Leaderboard

Popular Content

Showing content with the highest reputation on 11/02/19 in all areas

-

That's the last of the downstairs flooring finished with the slate tiles in the entrance hall and utility room completed. I have to admit I got the local tiler to lay them, they turned out to be some awkward tiles not (imho) correctly sized to be laid in a pattern like this (resulting in some very irregular grout gaps) and some, particularly the larger ones were not very flat. Given the challenges he did a good job. Grouting and sealing done by me and SWMBO A few more pictures on a blog entry at http://www.willowburn.net/ Look for the entry Hall and Utility Room6 points

-

@zoothorn you are now taking the piss and I’ve had enough. This is your first post on the thread Note your words ... Groundworks have been done (+350mm too deep) So your last statement about it being top down lower by 20cm is wrong. You know you started too low, but actually it’s done you a favour. Thats bollocks too - you’ve queried why it’s the shape it is from the point you posted the picture ..! In the words of the great Duncan Bannatyne - I’m out ..! Enjoy the rest of your build.4 points

-

The fact it's the wrong way round is competely irrelevant here, for reasons that are obvious. I've already stated, as has BigJim that there may be a small section of sloped ceiling. You can even see that in my drawing, but rather than have a daft tiny sloped bit I've elected to batten it out and ensure 90degrees. However if it's really important to have a sloped ceiling of 100mm, then yes, that's an option. I do kindly suggest that changing your attitude to problems, including your neighbours, may be helpful. The fact you refused point blank to start on the premise 'someone else is right' about this problem speaks volumes. I didn't at that point ask you to accept I was right, I asked you to look at the problem from the point of view that I was right. This is a community, with real people, people who care and try to help all comers. But if you don't play ball, especially given your serious lack of technical understanding, then you'll eventually find no-one responds to your posts.3 points

-

This is how I’ve done it on my last few houses: 1. Decide on light positions and create a measured plan (distances from wall etc). 2. First fix your electrics with a decent loop of cable. 3. Board and skim/tape as normal. 4. Paint (at least down to the final coat) 5. Cut out and pull loop of cable down and wire up. And for the clever bit........ 1. Start with an empty room. 2. Mark your lighting positions out on the floor. 3. Use a vertical line (plumb) laser to show where to run your cables to. 4. Use the same points on the floor to cut out your holes. Make sure you mark the floor well (use a small screw if it’s timber) or drill a very shallow hole if it’s concrete. Both assume it’s not your finished floor Plastering will be cheaper and cleaner. Plasterers will love you for not having to navigate holes and cable.3 points

-

2 points

-

2 points

-

Builders have done a great job working with Zoot the hoots fag packet drawing. They have given him the ceiling height he wanted in the upstairs room, and a reasonable working height in the workshop underneath. to give him these heights they had to dig deeper into the ground. Basically they have taken his crap drawing, and made it work. They have done him a favour, as they could have chucked it back at him, and told him to get some proper drawings done. I think the builder deserves a cup of tea, and a doughnut. A jammy one, not one of those cheap ones with a hole in the middle.2 points

-

2 points

-

2 points

-

The drawing is competely wrong and misleading. You should bin it and let the builder finish and never look at that drawing again. That's not being snipey - I'm completely serious. I know you do t accept this but the root cause of many of your issues is that drawing. It's not fit for purpose in any shape or form other than a general overview of the aspiration.2 points

-

2 points

-

Thats a good shout. If if you want a really great addition to your tool kit (come on who can resist more tools ?) then you won’t go far wrong with this set. Honestly they will take some serious abuse and are just too bloooomin useful. https://www.rutlands.co.uk/sp+hand-tools-nail-pullers-pry-bars-nail-pullers-japanese-claws-set-of-3-rutlands+jp1420pack32 points

-

2 points

-

Wow you guys, so much to take in already. Will def check out the recommendations. In no particular order and not to deliberately leave anyone out, @TheMitchells I’ve come across Barbara Jones before, I’m not sure if she was involved in the straw bale visitor centre I ran, so long ago I can’t remember. Loving the look of the cassette system. Thanks for the link @Cambs For me I just love the feel of straw, cob, wood etc. I’m not into more conventionally built homes. Straw bales are also really good for people with allergies as they are inert being just the hollow stem of wheat etc and not the seed heads found in hay. I know bales are more expensive and larger than they were when the building o was involved in was built but they can still be had. Q @AnonymousBosch I hadn’t seen that one as hadn’t looked outside of the west county but would certainly be worth checking g out next time I’m up that way. Interesting to look at others, a few of us are in conversation about starting our own community. I love a bit of idea pinching and info sharing. Thank you so much @NSS for the lovely kind words. The past year (its a year this week he finally entered the terminal stages) has been hard beyond belief, not least as I was also threatened with court action as unbeknownst to me a car rental co refused to pay out to third party after an accident two years ago and my dad also had a health scare. However, I finally feel like I am emerging from the fog. Don’t get me wrong it’s going to be years in the healing but I can feel my old positivity making an appearance. I know being a landlord is full of risks but I have an advisor I trust in the form of an excellent letting agent. I know I will lose some of the income to fees but I can trust them to do me right. I couldn’t face having lodgers in my house. If it doesn’t work it doesn’t work but I’m not earning anything with money in the bank. Sorry if I’ve missed anyone but I’m so grateful to all who have chipped in with advice, suggestions and kind words. I honestly can’t see which way this will pan out but we’ll see. Thanks all, Helen2 points

-

A blockage of what ..??!! Only thing in a utility should be a sink and a washing machine ..?? A 40mm waste into a 110mm swept elbow there is nothing really that can block ..? You’re not putting food or fat down it, and there is nothing such as wipes or other rubbish in the run ..?? Same with the kitchen - swept up into the floor with a socket in the top, utility tees in at 90 degrees just after the elbow and you’ll have basically 65c water flowing through that whenever your dishwasher or washing machine clears out. Washing machines are great at cleaning out drain runs - a 90c maintenance wash with a bio powder once a month will not only keep the machine clean, it will also sort the drains too ...2 points

-

2 points

-

@ykhan16 Nope, just tried to learn as much as possible before starting and then gained experience during the build. £165 seems cheap for a course, even if it just gives you a general overview of a number of areas. I did business management at uni and my day job is working as a chartered accountant so prehaps some skills have brushed off onto the build. @Mally, thanks I tried to spend as much as I could on the fabric of the house. We started outline planning process when we were 22, we saved and saved and then about 4-5 years ago we put in the services and made it into a plot. Until we dug our foundations it wasn't really a risk as we could have still sold the plot if our plans dramatically changed. Once we were at foundation stage I had a good idea of how long I wanted the build to go on for and finance was in place. It kind of been a phased build with lot of thinking time. I've never owned a property before so we will feel extra proud that our first home is our home. One of the benefits of a kit home, is that it all goes up in a week or so, that's good if you want to get wind and watertight as soon as possible. I planned for the house to go up during July/August and had glorious weather so the time in cutting and constructing wasn't as important if we were building in winter. Stick building allowed us to build bespoke house and it was much cheaper. I spend many an evening deconstructing the structural engineer plans to order every length of timber, nail etc my thinking being that I could save money before we started and this also gave me some satisfaction that I have been more involved in the building of the house.2 points

-

It’s madness (IMO), a mate of mine wants to move and buy a 1950s bungalow, I went to view it with him (as his tame retired builder) and it had age related issues but nothing major, the surveyors report was pages and pages of “it might have this” or “it might have that”, pure scaremongering in my opinion. Reminds me when my parents passed away and we sold their house, luckily I had lived there for many years and later did much of the work on it, the buyers surveyor made some absurd assumptions about the work that had been done. I wrote a very terse letter to the buyers explaining I was a builder, the previous owners son and apart from explaining the things that were wrong, not to pay the surveyors fee, which they didn’t, they bought the place and were very pleased with it. (Rant over?).2 points

-

The key to a condensation free house is insulation and lots of it. I am willing to bet your old house has very little insulation hence cold wall surfaces where moisture condenses and mould forms. If you build with a decent insulation level then the next thing is make it air tight and coupled with that an MVHR ventilation system That will give you a warm house free from condensation with low heating requirements. Which lends itself to heating by under floor heating at low temperature from a heat pump. There is no doubt a ground source heat pump is slighthy more eficcient than an air source, but when you properly cost it, there are a lot of additional costs and ongoing maintenance costs. Most of us who have looked into it decided the sheer simplicity of an air source heat pump wins hands down. An ASHP will do domestic hot water, I have a 300 litre tank. The key is you store your hot water less hot that you would with a gas boiler. Ours is set to 48 degrees which is plenty hot enough, but the lower temperature points you towards a larger tank. And hot water distribution and careful pipework is the key to quick delivery to the taps. Also some logical thought to the layout so all hot water usage points are close together, and the hot water tank central between them. Lastly solar PV. The FIT has gone, so anything now has to be self financing. That probably means forget paying an installer to fit it. I installed my own earlier this year for a cost of £1500 and we are on target to self use £250 of electricity in the first year giving a payback time of 6 years. Our generation is lower than it should be due to shading from trees, which I am gradually addressing with a thinning / felling program so I hope that will increase over time as I gradually reduce the shading. You need a different mindset for near 100% self usage like use all big appliances one at a time in the middle of the day, and a solar PV dump controller to put surplus power into hot water is a must.2 points

-

When doing bare root we tend to have 15/20 spares and they go into a corner to grow on. If there is a gap in the hedge a year later, one or two of these get transplanted into the gap - same batch so they tend to look and be the same size as the rest2 points

-

I'm posting this as a single blog entry for a number of reasons. One as it's the biggest bit of work we've done without professional help. Two as sheet roofing seems to be a topic of interest on BH and three because this stuff was hard going, with minimal information available on fitting guidance, so hopefully this might help others. We are using eternit profile 6 sheet roofing. It is fibre cement board and we initially chose it due to some perceived benefits over wriggly tin (principally acoustics, condensation management and durability). Cost wise it seems to come out roughly similar (from what I could tell). One of the biggest differences is in weight. Each cement board sheet is in the order of 55kg. All 54 were manhandled on to the scaffolding, and the roof. Without doubt this is the biggest downside and I'd strongly recommend anyone considering using this stuff to be sure they have a way of moving it safely. Another challenging aspect is the sheet thickness. At around 7mm thick, this means potentially 28mm thickness where 4 sheets overlap. To avoid this, the sheets are mitred, which is a pain to do accurately on a curved sheet. The profiled wavelength and amplitude is greater than on most metal sheeting which when combined with the sheet thickness makes neat fitting around velux quite hard, irrespective of the pre-planning we did. A profile 3 sheet is available which is more similar to traditional metal sheeting. This probably sounds highly negative, but we're pretty pleased with how it looks. We've had a few downpours recently and it's looking quite solid. Still a couple of small bits to complete, but nearly done. As to whether I'd use it again, jury's still out... While it's still fresh in my mind, the other things I'll note are: -there is a right and wrong way to overlap sheets which is not obvious in the eternit guidance. It's not crucial for weatherproofness, but it can make the roof appear bumpy if not done correctly. -eternit helpline was not hugely helpful, but the local reps were definitely worth speaking to and very useful. Anyway, the photos: Above shows the sheet overlaps, with the mitre clearly visible. When the top right sheet is added, this disappears. Above shows the sheet overlap in section, but it also helps illustrates the sheet thickness. Below are a couple of more general shots of the finished product.1 point

-

Really glad to hear it's all working well (and sorry for the delay in replying to the PM - my inbox here seems to fill up quickly!). I can confirm that since Sunamp resolved the issues with the controller firmware and sensor chain, our Sunamp UniQ eHW has been working very well indeed. The difference between the way it performs now, and the way it performed before the controller change is like night and day. We're now finding that our Sunamp is charging a bit during the E7 boost time, as our PV production does the usual and falls off the October cliff, although we've pretty much had 100% solar provided hot water until fairly recently, so we can't complain. We're on target for a sub-£80 annual hot water cost, which seems pretty reasonable, as we don't skimp on using hot water at all.1 point

-

1 point

-

Slightly, but if you turn off the AC, then turn off the DC at the isolator nearest the panels, then do a dead check, you're safe enough. Usual golden rule applies - never, ever, assume a switch works, always test to be sure it has! Second golden rule - never use a voltage detector pen/screwdriver, they are notoriously unreliable.1 point

-

Just tuck the cables up out of the way. If the cables are doubled up on themselves and folded up they will usually stay well away from any hole saw. Our joists were 225mm deep, IIRC, and the hole saw's only about 50mm deep, if that, so there's plenty of space to tuck the cables well out of the way usually.1 point

-

Pretty easy to do some basic running cost comparisons for different fuels. Just comparing cost per kWh of heat delivered (so allowing for boiler efficiency, heat pump COP, etc), then these are the approximate heating costs, excluding standing charges or tank rental (for all-electric heating this should really be apportioned across all electricity consumption, as it will be paid anyway): Peak rate electric boiler running UFH = £0.15726/kWh LPG fired boiler running UFH = £0.08471/kWh Off peak (E7) electric boiler running UFH = £0.08148/kWh Oil fired boiler running UFH = £0.07647/kWh ASHP at peak peak rate running UFH = £0.05242/kWh Mains gas boiler running UFH = £0.04274/kWh ASHP at off-peak (E7) rate running UFH = £0.02716/kWh For all the above the ASHP was assumed to be running with a COP of 3. In reality, ours seems to run at a COP of ~3.5, so a bit better than these figures suggest. The electricity cost figures above are for our E7 rate, so may well be different in other areas/for other tariffs.1 point

-

1 point

-

Had this discussion with our plasterers. I left all the cables looped up in the ceiling void (SELV DC, so no Part P concerns...) and had a plan showing the exact centres of each light. The plasterers were adamant that they very much preferred there to be no holes at all in the ceiling when they skimmed it. Worked OK, only thing I found that needed care was selecting a decent hole saw for the cutouts. The first one I tried chipped the plaster a bit. I switched to one with very much less set in the teeth and that was a great deal better.1 point

-

Hi @christianbeccy we're actually in a similar position as you -just starting out and considering designs, heating options and finding an architect. I was quite keen on ground source pumps at first and then air source but now i'm re-evaluating them. I'm not really sure what your priorities are but i'm looking for the best value system so I can have UFH in the home and its cosy throughout as well as, importantly, bathrooms staying dry (kids always leaving puddles around atm grrr ). I've kind of concluded that air-source is better than ground source, but its actually not that cheap to run even taking RHI into account. Atm i'm drifting towards solar heating for the hot water (no running costs, low maintenance + RHI) and maybe with a small boiler. Underfloor heating i'm now thinking along the lines of Infrared mats which are electric but very energy efficient, zone-able and also healthier (apparently!).1 point

-

Looks like the two strings are wired in parallel to me, so OK in terms of max voltage. The usual reason for wiring two strings to two separate MPPT inputs on the inverter is if the strings may produce slightly different outputs, from being differently aligned, or if the strings are of unequal number of panels (for example our system has12 panels in one string and 13 panels in the other). In this case, I doubt there would be the slightest difference if the two equal strings were wired to separate MPPTs. There might be a miniscule difference from the very slightly reduced voltage drop in the separate 4mm² DC wires, but not enough to be able to detect, in terms of performance, I suspect. No reason not to do it if you wish, though, especially as it looks as if you can isolate the panels to make the downstream wiring safe to work on.1 point

-

I may have this wrong but could it be lack of any cavity tray and weep holes above the lintel? This would normally be a DPC sloping down from the inner leaf and built into the brickwork above the lintel.1 point

-

Hey ! Let me know how you get on with them . It wasn’t care for my plaster so much but if I’ve got 30 recessed lights in a room I don’t want him moaning or the quality of skimming round each light is poor . Reluctant to skim/paint then drill my light holes - prefer to get it wrong earlier in the mission !1 point

-

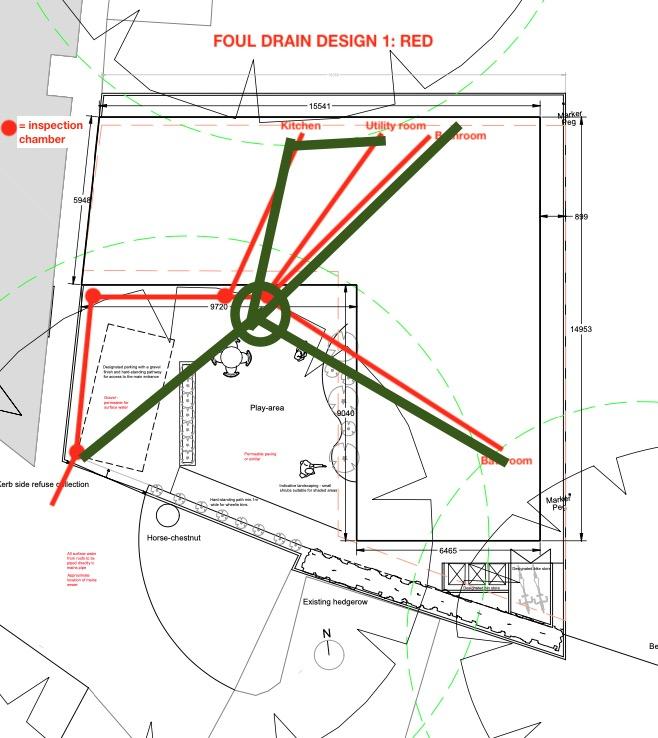

Red but scrap the kitchen IC. Use the bathroom near to utils in the main run inlet, with a bend just before the IC. Use the 2 inlets on the left of the IC for utils and kitchen, the R/H 45 inlet for the other bathroom and blank off the final inlet.1 point

-

Done carefully that is fine ..!!! The only difference when you’re working in the RPA is that you may need to do more work by hand - I’ve had to do this - basically went within 800mm of the trunk of a sycamore but had to do all excavation manually. Just put a note that says “x to y will be hand trenched where required to avoid tree roots.” At that distance out a HC will be no more than 60-70mm thick and will be deeper than your trench ..!1 point

-

why is it your stress..?? builder needs to make the roof to meet building regs. It won’t if the roof isn’t designed and built correctly. BCO can pick that up. I would suggest it may be a typo on an invoice or plan - or even a colloquial term ..!! Ask on here how many different names there are for a noggin....1 point

-

No difference Ian We have done both We've just one 20000 sq foot home in the lake district He had them ever were Including square ones on the walls When we built the cielings and walls We just needed a full wiring layout so as to put a pattress in for every one1 point

-

I drilled / cut all my ceiling holes before I plastered. Certainly slows things up imo. Had to be v.careful the plaster didn't thicken up around the hole edges and "slump" out. Somehow I got away with it.1 point

-

Yep lots They look really cool The Electrian normally attaches a string to the wires Then tapes it to the internal No chance of getting your hand in afterwards The ones I’ve plastered had a magnetic bulb holder1 point

-

I think a lot of the "include absolutely everything" in surveyors reports is driven by the need to cover the surveyors backside, in case there is a defect that he/she was unable to actually detect, but which might be there and show up later. It does waste a lot of time, and cause some unnecessary anguish for buyers, but without it I'd guess that some buyers might go after the surveyor if they bought a house and then found problems which had not been mentioned in the survey. There's also, I suspect, a bit of profiteering going on sometimes. When we sold our old house, I had all the key things done pre-sale, so as well as tidying the place up, replacing an old (but not leaking) flat roof, I also had the boiler and gas installation serviced and safety checked and inspected and tested the electrical installation, really just for our own peace of mind. I made sure the buyer's surveyor looked at all the warranties, safety chits etc I had for work done, when he did the survey, but I didn't mention that I'd inspected and tested the electrical installation, although had he looked he'd have seen that I'd put a label on the CU giving the date of the last inspection (which was a week or so earlier). He still recommended that the buyer get her own EICR, gas safety checks, boiler service etc done, and suggested companies to do this work. I suggested to the buyer that she could save the cost of the EICR, as I'd provide one, using the data I'd already got. She decided to follow the surveyors advice, which was fair enough. As it happened, the gas safety check company was the same one I'd used, and they were pretty honest, and told the buyer that they'd just done a check on the property and unless there had been any very recent changes there wasn't much point in her paying them to do another one. The electrical contractors were simply unbelievable, though. They charged her £384 for a four hour EICR (so over £700/day just for labour) and suggested that the cost to bring the installation up to current regs would be around £1,000. They wanted over £700 just to change a 6 way CU (materials cost ~£70 - £80, labour less than a day), and that was 99% of the work, as they'd have swapped out the 16mm² tails for 25mm² ones at the same time. Not at all sure where the other ~£300 was going, as they'd not flagged anything else in their report. The buyer passed me a copy of the EICR she'd had done and it was more or less the same as the one I'd given her, but only two C3s, one for the 16mm² tails, one for the absence of RCD protection in the CU (I'd flagged the cooker switch and outlet as a C3 for being slightly too close to the gas hob). I'm pretty certain that there was some sort of tie up between the surveyor and the companies he recommended, as the electrician who came out to do the EICR told me that he only did EICRs, and that most of them were as a consequence of surveys from the same surveyor.1 point

-

I am not necessarilly sure an architect is the best person to trust with siting the plant and planning the pipework runs. Once you have some initial plans post them on the forum and plenty of people will be able to suggest improvements. As above, MVHR is mostly about stopping / reducing heat waste rather than it being a heat source. You have to ventilate a house to provide fresh air to breath. Traditional uncontrolled trickle ventilation wastes the heat from all the expelled air and often does not ventilate properly (adding to mould problems) MVHR gives you a controlled rate of ventilation with most of the heat from the expelled air recovered and put back into the incoming air.1 point

-

A lot of your issues will be dependent on your design - do you have a fixed shape (planning granted..?) so you’re trying to retrofit all of the M&E, or have you got a blank sheet of paper ..? Plan in the plant space carefully - big tanks need reasonable spaces around them, but you also need to make them as central as possible to get the shortest runs of pipe work. As @ProDave said - you need to focus on installation and air tightness, and then look at your heating requirements. It’s highly unlikely you can make a GSHP pay - they have a 2-3 times capital cost and a continued maintenance that will dwarf running an ASHP. You will need and ASHP of 5-8kW I would expect for both heat and hot water for a decent spec new build using UFH. That depends on the MVHR - if like @PeterStarck or @JSHarris you fit a Genvex with a small internal heat pump then it will provide a small amount of heat. The real benefit is that you don’t lose all the heat from the continuous air changes of the building, retaining 80-90% based on the unit you choose.1 point

-

I looked at this with the quarry plot I got where it could be on front face of a big hill bottom line after frank discussion with a man that could supply a one and specialises in off grid systems+services and repairs wind and water turbines etc is that in reality the 40k cost of a proper one installed --not mickey mouse type would take close to 20 years to get back - and the life span of the major components is not much longer than that so it would only make sense if cost of mains supply was very expensive--and my site which will be about 30k --makes going mains the right way - I can still go PV when prices get better and resale of extra energy is worth while and you will still need a battery system to store it to get best use out of it or when wind does not blow and you can expect a very long argument with planning to get one now all i am saying is ask a lot of different people and consider long and hard about it and will the company that makes this turbine still be here in 10years there was a very popular one in scotland that loads of farmers bought --then there were problems with gearboxs --such that the company went broke --cos the peole making the gearboxs -folded as well would I allow a trubine on my ground --yes if it was a rental of land( PPA scheme) --but only if it was a long way off my house1 point

-

Local planning guidance varies a lot. Some council's have detailed policies on wind energy and others have no written policy at all. It would be essential to take any such written local policies into account, not least because appeal officers place great weight on policies that have been through public consultation and signed off as consistent with the National Planning Policy Framework (NPPF). In my area, where we already have many wind farms and individual turbines, they employed landscape experts to assess which areas were more or less sensitive to wind energy development and then workout which areas still had capacity to take additional turbines/wind farms without adverse cumulative impact. Heavy reading... Main SPD.. https://www.huntingdonshire.gov.uk/media/1238/wind-energy-development-in-huntingdonshire-2014.pdf Brief guidance.. https://www.huntingdonshire.gov.uk/media/2360/wind-turbine-developments-guidance-note.pdf From a planning perspective I would ask your planning department if they have an SPD on renewable or wind energy.1 point

-

Good read! Im in the same boat, funds clear this month to go for a build but I’m really apprehensive of our budget and going over or being near max before claiming VAT back! Going to do a test dig at 600mm and see what sort of ground we are on1 point

-

I would go for a 10kw minimum as the planning will be the same, and then cost will not be much more than 50% extra. Just need to remember it has to be as far away from a road, house, boundary or power line as it is tall. (Thats the guidance we were given)1 point

-

1 point

-

@KimBI haven't heard of them and I work in the industry. However, that doesn't mean much in the grand scheme of things as I tend to work on larger scale flood risk jobs. If you can get some recommendations, all the better. As with all professional services, the key aspect is what you are getting for your money. Are you paying them simply to get an independent rubber stamp of something you already know? Or are they potentially going to inform your design? Flood risk assessments can sometimes give clients an answer they don't want, but a good consultant will be able to help steer you through any problems. A bad one will just write a report assessing the level of risk and leave it up to you as to what to do next. The single biggest area of disagreement is usually when a client expects a flood risk assessment to give a clean bill of health and it doesn't do that. If it were me, I'd want to know the scope of their work, will it completely deal with planning requirements, might you need to do any more complicated assessment if this one turns up something concerning etc...?1 point

-

A little update on this: The Wayleave was eventually found a couple of days before we exchanged which stated a 6-month termination period from either party. After a quick visit from a nice chap at UKPN, they've agreed to underground the cables entirely at their own cost along the boundary in exchange for an easement - which is fair enough - so a good outcome all told.1 point

-

Kim, look to see if anyone else near has had a flood report done and see what the report is like and if they got the planning approved maybe asking for a quote. When I asked EA I got the feeling that they would be looking for all the reasons to say the area was not suitable for building on, you have also then put all your cards on the table face up1 point