Leaderboard

Popular Content

Showing content with the highest reputation on 09/25/24 in all areas

-

Hi all!, We we are building a low energy house in Caithness and, what with inflation and brexit and all, we're going to be finishing the build ourselves including kitchen, bathrooms, doors, floors painting & decorating etc. I'm also going to be installing the MVHR, which will be interesting. We're old hands at renovation type stuff, having completely gutted and replaced a kitchen and bathroom or two, so we're pretty confident about getting the practical stuff done well, particularly as we'll have a clean slate to work on. Currently boning up of building regs to make sure we don't get caught out by the paperwork... Anyway, thought we'd say hi. Cheers Pete & Joss2 points

-

Well done Ben that brief looks pretty good. The cost is middle of the road. Yes you'll need to pay the vat but hey ho. Make sure you meet them on site. Come armed with tea/ coffe and buns and a list of anything else. If near a road get some level of manholes etc, water toby cover levels and so on. Seriously and extra hour or two on site at this stage can save thousands later. From my end once we get into the detailed design we often need levels for obscure things.. it causes delay an uncertainty. Uncertainty = added cost and as designers we need to be conservative when there is a lack of quality information. Most folk want to help and will spend extra time if the Client engages. You can also get the gossip! and that can be invaulable later on. The gossip is things like what other sites have you seen nearby when work gets underway.. the ground.. who is the water board guy.. is he / she a wanker or pragmatic? As an SE I often refer to annecdotal evidence to back up some of my design decisions! If you feel they have engaged offer to pay a bit extra! Usually folks will say thanks but don't need more money! or just say and extra hundred in cash will cover it! To put this into context.. if you can save one day for a chippie or ground worker on site at £250.00 per day you get your money back! At this stage of the design you want to aim for the best quality of information you can get. I see this all the time on BH where folk skimp at the beginning and pay dearly later on. I'm not pelting folk self building as have done it myself when I was young. It is really hard to get the basic design info cf going to TF companies and so on for a guide price adding up the sums and hoping for the best.2 points

-

Best to ask now when you can remediate any issues easily. In your first post there is a screen shot of the roof spec? a mention of timber sarking. Is this missing? @Gaf your photo of September 17 shows a higher part of the building behind.. with gabled openings? Thanks for the kind words. However many of the posters have discussed a lot of the individual aspects of the works and made some great points. No point in me repeating as they have done a top job. Looking at the photos and assuming they are of your job I seems to me that you must have had some SE input? In the round though I would ask yourself / recognise and look at things in the round.. yes we have changed some bearings (slates as packers) and probably some of the connections.. but the really important question is.. have we done something that compromises the overall stability of not just the new bit but the old bit also. I'm happy to chip in more but need a lot more info before I do. If I was to come and look at your job I would take the grand tour of the house.. figure out how it stands up as existing. Then look at the new bit. Does it add both horizontal and downwards loads to the existing house found. If we add load to the old house founds and any existing lintels can they cope? If we knock a hole in the existing house to get to the new part how does that impact on the structural stability and so on. The sarking is important here. I think you need to be extra cautious and not pelt the Architect!. Often on a job the builder get's the "Client's ear" while cuttting corners at your expense! Get an SE in.. pay 300 - 400 quid for a once round.. it will be the best money you spend!. Often I can justify my fee by pointing out things the builder has cut corners on that that are nothing to do with SE work. Then there is a bit of negotiation so no one falls out.2 points

-

I emailed the EA and CC'd the planning office (both the officer who was on annual leave and the department inbox). Neither party seemed to think this is unreasonable, and I'm pleased to say that 12 days later we got the EA's approval of our drainage strategy - one which all the the drainage consultants I spoke to said would be impossible to get approval for. Cheers for your help, all.2 points

-

I just estimated based on room air volume requirement. The largest flow with no restrictor, then the others as a percentage of the largest flow ( I didn't use restrictors in any of the returns). Using pi r2 to calculate the rings to remove. This works out at approximately 70,55,36,19,16% which is a reasonable starting point. Having done this measure the flows with the room restrictors fully open. If the flow was too low then remove another ring to get to the right sort of volume +-20%. As changing each restrictor affects the pressure in the system you may need to repeat the process. I would not bother trying to be too exact, it really is a diminishing returns exercise I called quits when within 20%. Once you get to this point you can then adjust the MVHR fan speed to get the required flow in the room with the largest. The other rooms should also be correct at this point. After setting up this way I found that in practice I could run the MVHR at a lower fan speed and still have a comfortable environment (almost silent).2 points

-

Well to me the idea of screwing a "floor" to the undersides of the joists is the most ridiculous bit of the whole thing, I will state what should be the obvious, DO NOT stand on that plywood "floor" I would put a proper floor down from above if you want to crawl up there to use it for storage. P.S I am counting just 5 roof trusses. If at 600mm spacing that garage is just 2.4 metres wide. That is taking the mick calling it a "garage"? Or are the trusses spaced wider than 600mm?2 points

-

Morning all, I'm after you advice please on the poor/well aged finishing on the front exterior wall to flat roof flashing in the attached photos. I'm about to repaint the front of the house and found this after a thunderstorm and a small leak. My question is do I remove all the old sealant and just refill with mortar down to the flashing or do I need to consider anything else? I am certainly no builder but do have a basic DIY understanding. Thanks any help appreciated.1 point

-

Depends what those concrete lintel are supporting? Roof? Floor? Whatever it is will need to be temporally supported if they are removed. I used concrete lintels in my new build (inner skin only, brick arch outer) perhaps you could post up the engineers drawing so we can see the detail better.1 point

-

1 point

-

I doubt it, get the work done and meet in the middle.... And both walk away. Building house is hard enough, without added emotions seeking compensation for this complicated shitty occurrences. If he does try to charge for it, use the cost of scaffolding etc to cancel it out.1 point

-

Called ten engineering companies in the area flagged as including SE. Three SE’s may have capacity to have a look. Rest are not taking on work due to being too busy, only do consulting, or only do design with no on site surveying. Awaiting calls back tomorrow 🤞1 point

-

Great comment. I'm working with someone at the moment who has decades of life experience, a technologist who can easily grasp both structural and Architectural design concepts. They are managing the design process very well. I'm chipping in with a bit of SE design stuff and being a bit of a devils advocate in terms of the over all design elements of the project. Also like many self build the design evolves particularly say in terms of drainage / buildability = cost. I think it can be helpful to have someone who does design as a day job who you can call up and chew the fat with.1 point

-

Costco (oddly) are doing installed garage doors by Cardale. Products via Costco are usually good quality and they offer excellent customer service, but I cannot comment on Cardale specifically. They’re on the Costco website if interested. But I would add a condiderable weighting to any supplier personal recommendation by a regular BH contributor, especially from the likes of @joe90. (Not for a moment suggesting other BH member’s recommendations are not sound of course).1 point

-

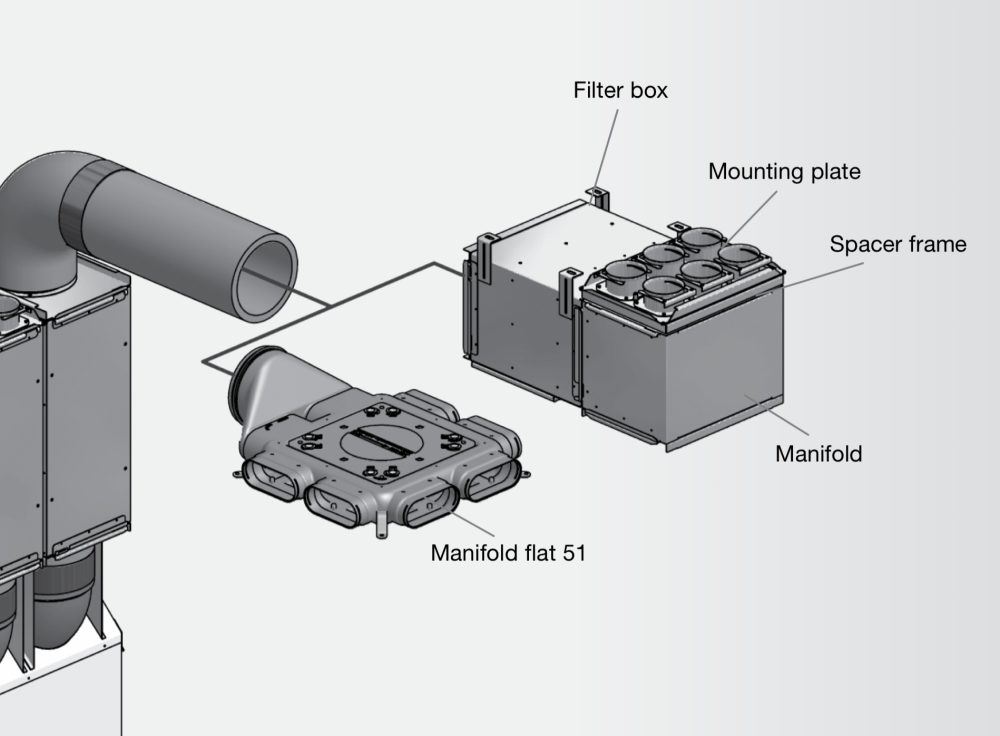

I have a Zehnder ComfoAir Q600. Looking at the design spec for my install the supply air (240m³/hr =67l/s). I went with the Zehnder ComfoWell filter housing, CW-F 625. https://www.zehnder.co.uk/en/productsceletons/zehnder-comfowell-filter-box/zehnder-comfowell-filter-housing-cw-f-625 Due to space constraints in my install, I have the filter on the intake before the MVHR unit. The filter is designed to be fitted on the supply pipe after the attenuator and before the manifold.1 point

-

We're building a 4 bedroom timber frame, low energy building on a 1/2 acre empty field in Caithness for me and my wife and youngest daughter, both of whom have chronic health issues. It's not quite a passive house, but heading in that direction. We're not right on the coast, about 10mins from the nearest beach, but have views of countryside and moorland all around us. Not sure what else to tell you.1 point

-

The Scottish reg's are a reasonably easy read. Worth referring to the English ones sometimes for more detail and a more prescriptive process. The deal us you tell us more first. What construction? Site summary ( sheltered, sun bathed, dense sand, etc)1 point

-

Hi and welcome. There is at least one other self builder up your way @Jenki building in a windy coastal spot.1 point

-

Really depends on your system design and where you sit with regard pressure drops. More pressure drops require higher fan speed and more potential noise. You can always go big and use reducer to you duct - bigger the filter the lower the pressure drop.1 point

-

My MVHR is still not commissioned. But I’m always amazed that this topic doesn’t generate more discussion. Of course circumstances differ, but I’m in the countryside with 2 neighbours that have log burners going all winter. I went with the Zehnder comfowell filter box because it will be easy to get hold of the filters over the long term. You will need to size the filter box to your system requirements.1 point

-

1 point

-

1 point

-

I made a pre-filter using tights as the filter element. Catches all the big crud before the air gets to the MVHR filters. Works well. There is a pig farm not too far from where we live and on occasions it stinks to high heaven. To date we’ve never smelt it indoors with the standard MVHR filters (and tights!)1 point

-

We have G3/4 filters in our MVHR and few houses around us use log burners quite a bit. No smells in house, but if you go outside in the evening you do smell the smoke. I bought a carbon filter, but have never installed it.1 point

-

We have designed one of the Liebherr ones in to our kitchen as a drinks fridge (in addition to a standard tall larder fridge). Having stayed at a friend's house where they had one filled with cans and bottles it seemed much more practical than sliding cans around a shelf on a normal fridge. They are about £950 though, so we'll have a blanking panel over the space that it will go in for a while.1 point

-

I reckon it sagged. They put the thin ply up and chucked stuff on it then panicked when they saw how it drooped between the rafters, hence the micro joists with half fitted hangers, a diddy ‘L’ bracket would have done. Would have been cheaper to buy a sensible thickness of ply in the first place.1 point

-

Above advice is laudable. However I know I'm v sensitive to this so so be installing a large carbon filter on the intake to the mvhr. https://www.growell.co.uk/products/mammoth-carbon-filters?variant=44069990924532 Something like this, with pre filter on the outside. Nice and large to give minimal pressure drop.1 point

-

Well there's your problem. Damp house, water getting in, no ventilation. It'll clear up eventually.1 point

-

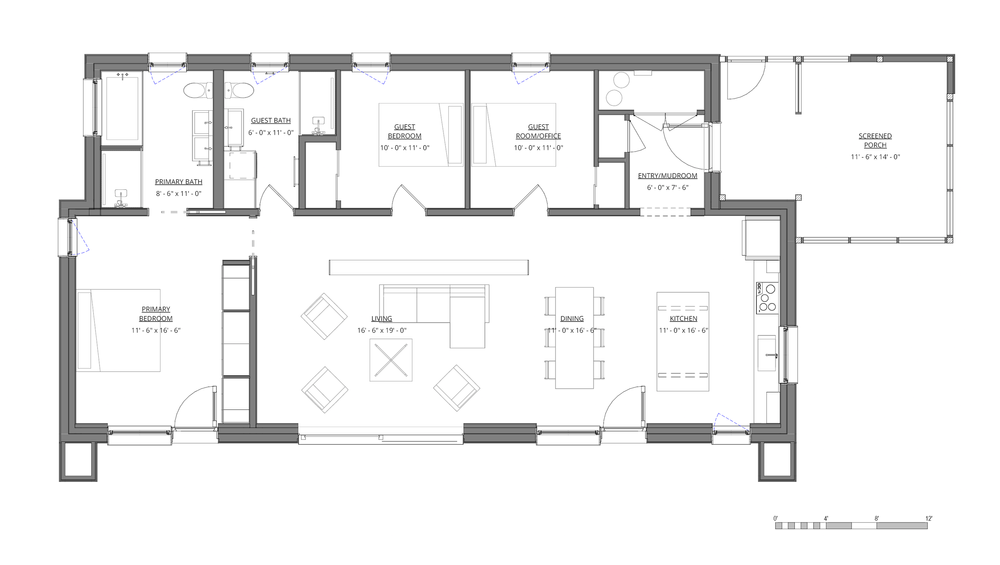

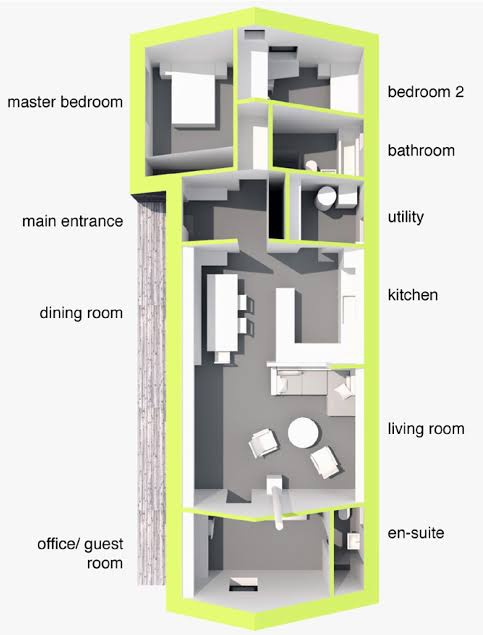

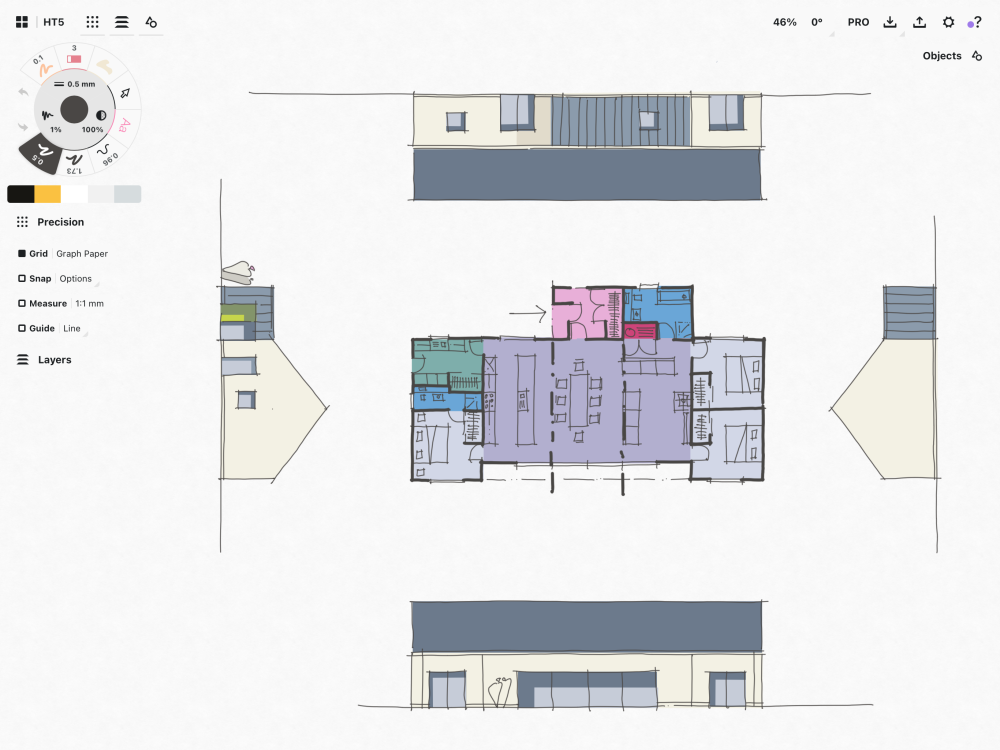

Welcome. 1. hold off on house design until you’ve got a plot. Though good that you know what you want at this stage. The house design should come after the plot. 2. What @ETC has presented / suggested is significantly better design & architecture. 3. The good news is that contemporary Scottish rural builds are very simple in their form - agricultural - and thus can be less expensive to build. Per 2. Above good luck !1 point

-

I would certainly contemplate a bungalow after our 2 story house build. Easier to clean gutters and paint the walls. Less hassle climbing stairs and accessable to everyone. You will suffer with form factor though so be prepared for +450mm walls for proper insulation. This one is my favourite. https://oldholloway.wordpress.com/ Really like this one too. https://www.gologic.us/1700-model1 point

-

I misread the dims. That central area is nearly 9m x 9m. That is a big span if you want ceilings to be higher than the wall level, so there is cost there. Easy enough to do, but there is a tradeoff between clear space and cost.1 point

-

And the inside painted. So nice to wave goodbye to that horrible grey. It needed to be vapour-permeable, and I went through a bunch of options. Ended up using "Farnovo", which comes as a powder you add water and pigment to - https://dpm-mashel.de/en/wandfarbe-farnovo.php. One 5kg bag + 40g "rusty sun" pigment was enough to do two coats with plenty left over - ~20sqm per coat - and it has hidden all manner of sins. That top coat of plaster ended up cracking a fair bit as it dried, but good luck spotting any. Expensive stuff though. I looked at earthborn "claypaint" which comes wet, but they add some preservatives to it which seemed unnecessary and allergenic to boot. The mixing is very easy, I might go this way for painting inside the house too ^^. I've also run some 4mm² SWA in conduit between garden room and garage - it's about 25M, going under the garden room, then the decking, then along a fence - but I've left it there for now and am poking electricians for quotes. Seems I can't just do it as a spur since it's an outbuilding - it needs to go from the consumer unit as its own circuit? Grumble grumble.1 point

-

1 point

-

1 point

-

1 point

-

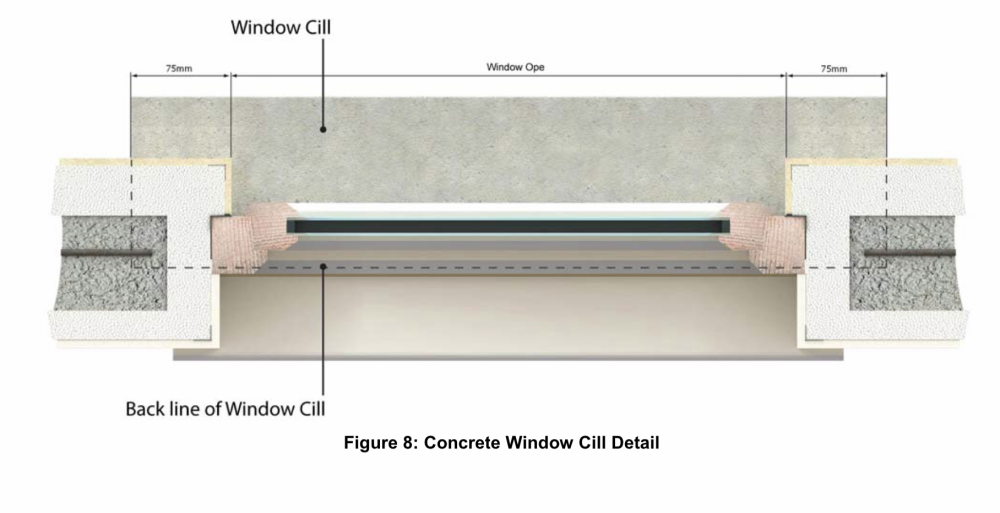

My wife and I did our window installations ourselves using some Illbruck products. We used TP651 Trio expanding tape, which is 35mm depth on 47mm depth window frames. We used the FM330 Pro Foam Air Seal expanding foam to fill the gap left behind the tape. I really rate the FM330 expanding foam. We then used Siga Fentrim IS20 airtightness tape, 10mm on the window frame, connecting across the foam to the ICF EPS reveal. Siga are one of the few airtightness brands that explicitly state their tape will bond with EPS. This was probably overkill, but we wanted to be sure that the windows were airtight. The Thermohouse ICF window blocks have a “Check Reveal”, which means the edge of the window frame is protected by 100mm of EPS. This is another layer of insulation and weather protection. Our renderer then fitted on the outside of the frame a window reveal bead, with a rubber seal. https://ewistore.co.uk/shop/external-wall-insulation/anthracite-window-reveal-bead-with-mesh/ I doubt any of this additional work will be reflected in our SAP score, but I am pretty confident that we have detailed the junction between the window frame and the rough opening in a way to provide us with a lot of long term benefits.1 point

-

At our previous house the farmers took all the old electricity poles when the whole area was upgraded.1 point

-

Cheers Gus, Infact I always wanted to be a pilot but I’m slightly colourblind so went down the engineering route to get as close as I could. It’s actually quite a common route to be a pilot. Pretty handy having a thorough grounding in what’s going on. It turned out there are degrees of colourblindness and I actually passed the test in 2007. I then got onto the cadet programme with an airline and the rest is history. I think I’d do a better job on the rendering if I did it again. The mix was too dry and I was also rushing as my wife had organised meeting friends down the pub that afternoon - not good for good rendering it turns out. 😂 I’m just saying it’s “rustic”1 point

-

Yes but the output from the 12kW unit is so much that it would be highly desirable to be able to run the compressor at less than the 50% setting that Eco mode gives you. Then there would be less delta T across the coil and even better CoP. Have been in correspondence with Vaillant tech about this but they have not been able to suggest anything useful. Just back from hol and will post some more analysis when I have crunched the figures a bit further.1 point

-

However I designed my build with no architect input and completely happy with everything. I think it depends on how sure you are with your requirements.1 point

-

I've fired off quote requests from three local topo surveyors specifying as much as I can, using the suggestions above, but also asking them for guidance given wehat we want to do. In case it's any use to anyone else, I'll report back what responses I get.1 point

-

Well....it looks to me that the ridge is not touching the horizontal timber, at the end we see anyway. To that extent it is not functioning.....yet. But that results in the rafters not bearing on the steel beam at all, i.e. the steel isn't functioning either...not yet anyway. In life, the rafters will spread out as discussed earlier, and drop. Then they will bear on the timber and steel. I'm saying no more as your advisers have the advantage of seeing the real thing. I'm just concerned that they understand what they are looking at. I would pack mortar between and around the slates as a minimum.1 point

-

yes that is rough. the principle is that the beam needs to be levelled, if the padstone has been placed too low, and that ALL the steel should be in contact. Thick mortar would shrink/crack. So slate is used WITH mortar. This isn't good. The slates may crack but then stability will occur. At least they must squeeze in what mortar they can to help spread the load and dress around that mess. Could be worse. They might have packed with wood or plastic shims1 point

-

The weight of a roof tends to push the walls outwards. The main way of stopping this on a two storey house is to use joists to tie the bottom of the rafters together to form triangles. This design only needs a ridge board not a beam. Problem is you can't do this with a "room in the roof"/ 1.5 storey house because the joists would get in the way. A common alternative is to "hang" the rafters from a steel ridge beam and that's what your architect did. The ends of the beam are supported on pad stones in gable walls or chimneys which carry the load down to the ground. I believe the rafters should normally be strapped together above the ridge beam with metal straps.1 point

-

At the moment it is weighing down the trusses. So get the gable wall built asap. Presumably a padstone will be under the steel, and somehow it will need to be packed hard up under the steel. slates hammered in is the usual .1 point

-

Might be the time to get yourself a new builder and joiner - sorry carpenter!1 point

-

The steel is necessary. Takes the load to the end walls. We used laminated timbers instead but the effect is the same. Without it you would need lots of diagonal truss bracing and would have an attic, not a room. Diagonal truss bracing stops the rafters from both bending and thrusting out. And relax.1 point

-

That steel is a ridge beam supporting the weight of the roof. If you took it away, then the weight of the roof would be supported on the timber rafters which would transfer the load to the walls, but in doing so would push outwards and the rood would spread. Those ties at the top are not enough to stop the roof spreading.1 point

-

1 point

-

The ASHP is only part of the system. I think this is where confusion comes in. Take UFH as a thermal distribution element. It is a simple component, a pipe loop, usually set in concrete, with warm water passed though it. Then the problems start. It has to be designed so that the power enters the room, not heat up the ground under the building. It has to be designed to deliver the correct power 99% of the time, so different spacing between pipes and different thicknesses of concrete it is set in. There will be some situations where the system is used incorrectly, we have all read about the self inflicted problems Zoot created for himself, and there will be times, as you mention, where part of the system is fine, but other parts are not. This may be as simple as the controller not set up correctly. It may also be necessary to have a combination of thermal emitters in the same room i.e. UFH and a fan assisted radiator. I may have found a solution to fit a wet heating system into my small house without seeing horrible pipework on the surface. Going to have a chat with one of our regular customers who has just done his MCS course and see if he thinks it is viable. Just need to find a physically small, inverter, ASHP that he can buy for me at a reasonable price. Then work out where the buffer tank is going to go.1 point

-

Let's take a step back from the heat loss / demand etc provided by companies trying to sell you something. How well insulated is your house? I'm tired of hearing horror stories of heat pumps installed in houses that simply aren't insulated enough to be effectively heated by a low temperature system.1 point

.thumb.jpg.bd36190ca2aa64106f84694d5c01f0fc.jpg)