JIH

Members-

Posts

61 -

Joined

-

Last visited

Personal Information

-

Location

Scotland

Recent Profile Visitors

2897 profile views

JIH's Achievements

Member (3/5)

3

Reputation

-

Thanks for your responses folks, very heartening. I'll stop fretting on this one. As said above my building inspector has requested such a certificate and I have requested of him why it's needed in my case, but no response - hence my query on here.

-

As part of completion paperwork Building Standards have requested a heat pump installation certificate for my ASHP. Has anyone in Scotland experience of this or have any idea of the regulation where this is cited? I've installed the heat pump myself and I'm not applying for any incentives. Thanks

-

I hope you're pleased with it! Did you use the controller to set the temperature? I remember reading you had problems. I've not tried mine yet.

-

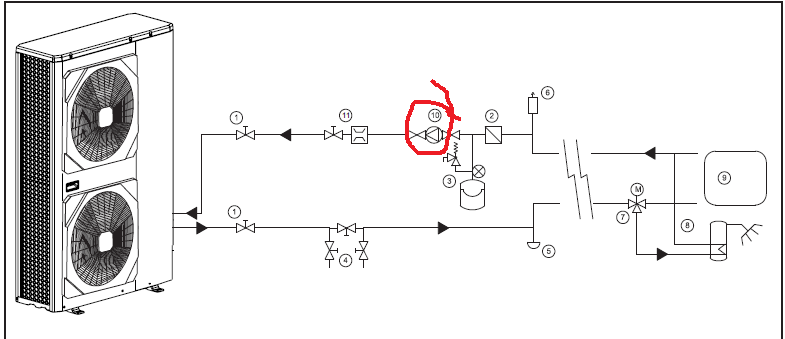

I have a Kingspan Aeromax Plus 6kW @Joe90. Looking at this diagram in the blurb it seems the pump should go on the return for the Kingspan, thanks @PeterW

-

Thanks @PeterW, you're a ?

-

Thanks @Joe90, I think I shall therefore try and position my pump as close to the ASHP as possible.

-

Thanks @PeterW, I don't have room for a buffer tank in the space unfortunately and have already bought the willis heaters.

-

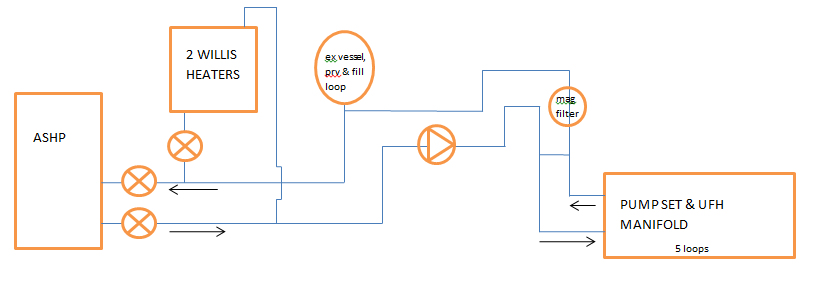

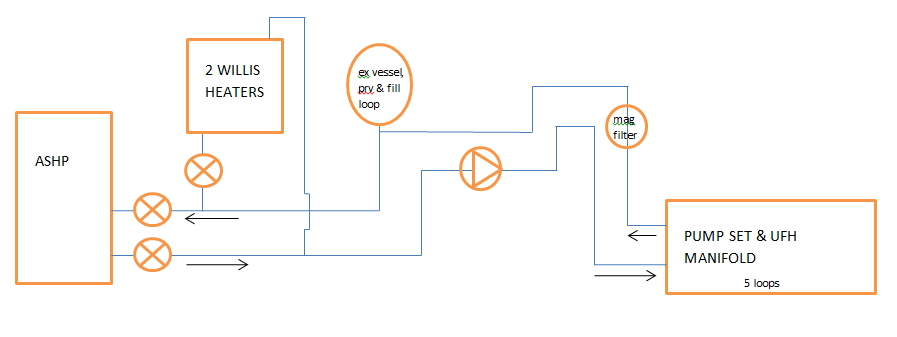

Yes, thanks @joe90 I have a pump attached to the manifold (as shown in the diagram in the box on right), but I thought I would need another pump in addition to the UFH circulating pump.

-

Can anybody help me here? Does this look ok? Correct to have circulating pump on the flow side? Should it be as far from the UFH manifold as possible?

-

Jilly - I'm happy that my ASHP will be adequate to heat my house, which has a high level of insulation and air tightness. You may be correct that additional heat could be required in extreme conditions - but this could be achieved with a fan heater and does not need to be part of the system design in my case.

-

After much heart ache, time and tears I'm looking for some advice from you guys regarding my heating system, which is completely separate from DHW. I plan to directly heat my slab with ASHP using Willis heaters as back up. Hydraulically does this look ok? Input much appreciated.

-

Vacmaster is my recommendation which I got after returning the smaller Titan vacuum which I thought was a load of shite! Much cheaper

-

Wall hung WC with horizontal outlet - possible?

JIH replied to JIH's topic in Bathrooms, Ensuites & Wetrooms

The evidence is clear @Onoff -

Wall hung WC with horizontal outlet - possible?

JIH replied to JIH's topic in Bathrooms, Ensuites & Wetrooms

Should ready more pipe clips