Leaderboard

Popular Content

Showing content with the highest reputation on 01/08/22 in all areas

-

+ one. Add up the labout time to fix it.. you'll need to find someone with the artisan type skills to do it. Compare with a new covering with maybe a guarentee?2 points

-

Welding lead (lead burning) is an art in itself, if your selling, what with the scrap price of lead and copper and the fact a “new roof” might clinch a sale, it might be prudent and cost effective to renew it. Food for thought !2 points

-

I can't believe this was three years ago now! Only feels like yesterday (I suppose the pandemic probably has something to do with that). With the multi-faceted issues it all got rather complicated and so with my ever-sensible father (whose OCD, obsession with details, bad luck when it comes to trademen etc all come from!) I went on to explore what the best solution would be best. The technical director of the firm that supplied the Desmopol (they supply all sorts of roofing products, they're not the manufacturer) and he was the one person that I found supremely knowledgeable on all things roofing and, most importantly, completely trustworthy. A decent bloke and so one I decided to put my trust in. He suggested that ripping the whole roof and starting again might not be as perfect a solution as one might hope given the inevitable disruption to the rest of the construction, particularly if done by a fuming builder! Furthermore, he said he's spent his life up on roofs and so can spot a roof that will leak vs one that won't and he was absolutely confident that mine was of the latter. He assured me that the usual issues that plague too-flat flat roofs wouldn't apply here given how small it was and that the Desmopol product was approved for zero-falls application anyway (the BBE certificate I had said it wasn't but it turns out that was out of the date - there was a more uptodate one than confirmed its suitability). So, I started to accept the flatness issue as more a case of less-than-perfect work that you get from many a tradesman and regarding the Desmopol application itself he and I end up recoating it together. His company paid for the products and we both spent the morning on the roof recoating it. He does actually run the training courses for this and other products and so was going to invite me along to one of them but that'd leave me doing it all myself which whilst I wasn't too concerned about I think he wanted to help a bit more than that whilst also ensuring that the issue was definitely concluded. In a way I'm glad I got the chance to reapply with his help as in 10/15 years time when I should be recoated I'll be confident knowing how easy it is. So that's what we did and, three years on and - touch wood - we haven't had any leaks or anything and I think something would've happened by now. After a rain shower the roof drains in the same way every time with a little bit of pooling in one area, but that's stretching the term I think as it usually evaporates fairly quickly. It still haunts me a little whenever I see it and that happens often as my daughter's bedroom overlooks it! If it wasn't overlooked I'd probably have forgotten all about it by now I'm sure.2 points

-

There are plenty of wireless systems for general use but perhaps see... https://plumbbox.co.uk/product/mains-switch-rf-solution-alternative-to-cabling/2 points

-

We had the "traffic management" nonsense when having our line installed. They needed to access a connection pit in the grass verge but deemed it too dangerous to do that with passing traffic so needed one lane of the road coned off with traffic lights. On the appointed day the traffic management firm came and set up the lights in the morning. They sat there all day annoying the motorists while nothing happened. At about 3PM the lights were removed having served no function other than delay the motorists. Shortly after Open Reach turned up, It was an old school bloke who just parked his van there with hazard lights on while he made the connection in the pit. What a farce.2 points

-

And I thought I was a political radical for wanting to defund the BBC. Mass execution of Eastender viewers is a final solution for the BBC I had not considered.2 points

-

In a sealed system the pressure within the system gives the suction head. An open vented system, the suction head comes the loft mounted cold tank, so as you say the pump can be mounted anywhere in the system. The suction head required increases with flow and generally in the range of just over 1 to 2m.1 point

-

No such thing as suction head in this system as it’s all ground floor, plus the pump should be more than adequate and in any case these are all 5 or 6m head pumps.1 point

-

Under the slab, or under the screed? 100mm is pretty poor if you're building to a good insulated, airtight standard, and if you are, 150mm isn't 'top spec' either. I assume we're talking PIR?1 point

-

50% less heat loss through the floor. The effect of better insulation with UFH will be greater than without, as the floor temp at the insulation level will be higher. UFH temp at insulation approx 35 deg, with radiators it will be closer to 18 deg.1 point

-

Not sure 150mm is enough! I have 200mm PIR and some here have 300mm EPS always go more with insulation, you only buy it once, electricity/oil/gas you buy forever and at increasing cost.1 point

-

I am using my present slack period to start compiling the "house manual" to document everything, before I forget it.1 point

-

@joe90 I’d start by replumbing the buffer and leaving everything else as is. The buffer - either plumbed how @Nickfromwales or I said will then just become part of the system and you’ll have a lot more system content to be flowing around but first off it will either prove or disprove you have an issue.1 point

-

Don't re invent the wheel. if you need to convey the signal from a room thermostat to a remote location without wires, start with a wireless room thermostat e.g. start with this selection https://www.screwfix.com/c/heating-plumbing/wireless-thermostats/cat4600004?cm_sp=managedredirect-_-plumbing-_-wirelessthermostat For just "simple" i would choose this one https://www.screwfix.com/p/danfoss-ret2001rf-rx1-s-wireless-room-thermostat-and-receiver/856jt1 point

-

1 point

-

I would not do this. Conversely I am in regular contact with Trevor of Cylinders2go and he has had to petition Telford to start producing small buffer tanks ( sub 100L ) as there are lots of enquiries for these to be retrospectively installed in ASHP installs where they should have gone on on day 1. You already have it, it’s bought and paid for, so my advice would be to plumb it in as I show above and keep the ASHP as happy as possible. No 2 instances are really the same, so this is general advice, but I’ll put money on it that removing it would be a bad choice. Measuring its success as is is not a fair representation of how it ‘could’ perform, so as it’s there anyway, plumb it as above and see how you get on. Around £150 of antifreeze will need introducing to keep the concentration levels as required.1 point

-

1 point

-

I would say no in that case. Does the frame not come with a pipe fitted in the exact correct place? most seem to.1 point

-

1 point

-

Temporary Building Supply is the usual term. Just check they have actually opened the valves properly.1 point

-

Separate lintels for me every time inner and outer alternatively check lintels which leave room for insulation in the head.1 point

-

Good point. Although we have spent a crazy amount of money building a false wall between us and our semi detached neighbours. The party wall was so thin and they are so deaf that I could tell you their exact TV preferences to the minute. They have the TV on all day every day and watch the same soaps and news programmes like clockwork. They spent the first 9 months of our build complaining about noise. Since the false wall made with I studs and SBx board has gone up, no more complaints from them. I looking forward to a house free of Eastenders. I used to love the programme as a kid, but now I have more refined background music taste. The sound insulation between our tv room and my daughter's bedroom above is not quite so good though!?1 point

-

I can tell you are genuine and can afford it as you haven't asked the cost.1 point

-

1 point

-

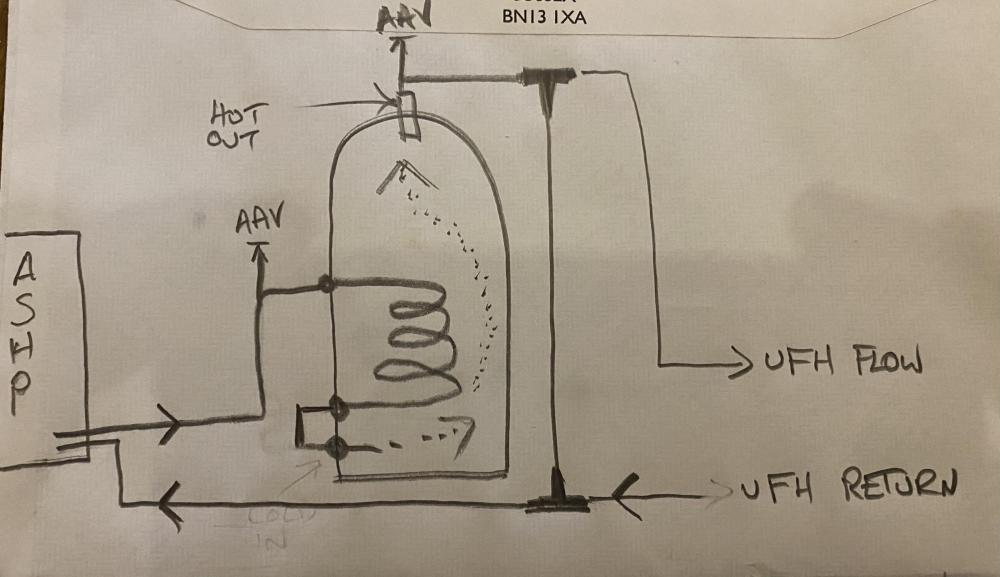

@joe90 are you heating the 'buffer tank' via the coil, or are you using the coil to extract heat? The whole idea of a buffer is to add volume to the primary side so going via a coil will not achieve that. In honesty, I do remember sorting the deal out on price, but I'm pretty sure I did not spec the cylinder you bought to use as a buffer..... IIRC you followed @PeterW's install that he was on at the time where he used the same UVC as a buffer? Been a while of course. Agree that it's a simple fix to reconfigure, but with the caveat that the system volume will increase, thus, requiring an additional volume of antifreeze when you mix ( combine ) the 2 bodies of water. You have 2 filling loops atm? One for the ASHP primary and a second for the internal heating system? Internal UFH on inhibitor only and antifreeze in just the external primary's? Run the ASHP flow through to the buffer coil inlet, and come out of the coil output and feed that into the bottom ( cold in ). Then take the flow from the 'hot out' back to the ASHP as the buffer return. You then need a tee immediately off the top connection of the buffer ( the 'hot out' ) where you will pick up the flow to the manifold, and then a tee lower down the same pipe run to pick up a return for the manifold.1 point

-

The thermal bridge is tiny - usually get left or if you really want to cover it you can glue something to it like @nod says1 point

-

Tempest should be ok - you could re-plumb it quickly to see if removing the coil helps. Add a tee to the inlet and outlet and then connect the flow from the ASHP to the top connection then on to the manifold, plumb the return from the manifold to the bottom inlet on the buffer then on to the ASHP return. The coil becomes redundant at this point, but it means the pumps need to be running roughly the same speed.1 point

-

I am just going to leave mine bud - can't use insulated pb as it is exposed to weather and would melt. Tbf - no-one but me would ever spot it tbh - you could always order up some upvc strips but it will look like a bodge and draw more attention than the bit of steel.1 point

-

I used a PU glue and fixed a plastic 50 mil trim to match the frames1 point

-

Not standard practice, our temporary building supply is full flow and pressure. And not been billed for it since connection nearly a year ago ?1 point

-

Some of us know a lot about very little. Some know a little about a lot. The above trades were people who knew very little about very little, but didn't know how little they knew.....they are scary... and they are out there now.1 point

-

Yes, in my experience tossers with a limited vocabulary of - massing, bulk, form, scale, incongruous and discordant used for refusing applications.1 point

-

I wouldn't cross the road to piss over Wren. Showroom is drop dead gorgeous, killer salespeople, "buy now or your children and the planet will die before you get back in your car".....etc......and then nothing after you have left and have paid, other than two fingers when the order all arrives smashed to bits by an over-worked angry delivery driver and huge turn-around times to get replacements 'when they can fit you in'. I lost a lot of money on 2 of their installs, when replacement panels and cabinets etc kept on getting redelivered by the same angry driver in the same state. The builder had to threaten the driver with a slap around the face due to just how badly he was treating the clients order whilst getting it out of the wagon and lobbed onto the pavement. 7 damaged deliveries of key decor panels which halted the whole install, and when the client went to the showroom to protest the showroom manager took over and got the transport manager to deliver the new white gloss decor ends, and proudly opened it up, removing all the 34 layers of bubble-wrap, to reveal the new hand delivered panel, damage free, in fcuking grey.1 point

-

My tank heating strategy is really simple. Heat the whole tank to 48 degrees with the ASHP. Then top that up with the bottom immersion heater from solar PV which on a good day will take the tank to over 70 degrees. It's all simple off the shelf stuff nothing too bespoke about it. If the immersion was half way up, there would not be enough capacity to absorb a good days surplus PV generation.1 point

-

5 mil onto the casing We normally butt 150x15 ply around the casing and run a bead of acoustic sealer onto the ply Then drive some screws through the pb the following day Partitions Simply double board Just looking to see if I’ve any picks We did a 18000 sq ft house overlooking Lake Windermere 2018 I will post them if I find some1 point

-

0 points

-

You will struggle to get more than 2kW on that gable end and the chimney creates a shading problem. I have a smaller hipped roof and hope to install about 1.2 kW. My motivation for doing this is that it should supply two people with hot water 200 days a year which equates to less wear on a gas boiler or ASHP and a £120 p/a saving. A DIY install would mean a 7 to 10 year payback plus @SteamyTeawill be my BFF which is an incalculable fringe benefit.0 points