machtucker

Members-

Posts

61 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

machtucker's Achievements

Member (3/5)

4

Reputation

-

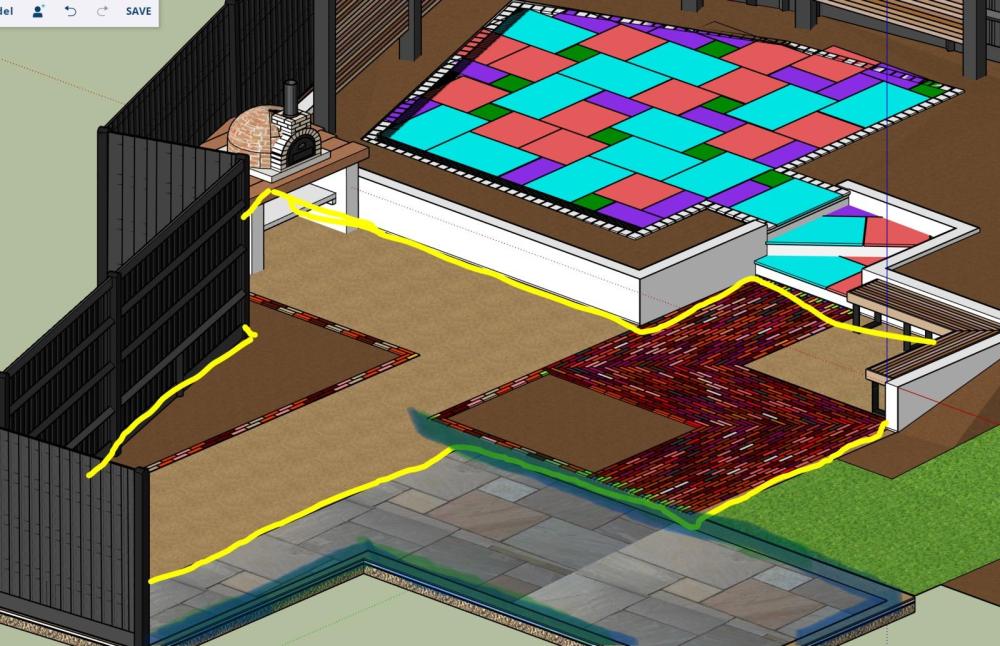

Thanks for the info. I had planned everything without the fall on the lower level but it could be done. There is already an existing French drain which I’ve highlighted in a blueish colour, so I could put a fall towards that. Or… I could just make it level and see what happens 😬

- 8 replies

-

- laying gravel

- laying clay pavers

-

(and 3 more)

Tagged with:

-

Hi everyone, I have a digger coming next week and I'm going to excavate the soil so I can complete the gravel patio area and clay paver path etc. I have a rotating laser level which I can use to initially check dig depth etc. What's the best way of making sure I get the correct dig depth? I'm guessing it's just to keep checking it with the staff etc. Then I think I'll put in a few stakes to the the finish height depth as datum pegs so I can easily set up string lines to gauge subbase depth etc. Cheers, Ed

-

On this topic does anyone know where I can buy MOT Type 3 aggregate from? Doesn't appear to be as popular as Type 1

- 8 replies

-

- laying gravel

- laying clay pavers

-

(and 3 more)

Tagged with:

-

Yes that's how I will do it, just like I did with the patio. I was wondering whether I could get away without a fall though. I did read something on Paving Expert website that talked about a suds compliant solution which requires a different subbase with fewer fines.

- 8 replies

-

- laying gravel

- laying clay pavers

-

(and 3 more)

Tagged with:

-

Hi everyone, Well the weather is looking to be better next week and I'm on leave so planning on doing a bit more landscaping in the garden. I'm going to excavate the bottom part of the garden (bounded by the yellow line in the model). There is a clay paver path to be laid on top of sharp sand bedding layer and also 6mm gravel in the other areas with a stabilisation layer and 10-15mm bedding layer of sharp sand. I'm planning to use a 100mm MOT Type 1 subbase layer for the whole lot. The question is should I put a fall on it or will it be OK level for drainage purposes? Many thanks, Ed

- 8 replies

-

- laying gravel

- laying clay pavers

-

(and 3 more)

Tagged with:

-

Best way to lay clay paver edging?

machtucker replied to machtucker's topic in Landscaping, Decking & Patios

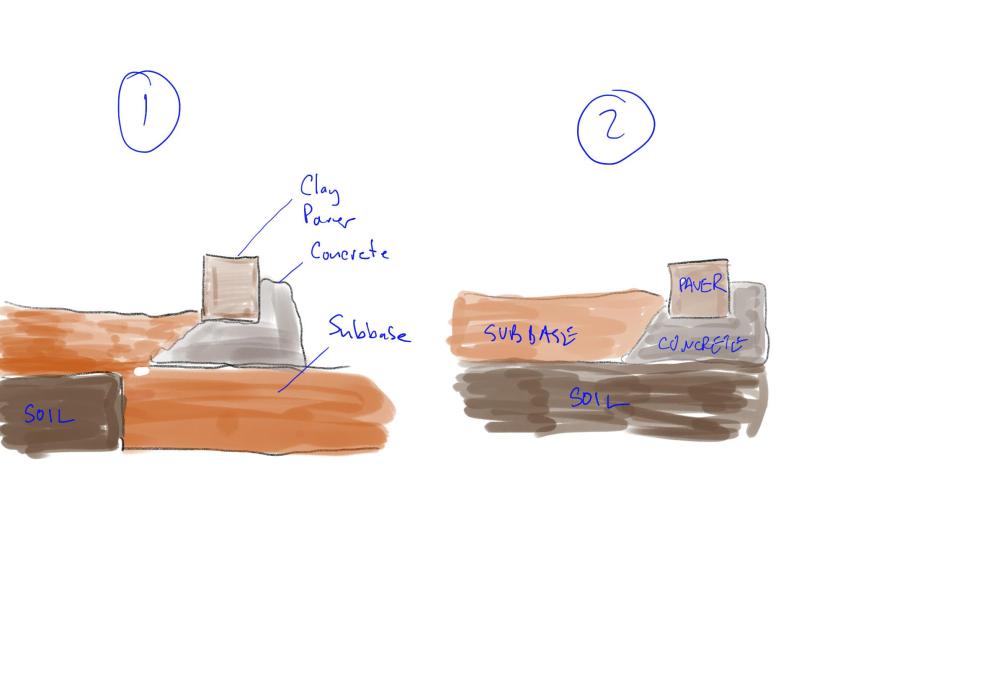

Thanks, yes that’s what I thought. That’s what did when laying the edging sections for the patio area but saw something recently which seemed to suggest you can lay concrete on the sub soil. It won’t take long to dig a shallow trench so I’ll do that. 👍 -

Hi, I’m mulling over the best way of laying clay paver edging at the perimeter of my garden (by the fence). I will be laying decorative gravel with a stabilisation grid and want the edging to restrain the gravel. Can I lay the edging on concrete which is laid directly on top of the soil or do I need to lay the concrete on a sub base? Basically deciding between option 1 or 2 below. Any recommendations/advice? cheers, Ed

-

Yes that sounds like a plan. I could put a number of stiffening cross beams along the length.

-

Of course, I could buy more legs!

-

Ahh I see. No the supports are a square section, so yes you're right they could be. I'm slightly concerned that there will not be enough strength in the cedar battens so might need to make a stronger frame for them to sit on underneath. This is the maximum span in the photo below:

-

Hi! Thanks for the comment. Can you explain what you mean here please?

-

Hi everyone, I'm planning to make a corner bench out of cedar like the one in the picture. I have a lot of spare cedar (18mm x 44mm section) from another project which I can use for the slats. I'm now looking into how I will assemble it. Cedar is very soft and I want a sturdy bench so I'm wondering whether it is best to use a different wood for the cross supports (indicated by the blue arrows in the second picture)?. What do you think? In the shown model I have used 18 x 68 mm section cedar but these cross supports won't be on show so I'm thinking of making them out of another material. The supports are directly attached to the legs Ed

-

Hi everyone, I'm ticking along with the garden landscaping and now starting to make up the cedar panels for the screen/pergola thing (See sketchup image).... I used a number of 150x150mm oak posts and made a frame that sits on the insides of the posts (See photo). The cedar battens are 44mm wide and with a 6mm gap between successive battens the planned height of each screen is 1794mm. I therefore made the frame 1794mm tall. I was toying with how I would make the screens and in the end I wanted a modular design so that I could remove the panels easily if I need to do maintenance on the fence etc, otherwise I could have installed each batten directly to the frame insert. Initially I was going to make each screen like this: Option 1 - https://youtu.be/isQc31uW2_0?si=PNjtrbVbdzPNVd3I. Here the vertical battens are marked with a tape measure where each horizontal batten should go and then the battens are positioned by eye on the marks before being screwed. This would ensure that the screen was perfectly the right height at the expense of getting an absolutely identical gap size. After chatting with my wife (not blaming her!) we discussed another method: Option 2 -whereby I used a 6mm spacer to lay the battens one by one and build it up that way. I opted for this method in the end to ensure a consistent gap size. However.....due to tolerances in the batten sizes etc the final panel size has come out at 1740mm for one panel and 1750mm for another. I kind of new this was going to happen so not sure why I opted for it. Anyway, the panels look great and the gap size is consistent but they are not as designed and will potentially all be different sizes. Given that I have 150mm Oak posts between the panels I think I could still use the panels as the difference is 10mm but I would have to modify the frame insert, which is doable. This could potentially be different for every screen and something inside of me doesn't like it, it'll basically be a bodge and rely on the viewer not noticing the difference in size of panel. I'm now toying with the idea of going back to option where I measure where each batten should be then manually place them at each location which will ensure the panel is the correct size. I should be able to reuse all the battens as everything is screwed from behind so you wont see any existing holes etc. Any recommendations/comments? Ed

-

Levelling Garden - what to do by the fence?

machtucker replied to machtucker's topic in Landscaping, Decking & Patios

I think I will install sleepers along part of the fence and gravel boards behind the pizza oven. The inspection chamber will be accessible as I will make the shelf removable.