Leaderboard

Popular Content

Showing content with the highest reputation on 10/13/24 in all areas

-

In the present climate sell the house and live on site, it may not be what you want to do, but you don't want to be stuck like we were with a part build house (basic shell) all money spent, and the old house would not sell in a dead housing market, not unless I gave away a 5 bedroom house for less money than the construction cost of the new 3 bedroom house (i.e pay to downsize)2 points

-

Hi, this is my 5th build: started with a decrepit timber terrace in Sydney pre pre internet. I was an inexperienced renovator, & needed to ask people how to do jobs. Bought 1972 for $au12500, sold 1999 for $au340000. The house was double the size, & quite eclectic. Built a weekender 200Kms out of Sydney, & moved a small prefab building onto the block. That was sold in 1993, when we moved to Northern NSW, & bought our current block. Designed our modest abode in the early 2000´s. It is 4 storey, & abt 700 M sq. The 4th floor ois Doug´s folley: a room that looks about 30km to the coast (with a glimpse of Evans Head). This house is built from dry stacked Hebel block (no glue) that is held together by the cyclone rods at abt 900 centres. Huge foundations (600mm wide strip, 900 deep!). Now up for 25 years. My next build is a Hempcrete house, as a 110 sq M secondary dwelling on this same block. Difference is it is fully accessible (900 wide doors, accessible bathrooms & kitchen, no steps or hobs. Designed as an extremely economical PassivHaus. Other than that, I am a retired Biomed Techniician (Medical Equipment), retired 10 yrs ago. I was a voluntary Energy Coach for Enova energy (a Community owned energy reseller, until we went broke!) My PV system is 15Kw, with 2x 5kw SolarEdge inverters, & 2 Victron charger inverters for my 12kw of Lithium Titanate batteries. We have 2 EVs: a 2020 Kona EV (130K Kms), & an Imiev that has 130000Kms. These recharge off PV. I have a Home Assistant controller looking after all my energy. (Love Home Assistant!) The new House site has a 7.2Mx7.2M carport with 6Kw of panels. 48v of 1000ah L/A batteries, (abt 50Kw of storage), controlled by a Selectronics Inverter. There is a Low current 240v feed to this site for backup. The system was bought s/h for a good price, so is now waiting for the house! What else can I say: I was chair of ´Politics in the Pub´ until during covid.. (a non-political talkfest where current topics are given by a guest speaker) Well, thats it basically.1 point

-

Hi, We are in the process of starting a build adding a 2nd storey to a 1970's bungalow near the sea in Cornwall. We've got lots of RSJ's and it's quite a build, mainly on here to explore heating options as it's a definite weak point for my knowledge set. Great to be here. Thanks for reading.1 point

-

1 point

-

1 point

-

https://www.gov.scot/binaries/content/documents/govscot/publications/advice-and-guidance/2020/03/accredited-construction-details-scotland-2015---timber-frame-construction-details/documents/accredited-construction-details-scotland-2010---timber-frame-junction-details/accredited-construction-details-scotland-2010---timber-frame-junction-details/govscot%3Adocument/Accredited%2BConstruction%2BDetails%2B%28Scotland%29%2B2010%2B-%2Btimber%2Bframe%2Bjunction%2Bdetails.pdf1 point

-

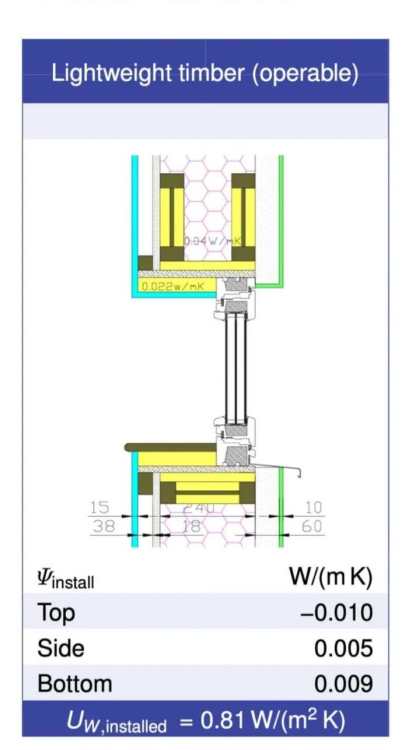

A quick check is can you draw a line straight to outside without hitting any insulation. As far as I can see, yes you can, straight through the syuds to outside, so it needs mitigating. I don't know the scale on the plan of the window, but it seems like at very least you could insulate the reveal. Could use PIR and 9.5mm plasterboard or splash out and use Aerogel and Magnesium Oxide board. It is expensive but for a relatively small area it might be worth the £££ expense /m2.1 point

-

Not so very different in S Devon. That price and breakeven CoP are about average but I am hoping for better on a ToU tariff, am amazed that more ppl are not on them. Almost borderline for us, I was told the flue for my 25 y/o boiler was not up to modern standards so would need to be changed as well. Through-the-wall flue might have been an option but significant building work with 60mm stone walls. After BUS we paid £7k5, so not a lot extra for the HP over a new oil boiler, some new rads were needed anyway. Admittedly we have not had the old flue removed and the roof re-instated. I think this is indeed the biggie. As well as costing north of 20k this would not be acceptable in many places, ranging from a Victorian terraced street to our stone barn conversion (in an AONB, with most deemed planning consents annulled, I can't see it getting PP). Perhaps stone facings could be used but roof overhang and detailing round openings would still be problematic - planners insisted (arguably rightly) that original openings be retained and they all incorporate big quoin stones interspersed among the smaller stuff). IME having had 4 different solid wall Victorian houses there are a lot of pickings to be had from WC and good zoning. They were certainly not wrong to incorporate these into the Building Regs, though whether the installers know what they are doing or the householders know how to drive them is another thing.1 point

-

I live in a listed building. It has a cost in having to do things properly, but what is wrong with that? You buy it with this knowledge and can bid accordingly, or go elsewhere. The trouble with a lot of people (I've heard them complain) is that they think they should be able to do whatever they want. "My house, my money !" The world revolves around them. Heritage, tradition and everyone else, don't matter to them and nobody had explained to them that listing had obligations.1 point

-

It could be because of the location. Old houses tend to be closer to the town centres, or in remote locations. Newer houses tend to be on the outskirts of towns or close to main roads.1 point

-

I have no history of lpg cost in this house as we have only been in it for a short Yes all radiators were swapped, Radiators keep the house warm, No underfloor, PV no illusions that i will get anything out of it for the winter months. We have only been in this house for a short time and we have no history of running cost with Lpg. although the short time we used Lpg last winter suggested it would get very expensive for the year. We have a 5kw log burner which we also use this is enclosed in a huge Stone fireplace that absorbs a lot of heat. for instance next morning after the fire has gone out the fireplace is still at 23/26 degrees. As I said all the interior walls of the exterior walls have been clad with 63mm closed cell insulation and the house itself is pretty tight.1 point

-

Yes, and beautifully highlighted by @ProDave's statement above. It is often a case of people mixing things up and not realising there is a difference. Reducing CO2/km has nothing to say about NOX or particulates. They have other limits layed down in legislation. In someways it is a shame that housing is not treated the same as vehicles. An annual check and if it fails, you have the choice to repair or replace. Failure to do so means it is effectively handed to the state for disposal. My car costs me more to run than my house, and mine did 72 MPG on my last tankful, but it has a mass on of 1576 kg dry. My first diesel was a 205 and that did around 50 MPG and had a mass of 935 kg. The emission were dreadful, though exact figures are hard to come by now. Pop my current engine into the 205 body and more power torque and milage.1 point

-

You are right, to an extent it is a money issue, but then so is installing a heatpump! You can't handwave the costs of installing to the aesthetic requirement as but then also point to the costs of installing a heatpump! Right now we could heat almost any building in the UK with a heatpump and achive a better than break even scop. The exceptions are off grid houses or those with an insufficient electricity supply for their demand (big stately home on a poor single phase supply) But a 40kw HP is bigger and more expensive to install than a 40kw boiler and UFH or fan coils or k3 rads are more expensive to install than some k22 ones you can grab down screwfix for £150 each. Dont get me wrong, we should be insulating houses, and looking hard at things like AONB and listing when they get in the way of efficency, but HPs are the absolute best way to cut our heating carbon emissions (which are significant) We will always need gas for some uses - high temp industrial,maybe some cooking, portable power even vehicles. But keeping you living room at 20C isn't one of those uses.1 point

-

3 years later. should this be a new discussion? It must be rebuilt. The bounce is an indication, but the whole floor is understrength. Did the builder save on joist cost or are they sitting around? It isn't just your comfort, but may make the house unsaleable.1 point

-

The cheapest thing to do in most cases is a like for like swap, but for co2 reduction it is always Heatpumps. So we need to decide (as a nation) which way to go. 3.4 is doable in most properties as long as you can get the flow temps down below 45C. The capital cost is the issue, both for upgrading the emitters to achive the lower flow (and any water cylinders if required) and also the unit itself. A large leaky farmhouse could be heated efficiently but the cost of the 30kw heatpump would be prohibitive. There is no reason HPs can't achive cost parity with gas boilers - it's just production volumes and supply chain. Any all electric houses (about 2m) should be converted ASAP. In fact it would be a good way to "prime the pump" for the supply chain. Offer really generous subsidies for swapping storage heaters and direct heater houses to HPs - air to air if necessary (cheapest way). Thwt will give you 2 m households to build up the industry with.1 point

-

Why did you let him do that? I am surprised building control did not pick this up?1 point

-

I guess it would make completion of that roof joint a whole lot easier if no one can see it.1 point

-

1 point

-

We've had to keep this a big secret. About 2 years ago, we were approached by Channel 4, asking us if we wanted to feature on Grand Designs. Like many of us on here, having watched the show a lot, and seeing how they typically go, we immediately said 'no' 😂 . After a fair bit of discussion, we came round to the idea, as we thought it would be a nice professionally produced story of our self-build, and so here we are. You can catch our full story and how it all went, on Wednesday 2nd October, Channel 4, 9pm. And for a sneak peak, you can see what we've been building on our Instagram: @thefoxesmaltings1 point

-

Spending several £100 thousand building a house, and you would actually want someone else body waste gong through you cellar or even under your house, when it is all finished. Perhaps you need to step back and have a think about it.1 point

-

and if it ever needs maintainence? no divert it aorund house although I would expect the water board will want to do it,and have rights to dig it up for maintaince if required1 point

-

It's down to the water company, it's their pipe. It's definitely a non -standard scenario, and hard to know until you engage with them and present your chosen solution. I've a feeling any kind of sewer in a habitable space will be a no. As above, a diversion is by far the best solution.1 point

-

You’d have no choice but to divert it. Wouldn’t appear to be a significant additional cost when already taking into the account the cost for the re-development works.1 point

-

We did 115mm PIR in block/ brick external wall. The block wall was perfect with cavity side beatifully pointed but still impossible to get a really tight fit between PIR and blocks. Even very small air gaps alows for a chimney effect, leading to thermal bypass and a massive reduction from the paper u value. Come January I'll find out what it really does to our heating bill. We were supposed to have a 10mm cavity between PIR and brick but this is also near impossible and gets too much mortar in while the bricks are being laid. The builder did use the correct tape to tape all pir joints, think the tape alone came to almost £1000 !1 point

-

1 point

-

Hi Adam. Can you post a few photos as that would help a lot. In the attic.. so we can see how the roof is constructed, the external elevations all round and how the house sits in the garden, the garden size and where the boundaries are. Maybe you kept the selling agents floor plan when you bought the house? At the moment it's so open ended that its hard to make meaningful comment that might help you. You should have a title plan.. the deeds.. sanitize that so you can't be identified and post it. That is a helpful comment. For attic conversions the design fees tend to be heafty. It may seem like a small job but some of the attic conversions I do require a huge amount of my Architectural, SE design and detailing time . I wear two hats.. I'm an SE primarily but also do the Architectural design side of things. In terms of Architectural and SE design fees these can amount to 15 -25% of the project value to get all the design work and detailing done and the LA / BC approvals. On a good day you may get this down to 10- 12% if what you are doing is simple. That said, a good experienced designer can save you a pile of cash. One week of labour for a good joiner (chippie) comes in at £1.0 to 1.2K a week! so please bear that in mind. Also a good design will have access to Contractors that they work with on a regular basis that they can trust not to rip you off. Now it may be that you want to go back and see if it is more economic to extend at ground floor level.. this gives you raw extra square footage that will also increase the value of the house.. often more than an attic conversion on a pro rata basis.. remember you often need a stair so you take a step back before you can go forward.1 point

-

One thing I am getting my head around is the need to DESIGN EVERYTHING! Even the hole thru the wall (requiring sealing) for the porch light. Most electrical work will be inside the sealed envelope (which is the interior lime plaster in a Hempcrete house). Electrics will pass from the ceiling cavity (~125mm also used for MVHR) through a conduit to the cable end (switch or power point for example), so that conduit passes through the rendered membrane, down the wall, then back thru the membrane, all requiring sealing. Australia does not have any decent sealed wall boxes, so I must work out how to effectively seal the available boxes. Of course all of this will be installed before the Hempcrete placement. Even the MVHR air supply return will need to be installed (or at least arranged for) before the Hempcrete placement. I am thinking of ´trussing´ up the window & door heads instead of using the usual timber lintels. Accomplished by diagonal struts between studs over the window/door. I will be having the frames factory made, so I can either ask them to fit the bracing, or retrofit on site. One thing with Hempcrete is that the noggins (horizontal timber between studs) are fitted not on the flat, but rotated 90 degrees (ie 90mmx45 studs, noggins similar size but 90mm is vertical). This makes it easier to place the Hempcrete. Remember we have no snow loads, so the frames are much lighter in Australia. Usually in Australia the wall frames are braced with ply or OSB. With Hempcrete, the ply is not used, so needs to be replaced by timber bracing. In my case, with 90mm studs, & 270mm Hempcrete I have 90mm each side of the frame. The Bushfire certification needs at least 75mm of Hempcrete, so the bracing is internal. The bottom wall plate is 45mm, sitting in a ~40mm slab rebate, so my solution is to double up the bottom plate so I can have room to attach the required bracing (probably 75x25mm pine bracing, but up to the Engineer!). Being in a sub tropical zone, we need hold down for the wind load, so the top & bottom plates are screwed to the studs as well as being nailed. The bottom plates are Concrete screwed to the slab, & the roof trusses are steel strapped to the wall frames. As I said previously, there will be an OSB layer under the trusses sealed as the air seal membrane, but als giving wind bracing. The internal walls are non-load bearing (basically ending at the celing cavity so services pass over) An explanation of the No soffits, no Barge board: basically roofing iron can self support for 300-400mm, including the guttering load (no snow!). The 600 eaves are supported by a purlin supported on steel brackets off the wall. No timber due to the Bushfire zone! All the mounts for these brackets also need to be designed & fitted pre Hempcrete. I am proposing using bolts that are a woodscrew one end, & Metric thread the other. Extended by a loctited double nut & extra thread. These can be found with a stud detector after the wall is hempcreted & lime rendered.1 point

-

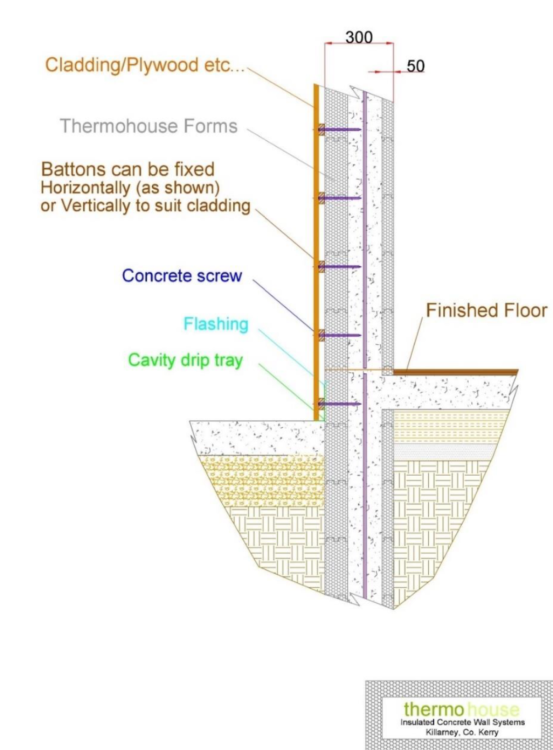

I like these screws from Swiftfix. These are the same screws @Chanmenie used. https://www.swiftfix.co.uk/7-4-x-180mm-TX40-Blue-Power-Timber-to-Masonry-Screws-Box-of-100-p141442218 https://www.swiftfix.co.uk/7-4-x-200mm-TX40-Blue-Power-Timber-to-Masonry-Screws-Box-of-100-p141878417 Strong, have good corrosion resistant coating. I think these are the ones I used to fit the battens for my cladding, but would have to check. I alternated my fixings between the web and the concrete. Also did a few holes with the spiral fasteners. Rawlplug 80mm SPIRAL FIXING FOR EPS. https://shop.rawlplug.co.uk/facade-insulation-fixings/facade-insulation-accessories/iso-plug-plastic-screw-in-fixings/r-iso-plug-insulation-fixings/spiral-fixing-for-eps-80mm-box-of-40-r--iso--plug--80 So for example a 2 metre batten, with 400mm spacing would have 3 concrete screws, 3 in the web, or 3 spiral if not on a web point. Batten spacing would be 400mm, but for where boards joined, I would double batten.1 point

-

Thanks for the kind words. Materials always seem to be divisive. Cor-ten, for example. We've had people call it 'scrap metal', and others love it. At the end of the day we've built it with materials that bring us joy, and don't worry too much about what others think. After all, we're the ones who have to look at it every day! That's the best advice we could give.1 point

-

So we lived in a house with no mortgage and money in bank. Bought a plot with a house to be demolished Funded that purchase by lending on current house. Knocked down house on plot did all the planning etc and once handed plot over to builder we sold our own house and moved into a rental property. Plot not suitable for caravan. So we took a hit on renting a tiny flat during build but meant we had minimum self build loan amount. Though numbers are different, your circs are similar to ours. The best thing we did was to sell our house and move into a rental. Because it was a clean and straightforward stages/ steps. we didn’t end up in situation where we owned one house and trying to fund building a second house. You never know what’s round the corner (in our case pandemic & lockdown). If we had stayed in original house until new one was built we’d have been in a dire situation. as far as I can see if you sold your house and paid off mortgage you’d have £210k plus your £50k savings. I cannot see how you could demolish a property and build a house for £260k quickly TBH. unless you physically do a lot if it yourself and it’s a very small basic spec house. Or lend more. if I was in your position right now I’d make sure I’d secured planning permission. Then establish the full demo and build cost. If it’s affordable, demo the old property and clear the site. (we did that ourself at zero cost). then sell your own house. You will then have financial clarity and money in the bank. You can then decide whether you can afford to rent or live on site. Your proposed strategy is to sell house only once new build is compete (exactly what we would have wished to do). That fine if your savings, or access to funds, would be in well in excess of your build cost. As it’s not, if something goes wrong whether job loss, illness, further economic issues, war, inflation, housing crash, labour shortage, builder problems, pandemic (all these things are not unrealistic) you’d be left potentially in your current house with a half built new house that you can’t finish. And facing financial ruin. The other option if you insist on keeping your own house would be to build in stages from your savings and release equity from your house. But even your £50k savings will be exhausted far quicker than you can imagine it a take £20k upwards just to get out of the ground. don’t give up, but think carefully. I see a lot of plots being sold with the foundations only having been completed. you’d be able to lend off the owned plot of course - speak to Ecology - but it’s possible the value of the plot would initially reduce because your removing a house from it. And you’d be hit with high interest rates.1 point

-

600mm posis standard spec - bloody awful for me really regret them.1 point

-

The golf club , or the Rotary Circle, squash club , Freemasons, or a friend of a friend .....0 points

-

0 points

-

0 points