Leaderboard

Popular Content

Showing content with the highest reputation on 12/15/24 in all areas

-

Open one valve to be in line with the pipe and just crack the other open a bit until you hear water flow. Then adjust the flow rate while watching the pressure gauge. If you open both valves fully to begin with the "whoosh" sound will swiftly be followed by the pressure relief valve going off and possibly water over your feet or elsewhere before you can react, particularly if you have not played this game before.2 points

-

I would not. I would take the door frame out. Build shuttering either side and pour the concrete IN PLACE. When dry, put door frame back.1 point

-

It's in the certification criteria - https://database.passivehouse.com/en/components/#certification-methods-info The effective dry heat recovery efficiency [is measured with] with balanced mass flows at external temperatures of between – 15 and + 10°C and dry extract air (ca. 20 °C) Presumably the worst reading is taken. However Heat Recovery Efficiency, as the name suggests, only measures heat recovered. On that basis a unit with expensive-to-run fans can look better than one with highly efficient ones. The Efficiency Ratio is the key figure that allows you to compare units like-for-like, taking into account the electricity used as well as the heat recovered.1 point

-

1 point

-

That's a lintel. Ready-made at b and q ir any builders merchant. But home made will fit perfectly and be satisfying. If you keep the concrete on the dry side, it can be forced up under an existing frame. Don't use oil. Either remove your timber formers after a couple of hours, or put a polythene face on it.1 point

-

Pics would help. For something like that 3:2:1 chips,sand, cement would be fine. It's so little you could mix it with a bucket and trowel. Jam a board against the edge and spoon the mix in. Give it a few kicks to knock the air bubbles out (or use a blunt bit and the hammer function on an SDS to vibrate the board). S1 point

-

1 point

-

Is the door frame already in place? Are you not creating a trip hazard having the door that high? (Pet hate of mine is high door threshold).1 point

-

Good to know, thanks. Is there any publicly available info on this? https://www.hvpmag.co.uk/New-AI-technology-signals-boom-time-for-heat-pump-installers-/18477 First of six paras near bottom of article says "Octopus Energy’s Kraken software already provides optimisation for its Cosy 6 heat pumps, which it manufactures itself, and for Daikin models through that company’s API. Octopus says it is also working to integrate with Mitsubishi, Vaillant, NIBE, and Samsung and hopes to make a series of announcements by this winter."1 point

-

Engineering bricks are definitely less porous than blocks or other bricks, but will allow moisture to pass over time. As @joe90 said, it’s going to be pretty much permanently wet below ground anyway so I wouldn’t worry too much.1 point

-

Or if you create shuttering and pour concrete, is is not really a "beam" as it will be fully supported on what is there already and will just fill the gap you want exactly.1 point

-

A beam suggests spanning a gap (lintel etc) but if this is just to fill a gap then why not do as @JohnMo says above, cut some block 40mm thick and bed on mortar 🤷♂️1 point

-

Can you not just do it with block work, way easier if frame already there.1 point

-

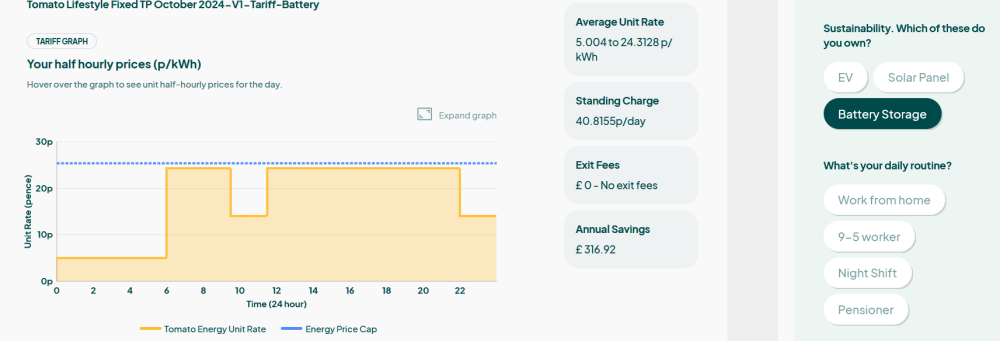

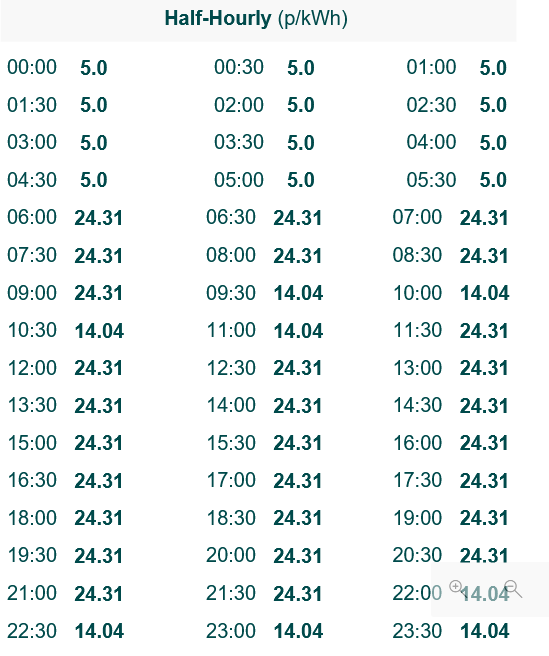

Yes, I have batteries (no solar) and charge them up overnight at 5p and then run the house for rest of the day from them. So far I haven't had to pay for any additional electric so looking good. My opinion is that it is better to spend on batteries than it is on solar especially when its the winter when you need the electric for the heat pump and generally no solar at that time. I calculate my payback is 3 - 4 years however I did source some great deals on my batteries. I am planning on installing solar myself in the spring but to get MCS install the figures just don't add up and there is no guarantee of long term SEG payments? Even without batteries I would seriously consider Tomato Energy Lifestyle, it gives 6 hours at 5p kWh, 4 hours at 14p and the rest at 24p so the average is still pretty good. A lot of people on the Tomato Energy forum appear to be running this way i.e. without batteries.1 point

-

Yes I had considered doing that, I have plenty soft sand on site so will mix up a 50/50 sharp/soft gauge tomorrow. I suppose given that the parge wont ever see weathering soft sand will be OK, it may even fill the finer gaps.1 point

-

Seems to be, here you are. The supplied neutraliser provides this function with the DS40. Then inhibit with F1. Other products are available but these have served me well in several houses. Current heating system dates from 1995, last cleaned and inhibited in 2015, HP installers were surprised how clean it still was this summer.1 point

-

I would read the Ts and Cs very carefully, you are giving them access to your HP's API in order to read its energy usage so they can credit yr account with the difference. The two schemes seem to be inextricably linked, the link says " * You’ll also need to be signed up to our Heat Pump Plus tariff and be an OVO customer." It sounds as though this is a necessary but also sufficient pre-condition for their "nationwide heat pump flexibility trial" as its web page name is actually "heat pump plus trial". Octopus have something similar in the works, I shall study it carefully but am not sure it would be compatible with my battery setup.1 point

-

Should not be a problem as ground is usually damp/wet at foundation level. Yes you could put In weep vents below DPC but frankly I think it’s a bit OTT but if it makes you feel better then crack on.1 point

-

I found this video helpful when setting up my ftc5. It looks as if you have got your offset turned down 2 degrees from what the curve is set to which also wont help. You could also try changing it from comp curve to say fixed flow of say 35 degrees just to test if that works. Sorry I don't know anything about external controls.1 point

-

No I never have Some BC insist in this But I can’t see any good reason I’ve asked the last two BC and they have said it’s up to you1 point

-

Well if the system was set-up to operate with third party thermostats you most probably DO need them. You might ultimately be able to disconnect them when you have found your way around the controls but it's too ambitious to do this in the first instance. My advice would be to disable use of weather compensation and set a fixed water temperature near the high end of what your heat pump is capable of. This is not the most economical way of operating your heat pump but it removes a level of complexity and potential for error and therefore should give you a better chance of telling if there is a fundamental problem or not.1 point

-

Thanks everyone. Got it reset and will keep my fingers crossed that these are just teething troubles1 point

-

1 point

-

I moved to Ovo from Octopus in October and am having problems with the "Heat Pump Plus" addon. I am giving them the benefit of the doubt for now but am not very impressed so far. I hope they will fix things soon. My baseline tariff with Ovo is just their basic variable-rate one. No tie-ins. Given the problems thus far I am keen to be ready to depart at short notice.1 point

-

1 point

-

Depends on the contractual arrangements between the three parties. If you run it and it provides heat you are effectively commissioning it. The Grant guy may not be best pleased particularly if you don't do something that needs to be done in sequence, or fail to spot something which needs to be rectified before it causes a worse issue. I was very annoyed when before I got there the plumbers fired up a new type of boiler which I had specified but they had not installed previously. And when I was a laser systems service manager I could instantly tell if someone had been on site before me and tried to make things "better". In the extreme you could end up voiding the warranty.1 point

-

Almost, but it's necessary to distinguish between the airtightness layer and the vapour control layer. With a perfect airtightness layer, then there will be nothing to drive moisture through the vapour control layer into the insulation - see my text on the 3 purposes of airtightness on page 2. You won't achieve perfection but the airtightness layer is the most important of the two layers. So: - Where air can leak through a VCL into the insulation but get no further due to airtightness layer, the moisture transfer will be limited - Where air can leak through the insulation (through the gaps in or the absence of an airtightness layer) to the outside, the moisture transfer can be dramatic, as per the illustrations above. With time + care + testing, you can achieve very good airtightness. Using service cavities you can likely get a pretty well sealed VCL too, but its positioning means that it's more vulnerable to damage. I meant to comment on this yesterday, but it may also be that your sand is too sharp - try a bricklaying sand instead (or a blend with what you already have).1 point

-

I said I would report back from the planning meeting. Firstly, it was personally useful as I said hello to our planning officer who I had only communicated with by email (he, by coincidence presented the first two applications on the agenda) and also the councillor for our area who had called-in a couple of the applications. The layout was interesting, with the councillors in a big horseshoe and the 'public' squeezed into a small rectangle. There was a small table for the 'public' to speak from with all the councillors and relevant planning officers bearing down on them. The planning officer spent an age going through each application showing a dozen or more drawings and photos, walking through the history etc, and doing a reasonable job of summarising the LPA's position and the issues at hand. The councillors were an interesting lot. Some said nothing at all, some reacted a bit to the officer's presentation, some were chummy with the planning officers, one sat apart and only had a list of pre-prepared points on a couple of the applications. Some of the 'public' spoke - an architect and a planning consultant speaking for some of the applications and a bevy of town council / posh residents / hired consultants obviously co-ordinated over their objections. As it was getting late, I left after 3 hours and 3 applications, but the meeting was sure to on for another hour or more. Pretty much as expected, but interesting all the same. I'm still not sure of the process for getting an application called-in.1 point

-

I moved from OVO to Octopus, would I ever go back NO. Octopus - Not a single issue, that couldn't be resolved by picking up the phone and talking to someone in the UK, that was happy to help. You can change your direct debit easily with Octopus and see projected costs. OVO - I voted with my feet and moved.1 point

-

That's a Shelly H&T, within Home Assistant. Shelly own webpage is pretty crude. Batch charging is using the floor as storage heater, in basic terms. Charging the floor similar to storage heater in cheap periods. We are single storey, so no real upstairs.1 point

-

The very left hand item in your diagram is an isolating valve and double check valve (non return valve) that will stop back flow. That is a requirement for any new house now. with or without accumulator or anything else.1 point

-

1 point

-

That is very nice! Love the galvanised guttering too. I'll keep this image to hand.1 point

-

Put 50mm liquid screed down and do the job right. Ours heats up in an hour and house goes from 18c-20c in about 4hrs with a 34c flow temp.1 point

-

I don't see any down side to a close pipe spacing apart from material cost. I suppose if you had very large rooms that might mean you need two loops in one room as they recommend each loop is less than 100m. That means extra ports on the manifold but not a big problem. I would certainly consider a buffer tank because oil boilers can't modulate so they can only cycle when (for example) only one loop us calling for heat.1 point