Leaderboard

Popular Content

Showing content with the highest reputation since 12/09/25 in Blog Comments

-

Well that's very kind. There are several things to say: Firstly, we have been lucky. What's the most important attribute of a successful project manager? Answer: Be lucky! Secondly, the blog no doubt gives a slightly rose-tinted view for a couple of reasons: I have not majored on the couple of trades who have been more 'difficult', primarily because it's not fair to trash them when they have no way of replying. Also, I am mindful that where we have had issues that might be down to me - lack of clarity of instructions, clash of styles etc. None have been fraudulent or dangerous. In terms of the process of finding good trades, it's largely down to previous contact and personal recommendation. Those trades we did not already know were mostly recommended by those we did know. Notably the few we have been less enamoured with were people I sought out directly through the internet, adverts etc. but equally that method did throw up some excellent teams (e.g. the plasterers, and indeed the main timber frame company Turners). For national suppliers/trades (e.g. our ASHP team Air2Heat and the MVHR guys Heat, Space and Light) a trawl of BuildHub has been very useful, and reliable. I thought about asking for reference sites but in truth I don't think these are at all reliable; ask any trade for a reference and if they want the job they'll provide one (and often those good trades that don't need the work won't be bothering to provide referees because the whole thing is a bit of hassle for a job you might not get). And has anyone ever followed up a reference and got bad feedback? So I didn't bother with that. The other big thing is communication. I spent quite a lot of time lining people up as early as possible, and talked to them - a lot. By which I mean I kept in regular contact every fortnight or so to confirm we were still on schedule, and check they were still lined up. Some people I just On a couple of trades I got cold feet due to difficulties getting hold of them or lack of confidence they could make our dates, so I switched to alternatives, giving them plenty of notice we were going elsewhere. I have tried to keep the communication up through their work for us too - everyone likes to be told what a great job they are doing and it costs nothing. Build up a stock of that and if you need to call out issues, change things, or beg some favours it lands much better. We have really worked hard to keep people on site happy too - tea and coffee making, free snacks, a well-stocked fridge - several contractors have commented that ours has been a great site to work at. It costs next to nothing and reaps lots of good will. Also boosting good will is paying invoices immediately - I mean the same day, within a couple of hours. We have the cash to fund the project so it does much better for us in keeping trades happy than sat in our account earning nothing in real terms.4 points

-

Keep seeing these threads, and still see zero point with most of what people do with automation. Waste of time and money. But fill your boots. My current lighting scheme, is side lights in the lounge from a normal light switch and 3A wall sockets. Don't need home assistant or shelly or any other smart relay. Got a box of them, all removed, in my cr@p I bought box and was waste of money. 4 years in house, no smoke or heat alarms have ever gone off. They will all be binned at year 10 and replaced with new. If they go there's an issue. Heat alarms in kitchen don't react to you burning your toast.2 points

-

I have been messaging @craig about this and he has suggested possibly replacing the current striker latch for a day latch on at least one door. It doesn't look that straightforward but may be doable.2 points

-

Checked - it's as I thought, they are going to fix a strip of the ash to the cross batten, they have already done this on the tall window (photo looks a bit odd due to it being an angled reveal + the camera perspective). We are not going to worry about weep holes because: ventilated cavity, small gaps between the half lap boards, and its a relatively sheltered east facing wall. The window itself is set back from the cladding and very well sealed.2 points

-

Yes it's Brimstone Ash from Vastern timber. Expensive but really excellent quality - straight as a dye, virtually no knots, and it came really well packed. It cuts cleanly and we haven't experienced any splitting, despite Vastern warning that it can be brittle. We originally intended using western red cedar but discovered that cedar reacts with zinc and we have some high cladding above our zinc roof. The Brimstone Ash is inert (so we are told!). It's about the same price as Canadian cedar but has the benefit of going silver quicker, and it's British, so lower transport CO2 costs. Stainless nails are an absolute must. We're using Timco FirmaHold 16G 50mm Stainless 2nd fix nails through the face - very hard to see. Regarding the edge above the windows. Although it doesn't really show in the photo all the bottom edges are cut at a 30 degree angle to leave a drip point at the outside edge. This was recommended by Vastern. The same for any joins in long verticals, though incredibly I think we have only needed 2 or 3 due to lots of long lengths being supplied and careful selection by our carpenters. For the bottom edges they have fixed them slightly over sized then run a rail saw. Anyway we feel the angled cut at the bottom should stop water pooling on those bottom edges. Further progress on the cladding today:2 points

-

We bought everything through them: design, kit, commissioning, and installed it ourselves. I am sure we could have done the design ourselves but we had too many other things going on. You would have to give Patrick Chester a call or email patrick@heatspaceandlight.com to see if they would just commission.2 points

-

1 point

-

Me too. Big time. I’ll take and post some pics tomorrow but you really should get out more lol She has served, and hopefully will continue to serve, with distinction. Bless her. I’ve become quite attached.1 point

-

Re hard to reach smoke alarms. All ours our Aico, hard wired mains powered. I also have the Aico remote control unit that allows you to test the alarms, silence them in the event of sounding, and locate which one has caused them all to sound. That is a wireless connected unit that you can mount anywhere, or use it portable, so no need to get the steps out or do the tea towel dance.1 point

-

It's impossible to cover every decision and get them all right. 'Mistakes, we've made a few, but then again... '1 point

-

I have put in 47mm back boxes everywhere for the light switches, and a number with backboxes twice the size of the cover plate to provide plenty of room for switch/dimmer modules. Despite this my sparky seems to belong to the abstract spaghetti school of smart module wiring. I find it frustrating how the manufacturers are so focussed on the retrofit market, there seems to be a big gap to be filled with products for people doing new builds and total renovations. Having smart things on show is all very well, but I do think the ideal smart home would have the devices hidden from view. Nobody seems to have worked out how and where to integrate in presence/motion detectors etc. Lots of things in white plastic boxes only. I like things like the Sensative strips that are invisible when installed. Have you integrated smoke and heat alarms into HA ? Because the England regs require wired detectors which is a PITA and seems to preclude all the smart home solutions that are almost universally retrofit battery powered and don't meet regs. Also are you using anything for smart control to turn the water mains supply or gas supply on/off - such as the robots that will turn a lever arm valve ? Are you using LED strips under your kitchen counter tops, and if so what type, and are they surface mounted or in routed channels ? (It is amazing just how many lights you can end up with. I have 8 dining spots+9 sitting spots+3 entry spots+10 kitchen spots+5 pendants + 7 led strips + 3 under cabinet pucks + 3 accent spots + 3 picture lights + 1 wall light = 52 individual lights in one open plan room, with another 11 external lights (6 soffit, 4 wall, 1 step). I guess I am as mad as mad jack mcmadman from madsville.)1 point

-

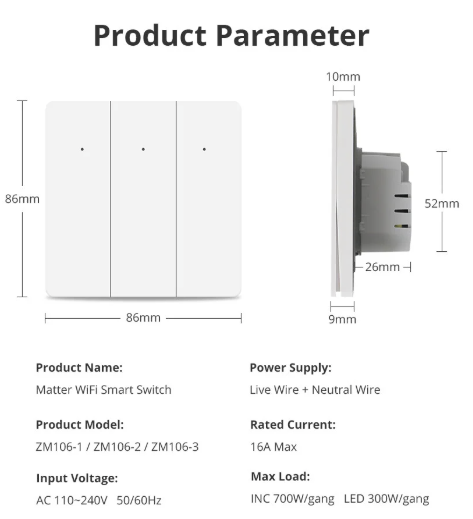

I got a few Aqara light switches to start with - they do Matter/Zigbee and take a neutral which is what I was after. The fixings/screws were tiny, the electrician dealt with them but not as robust as I'd like. I have a standard 3 gang switch in the hallway which does porch, hallway and landing, I just bought some zemismart matter wifi smart switches (3 gang) and plan to replace this with one of them so I can trigger the porch light when my doorbell sees me. The others I'll install in my bedroom / elsewhere as even though there's only 1 light I can use the other switches to trigger an automation and do something else. I had a long look around other light switches, the aqara dimmer one is really nice, the two gang above not so much, looks flimsy but is working well enough, zemismart TBC. I've a 4 gang switch in the living room, but no one seems to be making smart ones of these. Something for down the road! Getting switches to fit UK back boxes can also be tricky. I have a smart screen but it needs a EU backbox - but that doesn't fit behind plasterboard! The zemi below has perfect screwhole placement though for a single gang: I bought a zemi roller blind motor but it was 28mm and the blocout blind I got for my bedroom is 32mm. I found a 3d model on the web and printed it the local library but it didn't adapt correctly. Instead I purchased a couple of Aqara roller shade E1 drivers. I fitted this a few days ago and have the automation working fine tied to the sunup and sundown times. Must change it before the Spring!! It's a heavy blind but works well so far. I'll do the same with the other blinds as I buy them. Would have preferred the driver inside the roller itself but this is the next best thing. I have vertical blinds on a cord for the kitchen and even though there's no beads, just a string, this product can apparently handle them. I just can't find the other 4 E1's I bought, probably in a box somewhere.....!!! I've Luxor Perfect Fit honeycomb blinds for privacy and then the blackout blind for total immersion in the summer! I went with a load of Shelly Relays for the floodlights, towel rails and stairs LED but Sonoff for other things - presence detection, PIR, Door Sensor, push button remote, water sensor. It's been an interesting mix. I've two presence detectors in the bathrooms, one gets me in the shower 99% of the time behind the glass. There's no room door currently and when I exit the front door it triggers also which is weird. I don't expect it to penetrate plasterboard - I'll know more after the door goes on but it's facing into the bathroom so unlikely to pick anything beyond that I would think? Not sure of a use case for it....! I use a unifi poe to usb dingle to power it which is neat inside a double gang backbox and a blanking plate! Retrofit is a bit different to new builds so I get the need to keep things familiar. You really need smart switches to deal with legacy users. All my bulbs are non smart / traditional - they just dim etc. If you find a nice switch it's an easy win. It's the LED's around the kitchen etc that have more options / control requirements that need more than a switch can provide. I've only automated some lights to on / off via presence detection but I want to get it to dim the lights in the wee hours when they come on, that would be really nice. I was able to CAT6a around the house which worked well. I have a few smart sockets in strategic places that will come into their own in the coming months. I can move these around as I figure things out. Sometimes just a double socket with USB is fine. Just bought a raspberry pi and mounted a monitor in my room so I can put my cctv picture up there and turn it off at night but have a push button to turn it on if I get an alarm. I've hikvision cameras and NVR but looking to move to unifi as I can't get the HA integration to work so I can trigger floodlights etc on people detection / line crossing. That said I did get the tumble dryer to send me a notification last night for the first time when the load had finished! Some success, some head scratching. I also want Sonos voice alerts but haven't figured that out yet either! Really happy with the HA Dashboard though! I'll post an update in a few months here around HA stuff and any questions let me know. New to this myself too!1 point

-

Interesting idea but I can imagine Mrs. P's reaction when I tell her I've opened a Velux for her to climb through. I suspect she'd tell me where to go ('go and get a hammer').1 point

-

That's actually a really smart idea!! Thanks!!1 point

-

Maybe keep a spare remote for a Velux roof light in the glovebox! Not ideal but better than the brick-toss through the cheapest one.1 point

-

Left hand diagram looks very similar to our wall build-up. Right hand side: we haven't used an angled timber head drip but we don't have very much clad wall above the window, as single storey but I can't see any reason why your design won't work fine. IANAE though.1 point

-

No we haven't rendered that top reveal - too fiddly. There's a cross batten behind the vertical cladding and I think they have added, or are going to add, a strip of ash to cover that batten but that strip will only be visible from below - the vertical cladding comes down further. I need to check tomorrow. Also I am now unsure how any water that gets behind the cladding will drain, so I need to check that too but I'd be surprised if the chippies haven't already considered and addressed it. (There's a ventilated cavity behind the cladding of course.) I'll report back.1 point

-

Such great progress and blog. We are at least few months behind this build and I (J) am using it as a bit of a touchstone. Couldn't agree more on the points quoted above, they really do help, including people being happy to make recommendations for follow on trades and offer advice. Also of course, as mentioned, keeping people updated on progress (or delays!).1 point

-

They are doing a great job, I was only being pedantic. It is great seeing the progress through your blog. The local timber is special but quite challenging to work with, shrinkage was inevitable ( air dried in the garage for 3 months but not enough) but the half lap compensated for it. I also used about 150 sqm of local Douglas fir for the garage, no half lap as horizontal shiplap. Quite similar to Cedar, not as knotty, feels a bit denser. Weathering well and might stain it next summer. Onwards......1 point

-

Thank you. We start the new year with our chilly having a birthday at Christmas. With him and me on site the average site age has just risen to just over 70. You’ve heard of Jerry built. Well ours is geriatric built. lol0 points

-

Before or after you show her the invoice for the window0 points