Leaderboard

Popular Content

Showing content with the highest reputation since 01/03/26 in Posts

-

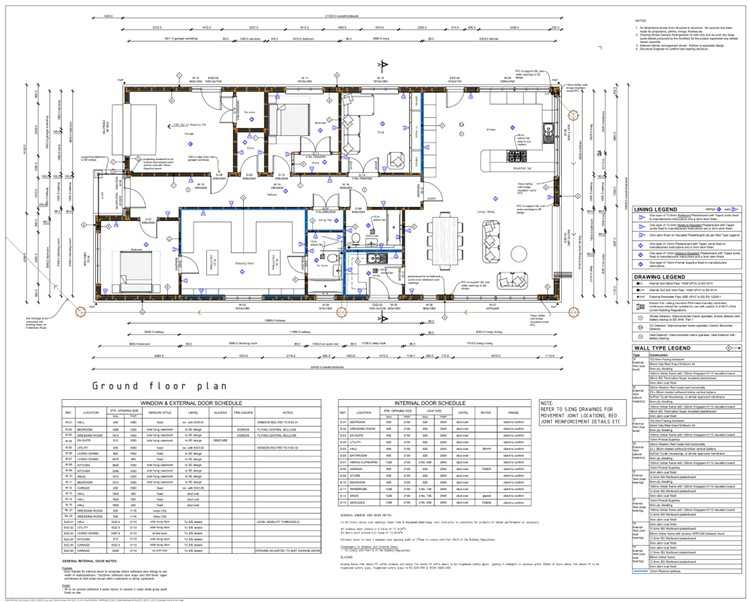

Hi all. I've been on here a while on and off and posted about 3½ years ago for advice on potential plots. We ended up getting a lovely plot in a nice village in Norfolk not long after that but was held up for 3 years because of neutrient neutrality and natural England stopping all new planning permissions being granted. We got full planning 4 months ago and have made a start, in the winter🫣. Foundation blocks are nearly laid to ground level. Me and my husband with a little help from others are running and building ourselves. My husband's a carpenter and was a site/contracts manager for a building company. We are building a single storey timber frame home with a brick skin up to window height then black cladding. A slightly unusual roof will top it off. We're both really excited and frightened especially regarding budget. We will have to stop the build throughout to earn more money to finish it but will be determined to get there in the end. If anyone has any words of wisdom or suggestions regarding internal layout we'd welcome your input. Also we're stuck with our heating and hot water system in terms of best and most efficient way to do it. It will just be 2 adults+a dog living in the house. We have no gas here and don't want oil so will be all electric. We'd love to have solar and batteries one day but it'll have to wait a while. The back of the house is south facing so will need to organise some shading but again budget may determine what we have. Thank you all in advance and I look forward to being part of your amazing community4 points

-

Yes, already proven here. Very early on in the build I confirmed the heat loss calculation was correct by leaving a single electric convector heater of known power on and plotting internal vs external temperature for several days. That gave me the Dt for a given power input, which tied exactly with the calculations. In any event I bought a 5kW ASHP to satisfy a max demand of just over 2kW. For me the only leap of faith was no heating in the bedrooms. SWMBO likes a cool bedroom about 18 degrees. Usually we have to keep the bedroom door shut to keep it down to that. In this cold spell we had to open the bedroom door occasionally to let a little bit of heat in, and still achieved the required temperature with no actual heating there.3 points

-

If you want to do as much as possible yourself then I think there’s a few options. icf you can do everything yourself timber kit, get that put up and then finish it yourself timber built on site, you will probably need a couple of carpenters to help brick block cavity you will need a bricklaying gang. will also depend if you have a large chunk of cash up front, timber frame erected on site will probably be the heaviest up front cost. icf has a large up front cost, but probably 20% of a timberframe then you can drip feed cash into it. brick n block lowest up front cost but large weekly payments for labour.3 points

-

Had some very minor domestic renovation experience but achieved possibly 90% of our self build. Paid professionals for electrics, plaster skimming, ASHP, window installation and screed. It is doable, time, money, quality consideration. 3 years before we moved in and 6 years later fitting final architrave ready for repainting!! Has been an amazing experience, learnt so much and the amazing contributions from Buildhub. My Dad, 75 years at the time helped me with the stick build. Would look at other build methods in the future.3 points

-

Not me, but G, and not finished, but have a look at our blog......demolished bungalow and timber frame build3 points

-

Full planning it is. Prepare yourselves for more questions. 🤠3 points

-

Triple glazed lift n slide from norrsken here. the back wall of my place is 90% glass, I can’t recommend them enough -3 outside here and the doors on the inside feel warm, open them up and the outside feel is freezing. a strange thing you notice with this quality is the outside door handles are freezing cold, the inner handle is warm, there is no heat transfer through the door via any lock mechanism.3 points

-

The mix is not important, getting your bricklaying team to mix it the same every time is the important thing. when you get the colour you want you need to discuss it with the bricky and get it in writing that they will use a gauge box to get it the same every time. any not up to standard gets taken down at their cost. you will need to buy sand in bulk and cement to get the same batch every time. DO NOT USE any form of mortar dye.3 points

-

Hi everyone 👋 I’m new here and thought I’d introduce myself as we’re about to embark on what feels like a fairly sizeable (and exciting!) project. We’re currently in the process of purchasing an old farm property that’s seen better days and is very much in need of some care and attention. The house itself has been a rental for a long time and, as you’d expect, has suffered from a fair bit of neglect. Phase one for us will be getting the main house brought up to modern standards – sorting the basics, improving comfort and efficiency, and generally making it a solid, future-proofed home again. Once that’s complete, phase two will be the big one: converting the existing barn into residential use. The long-term goal is to create a spacious five-bedroom family home, making the most of the character of the original buildings while blending in plenty of modern comforts – hopefully lots of underfloor heating and well-thought-out modern electrics along the way. I’ve already spent far too many hours reading through the forum and it’s clear there’s a huge amount of knowledge here, so I’m really looking forward to learning from others, sharing progress, and no doubt asking plenty of questions as we go. luckily we gutted/renovated a nice 3 storey property in Whitby over lockdown which has given us confidence to attack another project. Thanks in advance – I’m sure you’ll be hearing more from me soon!3 points

-

Passive class house here, not certified, no UFH. An actual measured heat usage of 3200kWh or 17kWh/m2/annum. Supplied by an electric plug in heater. It worked fine so long as you plugged it in anywhere downstairs and allowed it to gently input heat for 18hrs/day. Expecting it to batch heat on TOU tariff overnight wasn't as successful as i had hoped. it needed to be turned on at about 17:00 in winter to keep the living rooms warm enough(21deg). I added some electric heaters in the bathrooms for comfort as 21deg isn't quite toasty enough. Fan heaters are better than 2 Bar quartz heaters. The house is very comfortable. I replaced the electric radiator with an A2A HP for 2025. It's dropped our heating consumption to very close to 1000kWh or 5.5kWh/m2/annum. It works fine so long as you give it long enough run times for the heat to disperse around the house. It won't be quite as cheap as an A2W HP as you can't batch heat a slab on TOU tarriffs and a COP of 3 to 3.5 won't match a top end A2WHP. However it only cost €1500 installed so there isn't much in it. Add DHW demand or solar and the sums would change again. (FWIW an A2W + UFH was quoted at €14k in 2020) TLDR: 1. Anything will heat a passive house comfortably if you're prepared to give it a fair chance. Short run times and quick runups won't work with localised heat sources. 2. A2W HP's are best for comfort and running costs. However they only have the best long term costs if you can get a well priced install.3 points

-

Where was their rationale for the 2x potable (white) vessels needing changing?? Bloody nonsense. At (only) 5 years old they should be fine! Unusual to see two on the hot water, but I always add extra volume on all of my installs, simply as a good measure; you can't have too much expansion afaic. Does the UVC ever heat off the immersion, routinely, as that can seriously over-exert the expansion vessel(s), off solar PV divert etc maybe? If off the ASHP only then these should be living a very easy life, and last a fecking long time. Defo kick these lot to the kerb, and get a new plumber who actually gives a shit.2 points

-

In the end I've gone with the Norrsken 319A sliders. They have a fixed pane and the frame is chunky, but I'm ok with the aesthetics. I really liked the way that when you closed the door, it felt like you were closing and aircraft door. The sealing is very impressive.2 points

-

I should probably advise a condensation risk analysis for IWI on top of CWI. WUFI is good but Glaser is at least indicative. My reason for insulated stud (in my mind a glued laminate of, say, 12mm OSB, xmm plastic insulation, 12mm OSB) is to reduce thermal bridging. Metal stud leaves a bridge all the way through the sandwich, but is a narrower highly-conductive thing against a fatter less-conductive thing. So the end result may not be so different. I don't know!2 points

-

Yes, I think the fixed section only hence the isssue. Currently being plasterd so humidity is in the 90s hence the condensation, but there is more on the fixed pane that was glazed on site. For reference, all five of the other windows that were glazed on site have broken or porrly fitted trims with air coming through the holes in the trims on at least three of the windows. So glazing on site was rubbish. The fitters also left behind as box of internorm fix-o-round sealant that internorm supply to be applied round the glazing units. The missing sealant is probably why the air is coming trough the broken trims, around the glaxzing units. I did ask the fitters about the sealant at the time and they poo-poowd me, saying it isnt necessary. That isnt what internorm would say though, so they will be refitting all the glazing with the sealant applied. Although the box I have on site is out of date now. Thank you for this. So, your seals are the same on both fixed and slider section? That is very useful information. I'm compiling my list today.2 points

-

2 possibilities You have a leak somewhere You may have an issue with the expansion vessel (red tank) First check the expansion vessel When the pressure is near zero, like in the first picture, get a tyre pressure gauge and read the pressure in the red cylinder. There should be a valve exactly like a car tyre one on the top. It should be something like 0.7bar, 1 bar or similar. If it has pressure eg 0. 7bar but the gauge on the water reads near zero, it is possible you have a leak somewhere. If it reads near zero your expansion vessel has lost has pressure (you may still ha e a leak but it's a bit less likely) If the latter you can pump it up with a.tyre or bicycle pump. Then top it up with the flexi hose. You need to turn the. Slotted screwdriver thing so it's. Inline withe the pipe, then turn the black handle at the other end. There should be a whooshing sound and the pressure creep up. Once at desired. Level (1 - 1.5bar) turn both valves off and disconnect the pipe (get a saucepan under as some water will come out. Beware just topping up the pressure continuously. The water is going somewhere!2 points

-

Please don’t do this. As much as I hate conveyancers, a good one is with their fee several times over. You don’t want to make DIY mistakes on what’s likely to be one of the highest value transactions you havre ever entered into.2 points

-

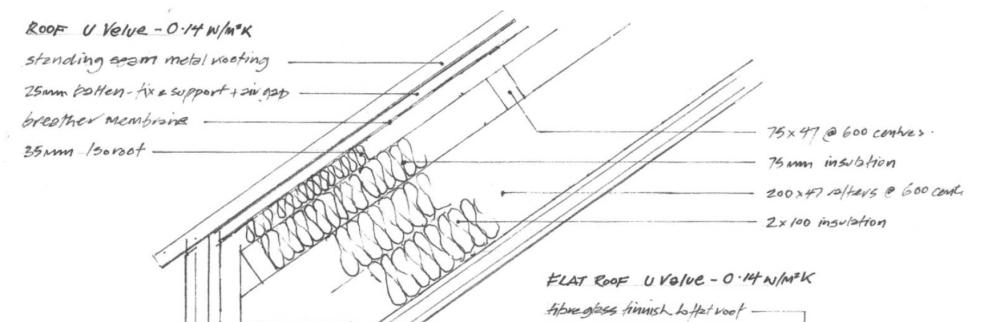

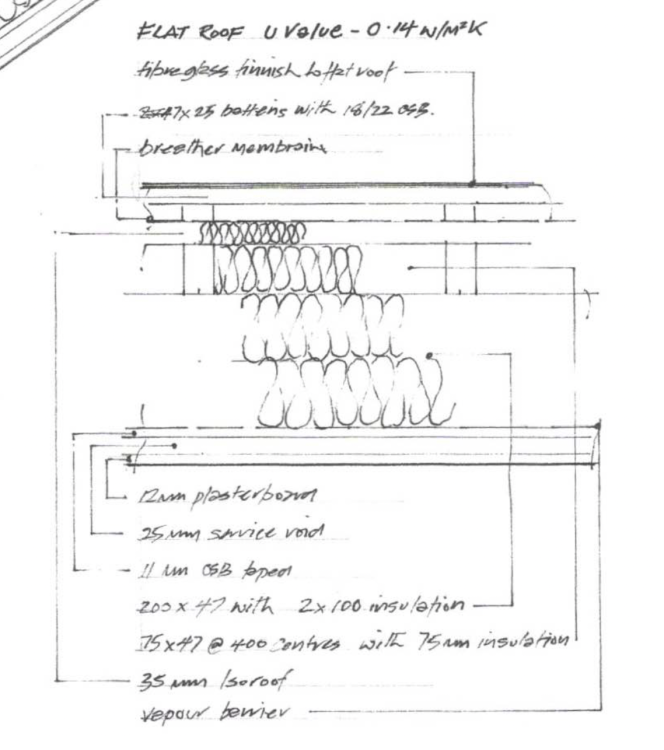

@Iceverge I do like this roof build up, similar approach to our roof, I have included drawings including my fibreglass flat roof. The drawings were all done by hand using Rotring pen! These are screen grabs. 200mm Rafters with Rockwool 75mm counter batten with Rockwool 35mm Isotherm T&G Breather membrane 25mm Batten for air gap Standing seam metal roof On the inside of rafters Vapour. barrier 11mm OSB 25mm Batten Plasterboard2 points

-

Here's an excerpt from the email that came with a quote I received in August 2025, if that's any help: "Pleased to provide a quotation for the airtightness works in your project - to view in full, please click the Quotation link above. For the supply and installation of the AeroBarrier system in your 190m2 project in [my postcode], your installation would be £2,538.40 (ex VAT but zero rated on new builds). This price is inclusive of travel, labour and materials and we do not charge a premium or any added fees for you end airtightness target (even to high performance levels)."2 points

-

An excellent improvement. That corner seal in the window is a bit gash though. I'd be having a word with the window man. Having gone to the hassle of manually doing this it's like climbing Snowdon and seeing there was a blasted train to the top when you arrived.2 points

-

Neither! It's a good room-by-room heat loss calculation that must come first which you then use to size the heat source, followed by the emitter design. Then you look at flow rate, velocity and pressure loss through your pipework.2 points

-

I can assure you, they absolutely hate having to do it and will charge to apply it. I prefer to source it direct, that way I know the install is with products I have discussed. They would rather not apply it, they'll try and offer alternative solutions but compriband, airtight pu foam, airtight membrane is the way to go.2 points

-

Good day for a test. (Did this about 95min ago) Outside temp according to the ASHP is 2°C. House Internal air temp is 18.4°C Here is a photo from my thermal imaging camera. The window pane glass is at 12°C, look at the heat outline of my body showing the reflected heat, which is 15.1°C. The frame is at 9.1°C.2 points

-

What @Russell griffiths says. This will take a bit of research and a lot of management. And you will have to pay a bit more for the materials and a very professional bricklayer. The typical bricklayer will engage a ' trowel' (another bricky) or two, and a labourer. He may understand your requirements but not convey that properly, or they don't understand or don't care. The labourer especially is unlikely to make much effort and will be under constant pressure for 'more bricks, or more pug/muck/mortar ' acc to region. Then next day it is a different labourer. Most just shovel in sand and cement and add some water. The same shovel holds different volumes of cement / dry sand/ damp sand. I have never witnessed the use of a gauge box. Even getting them to use buckets rather than shovels is a pain. Explaining is likely to be met with a smirk implying 'what do you know?' they dont know what they dont know. And then you must only use one brand of cement...fairly easy. And one source of sand. This week's big bags may be completely different from last week's as they come from a different sand pit or a different layer of the same one. The BM has little to no control over this. Some sand is remarkably orange and will never look like your pics. But I don't want to discourage you as the right mortar makes the wall right too. Perhaps you have to be cheeky and knock on the door of a house that has achieved what you want. a few compliments will excuse the intrusion and you might get the info you need. To me the answer is a professional and proud bricklayer or builder who knows how to achieve this, and will want an extra 20%. They exist. You will choose your sand and get it all delivered in one hit. Why's this? Again because of getting the mix exactly the same for every single mixer load. No chance really other than black.2 points

-

Very inconsistent results, it takes only a small mistake in measuring to alter the colour which might not be noticeable until properly dry, I’ve had some horrible results using dark browns which looked brilliant while wet but dried very inconsistent they also tend to not like being wetted after they have dried and tend to look patchy.2 points

-

We had 3g windows throughout our last house except for the patio doors which were 2g slide and folders. They were definitely cold. This time we have gone for 3g throughout (from Norrsken) including some 4m lift and sliders. Too soon to say how they feel because we aren't in yet but early indications are good - running the house at just 18deg for the 2nd fix trades it feels amazingly comfortable and those sliders are not giving any impression of feeling cold. I'd go for it if you can.2 points

-

Really appreciate the input @Nickfromwales, @Russdl and @BotusBuild - we are sticking with ONE BIG DOOR 🎉2 points

-

As you would on the sides and top, you should retain packers all around the frame and not install without any. The compriband should be on the outside aspect of the frame, packers every 150mm from corners and then every 300/400mm and I also recommend under every mullion if possible, as it helps the frame from dropping/twisting.2 points

-

Past experience. LED themselves are pretty reliable. Drivers on the other hand tend to be crammed into a little box with minimal cooling. Some types of capacitor are particularly sensitive to temperature with their expected life halving by every 10C rise above about 40C.2 points

-

Not clear where your boundaries are with neighbours etc from those drawings. Personally I find all this 'permitted development' stuff a bit unnecessary. If you are going to build something reasonable with due consideration for your neighbours and the local context and setting, why be trying to use permitted development ? The cost and timeline involved with getting planning permission is not excessive compared with the costs, timelines amd risks involved with a building project. I don't think LA planning are going to have spurious objections. You don't say whether you are engaging with neighbours regarding your plans - which is the recommended approach by all good architects and the planning office. Going through planning permission will at least ensure immediate neighbours are informed even if you want to shaft them. You never know, LA planning might have something helpful to say about your plans, and having planning permission can only be a positive when it comes to the sales value of the property, and dealing with neighbour relations during the build itself.2 points

-

The shoulder months are also problematic for us (!) we are in a well Insulated house (miles off passive though... 2.7 airtight, 0.11 floor, 0.22 walls, p. 14 roof). We also have a huge amount of glass & very high ceilings of 3.2 to 4.2m, and regularly during shoulder months the house isn't cool enough to trigger the heating (21 - 22 degrees) , but the tiles feel cold under foot and you can actually feel quite chilly... Maybe due to the large glass? As a result we actually need to force the heating to come in (set thermostats to 24 degrees) for a couple of hours to warm the tiles up. We are also heavily zoned, which works well for us, as we have a very complicated design, so can fine tune the boost to rooms that need it, and leave the bedrooms etc2 points

-

Think the bend radius for getting pipes through is way to small, firstly. Why run pipes through floor at all. Take them from outside direct in to house.2 points

-

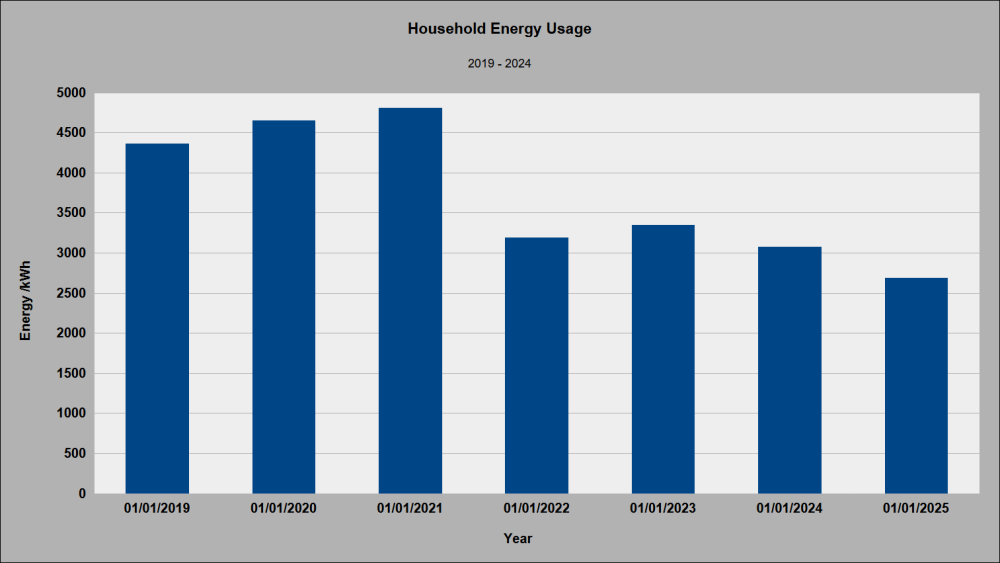

Take me 20 years, but very little cash to to reduce my household energy use to below 3MWh.year-1. When I first moved in, it was around 11 MWh. This last year, I used 2,780 kWh. That is 335 kg of CO2. Feeling pretty chuffed about that as I have been warm, but never too hot, fed and bathed. If you are wondering why there was a big drop from 2022, that is because I fitted my home made secondary glazing (making my windows triple glazed).2 points

-

The red bar thibgy won’t move unless you move it. It’s a marker to show where the black thibgy should be. You should never need to move it but it can be moved to indicate a different pressure by using a screwdriver in the centre.1 point

-

Oh you have 3 in total. The red one will be for heating, that is your one with the immediate issue. The TWO white ones are for the hot water. There is no indication that there is actually an issue with those yet. The fact this guy suggests replacing the 2 white ones but has not addressed the low pressure on the red one has done nothing to give me confidence in him. Lets tackle each separately. The white ones don't have a pressure gauge, they will be at mains water pressure. They are to take up the expansion when the water in the tanks gets heated. IF they have a problem, you will see water being discharged via the tundish after you have say had a shower and used up some hot water and the cold water that has entered the tank to replace it is being heated. If you want help identifying what the tundish is, post a picture of the pipework below those tanks. A further note, those tanks are of the type where you can take that bottom flange off and use that access to replace the bladder if it has burst. But I suspect the labour charge would make that more expensive than just replacing it, if they are faulty. Summary. If you just accept that quote, you will get 2 shiny new white tanks that may or may not be faulty, and the low pressure on the red one will still be the same.1 point

-

That's total *******. The entire point of land registration was to simplify the transfer process so that you didn't need to use a solicitor, which you don't - most of the people who do conveyancing are minimally qualified staff and not solicitors. Of course, they will still try to maintain their monopoly by implying that you're not allowed to do it yourself, but that's just an attempt at intimidation. Some of them will try to make life difficult for DIY conveyancers. Yes, the various aggravations make it not worth it now.1 point

-

OK this is fairly easy, although please take care to give the key relevant info when asking a question, otherwise you're asking us to write very long mostly irrelevant if-then-else replies. The most obvious questions are what is your drainage situation / what soil-type do you have / where will this drain to?. So: Pay 'Freeflush' £100 for the SUDS calc. You need to supply the plan area of your roofs and non-permeable hard standing and your location. Hint: make your hard-standing permeable and draining (using say, MOT3) to vastly reduce that requirement. That gives you your tank volume. Figure out whether you (a) want to use crates, tank, pond, swale, lake or Versailles-like water feature and (b) where it eventually drains to - ditch, culvert, soakaway, drainage field. You will need a soakaway test for the last two. Draw a simple drawing showing the arrangement. Check the levels and drainage fall if you're not sure. Add a short narrative written in the language of a 5-year old for people who don't understand numbers or drawings. Example calc below and no, you can't use those numbers.1 point

-

If the system pressure target is 1.5bar when cold, then your pressure vessel should be at a little bit below (say 1.4bar) when empty. This allows a little water into the vessel when at system pressure and the maximum volume change when hot. So if your water pressure gauge shows 0.2bar your vessel should show 1.4bar. Of it shows lower then the pressure is wrong. You can top it up but the fact the air has been lost points to a failure in either the valve or the internal membrane. If some water comes out of the valve, your membrane is almost certainly shot. Swapping the vessel is the easiest.1 point

-

I have an expandastore they can be put up and taken down by a few guys. Can be handballed around when in pieces. Don't see how it solves your problem entirely though.1 point

-

If you are happy with the container, clad it with nice wood cladding, put a window in one side and tell here the new workshop is finished. If you really want a new workshop, it is obvious, the new workshop is NOT built where the container is, so the container can remain until the new workshop is complete and everything moved, only then can the container go. This is the very reason we got the static caravan included with our planning with permission to retain it. It does look better than a shipping container.1 point

-

Depends if the land is valuable. Id build a bungalow tommorow if i could. But my land is near worthless........... Oh, and one day we will be old and infirm1 point

-

Think the thicker ones, roof installer did everything including nail supply.1 point

-

1 point

-

Go full plans, at present the rear extension is greater than 3.0m deep and more than one storey as well as being a side extension to the existing rear single storey part and is more than half the width of the original house. I'd rather not risk building that without a certificate of lawfulness to confirm it's PD and if you're doing that (and I think you would fail) you might as well go for full planning.1 point

-

We have HS330, triple glazed timber / aluminium lift sliding door. A lot of timber in the doors and no condensation except outside on certain days. No problem with the fixed seals. Not an expert but would say fitting error. Like you the fitters and some parts of manufacturers were poor quality. Disappointing. Add to the list.1 point

-

circuit vs zones.yes, aware of the difference which prompted this thread - I was surprised the company had only recommended one circuit for a rather large zone. We don’t have a design yet - that company just gives an initial quote but then you have to pay for a design (I’ve found someone else who I’m waiting on a design from now). Pipes are only in the coloured areas - i.e. not under permanent fittings such as bench seating and island. I was expecting multiple loops simply because of the pressure losses (building being 18m long means a single circuit would be huge!) We’ve had a full part O modelling done, so all good for the solar aspects. You’re correct - the X is a washer & drier stacked.1 point

-

Agree with @MrSniff buy good quality kit. I am one room away from rollering the whole house (with my sister’s help) and we have used the same 2 brushes and 2 rollers. @Lincolnshire Ian My top tips (which might be obvious to BH-ers): - when cutting in paint 10cm or two brush widths on each wall edge - so you can roller up to the edges and it blends better. - Wooster 4-8’ extension pole was worth the money - easy to do the 2.4m wall in one movement up and down, hardly ever needed scaffolding except for cutting in the top of the vaulted ceilings. - the related roller is a must as it clips in so can’t swivel round the pole like screw on pole attachments, meaning you get good pressure. - get a paint scuttle or two, we used pelicans with liners for brush work (has a magnetic side so your paint brush doesn’t fall in!) and Wooster 15litre scuttle for the roller. - paint kept for a week or more with lids on, great for self-builders like us when it was a week between site visits. - wrap brushes and sleeves in cling film, just wash brushes every so often when clogged. Wooster sleeves still not yet washed/replaced so were definitely worth the ~£9 each cost. - wipe the roller frame ends and frame down at the end of each session though, magic wipes good for this. - make sure the brushes are stood up in the pelican when not in use - bigger people might cope with big rollers, being little myself I went standard 9’’. - found paint drips came off our window frames with a soft cloth and water so just kept a bucket handy and wiped spots up when touch dry - might be worth seeing what your paint does on an inconspicuous area rather than trying to mask off. - on that note, don’t try and paint window reveals when hungover 😆 - get a couple of work lights if you don’t have natural light/ lights up yet, hard to see drips if there’s just one direction of light source. - drips can be gently sanded back with 240 sandpaper so don’t stress if you miss any, just make sure they’re totally dry first. - get friends/family in for a painting party if you can. our mist coat (60/40 paint/water) downstairs was done in one day! To go from dry plaster to a patchy white coat in a matter of hours was a huge boost. - if you do get help then give instructions- the mist coat shouldn’t be perfect but my experience is that people will try going over the same bit again and again, so you do have to explain what you need. - take before and after photos from the same angle, it is so satisfying to look back. Best of luck1 point

-

Breathable Water repellent Acoustics Thermal Are just some of the key benefits and why it is the preferred option for most suppliers/manufacturers.1 point

-

Timber building is standard, but some insurers don't know anything about construction and rule out cover on a whim or misunderstanding. If you get building regs you will get insurance. But timber cladding on a timber building? Of course there is more risk. You would want a fire barrier between them, but would still have to tick the insurance boxes for timber structure and timber facing. On what basis are you choosing the construction? Why twin wall?1 point

-

If you alter the sides then it’s a complete new set of structural engineering drawings.1 point

-

Personally, I'd scrap the PIR and Impey Waterguard and put 60mm Marmox straight to the slab with tile adhesive (possibly another 10mm on top at 90-degree depending on existing floor height). Stick the UFH mat on top of that. A couple of conduits with temperature sensors in them (one for backup).Self-levelling compound over it (fibre reinforced). Tile on top of that. You'll probably end up very close to the height of your other flooring, and it will be a very straightforward buildup.1 point