Leaderboard

Popular Content

Showing content with the highest reputation since 12/09/25 in Posts

-

Ufh pipes will cost a grand to buy, if you don’t put them in you need a serious word with yourself. I don’t understand the figures like some on here, but I know I’m sitting in the most comfortable house I’ve been in for a long time, just a gentle warmth in the tiles emits to every point of the house. it’s just an absolute pleasure.7 points

-

As above. All the best for another year of staring at one tiny problem for waaaaaaaaaaaaaaaaaaaaaaaaaaaaay too long. And then realising it didn't REALLY matter that much after all. Adios 2025, here we go for 2026. Get your house built asap, or it'll be 2027 and I'll be telling you off again6 points

-

OP states this is a ‘new block of flats’. If this ‘new build’ then surely all design, method statements, competencies etc, etc should be sorted. Not the sort of question to be thrown out to a load of strangers on the internet.5 points

-

Panels now upgraded, photos tomorrow. Day one, took 12 panels off the hill Day two, very windy, modified the steelwork for new panels Day three, new panels lifted up hill and installed, reused all old wiring without issue. Switched it on and all worked fine. Materials 2x 6m lengths of 41mm galvanised channel 12 panels 28x 30mm panel end clamps.5 points

-

5 points

-

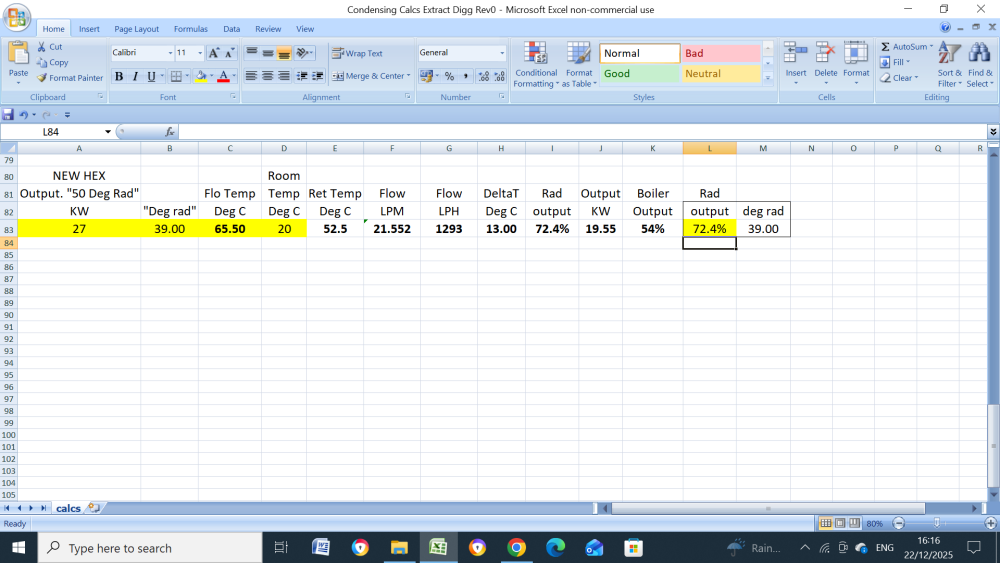

Been playing with ChatGTP over the last few days, generally going down a rabbit hole. Was looking for a simple way to model Weather Compensation fine tuning and or boosting during low tariff periods. So generally ChatGTP was no help. Had a search for something unrelated on Google and came across this site https://www.diyenjoying.com/2025/04/11/harnessing-the-power-of-predictive-heating-revolutionizing-home-comfort-with-home-assistant-and-derivative-sensors/ And finally a very simple modelling tool became realistic. So using the data on site above to add a couple of helpers to home assistant (hardware is already there - temp sensor). Then fine tuned for my UFH (thick screed etc). You now have a simple hourly and now 4 hourly look ahead at likely room or house temp if nothing changes. The author of that site used the information to start and stop heating, based on a generic thermostat, but taking account of floor inertia to not get swings in room temperature. So start boiler early and stop early, based on likely house temp - not actual house temp. But for weather compensation you just need a simple notification house temp is increasing or decreasing and you can simply adjust the curve. Add a bit of human looking at the day, it's stunning and room temp is increasing - no shocks don't do anything. But if it's dull outside you can decrease curve. So went back to ChatGTP for assistance. I have actually extended everything out to 4 hours to make it a little more meaningful for my house. There are few things this allows Intelligent fine tuning of WC curve. So you can see the likely house temp in 1 and 4 hrs and rate of change as a positive or negative. Options you could implement - you could run a cooler WC curve and boost during cheap periods. Could use it for batch charging alone, add some simple energy calculations based on you heating system store energy etc. Will add a few screenshots later5 points

-

Just as an update and close out of this - we agreed on a 30% refund. Happy with that, and we can paint some of them white (warranty won't be affected). Cheers for all the help.5 points

-

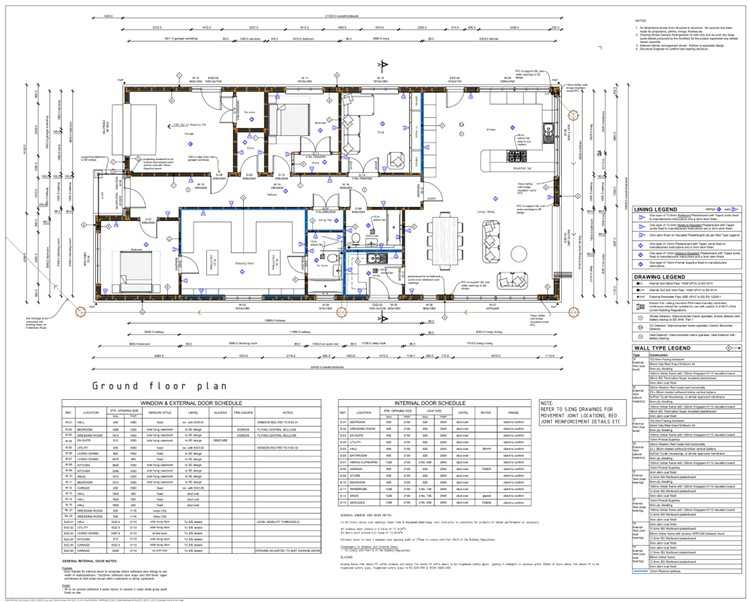

Hi all. I've been on here a while on and off and posted about 3½ years ago for advice on potential plots. We ended up getting a lovely plot in a nice village in Norfolk not long after that but was held up for 3 years because of neutrient neutrality and natural England stopping all new planning permissions being granted. We got full planning 4 months ago and have made a start, in the winter🫣. Foundation blocks are nearly laid to ground level. Me and my husband with a little help from others are running and building ourselves. My husband's a carpenter and was a site/contracts manager for a building company. We are building a single storey timber frame home with a brick skin up to window height then black cladding. A slightly unusual roof will top it off. We're both really excited and frightened especially regarding budget. We will have to stop the build throughout to earn more money to finish it but will be determined to get there in the end. If anyone has any words of wisdom or suggestions regarding internal layout we'd welcome your input. Also we're stuck with our heating and hot water system in terms of best and most efficient way to do it. It will just be 2 adults+a dog living in the house. We have no gas here and don't want oil so will be all electric. We'd love to have solar and batteries one day but it'll have to wait a while. The back of the house is south facing so will need to organise some shading but again budget may determine what we have. Thank you all in advance and I look forward to being part of your amazing community4 points

-

We’re self builders. Faffing is what we do. Why do the obvious when one can avoid doing anything for weeks while researching? 😕4 points

-

Impossible to calculate payback on MVHR, it’s about health and comfort which are priceless IMO! I I self installed a simple system for less than £2k, one of the best things about the house. Fresh clean air, without drafts and low heat loss. Trickle vents are uncontrolled ventilation, too much in high winds and also admit a surprising level of noise.4 points

-

If you have to ask the question here, you are not competent to undertake this work.4 points

-

I was under pressure to get PIR down, UFH installed and pressurised to get the CemFloor installed pre Xmas so I got a fella in to do it in the end. He flew through it and did a great job tweaking a few bits on site that the layout plans hadn't allowed for. It was sad, yet a relief to see it disappear under the screed! And another +1 for liquidscreedpumping.com if in the East Anglia area 👍🏼4 points

-

Starting my first major project trying to extend a 60s bungalow in the surrounding Guildford area and make it more of a family home with cottage charm but modern performance! Excited to get stuck into everything in the new year and love the invaluable resource that is this website!4 points

-

A major revision to the NPPF landed this week and makes for very interesting reading. Many of the things that have had our project in tangles seem to be getting ironed out - from conservation areas, heritage assets and Non Designated Heritage Assets - (NDHA)s to sustainability and a new set of 'substantial' weights given to a raft of things including design. It's pretty amazing reading. And - in other news - the Biodiversity Net Gains (BNG) for small sites (up to 0.2ha) is being dropped altogether which means no more Unilateral Undertakings (UUs) for self-builders. Keen to hear the takes of the hive mind here. I feel like even if our (overdue!) appeal is dismissed, we have enough here to get planning next time.4 points

-

Popping my head through the door to say hi! Have read about a gazillion posts over the past few months... gearing up to potentially do a new build in Bristol, several bits of the puzzle yet to fall in to place, but hoping to get cracking next year. Aiming for a close to passive house spec, budget depending!4 points

-

Marvellous. The most important thing when renovating an old bungalow is to immediately bulldoze it.4 points

-

I know my friends who own their own window supply company and I work with them closely, are looking to distribute Finstral and have been down in their showroom and so forth. The ex UK MD for Internorm (Andreas Simmer) is now the MD at Finstral. Good outfit, good window systems from the feedback I have received.4 points

-

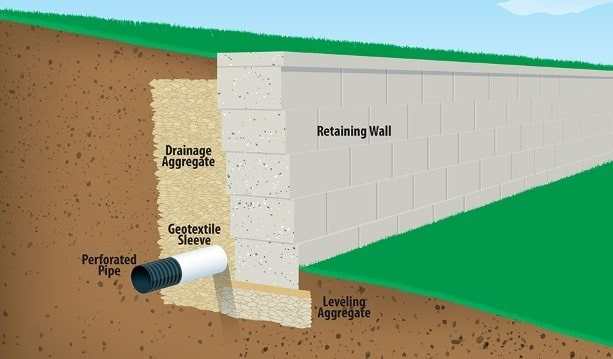

Hi @slystallone, the wall shoulld have the soil side waterproofed with a perforated pipe running around the bottom “French drain” style and backfill with pea gravel, pebbles or similar to allow any water behind the wall to go down into the perforated pipe and then away around the side. idea is to take any water away to prevent the wall from being a Dam and being subjected to water pressure. It would be worth doing a bit of digging at the wall ends to check for any existing drainage that may have been blocked etc. failing that you are looking at water management which means a lot of digging or back to cutting holes in the wall and then collecting the water to take it away in visible pipes on your side,4 points

-

Yes, already proven here. Very early on in the build I confirmed the heat loss calculation was correct by leaving a single electric convector heater of known power on and plotting internal vs external temperature for several days. That gave me the Dt for a given power input, which tied exactly with the calculations. In any event I bought a 5kW ASHP to satisfy a max demand of just over 2kW. For me the only leap of faith was no heating in the bedrooms. SWMBO likes a cool bedroom about 18 degrees. Usually we have to keep the bedroom door shut to keep it down to that. In this cold spell we had to open the bedroom door occasionally to let a little bit of heat in, and still achieved the required temperature with no actual heating there.3 points

-

If you want to do as much as possible yourself then I think there’s a few options. icf you can do everything yourself timber kit, get that put up and then finish it yourself timber built on site, you will probably need a couple of carpenters to help brick block cavity you will need a bricklaying gang. will also depend if you have a large chunk of cash up front, timber frame erected on site will probably be the heaviest up front cost. icf has a large up front cost, but probably 20% of a timberframe then you can drip feed cash into it. brick n block lowest up front cost but large weekly payments for labour.3 points

-

Full planning it is. Prepare yourselves for more questions. 🤠3 points

-

Triple glazed lift n slide from norrsken here. the back wall of my place is 90% glass, I can’t recommend them enough -3 outside here and the doors on the inside feel warm, open them up and the outside feel is freezing. a strange thing you notice with this quality is the outside door handles are freezing cold, the inner handle is warm, there is no heat transfer through the door via any lock mechanism.3 points

-

The mix is not important, getting your bricklaying team to mix it the same every time is the important thing. when you get the colour you want you need to discuss it with the bricky and get it in writing that they will use a gauge box to get it the same every time. any not up to standard gets taken down at their cost. you will need to buy sand in bulk and cement to get the same batch every time. DO NOT USE any form of mortar dye.3 points

-

Hi everyone 👋 I’m new here and thought I’d introduce myself as we’re about to embark on what feels like a fairly sizeable (and exciting!) project. We’re currently in the process of purchasing an old farm property that’s seen better days and is very much in need of some care and attention. The house itself has been a rental for a long time and, as you’d expect, has suffered from a fair bit of neglect. Phase one for us will be getting the main house brought up to modern standards – sorting the basics, improving comfort and efficiency, and generally making it a solid, future-proofed home again. Once that’s complete, phase two will be the big one: converting the existing barn into residential use. The long-term goal is to create a spacious five-bedroom family home, making the most of the character of the original buildings while blending in plenty of modern comforts – hopefully lots of underfloor heating and well-thought-out modern electrics along the way. I’ve already spent far too many hours reading through the forum and it’s clear there’s a huge amount of knowledge here, so I’m really looking forward to learning from others, sharing progress, and no doubt asking plenty of questions as we go. luckily we gutted/renovated a nice 3 storey property in Whitby over lockdown which has given us confidence to attack another project. Thanks in advance – I’m sure you’ll be hearing more from me soon!3 points

-

Passive class house here, not certified, no UFH. An actual measured heat usage of 3200kWh or 17kWh/m2/annum. Supplied by an electric plug in heater. It worked fine so long as you plugged it in anywhere downstairs and allowed it to gently input heat for 18hrs/day. Expecting it to batch heat on TOU tariff overnight wasn't as successful as i had hoped. it needed to be turned on at about 17:00 in winter to keep the living rooms warm enough(21deg). I added some electric heaters in the bathrooms for comfort as 21deg isn't quite toasty enough. Fan heaters are better than 2 Bar quartz heaters. The house is very comfortable. I replaced the electric radiator with an A2A HP for 2025. It's dropped our heating consumption to very close to 1000kWh or 5.5kWh/m2/annum. It works fine so long as you give it long enough run times for the heat to disperse around the house. It won't be quite as cheap as an A2W HP as you can't batch heat a slab on TOU tarriffs and a COP of 3 to 3.5 won't match a top end A2WHP. However it only cost €1500 installed so there isn't much in it. Add DHW demand or solar and the sums would change again. (FWIW an A2W + UFH was quoted at €14k in 2020) TLDR: 1. Anything will heat a passive house comfortably if you're prepared to give it a fair chance. Short run times and quick runups won't work with localised heat sources. 2. A2W HP's are best for comfort and running costs. However they only have the best long term costs if you can get a well priced install.3 points

-

3 points

-

Happy new year folks, Thankyou for being such a treasure chest of information, and laughs.3 points

-

Stop faffing, get PIR, spend once, save for ever more. Once in you cannot upgrade. I shopped around, bought online saved a small fortune, it came on lorry direct from factory - I had a full lorry load of 100mm thick, so 2 layers.3 points

-

Where is your structural design? Should be zero need for such questions, if your building is designed.3 points

-

Hi. Something’s not right if your design flow temp is as high as 35°! GF UFH, I assume, is going into a slab? If so, 35° into that will cause the house to overheat. You should be mid-high 20’s and certainly under 30°, if well built, airtight, and you have heat recovery too. Buffer “delete” may be subject to the manufacturer’s installation instructions, and an MCS reg’d installer may refuse to stray from that. On a recent Heat Geek install I witnessed they put either a 25L or a 50L 2-port volumiser in, on the flow which makes more sense to me, as that was stipulated in the MI’s vs what the low heat demand called for. That was a refurb, prob got to EnerPHit levels, and the flow temps at 25° made the place almost unbearable to work in. @jimseng As we don’t know much about your particular project we can’t possibly size a heat pump here yet, but 3.5-4kw will be quite slow to reheat a decent sized UVC; your game plan needs thought which considers your DHW needs / frequency / number of occupants. Heating is a doddle to resolve, DHW needs to be considered in isolation and planned for pragmatically. You can, for eg, use an immersion strategically to boost for times of duress, so many ways to ‘make this happen’. Do you have solar PV in the plan?3 points

-

Regardless of any assurance, before ordering windows I would MEASURE the actual window openings as built. I paid a local builder company to build and erect my frame, and then later paid them to supply and fit windows. Even they did not trust they had built the openings to the drawing, and measured them before ordering windows.3 points

-

Don't listen to him, nobody uses bulldozers any more! Welcome to THE forum for people like us.3 points

-

Hi. Just joined. Panning on demolition/deconstruction then rebuild with to Passivhaus standard. Wish to use as much high eco-standard materials as possible. Looking forward to making connections in this forum! Cheers.3 points

-

First unit was the fan, the second was a 3 stage, digitally controlled diesel heater. It was a very cold day, and it was very reassuring to see that they heated the incoming air to aid the process. Only negative was that every single flat surface, and I mean EVERY one of them, gets a layer of product left on it. This included the screeded floor which was like walking on fly paper for the next 2 days. I was horrified when the team prepped and just laid 2” masking tape onto the flat sections of the new Norrsken doors and windows……with zero dust sheet or other over the glass or vertical sections of the frames. All these guys did was throw poly sheets over the precious stuff and get to work. My only criticism was that this could have been better, and a few things got residual goop on them that I’d have preferred they didn’t. Was this a problem? Nope. It just wipes / washes away pretty easily, so things like pipes and lagging in the plant room will need a bit of cleaning after, which is fine. Just could have been avoided with some better prep. This was the first time I’d been on site during one of these treatments, so next time I’ll do the shitty (more intricate) masking / sheeting ahead of their arrival. In one of the pics you’ll see a tripod near a window, and that was guffing this stuff out at a rate of knots. I inspected the window after AB stripped their seemingly rudimentary masking off, and I can report that there was absolutely no evidence of them being there. This stuff just doesn’t stick to ANYTHING vertical. Not one bit. Happy days! All told, a great team arrived on site, they were speedy and got straight to business. Prep was done (looks a bit underwhelming but does what it needs to) and they were off to the races in no time at all. Quite an impressive setup with no reliance on electricity etc; as seen they just plonk gennys down and get on with it. I’ll defo be using and promoting AeroBarrier, anytime it’s the obvious choice.3 points

-

They price per m2 iirc, and I asked the same question. So no matter if you’ve parged the place and use very little product, or you’ve a woodcrete ICF or bare masonry structure, price is the same. The larger holes? Well anything that you can see should be dealt with beforehand as best you can, obvs, but to give you some idea of how good this is, bearing in mind this product gets atomised, the results can be seen here. Look for the marble lines in these pics, and the ‘hole’ in the first pic, that was not obvious to the eye, got plugged PDQ! @Mike I’m referring to the ones that your method just won’t find, not the ones it can. Have a look at these micro fractures in the pointing of the masonry, and where masonry meets blocks. The blocks / bricks themselves are surprisingly airtight as is, and no real evidence of the product having sealed them, but I’m sure it has but it’s just not as easily seen. It got into gaps thinner than a cigarette paper, as you can see right at the bottom of the last pic. Two slight white lines 10mm apart or so, which the eye, candle, or other, wouldn’t have ever detected. There was a 3.4m long metal lintel which was perforated with hundreds of 6mm holes, and this stuff went into each one and plugged them up nicely.3 points

-

3 points

-

AI "The revenue from the Crown Estate goes to the UK government's Treasury, also known as the Exchequer, not to the Monarch personally. Each year, the Monarch surrenders the entire net revenue profit in exchange for the Sovereign Grant, which is provided by the government to fund official duties and the upkeep of occupied royal palaces."3 points

-

"With hindsight I'd have knocked it down and started again".3 points

-

Hi, Moved into a 1.5 story 1960s 'Chalet' style house a year ago. After living in the property for a bit we have got more of a feel of what works/ what doesn't and what we want from to achieve. The two main aims will be to alter the floorplan on the ground floor and to significantly improve energy efficiency (it's freezing). I have also become interested in retrofit. I am currently researching as much as I can whilst planning to meet with a few potential architects in the new year. Looking forward to learning from everyone on here! Dan2 points

-

Neither. For simple white switches, I don't think you will beat Click Mode for quality, value and reliability. But Screweys don't sell them. Toolstation do. https://www.toolstation.com/click-mode-10a-switch/p73508 A little "quirk" of these switches is the switch mechanism can be removed from the plate, enabling you to mix normal and intermediate switches on the one plate. Almost like a grid switch.2 points

-

If youve got a near new working system then your primary motivation for change is likely only for environmental reasons?? If your boiler is still running perfectly in 20 years time that would be an awful lot of carbon emitted that you could have avoided if you'd made the change now. I'd bin the boiler now but my measure of ROI isn't just £££. Only you know your measure of ROI.2 points

-

I’ve got a few hours this morning before the in-laws come for lunch to do some building. The best way to start 2026! Happy New Year.2 points

-

2 points

-

Looks like water is running down the pipe from above. Likely an ill-fitting tap letting water down from splashes in the sink area.2 points

-

In the end I went with Sany SY16C and it arrives Thursday. I am still trying to muster up the courage to tell the other half 😂 she just doesn't understand! I have been thinking about all of the jobs that I will need a small machine for to build the house and it's loads. I currently have a skip which is due to be returned soon, and there is a pile of wood and a tree stump. No chance I can lift it in by hand. Even though the hire of a 3 ton machine was only £280/week, by the time I factored in the £55 charge each way for delivery and collection and the VAT. You are suddenly at £500 for a weeks hire. I am also contemplating a one ton dumper, but I think I may wait before having that conversation.2 points

-

Let’s be realistic? Going around on a windy day with a candle isn’t really going to cut it . I’ve recently been working on what is basically now an EnerPHit refurbishment of a mid 60’s brick and block bungalow. I advised the client to go for a posi joist roof, with an AVCL internally. At the tops of the masonry walls we parged 300mm or so with standard set tile adhesive, after SBR primer was applied to the new thermalite blocks / original masonry. That was covered in Passive Purple, primarily to act as a quality primer for the AVCL to get taped to. At the junctions between the kicker blocks and the infill screeded sections of floors, we injected 330 foam and then multi-tooled off the excess. This was spot foamed and trimmed again. Then the screed was primered and the sole plate of each internal stud and 100mm of screed against the plate was PP’d. Then these got taped over with an 80mm tape. This bit was prob overkill seeing as AeroBarrier were in next to “seal the deal”. The brick / block / masonry walls were left untouched, just a bit of foam and some leftover PP applied to the obvious bits. No additional parging necessary. Started off at a respectable 1.2ach, and that was down to 0.5 at 38 mins into the treatment. It got down to 0.2 by about 2 hrs in, and then the chap in charge decided to go batshit crazy and upped the fan pressure to 200pa (from 50); he said “we don’t see these types of projects getting such good results, so let’s get it to a 0.1”. And he did. 👌🤝👍 The only piss you off was the laptop didn’t do 2 decimal places, so let’s assume the 0.1ach was something like 0.18, so on the rebound I can say it was definitely a rock solid <0.20ach final test result. Shit hot afaic, for an old masonry hybrid refurb. Around doors and windows, all that was done was the foam, but the windows did get taped afterwards; whether they actually needed this afterwards is anyone’s guess, but for longevity, they got taped a few days after. The roof lights had the splays done in the green propassive AT OSB, and they were taped to the AVCL and then the OSB was taped to the roof lights. This was after Gordon Lewis had been to work his magic, fully filling a rather complex roof structure. He was VERY thorough and even came back the morning after; he was supposed to have been elsewhere, but wanted to go around one more time so he could just work some of the smaller, more awkward voids to his then satisfaction. In a nutshell, he stayed until the job was done and 100% over the finish line. Big thanks and a shout out here to Gordon, so anyone wanting Warmcell blown in please PM me and I’ll zap you his details. FYI he tapes up everything after he’s done, so an AT tested build will still be AT after his attendance. The AB product is more like PVA than caulk, so it’s stretchy and won’t crack or fracture like caulk does. They were adamant that taping the doors and windows was pretty much a waste of time / money. I’ll post some pics in a bit. Places where this got in and sealed up were quite fascinating to see (if you like that kind of thing).2 points

-

There is a discprecancy here. Go back and check what parmeters the Larsen truss designer was given. Ask; how do the Larsen trusses cope with the wind load. Larsen truss design is a bit of an art, it's a lot of fun mind and massively elegant, the wind loads get applied in a different way compared with a standard timber frame. The detail you show indicates that the outer and inner flange of the Larsen truss are restrained. It seems that your are on the face of it committed, but if there is an error then no point in compounding this. If I was you I would be confirming in writing to your Architect that a 40 mm screed is achievable, buildable at reasonable cost and it is going to remain serviceable ( i.e) not cause problems with the flooring. I've dabbled with this over the years and I feel that you tolerances are too tight and you are in for a nasty shock At least you'll end up paying for something that does not get delivered on site. My suggestion is that you get together with your Architect.. find out just how much they know about what is deliverable in reality. Give them a way to save face and see if you can change the levels. Bite the bullet now as later it will likely get worse. Well it will be a disater if what you are laying on is 5 - 10mm high? so now the pipe cover will be a bit of a joke. As an SE I'm very careful to set buildable tolerance limits. Ask your Architect how they are going to account for the variation in level and flatness of what you are laying on. In summary you take your chances! As an SE I'm not that fussed if your UFH does not work so well. With my desinger hat on I think this is vital to get it right, even if you have to go back and review the potential desing flaws which I think are there. It does not have to to result in a big falling out!2 points

-

2 points

-

that could be changed very readily if there was the will.2 points

-

We've been watching 'Yes Minister' and 'Yes Prime Minister' on iPlayer recently. It shows that off exactly. Just as brilliant the second time around.2 points