where the main living area will be. Most of the puddles that you can see are barely a couple of millimetres. I'm not sure how long it had been since the shower that caused these, but it was a breezy day and not hot. The next is taken from the other end of the right hand side of the property, as seen above. Between the brown foul waste pipe and the white UFH pipes, you can just about see that there is a hole in the slab. This is meant to be there right now, but is due to a mishap yesterday. As the concrete was being transferred in the digger and poured from the bucket, the digger rocked slightly and the bucket bounced on the exposed UFH pipes. Harry from MBC reckoned that one of the pipes has been damaged as a result, and so the area around the punctured pipe has been left uncovered. My trusty plumber/UFH person will be coming early next week to fix the damaged section of pipe and make good on the concrete floor, and MBC will be covering the cost of this. Once I have the bill for the repair, I will pay it and MBC will deduct the amount from my next stage payment. This was all agreed this morning without any arguments or quibbles. So far, all the puddles in the photos have only been a couple of mm deep. The deepest is on the far north west corner of the living area, shown below. It's not easy to guage the depth of this area, but I think it's about 4mm at the deepest. The thingies are a couple of end caps that get put on the pile rebar, but the wind was blowing them towards me. You can see how they are tilting. Here's another view of the same: I don't recall the exact tolerance that the slab needs to be within off the top of my head, and I'm not going hunting for it right now as I'm one g&t into Friday evening with a couple more to follow, so no point now. However, the figure of 5mm is scratching away in the deepest recesses of my grey cells, so I think this should be acceptable. If anyone knows otherwise, please speak up! The finish on the surface overall is very nice. I had a walk over the whole thing and couldn't see anything obvious, but then apart from squishy concrete under my boots, I wouldn't know quite what to look for anyone. To my unpracticed eye, it looks pretty good. One very good think that came about from all that excess concrete being dumped all over the place yesterday is that the team spread it all out between the hard standing and the slab, so I now have an even more level and sturdy surface for the crane when it arrives with the timber frame:

- 5 comments

-

- 2

-

-

- power float

- powerfloat

-

(and 4 more)

Tagged with:

-

My thoughts are turning to screed for our new build, as with the roof scheduled in about 4 weeks, it will be time to get it organised. I keep hearing horror stories of 8 week drying times and cracking floors etc etc, and as i know little (very little) about screed ..I did a bit of reading up. Now I have a good drainage site, with suspended B&B and it will have Kingspan insulation on top. The only issue at present is whether we will go for UFH...as due to budgets...we will be tight... ...but we WANT to have it...So We will look at things from that perspective (optimistic!) I suppose the Floor Area is around 100m2 when all told ...Still not sure if UFH goes everywhere or just in "rooms" ...I mean downstairs WC, Utility Room, Hallway ..is it common to UFH those ? But either way ...Does anyone have any advice as to Cost and timings for various options on Screed for me?.... the builder seemed to think it would require a "standard 75mm" ...I am presuming depth ...I thought that sounded deep but looking online it seems common ...especially as it has to "hide" UFH tubes. I mean does having UFH in there make it "weaker" ? ...Will it be prone to cracking with heat? ...just how accurate is it when people (anecdotal) say it shouldn't be walked on for 4 weeks or worked on for 8?

-

...for the MBC team, and not their fault, but I have a slab. This is only down to the tenacity and incredible hard work from the MBC team who snatched victory from the jaws of defeat today following horrible equipment failure on the part of the concrete company. So, let's start at the beginning. The slab team worked like frenzy yesterday morning to get all of the EPS down, followed by the mesh which then got tied into the ring beams. After that, they put all the underfloor heating pipes in (there are several zones and many, many pipes to come into the manifold). The building control officer turned up just before 6pm last night and gave everything the okay for the pour today. Here's the slab with everything on it first thing this morning, just waiting for the concrete, at shortly after 8 this morning. On site already is the pumping lorry and one mixer of cement. Very exciting, so far, so good. They started with the furthest part first, and the first lot of cement went onto the garage area, where the chaps are standing in the above photo. Here's the pump, concrete lorry and plenty of other equipment all good to go. Except, it wasn't good to go. Well, it was, because that's what it did in the end. Go, that is. The concrete pump packed up and after a good while of trying to fix it, nothing was happening so off it went. All wasn't lost, however, as one of the drivers was also a pump operator and offered to get a fairly old pump out of retirement and use that. Brilliant! This is the ageing pump putting the concrete over to the garage. Meanwhile, several hours have passed and after a bit of grumbling earlier in the morning about the concrete lorries not turning up on time, suddenly, they're coming thick and fast and are all parked up our narrow country lane. Then the second pump got blocked and couldn't be cleared. A very large man with a very large mallet did all he could to clear it, but it wasn't working. By now, it was nearly 2pm and the slab should have been poured a good few hours ago and power floating started. Left with no other choice, Harry, who was heading up the team, got the bucket onto the whopping great digger and ALL of the rest of the cement got dumped onto the slab by digger, and then the guys had to drag it over to wherever they needed it. This was for a floor area of about 180 sq metres. Fortunately, there were 5 on the team today as they had brought in an extra guy to cover for one who was late back from holiday, but turned up straight from the airport to the site so the numbers were beefed up, and boy, did they need all of them today. The garage slab was screeded (is that actually a verb? Dunno, it is now), and was looking fine. Eventually, the rest of the concrete got where it was supposed to be and the lane finally emptied of concrete lorries - there were 5 on or around the site at one point this afternoon. Now, the eagle-eyed amongst you will realise that there are no photos of the final, powerfloated slab. This is because I pushed off at 5.30 this evening and they were only just starting on the garage; they reckon that they would just about get it finished this evening by the time the light went, so I'm afraid, dear reader, that you really will have to wait for those photos. One final photo from earlier in the day has something of interest, as it shows the shuttering that was put in place on the threshold for the lift and slide doors that are going in the living room area. Tune in soon for the next thrilling update!

-

MBC are currently scheduled to pour my slab next Tuesday, no idea what time yet. If anyone would like to come along, let me know. There are details on my BH blog of today's work on the slab with some photos of progress.

-

Embedding threaded bar in concrete.....

ToughButterCup posted a topic in General Construction Issues

.... shouldn't be too hard - I know now, because I've done it before ? This time I want to keep the threaded bar (inserted horizontally into the hole) perfectly level while the chemical anchor dries. I'm thinking I need some of jig (or thingamajig even) to keep the threaded bar perfectly horizontal while the chemical dries. Anyone done summat like this before? I have 40 to insert.....- 5 replies

-

- concrete

- chemical anchor

-

(and 1 more)

Tagged with: