Search the Community

Showing results for tags 'pir'.

-

I am about to insulate a wall. I am comparing Jablite (not basic polystyrene) to PIR board. I can make the wall thicker when using Jablite rather than PIR so thickness is no problem. It will not face compressive forces so no compressive strength issues. The cost seems to be about half. Both products seem to be combustible. If I understand it right, PIR encapsulates a gas which leaks out over time eventually reducing the product to the same u-value as Polystyrene. Why shouldn't I use Jablite?

-

I need to replace some old glass mineral wool insulation in my loft. I have very reduced head height (approx 1.2m) and being a listed building I am not allowed to insulate between the rafters. I have a load of left over foil backed PIR which I was going to stick on eBay. Is there any reason not to use it between the joists on the floor? All searches seem to show PIR between the rafters and rockwool on the floor but I can't find anything which says this would be a bad idea. The loft is very well ventilated and I'll make sure I don't cover any soffit vents etc.

-

What are others' thoughts on the efficacy of PIR retaining clips. I have anecdotal evidence from someone about them working lose over time thus leading to draughty gap between inner leaf and PIR. My wall build up (just starting) is: 100mm Thermalite, 150 gap with 100 PIR batts, 125 cotswold stone. I will say in advance that I have an excellent blockworker who is a stickler for detailing, knocking snots off, etc. He already beat me to the punch on foil taping all PIR joints (assumed I'd have to nudge on that). I was going to start a convo with him re: sticky foaming the PIR to inner face as they work, as well as the retaining clips on wall ties of course. Overkill? Cheers Tom

- 2 replies

-

- pir

- insulation fixings

-

(and 1 more)

Tagged with:

-

So the floor is going in. The second half of the sub-floor area of concrete was done diy by family and friends, using fibre reinforced concrete. A great success, and who needs groundworkers, as long as you have one skilled person and 4 barrows with 4 helpers? 150mm of insulation is next. Planning on 2 layers, 100 over 50, thanks to the very helpful older discussions. as it is slightly cheaper, allows laps, and also better for cutting in isolated pipes and ducts. Then there will be 50mm Cemfloor with UFH. Maybe use 50EPS for the bottom as it will save about £1,000 and there is a diminishing return as it gets thicker. On the other hand, for a big order perhaps PIR will reduce in price enough. Any suggestions as to buying from the national specialist merchants, local merchants or the online companies? I think someone said that PIR only comes via merchants but EPS can come from manufacturers. Total area is 270m2, so pretty well a small lorry load. Perhaps that can come straight from the manufacturer and save double handling by the merchant that takes an easy fee. FYI online prices are, per single sheet, PIR 50mm £22 or EPS £11 100mm £39 150.. £62 (and sometimes 125mm is dearer than 150.)

- 12 replies

-

I've messed up and set the block and beam too high, I now only have 150mm to the top of the bi-fold reveal and am concerned that a ufh system will leave the room permanently freezing. The back wall is only 6.66m and 3m of that is Bi fold doors but space is tight and a radiator will really make the modest dining section too small. We wanted a tiled finish, so allowing 20mm for that I've got 130mm for pir and screed; Is that a bad idea or will the room be ok? I don't want to freezing every time we sit down to eat.

-

Could someone please sense check this insulation for a solid wall for a garage conversion. I have asked building control but they said they weren't interested. Things I'm not sure about. I have a very small air gap but I think this is countered by the breather membrane, does this make sense? Using uncoated PIR (thinking this General-Purpose-Polystyrene to save quite a few pounds) between the battens because the outer layer of PIR will be coated and act as the vapour barrier. Apologies have asked this question before but slight change here in the makeup so want to make sure I get it right. Thanks in advance

- 8 replies

-

- solid walls

- insulation

-

(and 1 more)

Tagged with:

-

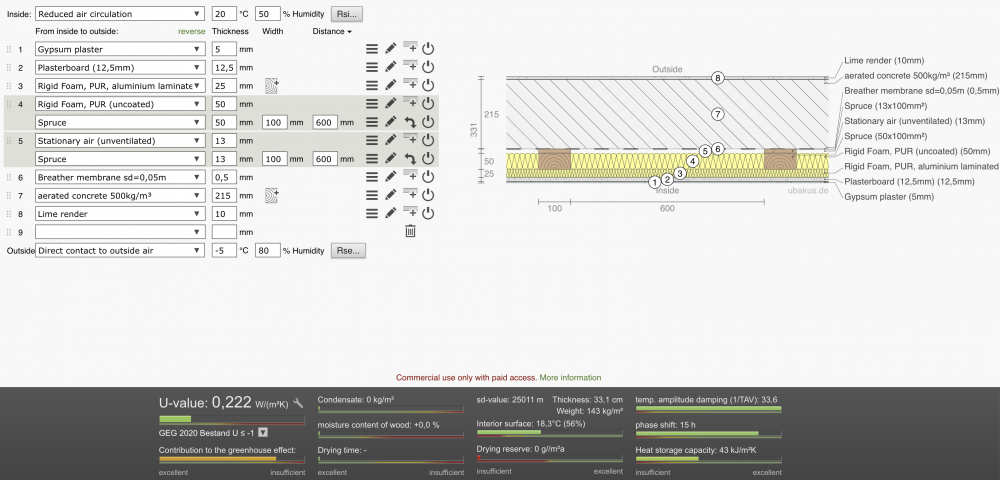

Hi, anyone have any links to good u value calculators? Tried some from PIR manufacturers - unfortunately not all options are listed. I'm renovating a house and the spec seems stricter in Scotland than elsewhere regarding u-values for new builds, refurbishments, extensions etc. Building Control have specified my walls to be within this spec which is 0.22. The house is built with double block, outer leaf rendered 15>20mm, dense block. There is a 75mm cavity with inner leaf dense block. The entire structure will have a certain value before I add the insulation etc. I will be going down the route of installing PIR directly onto the inner face of inner leaf, taping then battening and dry lining the walls (warm batten). I'm looking for a calculator which will allow me to enter all these details if there is one out there. I have been looking at 100mm PIR but if I can reduce this even a wee bit, I'd be delighted. No biggie if I can't. Thanks

- 4 replies

-

- u value

- insulation

-

(and 1 more)

Tagged with:

-

I'm looking in to converting a detached garage to a living space. The wall construction is 200mm lightweight blockwork rendered externally. As the garage goes right up to the boundary my only option is internal wall insulation. I will need multiple things attached securely to the wall (toilet, boiler, sink etc) so I think insulated plasterboard is going to be too much of a pain to use. If I use internal studwork with foil backed PIR between studs does anyone have an idea of the best construction for this which will achieve a 0.28 u-value or lower to satisfy building regs? I was thinking of 100mm studs with 75mm foil backed insulation pressed up to block work 25mm void OSB board pattress where strong fixings are required 300GA Vapour Barrier 12.5mm Gyproc Wallboard Plaster Skim Questions are: Does this sound sensible? Would it be better to have insulation flush with front of studs? Can I use the 25m void to run cables/pipes?

-

- insulation

- fixing through pur insulation

-

(and 2 more)

Tagged with:

-

So I'm finally starting on the ground floor buildup. It's 50mm poured screed on 150mm insulation (100mm PIR/50mm graphite EPS). I'm unsure of how the tray works in this situation... The tray is (IIRC) about 45mm thick, so I'll need to set it on ply/OSB/cementboard to get the levels right. That bit's OK. But how does said underlayer sit on the PIR, is it just bonded down or should it extend under the screed edge too, to "key" it in? It's in a corner so two walls and two floor edges. ta

-

Hi there, I've a 125m2 extension being erected next year with a pretty basic floor slab planned. Floor covering 65mm Screed UFH Pipwork 150mm PIR insulation 100mm c35 concrete with mesh Whilst looking at the overall prices of each piece of work there's a couple of questions that have come up would it beneficial to change the floor structure to incorporate circa 250mm of eps insulation under the concrete slab, instead of the 150mm pir above slab. And whilst I am at it, possible to incorporate the Under floor heating pipework into the slab, as opposed to having the pipework in a screed on top of the slab? The reason for looking at this is to save time and money. The 250mm of eps insulation has similar u value to 150mm pir, whilst being cheaper - circa 1k at the moment, but there is another price increase on pir due in February. If I incorporated the pipework into the slab, I could save circa 4k for the screed work post panel installation, but it would also mean I could crack on with the studwork immediately after the kit erection as opposed to laying pipework and ordering in self levelling screed. any thoughts/drawbacks?

-

Just getting my head around wall construction and the balance of vapour, heat and draught resistance and how they work together. I'm planning to renovate my walls (internal, as neighbours in the terrace aren't necessarily enthusiastic) house-wide - the solid double-brick victorian design (basically just bricks with plaster on it) has some significant room for improvement. But there are a dizzying array of options and configurations for internal wall insulation and it seems like information "out there" hasn't quite kept up with our developing understanding of water vapour and airtightness. Here's my current understanding, am hoping folks can correct me where I'm wrong (from outside to inside): 1. The air outside: The weather here in the UK is rarely on average over 21C, so the inside of the house will almost always be warmer. So the design needs to address water vapour that is *leaving* the house, getting cold and turning to condensation at some stage during its exit from the inside rooms. Not much reason to worry about water vapour coming in from outside. 2. The outer structural layer, that is in my case a solid double brick layer has a Vapor Resistivity, N s/(kg m) of 45 - 70 (got that from here: from here: https://www.engineeringtoolbox.com/vapour-resistance-d_1807.html). This means that it is "semi-permeable" 2b. Leaving on plaster (or not): Most of my walls have plaster (in some cases lime plaster, but haven't done an exhaustive survey), which I gather is straight-up "permeable". I can't see a consensus as to whether it's better to remove or not remove plaster, but I gather it may be necessary to remove (a) so that one can assess damp problems in case they aren't fully permeating the plaster to the inside layer of the wall (to show on paint etc.) and (b) so as to install some sort of membrane, or (c) obviously to address where there has been damage, and it seems to make more sense to leave it off if it's already off. But it seems like some folks like to save time and energy by leaving it on if there aren't mitigating situations. I'm about 70/30 leaning towards removing paint and plaster to expose the brick and check things out properly. 3. Air gap (or not): I've noticed some disagreement as to whether an air gap is now necessary. I gather an air gap is needed so that air can circulate vapour so that it can evaporate or vent out through the brick wall rather than condensing as it might in a tighter space without air. For the air gap, I can do battens over walls - and it seems that wood and stainless steel are the likely options here, nailed or screwed. Steel is more expensive, but will avoid rotting better than wooden battens (though damp proofing should ensure this isn't happenning!). Seems like Damp Proof Membranes are also an alternative, but a bit of overkill for my purposes here as it's not a cellar and all walls are above ground. But then the 4. PIR boards. I'll get these with foil backing, as this has an astronomical Vapor Resistivity value (4000), putting it on the very high end of "vapor impermeable". But it seems that some folks prefer the more labour intensive but easier-on-battens-long-term "warm battens" approach, where a insulation is split into two layers (a) a membrane is put down with half or more in layer of foil-backed insulation and then (b) an inner layer of battens with more insulation boards inbetween. This keeps warmth around the battens and ensures that moisture will condense further out in the wall. This seems reasonable to me - and I don't mind the more challenging job if there's an efficiency to be gained. What I'm not sure about is whether to use a membrane or foil-backed insulation boards for the vapour membrane at this stage. And if I use a membrane can I skip the air gap? 5. Plasterboard. "semi-permeable" here, skim on some plaster and ready to go. With regards to thermal transfer and insulation performance, here's what I've got: 1. Air = cold 2. Brick wall has u-value of 2 W/m²K or so 3. Air gap will reduce this slightly 4. PIR boards have a very low U value, which is why they'd be preferrable in walls to various wolls, cellulose, or other good options. I'm aiming for 70mm PIR or more (if possible) to try and get as close to or lower than my target U-value of 0.30. 5. Plasterboard adds a bit here too, but not much. Compliments of diydoctor, here's a diagram of what I'm doing: Option 1 (keep plaster, cold battens): Option 2 (warm battens - ignore blocks in picture): Option 3 (with service void): So questions are: (1) Is there a way of adding internal wall insulation on a solid double brick wall using new "tech" which will enable me to skip the air gap? (2) Should I strip plaster off the wall? (3) What's the best material for battens? (4) Any tips on how/whether to do a service void? I'm going to wire the whole house with ethernet and rewire electrical, so this wouldn't be out of place. (5) I've noticed comments elsewhere by @Jeremy Harris regarding a need to do graded vapour permeability, starting with (as he suggests): "the least vapour permeable and the outermost layer is most vapour permeable". This approach seems to be pretty difficult with internal wall insulation. Or am I allowed to ignore the plasterboard for the purposes of this kind of calculation? Would love to be enlightened. Note: this was quite helpful: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/658604/BEIS_-_SWI_Innovation_Final_Report_-_FINAL_Approved.pdf

- 7 replies

-

- vapour control

- pir

-

(and 4 more)

Tagged with:

-

Hi I’ve stumbled across some very informative details on this forum with regards to portal frame builds and have a few questions that I’m hoping folk can help me with. We are looking to build a new church building for our congregation of +250 folk. We have been renting but in the current ‘covid’ climate, renting large buildings is likely to be difficult. One suggestion, to allow a quick build, has been to build a large portal frame building, Approx 17m wide by 22m long and 6m high (ridge) with a 6m wide ‘lean to’ running the full length. With regards to the main building, it will be entirely open to use as a sanctuary and my suggestion to overcome the steel frame thermal bridging problem would be to panel the entire inside of the building, flush with plain insulated PIR sandwich panels, walls and ceiling. One wall will have tall windows in it, one gable will likely have some windows in it, one gable will have very little in the way of windows and one wall will have a ‘lean to’ attached to it. The outside would ideally be panelled in ‘as attractive as possible’ sandwich cladding, possibly with a view to over cladding some of it with timber to improve asthetics. Acoustics will need to be considered, possibly by way of special ceiling panels? With regards to internal asthetics, I understand it could be a fairly clinical looking building but perhaps with decorative timber paneling half way up the wall and regularly spaced fake wooden pillars a warmer look may be achievable - these things could be added later, the main issue being the speed of build presently required. With regards to U/values, SAP calculations and general feasibility, does this idea sound plausible? All input is welcomed and thanks for letting me join the forum Ian

- 8 replies

-

- portal frame

- pir

-

(and 2 more)

Tagged with:

-

Hi, We were planning a frame with 140mm Frametherm 32 between the studs and 40mm PIR over the studs to get a quoted U-Value of 0.14. Apparently there is a shortage of Frametherm 32 and so they have changed the spec to 70mm PIR between the studs and 50mm over. Using Kingspan K12 with a 0.02 thermal conductivity I do not get 0.14 U-Value. which I have not queried yet. However, when offered the option of PIR fill I suggested changing to the 0.11 U-Value option which I had previously discounted due to the thicker wall. This would be 140mm full fill PIR and 50mm over, which does give a 0.11 U-Value. TBH the difference between 0.14 and 0.11 does not pay for itself, around one third if the outside walls are windows, but I feel that thicker full fill insulation should be better for a modest extra cost. However, I am wondering if using only PIR could cause any issues. I liked the idea of a mix of PIR and Frametherm as the Frametherm will help with noise insulation and decrement delay. Should I be concerned re noise or decrement delay with only PIR. The wall build up will be render on render board, 50mm cavity, 9mm OSB, 140mm stud with 140mm PIR, 50mm PIR over stud, 35mm service cavity and then Fermacell. Maybe the extra weight of the Fermacell means that I do not have to worry. The builder was somewhat incredulous about using Fermacell instead of plasterboard. I did wonder if an alternative to get some of the benefit of a different kind of insulation in the wall is to put 25mm acoustic insulation in the service cavity. I am also wondering if I take the walls down to 0.11 am I getting to the point where at least we do no need heating upstairs. We will have roughly 0.1 floor, 0.11 walls, 0.7 windows and 013 roof(maybe a bit better if we can get more insulation in). The only issue is that of 225 square metres of outside wall, 70 is windows and doors which increases the heat loss, although most of the windows are downstairs. Ex the hall, which is double height, only around 15% of upstairs wall is window.

-

Anyone know the best way to join PIR to itself to prevent thermal bypassing caused by even very tiny air gaps? Is it practically possible to tape the underside edges together? I am thinking of using the same expanding foam tape that I have used in between all my insulated timber-frame wall panels. Kingspan's Thermafloor TF70 product installation guide says to lightly butt together, which would surely reduce its effectiveness considerably. I would rather not use PIR at all (I'm not using it anywhere else in the build) but it seems the only option due to difficulty of excavating the ground floor deep enough without disturbing the ground under the existing old stone walls.

-

I would like to re-design outside lighting. At present I have 4 separate PIR LED wall lights, the stainless steel up-and-down tube type a flood further away. Also some manual switched flush led lights over the front door I would like the front door ones to switch on automatically at dusk and off at midnight, or if this is too challenging, then stay on all night. One of the wall lights on a narrow path alongside the house has a c.150deg catchment, so one is past it before it wakes up to one's presence. Needs adapting with a separate Spectra200 detector perhaps. Please advise if this is best strategy and recommendations for specific kit required. Thanks

-

I am adding 25mm of calotex to the underside of my rafters which have 170mm already in them. I will then be putting up osb and then plasterboard. My question is should i use everbuild pink grip or soudel low expansion foam to initially hold them in place. I imagine i would cut the sheets to size, foam or pink grip the sheet and push it into place, temporarily fix a batten across to hold the sheets in place until its all finished and then remove battens and foam up the gaps, cut back and tape the joints. Its just a matter of what would work best on that initial pushing up into possition. Once the osb is screwed up its not going anywhere. Or should i be using something completely different? Thanks in advance.

-

I have any number of these left over from the build. I'd like to stick them in my roof between the rafters.... but I have a dreadful feeling Mr @JSHarris will say ' No you can't ' . I think we've had this conversation before but for the life of me I can't find it. Wasn't it the small gaps between the blocks that'll prove too hard to seal off? Please tell me I can use them. It's such a huge waste not to....

-

I have just bought a property which was newly built in 2013 , shortly after being occupied the property was fire damaged. The UFH system was decommissioned shortly after the fire which extensively damaging the wooden joists & rafters however did not impact on the floor slab. The building was left exposed to the elements for the past 4 years, my question , is the UFH pipe work in the slab still fit for purpose ?

-

I have a long winding 45m access path, including a zigzag that would be the envy of any Tour de France cyclist, to achieve height gain between trees and not to disturb their valued roots. I would like to have lighting on the path, and have identified some post lights that might fit the bill, both separate lights and plug and play 'kit systems'. I would prefer to use LED lights. I would like them to have PIR detectors that would switch them on at either end - but that may not be feasible. I would prefer to use low voltage SELV, and to power the transformer within the house, but I am not clear what cable might be required for this - the consensus on the thread 24V DC or 110V AC or 240V AC in the garden? seems to favour 240v since this curtails the size of cable. I have put in ducting, in which I oculd run pond cable as suggested by JSH in another thread here: OTOH 240v seems to present more complex installation issues, which I would be most happy to avoid. I look forward to reading your learned opinions.

-

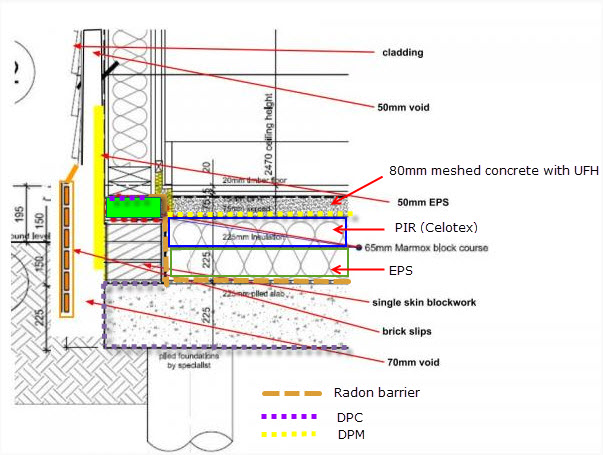

Okay, big iceberg delivery yesterday, so now I need to start laying the insulation for my slab: Bungalow has two extensions which are piled slabs – both extension slabs will have a mix of PIR and EPS. The bungalow floor has been dug up, hardcore is down and I am ready to fill that with EPS. The extension slabs both have SIPS sitting on blockwork, with cold-bridging around the sole plate best mitigated with marmox block beneath and external insulation on outside SIP wall (see pic). No feedback required on that please! : ) I just need a sanity check on the slab insulation please: Bamboo flooring 80mm meshed concrete with UFH (with 25mm EPS upstands) DPM 100mm PIR 160mm EPS Radon barrier (lapping with DPC under sole plate) 225mm Existing piled slab A mix of PIR and EPS to attain desired u-value / get correct FFL height. My thoughts were that it’s safest to get PIR on top of the EPS away from piled slab in terms of moisture. I was also thinking the PIR is better at withstanding point loads from the mesh chairs/spacers that will keep the mesh elevated above the insulation. Should I wrap it entirely in polythene/DPM to prevent moisture travelling up into the PIR? I was just going to cover the top with DPM as it is foil faced. Or should I have EPS on top and PIR at the bottom? Or does it matter?? Feedback appreciated. OB

-

So I visited site today and found this. This is one of two layer of PIR insulation being fitted between timber studs. The height between studs is around 2.6m so it is inevitable that there is atleast one join and perhaps sections where 3 or 4 pieces make up the insulation but 20-25 pieces doesnt sit well with me. Your thoughts?

- 30 replies

-

- timber frame

- insulation

-

(and 2 more)

Tagged with:

-

In the process of specifying our house lighting switches. We'd like to use as many occupancy sensors as possible (back door, loos, boot room, store room and maybe stair well). We'd also like to use those light switches that are switched by (say) a hand being placed near the switch - ie. no moving part in the switch. I have heard rumours about tiny LED lights which have PIR in built: strikes me as a perfect system for those of us who need a Precision Approach Pathway Indicator System (PAPI ) for the loo at night. When it comes to specifying in this area, I don't know what the Hell I'm on about.... you get the picture. Is there a Ladybird book for electric switch specifying? Or an online resource for neophytes like us? I want to avoid the scenario in which the electrician ends up doing our specifying for us. We're both prepared to put in the leg work. Thanks in advance. Ian

.thumb.jpg.a0b468669b9a0d8fbed35a99693c874e.jpg)