Leaderboard

Popular Content

Showing content with the highest reputation on 08/24/22 in all areas

-

I doubt they’re massive tbh, so I’d stop worrying about that and look at practicality. Go with the garage, as when converted to AC all you “need” to do is upsize the cable to combat any losses vs distance. Say upgrade from a 4mm2 cable to a 6mm2 cable for eg. Done jobs where we’ve run the AC for 135m ( ground mounted PV with external inverter ) and was still performing extremely well as we upsized the SWA back to the CU. I think you’re over thinking a little. It’s all within the footprint of a single domestic dwelling so afaic you can relax a little and just apply a little sensible mitigation to get the best result from a practical installation2 points

-

According to the helpdesk at the DNO, they found my installation details and dates etc whilst we were talking, and he phoned up the relevant team to see if he could send me a copy of the DNO Notification Confirmation letter on the spot. They were closed, so he has emailed them to ask for one to be sent AM tomorrow. And he has given me their phone no for if I don't hear by 10am. Failing all of that, Plan B is for them to generate a new one, and Plan C would perhaps be for me to re-register. Hopefully I get a nice email tomorrow early. This was a familiar scenario, so I guess they have a way to deal with it, and that it should become more efficient over time. My surmise is that Octopus are demanding at the front end of the applicaton, as they have found that it ends up in the soup without full proven details if they don't. F2 points

-

Re: Appleby v LAP.. check out the earth terminal? The one on the photo of the Appleby looks odd/different? Might be just the photo? If in doubt ask your electrician.1 point

-

1 point

-

Another 60p on the gas price today. Probably adds another £600 to predictions tomorrow. As @SimonD said at this rate we would simply be giving all of our money to the owners of gas. They must think we are stupid/crazy. Amazing how little coordinated effort there is to do something. This is worse than COVID. Gas price now more than 15x what it was 18 months ago.1 point

-

No not interested as internal floor area is under 30sqm, made of incombustible material and not used to sleep in.1 point

-

1 point

-

1 point

-

Ah smarty bollocks - I’m a step ahead of you ! . The basic upstand is built - but I can add block work / lintels to ‘suit’ said glazing when it arrives . So too large or small can be adjusted for ( within limitations of course ) .1 point

-

1 point

-

1 point

-

Top one, technically you don’t need a dpm under the insulation unless you are using wool or some other absorbent insulation1 point

-

1 point

-

As we head into uncertain times with the very real risk of small companies going bust I am looking at how to protect myself as we start the build. I know about buying on a CC to get consumer credit protection and getting goods you’ve paid for clearly marked as yours with pictures etc. The biggest single cost for us is the timber kit as it includes the windows from Nordan so will be around £155,000. I’ve yet to ask if I can split the contract and pay Nordan directly. The payment schedule is I pay 20% prior to kit production. Another 40% at fabrication, 17.5% after delivery and 2.5% post erection. The timber kit company will have a large sum of our money before the kit gets delivered. I’ve asked them what client protection they have in place should the worst happen. They were quite surprised I asked this question as apparently no one else ever has. They have suggested some form of insurance performance bond which I know is common in the building trade on larger projects. However this would be at my cost and won’t be cheap. Alternatively they will issue a personal guarantee from the MD. Not entirely sure what that’s worth legally. I know someone who lost £40k to a timber kit company during the 2008 financial crash hence my concern. Any opinions on this?1 point

-

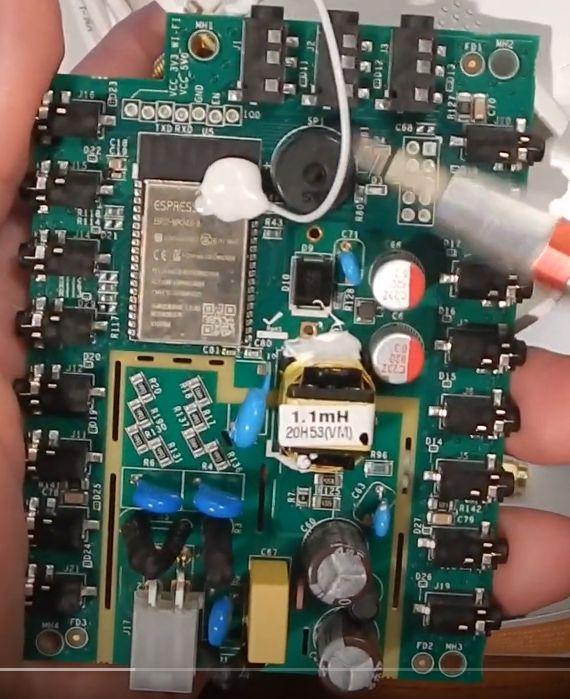

As an update to this, the manual makes no mention of PV diverted power, the second wiring option is for a 24hr timer function only. On/Off and not for granular 'excess' power Thankfully Sunamp have been very helpful. They acknowledged that i should have had a model that accepts PV through a diverter and have sent me a new controller. The Sunamp now charges top to bottom instead of bottom to top, as such the in and out pipe work has had to be reversed. Working well now though. @ToughButterCup I'd check your installation is ok with Sunamp, they were adamant an eHW should not be connected to a diverter and said it would effect longevity and capacity. Must be the eHW +iPV.1 point

-

thanks. the electricity is converted to AC by the PV inverter in the loft so I don't have to worry about that apart from the upsizing of the cables. the plant room for my electrics is pretty much a cupboard. it's about 1.7m x 1.4m and will also have my Loxone cabinet, CU and network/server rack in it. so that room will get warm but it has an MVHR extract in it and 3m high ceilings so I'm hoping that the warm air will rise to the ceiling and get extracted! plus it's underground so will be cooler than elsewhere in the house. then again, maybe the garage is the best place for it, just not in the cupboard. I've got loads of space there. ahh man....I just don't know and I've so many other things to think about as well. this self-building malarky is tricky when you're winging it! 😂1 point

-

Yes, horizontal battens attached to the post low down maybe sat on bricks outside the hole. Then bottom of spike I assume will be hanging in mid air, in the hole? Fill up with concrete.1 point

-

Hi chaps. notches cut y'day, couldn't use chopsaw/ mechanism got in the way.. dammit. So took most of the day using a circ saw handsaw & chisel. Painted notches, shoe spikes on. So sort of ready to fix posts in place. Would the idea be: 1) offer up post, rest it on something, temporarily screw front beam into it. Use batons fixed to lower area of post & fettle into place to get frame above it level.. & post plumb. Then add hardcore ( into bucket, bottom jigsawed out). Ready for postcrete. ? I can't quite do Onoff idea of resting spike onto a slate or so, lying on hardcore.. as I'd need to fill each bucket 2/3rds full of hardcore, in order to get the slate high enough. Unless I'm not thinking right. Thanks, zoot.1 point

-

There may be a restriction due to CT placement have you considered that? I wanted to install AC coupled battery in a detached garage next to the inverter for a PV on the roof but the installation is on a sub main 25m away from the CU and meter tails in the house. The battery systems all seem to need a CT cable back to the meter.1 point

-

1 point

-

Not sure you need to double any flow rates. Ours is set at normal flow 45m3/h and a 25% uplift in flow rate when asked to boost.1 point

-

I would just install a manual MVHR boost switch near the hob. We don't use the cooker hood that much, unless doing smelly stuff. Then as above recirculation, carbon and grease filter.1 point

-

Anywhere that studs land between joists should have nothings between each joist and under the floor deck every 600 You can do this from underneath by following the screws1 point

-

Before we can say more we do need, as Gus says, to know more. Type of tree, and nature of the ground. Conifer...ususly no structural problem but lots of needles and mess. Deciduous...can vary from small up to 25m, with as much in the ground (over and under your house) The roots near the surface are usually much finer than this, but I guess the lack of competition is encouraging this growth. Generally if you cut away or through more than 1/4 of the surface (feeding) roots the tree will die. Once we know the type of tree we can predict its eventual size, and effect on your house..that may affect the most appropriate treatment. If you don't know tree types then a photo of it, plus of the leaves and the bark would help.1 point

-

It is indeed. @pocster.. thanks for the response.. it took me a bit of time to write that while trying not to sound too much like an.. @pocstercan fill in the expletives.. I maybe failed as concrete lintels are not that sexy.. The thing I like is that there are folk here on BH that have forgotten more than I know an don't mind sharing their knowledge and experience.1 point

-

1 point

-

Hi pocster. That looks like a typical lintel that may be produced by say Robslee, they call it a type A lintel which is what we call a composite lintel. It has the rod in the middle. For all they are two types of generic lintels, one is called a composite lintel, the other a non composite lintel. They are two different animals. The composite lintels tend to have the rod in the middle and a bit of prestress in the rod to keep the concrete in compression, also helps it not to fall apart while you are laying the bricks above. Long composite lintels need to be propped until the brickwork cures so read the manufacturer's instructions. If you have a good height of brickwork above they can span quite a long way if you are careful. If you think about a reinforced concrete beam. It has steel in the bottom with a bit of cover to the steel to prevent corrosion (plus often fire protection) and provide bond between the concrete and the steel rod / wire. Concrete is good in compression, steel good in tension so when you load up the beam from the top the bottom goes into tension (resisted by the steel) and the top into compression (resisted by the concrete). Now for a composite lintel you can mix up materials. You can have a rod encased in a bit of concrete, like your's pocster. If you make sure the top of the lintel is clean and put say 5 -7 plus courses of brick (see manufacture's spec) on top then you now have a deep beam.. (the top 80 odd % is of brick if you have 5 courses or more of brick) .. the depth of the lintel plus the brickwork above and that works quite well in places. In fact surprising well.. What happens here is the courses of brick above acts in compression and the rod in the lintel is in tension. The concrete in the lintel is not doing that much. In other words the brickwork acts compositly with the steel rod / wire in the lintel.. like say a SIPS panel where the sheeting and internal timbers act together and to make this work the sheeting has to be well fixed to the internal timbers.. thus the brick work has to be well bonded to the top of the lintel and the perpendicular ends of the bricks fully filled with mortar. In summary the lintel per say does not act to resist the majority of the bending effects.. the concrete around the rod / wire just acts arguably as a medium to transfer the horizontal shear forces (tension) in the bottom side of the brick to the rod in the lintel, which happens to be encased in concrete. A big mistake folk make is to put a DPC (cavity tray) between the top of a composite lintel and the brickwork above. Here you create a slip plane and the whole system stops working.. please don't do this. Now a non composite lintel acts much more like a reinforced concrete beam. The major difference is that it does not rely on having masonry above. This lets you introduce say cavity trays and put floor joists on it for example... maybe a bit of point load. The rods are more heavily prestressed and are in the bottom. They are marked top. If you can't see the mark, (sometimes the lintel may have been cut down) then look for the rods and put them at the bottom.. unless your SE tells you otherwise. Sometimes you can use a lintel upside down to create a cantilever / corbel but this is not that common. Prestressing? An ordinary precast reinforced concrete beam has say steel in the bottom, a rebar cage is made and the concrete poured round about it. It all cures and you load it up. Now steel is quite a stretchy material so when you load up the beam it drops (deflects) a bit before the steel really starts to work. The concrete is also a bit elastic so it has to "shorten" on the top of the beam and this gives rise to more deflection. Also concrete shrinks so that relaxation has to be taken up and that can manifest as more deflection. When they make lintels they don't make them one at a time. Commonly they have a very long mould and run a long wire near the bottom. The wire is put under tension and the concrete poured and cured. Then they release the tension blocks at each end of the wire and saw up the long prestressed beam into common lintel sizes. Once they release the tension blocks the wire in each section of lintel it wants to shrink, but it can't as it's bonded to the concrete in the bottom of the lintel. What happens here is that the wire compresses the concrete in the bottom of the lintel and this makes it bow up a bit.. which is good as when you build it into your house it bows back down. the idea is that the bottom of the lintel ends up about flat... in an ideal world.. just like us on BH! If you are curious if you take a longish non composite lintel.. say a 145 high x 100mm wide (type C that look like a concrete beam higher than it is wider) and lay it flat with the rods near the bottom you should see a bit of a bow upwards. But @nod some non composite lintels do have the rod in the middle!! and !!! The explanation for this is very lengthy but so have left it out. These tend to be wider and flatter. There you go.. hope this helps to give you a flavour of how the different type of lintels work and hopefully this will help you select the right lintel and use them in the right way. For me I tend to stay away from composite lintels on longer spans even if I have a good few courses of brick above as the workmanship / site supervision is often so poor these days. Yes I know the heavier non composite lintels cost a bit more but they are more "idiot proof" to some extent. Also, on self builds we often make late changes so non composite lintels give you a bit more flexibility here.1 point

-

Not like your windows, but IIRC I used two strips of Compriband, which fitted into grooves in the side of the window frame, which were 15mm wide and 10/18 expansion. I then used the Soudal foam to seal up to the Compriband tape inside and outside. The advantage of the Soudal foam was that it was very flexible after it had set. In your situation I guess you could use a wide strip of Compriband, with appropriate expansion, to seal the glass to the stone and then use burnt sand mastic to point the glazing.1 point

-

1 point

-

How about remove the stones, add some permeable sub base to level with drive then strip of artificial turf on top with edges pinned down.1 point

-

Don’t be a pussy . Outside with a little cover over them to keep direct sunlight off . (expletive deleted) the spiders / bats / unicorns. You in Narnia or U.K. ?0 points

-

Didn’t read any of your posts as don’t need too . You put them outside . Easy to expand ; and cool ( assuming direct sunlight isn’t cooking them ) . You know I’m right because that’s what I did .0 points

-

0 points

-

0 points