Leaderboard

Popular Content

Showing content with the highest reputation on 09/25/23 in all areas

-

2 points

-

Copper out the wall is still naff to plaster around/look at if you're then going to a tap of some kind. How about wall plate elbows? https://wavin.com/en-sg/product/f0bb1231-b2fc-4949-8c8d-bd4a6615a933 Run hep to that. Screw in a plastic dummy. Plaster. Unscrew plastic dummy. Screw in either an ISO valve then the tap hose or a hose with a 1/2" male end; through a rosette to hide the plaster edges. As above is how they do this by default over here; looks neat to my eye and is easier to plaster over / around than flexible pipe at a jaunty angle too. If working in a 45 mm battened service cavity you take a lump of 25 mm decking board, use that to span two upright studs, and screw the wall plate elbow to that. The threaded bit then sticks into a hole in the plasterboard a convenient amount. If working in metal stud partitions you again whack a wooden noggin across two studs and screw your wall elbow to that; thickens of noggin to suit metal stud width. If chasing into a masonry wall...resin fix / glue is your friend whilst jaunty angled screws into wallplugs into dust sets. If doing a shower it can be easier/cheaper to buy one of those 2x 1/2" female-female-brass fittings-onna- wallplate thingamies and screw two 1/2" male to help adapters into it.2 points

-

In my GF bathroom I brought the pipes up in the footprint of the pedestal, so you can’t see any plumbing other than the waste pipe existing horizontally through the wall. 1, best of the worst, but defo convert to copper and clip it. 2. not whilst I’ve a hole in my you-know-where 👎👎👎 3. #1 choice, using a Hep 90 in the wall to allow copper to be on show. Behind a radiator is where those plates get used, eg where they’ll never be seen and where there is no need to fill / sand / decorate around them.2 points

-

I’m really sorry you’ve been ripped off. It pains me to see this happen so often when people don’t have an aptitude for these things and have to trust someone else to do it. The job they have done is so simple and there really is no excuse to have not done a competent job, even at half the cost. If you have already paid them then I don’t think there is much hope of progress. There ought to be, but their attitude thus far suggests not. As @markocosic says, I’d buy in one of those sturdy manhole covers and do it yourself. I wouldn’t go in the direction of silicon - it probably won’t be terribly successful and will just make a bad job worse.1 point

-

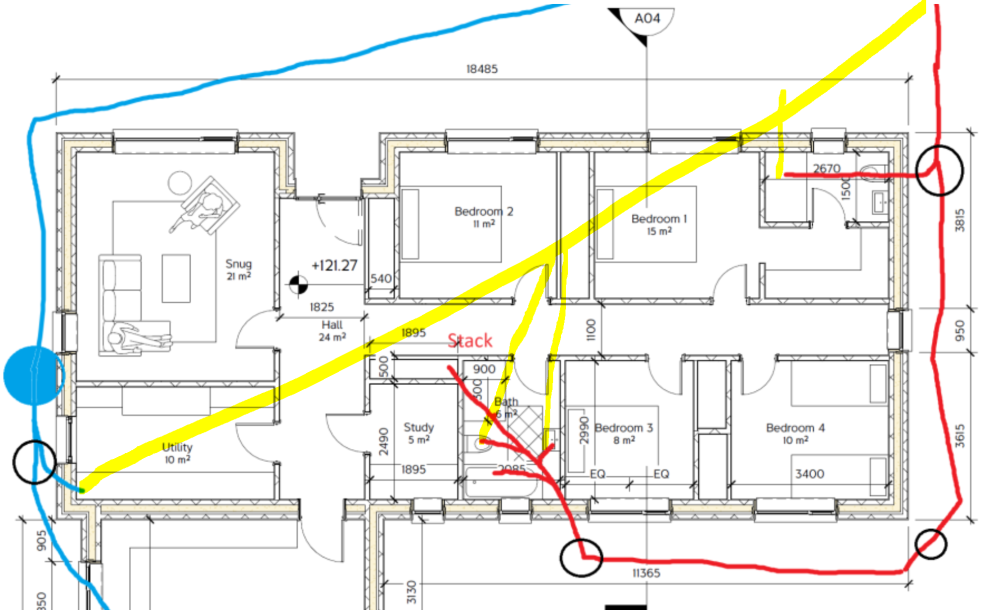

Removing more from the bottom is going to give you a top heavy stack rotating around the ridge line. Stick to a lintel at loft floor level if you are keeping the stack1 point

-

Different subject, but 100mm PIR is a bit on the low side, you want 150mm or more.1 point

-

Still waiting on planning permission... But still planning on installing the ducting in the chimney at the front of the house.1 point

-

1 point

-

Good to see good work being installed no matter that it’s in a cupboard. Looks great!1 point

-

I have emailed Eskimo Technical Services who are assuring me that there is no error, I've followed up asking for any independent validation, they work closely with Birmingham Uni, so hopefully they'll have some independent data.1 point

-

If that indicates the height you are going to raise the ground level to, check you are not too close or even above the Damp Proof Course first.1 point

-

1 point

-

1 point

-

Yep, I'll dig out an old invoice. Suppliers are having our pants down.1 point

-

There is nothing in a smart meter that can create interference ..? More likely something in your house such as a fridge or another motor that is creating noise.1 point

-

1 point

-

@Barking99, you keep saying you disagree with the planners so your only course of action, that I and others have said is to appeal, that’s why the appeal procedure exists. You can argue with the planners till the cows come home but that will do no good. Drag it out as long as possible, go to appeal and by that time the hedge will have grown. I have fought planners a few times as their rules are often grey areas open to interpretation so don’t get me wrong they can be a nightmare. If you do go to appeal and win (and I find the appeal officers are far more practical than planners) you can give them the bird 🖕1 point

-

Would cost a small fortune, I doubt its even available at that thickness.. No one would buy it that thick 10mm thick 1.2m2 is £230! Old buildings you need to be careful with condensation also.1 point

-

If you submit your appeal near to the 6 month deadline it will probably be over a year until the Planning Inspector sees it.1 point

-

I'm using HEP in our reno. Cheapest I found the pipe was from our Builders Merchant. 50m 22mm pipe @ 91.92 + VAT 50m 15mm pipe @ 49.67 + VAT 100mm 10mm pipe @ 82.79 + VAT1 point

-

We finished off the pointing this morning. The old lime mortar was just wasting away, so raked a load of that out and put fresh in. There's a load of cement up there too which is causing some bricks to spall, so I need to tackle that at some point, but it was getting pretty windy by lunch time. We also have a wet verge, which was falling to bits, so replaced that at the same time. Still pretty frustrated we've had 4 roofers come take a look at this leak and none of them spotted these problems. The pot, and cement around it, literally lifted off in my hands without any "encouragement".1 point

-

Its interesting isn't it: brings to mind that dreadful saying - " If you know, you know " Most of us don't, and I suppose thats why so much poor work is accepted by so many (me included) . We just don't know. I paid my university fees by starting a window cleaning business. It paid well - and I worked at it for seven years while qualifying. It has taken me twenty-odd years to look through windows, rather than at them. @twice round the block , it must be hard for you sometimes looking at brick-work done by a (say) DIYer. And @Dave Jones keeps a sledgehammer in the back of his car I bet....😏1 point

-

1 point

-

As Nick says, if not out in the rain I don’t think it will be a problem and I have used non galv in the past.1 point

-

1 point

-

Plastering the sand and cement? is there no internal insulation, walls? what are you building?1 point

-

He may just be trying to be efficient and clearing up loose ends before he starts his next job. If so it's not really the time to punish him financially.1 point

-

If, in your opinion, he's rushing, make your snagging retainer larger, and longer before he's paid. You'll have done Due Diligence beforehand ..... Yes?1 point

-

0 points

-

0 points

-

huge thanks for the reassurance! none of the nails are directly exposed to the environment and are protected from water ingress from above so fingers-crossed! off to do the rest of the wall frames now, and the roof. after a quick trip to paris in a clapped out skoda fabia to help my eldest move flat. again.0 points

-

As I may have expounded before, roofing is perhaps the easiest job to get away with incompetence. It is way up high, difficult to get to and dangerous. So the field of potential roofers is reduced, and few clients will look before or after. I had one who didn't even know which way to lap felt, or why.0 points

-

Why ..?? Can only really get it as sleeved MLCP or PEX and it’s 4 times the price ..!! Buy some rolls of insulation tape if you are worried about mixing pipes up. Or buy proper tracer tape if you want to do it really nicely !!0 points

-

thanks. I started my build so long ago that those regs don't apply! 🤣0 points

-

A very clever use of space. Well done. you need some sun on those legs though.0 points

-

Put dehumidifiers in doors on full bore to dry it out as fast as possible, when the plaster cracks you know it's dry and ready for painting. Paint outside the day before the first frosts. note. do the opposite to the above.0 points

This leaderboard is set to London/GMT+01:00