Leaderboard

Popular Content

Showing content with the highest reputation on 04/08/20 in all areas

-

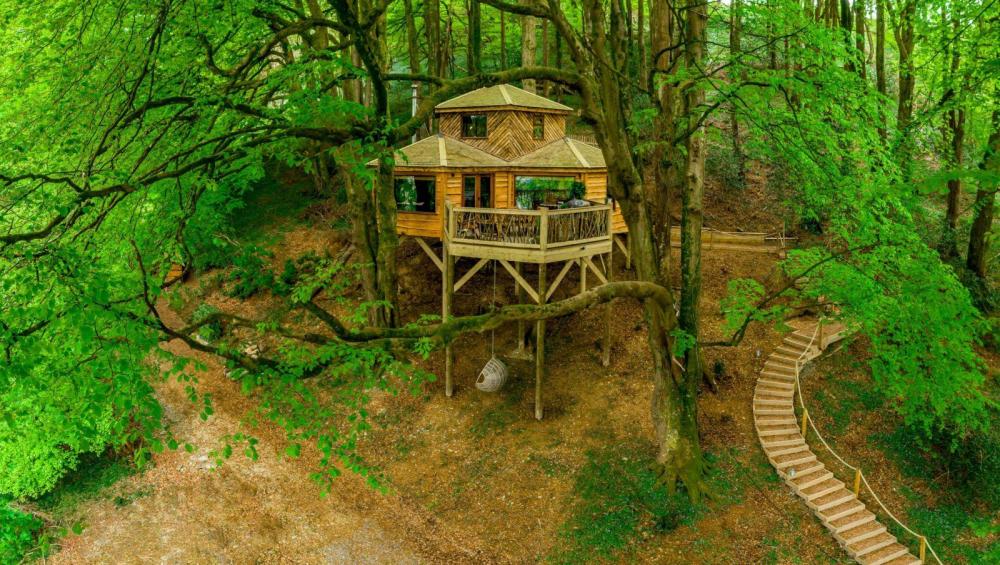

Hi All, New member, but got a few referbs, outbuildings and now residential holiday lets under my belt, another new build coming on soon hence the registration, then a self build house on the cars in the next few years. Here are some pics of my recent treehouse build completed in 2018: Look forward to getting to know you and hopefully getting some of your knowledge6 points

-

My local merchant who have a big online and ebay operation are delivering and doing collection. https://roncurrie.co.uk/2 points

-

6 W sounds reasonable for a fairly powerful/wide movement range wax stat. UFH actuators are probably a fair bit less power (tiny range of movement and modest force) and they tend to be around 2 W to 4 W.1 point

-

Bought all my kit from BPC last October. Vent Axia unit + all ducting, plenum etc. for about £2600 for self install which I’ll be doing in the next month or so. Extract from 3 bathrooms, WC, utility and kitchen. Supply to study, hall, dining, living and 3 bedrooms. About 170 sq. m over two storeys. They did the design, cost then was £100, deducted from the order. They’re still working during the lockdown, so might be worth a call.1 point

-

I paid BPC £150 for design which was knocked off the cost of the kit when I ordered it from them.1 point

-

I used their ducting/manifolds etc. Set up a trade account online and they're nearly half the cost of most others.1 point

-

1 point

-

Previous house was a cold roof with trusses. That had a habit of making some loud creaks and cracks when the roof heated up on a warm day. The NO1 thing I would say is make a warm roof with a ridge beam. SO much easier to make air tight and so much better use of space.1 point

-

Twin wall pretty smooth on the inside. Total cost £1072 from BPC for all ducting, terminal vents, plenum boxes etc but not the large duct from the plenum boxes to the mvhr unit, they came from another self builder left over from his job. BPC did not do the design, I am not sure what they would have charged if they did,1 point

-

I paid £1.5k or thereabout for the unit, then about £2k on ducting/manifolds/plenums. Self designed and installed. Up and running but only 1/3 of house actively being conditioned (other outlets plugged for the moment). I've said it many times on here my choice of unit (vent-axia) was because I want to use it as kitchen extractor over an island hob so saved the expense of downdraft set-up. The unit I have allows a cooker mode with upto 100% speed on extract and bypass the heat exchanger to prevent fouling.1 point

-

1 point

-

Still got next years firewood to chop and stack. A shed to tidy up and reoorganise. A deck to finish (until I run out of wood for that) and some work to do in the garden. Then there is starting on the VAT claim. Not completely bored yet. but mustn't rush things.1 point

-

Ours is a 195mm frame (filled with Frametherm 35) and 100mm wood fibre board on the outside then render. The house with 3g Rationel windows is extremely quiet. It does not creak or groan in strong wind, No steelwork in ours. The SE specified two layers of OSB on the frame as the racking layer with staggered joints. Same 100mm wood fibre used as the roof sarking and same frametherm insulation making a warm roof supported on a ridge beam. We have 25mm service void, that and 12mm plasterboard is a perfect fit for 35mm back boxes for the electrics. 15mm (soldered copper) pipework fits in the 25mm gap. The utility room is the only place we have any 22mm pipes in the wall and that has a 45mm service void. Our bathroom was tight on space, so the outside wall there has no pipes or cables and the plasterboard goes straight on the frame with no service void. No difference in accoustics noticed.1 point

-

Super Leytex first two coats then anything you want. Short pile roller, pole and a big scuttle work best.1 point

-

If your using a solid construction You can run the wiring on the surface following safe zones on the surface of the block or brick The pipe work can also be run on the surface If you are using dot and dab as a posed to wet plaster the gas pipe needs to be fully covered with drywall adhesive To prevent any gas leaking behind the boards1 point

-

Most of us self building are using more modern building methods. e.g. we are timber frame and between the frame and the plasterboard is a battened "service void" for all pipes and cables. Cables must follow "safe zones" as defined in the wiring regulations, I am not aware of any such regs for water pipes but I suspect there are for gas pipes.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Slightly ouch, but their prices are usually OK. They have an ebay operation here: http://www.ebaystores.co.uk/Ron-Currie-and-Sons-Ltd which may have a different price structure, but that online shop is currently not operating.1 point

-

1 point

-

1 point

-

I love being retired, always busy with what I have, buy stuff on toolstation or Ebay most days. SWMBO says I am not a social person, she is dead right, spent last two days digging a 40m French drain (with JCB) As the ground is finally dry ?, if it does rain I have multiple garage projects to get on with. It’s people in flats with family I feel for.1 point

-

Do you know anyone with a Bradfords trade account? They're still delivering, but not sure what quantities.1 point

-

If this is what retirement is going to be like I’m sold. It’s going to be f****** lit. I’m technically on leave this week rather than “working from home” so I have finally used the Vax as carpet washer. It only took me 5 years to get here.1 point

-

It depends very much on the total load, both on the installation at the end of each sub-main, and on the incomer. This needs to be determined and stated on the lodged EIC by the competent person undertaking, inspecting, testing and signing off the work, so before getting materials a few things must be done. Firstly, the actual rating of the incoming supply needs to be determined. This could be as high as 100 A, but may be as low as 40 A. The DNO will do this on request (they have to do it, as the fuse is their property). Next the total load at each installation (in this case the house, flat, barn 1 and barn 2) needs to be determined, or measured in a representative way. Bear in mind that fuses don't rupture at all quickly for modest overloads, so you cannot use a fuse rating to determine the maximum load (for example, a BS88 100 A fuse can take about 10 minutes to rupture at 200 A, or maybe 5 hours to rupture at 150 A). For an existing installation it may be possible to do a 24 hour peak load measurement to get a feel for the true load, which is OK if done at a time likely to be representative. The other way to do it is to calculate the load, using the expected circuit loads, allowing for diversity where applicable. For example, here's a sample calculation for a fairly typical domestic installation: 2 off ring final circuits, with 32 A over current protection 2 off lighting circuits, with 6 A over current protection 1 off cooker circuit, with 40 A over current protection, supplying a cooker rated at 7 kW maximum, with no additional 13 A outlet 1 off immersion heater circuit, with 20 A over current protection, supplying a 3 kW immersion heater load. The two ring finals are calculated as presenting a load of 100% of the total up to 10 A, plus 50% of anything over 10 A, so would be 10 A + (50% x (32 A - 10 A)) = 21 A each, 42 A in total The two light lighting circuits are calculated as presenting a load of 66% of the total, so 6 A x 66% = 3.96 A each, ~8 A in total The cooker circuit (7 kW / 230 V = ~30.4 A), is calculated as presenting a load of 10 A + (30% x (30.4 A - 10A)) = ~16 A in total The immersion heater circuit presents a total load of 3000 / 230 = ~13 A in total (diversity cannot be applied to water heaters or electric heating) Adding up the total from the above calculations gives a total load from this installation of ~79 A There are ways to reduce the total load by using load priority devices, or by restricting the maximum load on some circuits. I suspect you may well have to consider doing this if your total load looks as if it will exceed the rating of the incoming supply. The competent person that must do this work and sign it off (this cannot be DIY'ed, I'm afraid) may be able to suggest ways to keep things within limits and safe, if this is practical to do. It's possible to reduce the rating of ring final circuits, perhaps, if the loads are only ever likely to be fairly low, or it may be possible to wire one or more of the sub-mains with some form of load limiting or priority load relay system.1 point

-

I always use Loctite 55 on brass to brass threads. Brilliant stuff. And WRAS approved.1 point

-

I'm sure I've shown this picture before. But I had the exact same issue. So i use 3/4 bsp male to 15mm compression, which I joined on to 15mm hep2o elbows. Make sure you use copper olives, not brass ones.......brass will not work, its just too stiff. To test the system I attached spare hep2o shutoff valves to all the outlets and let the system come up to mains pressure and left for a day to see if anything dripped.......it did drip....from the 3/4bsp. They take alot of tape. Also, don't make my mistake. I made the central space for my shower valve too wide. So the ply on the left which was for the shower screen to have something substantial to mount to is too far over. The stud needed to be at least another 50mm to the right.1 point

-

Brilliant Tell us the Planning Permission story - please.1 point

-

I don't have a photo to hand, but I've done it in the past and it's easy enough. just fit glands in the box for the SWA and fix a couple of Henleys and an earth block inside, screwed through the back to the base board. Needs one of the larger adaptable boxes so there's enough room, but easy enough to do. I always tend to use piranha nuts on SWA glands now, as they are a lot easier than faffing around with brass banjos.1 point

-

Welcome. A fascinating build, and next project. I have lots of questions I would love to ask, about the tech. side and the planning side and some of your interior decor (does that shower have any screen at all - how does it do if so?). I love the blue herringbone tiles on the wall. The game of Planning Poker must have been interesting. There are people here with wooden builds, and builds on stilts because they bought a bit of a hill, and maybe some potential cross-feedback from people building under 'caravan' rules in wood (which have to be movable) which may have some structural similarities. But I do not think we have any treehouses until now. All questions are welcome. Ferdinand1 point

-

1 point

-

Thanks @PeterW, love it. Nice and simple. Perfect for my addled brain. And I can still get that in time for the weekend! Plan is a go! @Russdl hah! We did some walls ourselves but I did snap after 300m2 of DIY (tacking that is) before I called in the pros! I am not sure I'd call that a success of the fermacell DIY-ability but it'll get me in sometime this year I hope! Now to pick what shade of white to go for the ceiling... Off-milk, split meringue or millionares cocaine.0 points

-

0 points

-

0 points

-

But a bird in the hand is worth two in the bush. (Not sure I've said that to the right person.......might get misconstrued )0 points

-

0 points

.thumb.jpg.196bd613f2836059b66de6e3c259ed24.jpg)